Documente Academic

Documente Profesional

Documente Cultură

SCS T3 16219

Încărcat de

Kemal GokovicTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SCS T3 16219

Încărcat de

Kemal GokovicDrepturi de autor:

Formate disponibile

PMCES d.o.o.

w/ AGHIM

NAM KONG 2 HYDROPOWER PROJECT

LAO PEOPLES DEMOCRATIC REPUBLIC

DOCUMENT TITLE : SCS-T3-16219

NO. OF PAGES : 7

Rev No.

Page 1

PMCES

d.o.o.

Standard Coating Specifications

WHERE PROMISE IS A PROMISE

Product: T3-219

Surface preparation and coating procedure:

For surfaces:

In contact with water

Surface preparation:

Sand blasting SA 2

Grease and rust removal with solvent

Primary layer(s):

AgrozincSW, reddish

1 x DFT 80 m

Intermediate layer(s):

N/A

Top layer(s):

Agropox HS SW, RAL 7032

2 x DFT min. 100 m

Method:

Airless spray

Drying and application as per manufacturer's datasheets.

PMCES d.o.o.

Masarykova 37, BA-72000 Zenica

info@pmces.com

www.pmces.com

-1SCS-T3-16219

Company Data:

UID: BA-4218902940006

RN: 43-01-0606-15

Edition Jan. 2008

Agrozinc SW

Epoxy resin zincrich primer

PRODUCT OUTLINE

Product description:

Two-component zinc-rich primer based on epoxy resin, quick drying,

weldable.

Special properties:

Water condensation and weather resistant, good mechanical resistance.

Weldable. Corresp. to ZTV-KOR-Stahlbauten, Blatt 87, Stoffnr. 687.03-05.

Fields of application:

High quality primer for corrosion control of steelwork especially for hydro

power plants. AGROZINC SW up to 20 m dry-film-thickness is weldable.

Do not overcoat with alkyd resin based coatings.

Resistance:

Cured material is weather, water and mechanical resistant.

Temperature dry:

wet:

180C, up to 200C for a short time,

up to approx. 50C.

Color:

Grey, reddish.

TECHNICAL DATAS

Mixing ratio:

94 parts by weight of part A

6 parts by weight of part B

Pot life:

At 10C: appr.12 hrs,

at 20C: appr. 8 hrs,

at 30C: appr. 6 hrs.

Density:

2,8 kg/ltr

Volume of solids:

64 %

Flash point:

Part A

26C,

part B

27C,

ready mixed paint 27C.

Agrozinc SW, Edition Jan. 2008, Seite 1/3

Filmthickness:

dryfilmthickness

wetfilmthickness

application

20 m

45 m

incl. appr. 15 % VERDNNUNG 224

40 m

65 m

brush, roller

60 m

100 m

brush, roller, airless

80 m

130 m

airless

In case of airless spray application max. 60 m dryfilmhickness per coat

are recommendet. Do not exceed the max. DFT 120 m.

Number of coats:

1-2

Consumption:

Theor. for 40 m dry film ........................................................ 0,18 kg/m,

pract. for 40 m dry film ......................................................... 0,25 kg/m.

Drying degree 6:

Acc. to DIN 53150

Thinner:

dryfilmthickness

+ 5C

+ 23C

+ 40C

20 m

45 min

10 min

5 min

60 m

1 hr

30 min

20 min

VERDNNUNG 224

INSTRUCTIONS FOR USE

Surface preparation:

Sandblasting Sa 2 . Clean, dry and free of greese and oil.

Coating systems:

System without top coat: 2 x AGROZINC SW

Prime coat underneath top coat: 1 2 x AGROZINC SW

Recommended top coats:

a) outdoor application, chemical aggressive ambient:

AGROPOX 250 EG, AGROPOX EG 10, AVERTOL EPOTAR, AVERTOL EPOTAR SF, AGROSIT EG 80, AGROSIT MG 80, AGROLIT

411 DS, AGROLIT 411 EG.

b) indoor additional to products a):

AGROPOX 245

c) direct water contact:

AVERTOL EPOTAR, AVERTOL EPOTAR SF, AGROPOX SW.

Application:

Mix well both components in the correct mixing ratio. The mixed primer

must be worked up within the potlife, stir up sometimes during working.

Apply by brush, roller or airless spray. Add max. 3 % VERDNNUNG 224

(thinner) if necessary. Do not work below + 3C and above 80 % relative

humidity of atmosphere.

For weldable coating propose please add appr. 15 % VERDNNUNG 224.

Waiting periods:

At least 2 hours at 20C in-between AGROZINC SW-coa tings (at lower

temperatures at least 24 hours), prior to topcoating 1 - 2 days, extansion

of waiting period does not matter.

Between AGROZINC SW and AGROPOX EG 10 resp. AGROPOX HS

COLOR at least 4 hours (20C).

Agrozinc SW, Edition Jan. 2008, Seite 2/3

Final drying time:

Cured after 1 - 2 days.

Cleaning of implements:

Use VERDNNUNG 224 or REINIGUNGSMITTEL K

Storage:

Store in well closed original tins at dry and cool conditions. Shelftime 2

years.

Reference to hazards and

safety recommendations:

Reference to hazards and safety recommendations when dealing with

our products can be found in the most recent Material Safety Data

Sheets. The appropriate Material Safety Data Sheets can be downloaded

from our homepage www.avenariusagro.at; on request, they can also be

sent by mail.

Avenarius-Agro GmbH

Industriestrae 51

A-4600 Wels

Phone +43/7242/489-0

Fax +43/7242/489-5700

Internet: http://www.avenarius-agro.at

e-mail: office@avenarius-agro.at

"Important directions for use"

Agrozinc SW, Edition Jan. 2008, Seite 3/3

Edition Feb. 2010

Agropox HS SW

Two-component epoxy highsolid

thick coating

PRODUCT OUTLINE

Product description:

Twocomponent, robust, premium, thick highsolid corrosionprotective

coating containing micaceous iron oxid, created on epoxy resin basis.

Special properties:

The coating is ductile yet not brittle, largely shock and strike resistant;

with special abrasion resistance. Possibility of high coating thickness per

layer.

Fields of application:

To be used as a multipurpose highsolid thick coating for all kinds of

steel structures, in particular steel constructions used in hydraulic

engineering, due to the coating's high level of abrasion resistance.

Resistance:

Chemical:

Wastewater, condensates, diluted acids and caustics, fat and oil,

occasional effects of solvents and fuel.

Mechanical:

Very robust and highly resilient.

Temperature:

Dry heat up to approx. + 100C, damp heat and warm water up to

approx. + 40C.

Color:

Light grey, RAL 6011, RAL 7032.

TECHNICAL DATA

Mixing ratio:

88 parts by weight of part A

12 parts by weight of part B

Pot life:

At 20C: approx. 1 hour,

at 30C: approx. 45 minutes.

Density:

Approx. 1,5 1,6 kg/ltr

Volume of solids:

85 % (DIN 53219)

Number of coats:

13

Consumption:

200 m dry film is equivalent to 240 m wet film ..................... 0,36 kg/m,

practical for 200 m dry film thickness ..................................... 0,50 kg/m.

Agropox HS SW, Edition Feb. 2010, Seite 1/2

Drying:

According to DIN 53150 for 200 m dry at 23C

Drying grade 1: 1 hour

Drying grade 4: 6 hours

Thinner:

VERDNNUNG 215

INSTRUCTIONS FOR USE

Surface preparation:

Steel:

Blastcleaning to Sa 2 , according to ISO EN 12 9444. Free from dirt,

fat and oil.

Coating system:

1 x AGROZINC SW or AGROPOX 10 EG (optional)

1 3 x AGROPOX HS SW, according to expected stress.

Application:

Stir component A with electrically stirrer, add subsequently component B

and mix again thoroughly. Take also care of walls and bottom.

Mix Part A and Part B thoroughly in correct mixing ratio. Add only such

quantity of material as can be processed within the given pot life period.

Apply by paint roller, paint brush, airless spray.

When applying by paint roller, the coating layers tend to be somewhat

less thick. Not to be applied on surfaces with temperature of less than +

5C and at air humidity of more than 80%. Make sure the painted surface

is well ventilated.

Waiting periods:

Min. until drying grade 6 is achieved (s. above), max. 3 month.

Final drying period:

Dry after 12 hours, full exposure to chemical and mechanical stress after

710 days.

Cleaning of implements:

VERDNNUNG 215

Storing:

Can be stored cold and dry, properly enclosed in original containers for

up to 1 year

Reference to hazards and

safety recommendations:

Reference to hazards and safety recommendations when dealing with

our products can be found in the most recent Material Safety Data

Sheets. The appropriate Material Safety Data Sheets can be downloaded

from our homepage www.avenariusagro.at; on request, they can also be

sent by mail.

Avenarius-Agro GmbH

Industriestrae 51

A-4600 Wels

Phone +43/7242/489-0

Fax +43/7242/489-5700

Internet: http://www.avenarius-agro.at

e-mail: office@avenarius-agro.at

"Important directions for use"

Agropox HS SW, Edition Feb. 2010, Seite 2/2

S-ar putea să vă placă și

- Sikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing SystemDocument6 paginiSikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing Systemthe pilotÎncă nu există evaluări

- Tankguard 412 Jotun PaintDocument6 paginiTankguard 412 Jotun PaintGurdeep Sungh AroraÎncă nu există evaluări

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDe la EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryÎncă nu există evaluări

- Hempadur Pro Zinc 17380Document2 paginiHempadur Pro Zinc 17380prabha221Încă nu există evaluări

- Detailers Dictionary Volume 2: The Industry StandardDe la EverandDetailers Dictionary Volume 2: The Industry StandardÎncă nu există evaluări

- Ti e Protegol 32-55 R Nov 07Document4 paginiTi e Protegol 32-55 R Nov 07A MahmoodÎncă nu există evaluări

- Ti e Protegol 32-60 Apr08Document3 paginiTi e Protegol 32-60 Apr08A Mahmood100% (1)

- Water-Based Paint Formulations, Vol. 3De la EverandWater-Based Paint Formulations, Vol. 3Evaluare: 4.5 din 5 stele4.5/5 (6)

- Ti e Protegol 32-55 RRM Nov 07Document4 paginiTi e Protegol 32-55 RRM Nov 07A MahmoodÎncă nu există evaluări

- Pds Hempadur Mastic 45881Document3 paginiPds Hempadur Mastic 45881kasosei0% (1)

- Modern Surface TechnologyDe la EverandModern Surface TechnologyFriedrich-Wilhelm BachÎncă nu există evaluări

- Ti e Protegol 32-55 M Jul 08Document4 paginiTi e Protegol 32-55 M Jul 08A MahmoodÎncă nu există evaluări

- Ti - e - Protegol 32-99 Nov 07Document3 paginiTi - e - Protegol 32-99 Nov 07A MahmoodÎncă nu există evaluări

- Penguard Primer Datasheet " Azadjotun"Document3 paginiPenguard Primer Datasheet " Azadjotun"AzadAhmadÎncă nu există evaluări

- Penguard Special: Technical Data SheetDocument5 paginiPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Pds Hempadur Pro Zinc 17380 En-GbDocument2 paginiPds Hempadur Pro Zinc 17380 En-GbThines Kumar0% (1)

- Painting Data SheetsDocument12 paginiPainting Data SheetsRachidNakhil100% (1)

- Hempadur Mastic 45880 Product Data SheetDocument3 paginiHempadur Mastic 45880 Product Data SheetDeepak YadavÎncă nu există evaluări

- Ti e Protegol 32-55 TD Jan 08Document4 paginiTi e Protegol 32-55 TD Jan 08A MahmoodÎncă nu există evaluări

- TDS Jotafloor EPC 300 Plus Euk GBDocument6 paginiTDS Jotafloor EPC 300 Plus Euk GBAhmed IbrahimÎncă nu există evaluări

- Method Statement For Surface Preparation Prtective CoatingDocument10 paginiMethod Statement For Surface Preparation Prtective CoatingJaved MAÎncă nu există evaluări

- Sikafloor - 2530 W: 2-Part Water Based Epoxy CoatingDocument5 paginiSikafloor - 2530 W: 2-Part Water Based Epoxy Coatingthe pilotÎncă nu există evaluări

- PC 1752 - Asian Bituminous CoatingsDocument3 paginiPC 1752 - Asian Bituminous CoatingsRamesh BabuÎncă nu există evaluări

- Data Sheet Proguard CN 200 A.SDocument3 paginiData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieÎncă nu există evaluări

- APCS-26T HempelDocument5 paginiAPCS-26T HempelarjunmohananÎncă nu există evaluări

- TDS 25740 Jotafloor EP SL Euk GBDocument5 paginiTDS 25740 Jotafloor EP SL Euk GBDavid TumboimbelaÎncă nu există evaluări

- Ti - e - Protegol 130 HT L - Jan 08Document3 paginiTi - e - Protegol 130 HT L - Jan 08A MahmoodÎncă nu există evaluări

- Sonneborn NP2Document4 paginiSonneborn NP2Edward FlynnÎncă nu există evaluări

- Pds Hempadur Mastic 45880 En-GbDocument3 paginiPds Hempadur Mastic 45880 En-GbQA QCÎncă nu există evaluări

- Rust O Cap: Surface Tolerant EpoxyDocument3 paginiRust O Cap: Surface Tolerant EpoxySanthana SaravanaÎncă nu există evaluări

- Penguard PrimerDocument5 paginiPenguard PrimerPutroedidohÎncă nu există evaluări

- Pds Hempadur Mastic 45880Document3 paginiPds Hempadur Mastic 45880sibi_s_rajÎncă nu există evaluări

- Jotafloor Epc 300 Plus TDSDocument6 paginiJotafloor Epc 300 Plus TDSMuneer ahmedÎncă nu există evaluări

- Pds Hempadur Mastic 45881 En-GbDocument3 paginiPds Hempadur Mastic 45881 En-Gbshujad77Încă nu există evaluări

- Sikagard®-62: Product Data SheetDocument4 paginiSikagard®-62: Product Data Sheetantonsugiarto20_7049Încă nu există evaluări

- Tankguard 412: Technical Data SheetDocument6 paginiTankguard 412: Technical Data SheetMuneer ahmedÎncă nu există evaluări

- Epocoat 111 PDFDocument3 paginiEpocoat 111 PDFjunaid112Încă nu există evaluări

- Pds Hempadur Multi-Strength GF 35870 En-GbDocument3 paginiPds Hempadur Multi-Strength GF 35870 En-GbThines KumarÎncă nu există evaluări

- Tankguard StorageDocument5 paginiTankguard StorageBiju_PottayilÎncă nu există evaluări

- Penguard Tie Coat 100: Technical Data Sheet Application GuideDocument7 paginiPenguard Tie Coat 100: Technical Data Sheet Application GuideIrawan FajarÎncă nu există evaluări

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 paginiAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueÎncă nu există evaluări

- Sikagard Wallcoat PdsDocument5 paginiSikagard Wallcoat PdscharlessimoÎncă nu există evaluări

- Chemflake SpecialDocument5 paginiChemflake SpecialBiju_PottayilÎncă nu există evaluări

- Decora Synthetic Gloss EnamelDocument2 paginiDecora Synthetic Gloss EnamelMuthuKumarÎncă nu există evaluări

- Interbond 808Document4 paginiInterbond 808shameelÎncă nu există evaluări

- E - 9039 - Sika - Per - 3326 EG-HDocument4 paginiE - 9039 - Sika - Per - 3326 EG-HBogdan DavidescuÎncă nu există evaluări

- Ti e Protegol 32-47 R Jan 08Document3 paginiTi e Protegol 32-47 R Jan 08A MahmoodÎncă nu există evaluări

- Interfine 629HS: Modified AcrylicDocument4 paginiInterfine 629HS: Modified AcrylicTrịnh Minh KhoaÎncă nu există evaluări

- Intergard 269 DatasheetDocument4 paginiIntergard 269 DatasheetBalasubramanian AnanthÎncă nu există evaluări

- Naviguard ME - English (Uk) - Issued.06.12.2007Document3 paginiNaviguard ME - English (Uk) - Issued.06.12.2007Mohamed FaragÎncă nu există evaluări

- Ti - e - Protegol 32-97 Jan 08Document3 paginiTi - e - Protegol 32-97 Jan 08A MahmoodÎncă nu există evaluări

- Barrier 80Document5 paginiBarrier 80adeoye_okunoyeÎncă nu există evaluări

- Tankguard SF: Technical Data SheetDocument5 paginiTankguard SF: Technical Data SheetRifki ArifinÎncă nu există evaluări

- Graphit 33Document2 paginiGraphit 33Manuel Armindo RibeiroÎncă nu există evaluări

- Gehotex w8 enDocument2 paginiGehotex w8 engoing22Încă nu există evaluări

- Hempadur Mastic 45881-12170Document3 paginiHempadur Mastic 45881-12170Bang OchimÎncă nu există evaluări

- High Pressure Sluice Valves - VPZDocument6 paginiHigh Pressure Sluice Valves - VPZKemal GokovicÎncă nu există evaluări

- Sluice Valves - Pljosnati ZasuniDocument8 paginiSluice Valves - Pljosnati ZasuniKemal GokovicÎncă nu există evaluări

- Turbine Inlet Ball ValveDocument7 paginiTurbine Inlet Ball ValveKemal GokovicÎncă nu există evaluări

- GCBV2e V1Document11 paginiGCBV2e V1Kemal GokovicÎncă nu există evaluări

- Ba Sar1!25!48 Am1 Parallel enDocument72 paginiBa Sar1!25!48 Am1 Parallel enKemal GokovicÎncă nu există evaluări

- Operation and Maintenance Manual: Turbine Inlet Butterfly ValvesDocument16 paginiOperation and Maintenance Manual: Turbine Inlet Butterfly ValvesKemal GokovicÎncă nu există evaluări

- 8RKS - M - Slanted Type Check ValveDocument4 pagini8RKS - M - Slanted Type Check ValveKemal GokovicÎncă nu există evaluări

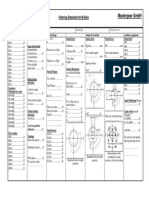

- Mastergear GMBH: Ordering Datasheet For M-SerieDocument1 paginăMastergear GMBH: Ordering Datasheet For M-SerieKemal GokovicÎncă nu există evaluări

- 2-Way Flow Control Bosch-RexrothDocument12 pagini2-Way Flow Control Bosch-RexrothKemal GokovicÎncă nu există evaluări

- SBValve WaferDocument8 paginiSBValve WaferKemal GokovicÎncă nu există evaluări

- Operating and Maintenance Manual: For RKS Plunger ValveDocument9 paginiOperating and Maintenance Manual: For RKS Plunger ValveKemal GokovicÎncă nu există evaluări

- ANSI B16.5 Dimnsion ToleranDocument1 paginăANSI B16.5 Dimnsion Toleranabhaysharma99Încă nu există evaluări

- Oval SleeveDocument2 paginiOval Sleevenedim cılızÎncă nu există evaluări

- Peptic Ulcers: PHRM 304Document24 paginiPeptic Ulcers: PHRM 304Apurba Sarker Apu100% (1)

- Penyimpanan Obat - Anjar Putri W - 24185650aDocument49 paginiPenyimpanan Obat - Anjar Putri W - 24185650aGista Andita100% (2)

- Characterization of Chitin, Chitosan by DSC PDFDocument9 paginiCharacterization of Chitin, Chitosan by DSC PDFtaufik ismullahÎncă nu există evaluări

- PS 870 B-2 - Part A - SDSDocument16 paginiPS 870 B-2 - Part A - SDSOperations AdminÎncă nu există evaluări

- Introductory Chemistry 8th Edition Zumdahl Solutions ManualDocument19 paginiIntroductory Chemistry 8th Edition Zumdahl Solutions Manualjonathantruongylunfl100% (13)

- DC Boiler Tube FailureDocument56 paginiDC Boiler Tube FailureDivyansh ChaturvediÎncă nu există evaluări

- Movement Into and Out of Cells: A.2.1 Matter and EnergyDocument13 paginiMovement Into and Out of Cells: A.2.1 Matter and EnergyRovina Narayan DiasÎncă nu există evaluări

- Expt.. No. Comon Lab. OperationsDocument13 paginiExpt.. No. Comon Lab. OperationsMaxine de la TorreÎncă nu există evaluări

- Activity 1Document6 paginiActivity 1Junaid KhanÎncă nu există evaluări

- Stainless Steel Grades 2008 01 PDFDocument2 paginiStainless Steel Grades 2008 01 PDFRahul LavandÎncă nu există evaluări

- Some - Basic - Concepts - of - Chemistry 1-7 DPPDocument11 paginiSome - Basic - Concepts - of - Chemistry 1-7 DPPVineet OhriÎncă nu există evaluări

- The Management of Heat Stress Through NutritionDocument45 paginiThe Management of Heat Stress Through NutritionaaronjulesÎncă nu există evaluări

- MSDS of Nature Face CreamDocument2 paginiMSDS of Nature Face CreamLeni MeifitaÎncă nu există evaluări

- Ore Deposirs Related To Intermediate To Felsic Igneous RocksDocument15 paginiOre Deposirs Related To Intermediate To Felsic Igneous RocksKamalÎncă nu există evaluări

- Piping Material and Class Summary: Material Standard Specification FORDocument19 paginiPiping Material and Class Summary: Material Standard Specification FORHamid Mansouri100% (1)

- CH U6 A4 Stoichiometry WorksheetDocument3 paginiCH U6 A4 Stoichiometry WorksheetUltrapure Analytichem100% (1)

- 30 Faraday's Law - SDocument6 pagini30 Faraday's Law - SLeia JonesÎncă nu există evaluări

- GB1 Q2 Week-3bDocument10 paginiGB1 Q2 Week-3bAnnejhel Mae PoralanÎncă nu există evaluări

- 16 Chemistry Benenden 2018Document24 pagini16 Chemistry Benenden 2018HaydenÎncă nu există evaluări

- SISCORBV020 Series Butterfly ValveDocument10 paginiSISCORBV020 Series Butterfly Valveloli2323Încă nu există evaluări

- An Overview of Organic ReactionsDocument80 paginiAn Overview of Organic Reactions110003551 110AÎncă nu există evaluări

- Hose Reel Catalogue 2018Document12 paginiHose Reel Catalogue 2018FrancisÎncă nu există evaluări

- Accepted Manuscript: LWT - Food Science and TechnologyDocument37 paginiAccepted Manuscript: LWT - Food Science and TechnologyMohsenÎncă nu există evaluări

- Chemistry MCQsDocument11 paginiChemistry MCQstayyaba farooqÎncă nu există evaluări

- Centrifugation TechniquesDocument4 paginiCentrifugation TechniquesselviÎncă nu există evaluări

- Airborne ContaminantsDocument44 paginiAirborne Contaminantskavi_prakash6992Încă nu există evaluări

- Name: - Date: - REVIEWER 5 - ScienceDocument8 paginiName: - Date: - REVIEWER 5 - ScienceKim Carlo AglinaoÎncă nu există evaluări

- All About Gases/ O Level: SolubilityDocument2 paginiAll About Gases/ O Level: SolubilityMuhammad KhanÎncă nu există evaluări

- Aerospace Material SpecificationDocument9 paginiAerospace Material SpecificationAnonymous T6GllLl0Încă nu există evaluări

- Pale Blue Dot: A Vision of the Human Future in SpaceDe la EverandPale Blue Dot: A Vision of the Human Future in SpaceEvaluare: 4.5 din 5 stele4.5/5 (588)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDe la EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellEvaluare: 4.5 din 5 stele4.5/5 (82)

- Sully: The Untold Story Behind the Miracle on the HudsonDe la EverandSully: The Untold Story Behind the Miracle on the HudsonEvaluare: 4 din 5 stele4/5 (103)

- Hero Found: The Greatest POW Escape of the Vietnam WarDe la EverandHero Found: The Greatest POW Escape of the Vietnam WarEvaluare: 4 din 5 stele4/5 (19)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDe la EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincEvaluare: 3.5 din 5 stele3.5/5 (137)

- The Future of Geography: How the Competition in Space Will Change Our WorldDe la EverandThe Future of Geography: How the Competition in Space Will Change Our WorldEvaluare: 4 din 5 stele4/5 (6)

- The Fabric of Civilization: How Textiles Made the WorldDe la EverandThe Fabric of Civilization: How Textiles Made the WorldEvaluare: 4.5 din 5 stele4.5/5 (58)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDe la EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyÎncă nu există evaluări

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreDe la EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreEvaluare: 4.5 din 5 stele4.5/5 (33)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDe la EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureEvaluare: 5 din 5 stele5/5 (125)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDe la EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaÎncă nu există evaluări

- Highest Duty: My Search for What Really MattersDe la EverandHighest Duty: My Search for What Really MattersÎncă nu există evaluări

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- System Error: Where Big Tech Went Wrong and How We Can RebootDe la EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootÎncă nu există evaluări

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (54)

- Packing for Mars: The Curious Science of Life in the VoidDe la EverandPacking for Mars: The Curious Science of Life in the VoidEvaluare: 4 din 5 stele4/5 (1396)

- Reality+: Virtual Worlds and the Problems of PhilosophyDe la EverandReality+: Virtual Worlds and the Problems of PhilosophyEvaluare: 4 din 5 stele4/5 (24)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (242)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeDe la EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeEvaluare: 4.5 din 5 stele4.5/5 (99)

- Square Foot Gardening: How To Grow Healthy Organic Vegetables The Easy WayDe la EverandSquare Foot Gardening: How To Grow Healthy Organic Vegetables The Easy WayEvaluare: 5 din 5 stele5/5 (3)

- The Weather Machine: A Journey Inside the ForecastDe la EverandThe Weather Machine: A Journey Inside the ForecastEvaluare: 3.5 din 5 stele3.5/5 (31)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachDe la EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachEvaluare: 4.5 din 5 stele4.5/5 (28)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterDe la EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterEvaluare: 5 din 5 stele5/5 (3)