Documente Academic

Documente Profesional

Documente Cultură

12 Drying Kinetics of Sandge, An Indian Traditional Food Adjunct in Air Convective Drying

Încărcat de

IJAERS JOURNALDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

12 Drying Kinetics of Sandge, An Indian Traditional Food Adjunct in Air Convective Drying

Încărcat de

IJAERS JOURNALDrepturi de autor:

Formate disponibile

International Journal of Advanced Engineering Research and Science (IJAERS)

https://dx.doi.org/10.22161/ijaers/3.10.12

[Vol-3, Issue-10, Oct- 2016]

ISSN: 2349-6495(P) | 2456-1908(O)

Drying Kinetics of Sandge, an Indian Traditional

Food Adjunct in Air Convective Drying

Renu Khedkar, Amarinder Singh Bawa

Amity Institute of Food Technology, AUUP, Noida, 201303, U.P., India

Abstract Sandge an Indian traditional food adjunct was

prepared by using standardized recipe of carrot(80%),

okra(9%), green chilies(3.5%), coriander leaves(2%) ,

sesame seeds(3.5%) and salt (2%) in an air convective dryer.

Studies on drying kinetics of sandgewere conducted at 45,

50 & 55C.The graph of drying rate and the drying curve

revealed that drying took place in the falling rate period

and increase in drying temperature accelerated the drying

process.The experimental data of drying kinetics was

satisfactorily fitted to four different empirical models for

thin layer drying: Newton, Page, Logarithmic, Henderson&

Pabis.With the selectioncriteria of high values of coefficient

of determination (R2), low values of root mean square error

(RMSE) between and chi-square (2), Newtons model was

selected as perfect fit. Applying the model of Fickian

unsteady state diffusion, effective moisture diffusion

coefficient (De) was calculated.The diffusivity varied from

17.5 x 10-7m2/s to 1.75 x 10-5m2/s within the temperature

range and fitted the Arrhenius equation. The molecular

diffusivity at infinite temperature, De was estimated to be

0.038m2/s and the activation energy for moisture diffusion,

E to be 9.57k J/mol.

KeywordsFood adjunct, drying kinetics, empirical

models, molecular diffusivity.

I.

INTRODUCTION

Drying is probably the oldest method for preserving foods.

Ancient civilizations preserved meat, fish, fruits and

vegetables using sun-drying techniques1.Drying is

considered as the complex operation which involves heat

and mass transfer along with several rates of processes, like

physical or chemical transformations which may result in

the product quality changes2-6.In countries like India where

poorly established low temperature distribution and

handling facilities are existing, drying is the alternative

treatment for post- harvest management. Over 20% of world

perishable crops are dried to increase the shelf life and

provide food security7.Currently hot air drying is the most

widely used method in post-harvest technology of

agricultural products. Using this method, a more uniform,

www.ijaers.com

hygienic and attractively colored dried product can be

produced rapidly8.However, this process has adverse effect

on colour and quality of the processed products due to the

higher temperatures and longer duration of drying9, 10.

Kinetic parameters, such as reaction order, rate constant and

activation energy could be helpful in the prediction of

change in colour and quality parameters during thermal

processing.The increasing demand for high-quality, shelfstable dried productsrequires the optimization of the drying

process conditions, especially temperature, with the purpose

of accomplishing not only the efficiency of the process but

also the final quality of the dried products11.

Drying kinetics data of food materials has been presented

by Marinos-Koulis and Maroulis12 (1995). The effect of air

temperature, air velocity, relative humidity and material size

have been studied and simulation models proposed by

various investigators for thin layer drying of many

agricultural products13-22[Vazquez- Vila et al. (2009),

Mazza (1983), Bakalet al. (2011), Lee and Kim (2009),

Abbasi and Anzari (2009), Doymaz (2007), Akpinar (2006),

Krokidaet al. (2003), Ahmed et al. (2001)and Kayamak

Ertekin (2002)]. Although the literature on the studies of

drying characteristics of raw agricultural products is

available, but few studies have been reported on the drying

kinetics of processed food products.

Traditional food adjuncts in Indian cuisine include pickle,

wet chutney, dry chutney, preserves, dried vegetable

products such assandgeandbharwanmirch,papad, etc.

Sandgeisa dried vegetable product made by mixing grated

carrots with okra, coriander leaves, sesame seeds, green

chilies and salt; making it into small balls of around 2 inch.

diameter and sun dried at 42-45C for 2-3 days . The dried

balls are then fried and served.

The research was carried out to investigate the drying

kinetics of sandgein an air convective dryer. The objectives

were to study the effect of drying temperature on drying

characteristics, selectthe best mathematical model and

determine the effective moisture diffusivity and activation

energy forsandge.

Page | 58

International Journal of Advanced Engineering Research and Science (IJAERS)

https://dx.doi.org/10.22161/ijaers/3.10.12

II.

MATERIALS & METHODS

Fresh vegetables e.g. carrot (Daucuscarota), coriander

leaves(Coriandrumsativum), green chilies(Capsicum annum),

okra (Abelmoschusesculentus L. Moench) of uniform

maturityand quality were procured from the local vegetable

market at Noida, India. All the vegetables were washed under

running water till completely free of dirt, the surface water

was soaked with a muslin cloth and the vegetables were

stored in a refrigerator at 7-10C till use. Sesame

seeds(Sesamumindicum) and common salt (Tata brand) were

procured from the supermarket at Noida. Sesame seeds were

also cleaned and checked for any impurities.

Dryer Set Up

A laboratory scale batch Tray Dryer (SM Scientech,

Kolkata) was used for drying of sandge balls. The dryer

contained 8 trays, loaded one above the other. The material

to be dried was placed in thin layers on the trays and the

trays were placed inside the dryer and hot air blown through

it. Two heaters heated the air from both sides of the tray

loading area. Thermostat was used to control the

temperatures in the two heating zones.Dryer was started

2hrs.earlierto the start of experiment to get steady state

conditions.

2.1 Preparation of Sandge

StandardizedSandge recipe of carrot(80%), okra(9%), green

chilies(3.5%), coriander leaves(2%) , sesame seeds(3.5%)

and salt (2%) was used in the experiments. Carrots were

peeled and grated using food processor (Inalsa, India).

Coriander leaves were separated from the roots and stems,

dried on muslin cloth till surface moisture was

soaked/evaporated and finely chopped. Both ends of the

okra pods were removed and the pods were crushed in the

mixer. Green chilies were separated from the stalks,

chopped and ground to a paste. The vegetables were

weighed and mixed well with weighed quantities of sesame

seeds and salt in a large bowl. Loose balls of around 2

inchdiameter were made manually and kept on the

perforated tray in the tray dryer. Each tray of size 24 cm x

33 cm contained around 20 balls weighing around 20-25g

each. The trays were weighed and placed in the dryer one

above the other. The drying kinetics of sandgewas studied

at three different drying temperatures 45, 50 & 55C. The

sandge samples dried at the three different temperatures

were weighed every hour using a digital weighing balance

with 0.01g sensitivity. The relative humidity of air varied

between 45-50% during the experiments. It was measured at

regular intervals with

hygrometer. The drying was

continued till constant weight was obtained. The position of

the tray was changed every 2 hrs. to allow uniform heat

www.ijaers.com

[Vol-3, Issue-10, Oct- 2016]

ISSN: 2349-6495(P) | 2456-1908(O)

transfer and the balls were moved upside down to get

uniform surface heating. The experiments were conducted

in triplicates at each drying temperature.

2.2 Drying kinetics for Sandge

The drying rate curves for the three drying temperatures

were obtained by plotting the drying rate against time. Also

the drying curves for moisture content (kg/kg db) versus

time of drying (hrs.) for the three drying temperatures were

plotted to see the influence of temperature on the time

required for drying.

2.3 Mathematical modelling of drying curves

The data obtained experimentally for the three different

temperatures studied (45C, 50C and 55C) was plotted in

theform of the dimensionless variable moisture ratio (MR)

versus time (expressed in hours), where

MR =

W We

Wo We

. (1)

With W the moisture content at any time t, We the

equilibrium moisture content and Wo the initial moisture

content,all expressed in dry basis (g water/g dry solids). The

value of We was found to be relatively small as compared to

Wo&W, hence the error involved in simplification was

negligible23 and the moisture ratio was calculated as

MR = W/ Wo

(2)

For drying model selection, the experimental sets of (MR, t)

were fitted to the four different empirical models from the

literature, shown in Table 1. Statistical analysis of the fitting

of data was carried out using XLSTAT, 2016, 0.2.

A non-linear regression procedure was used to fit the thinlayer drying models available in the literature to the

experimental moisture loss data and the models were

compared based on the coefficient of determination, root

mean square error, and the reduced chi-square between the

observed and predicted moisture ratios. The higher values

for R2 and lower values of 2and RMSE were chosen as

the criteria for goodness of fit24.

(3)

Page | 59

International Journal of Advanced Engineering Research and Science (IJAERS)

https://dx.doi.org/10.22161/ijaers/3.10.12

[Vol-3, Issue-10, Oct- 2016]

ISSN: 2349-6495(P) | 2456-1908(O)

-De ( b12/r2) t

ln(MR) = ln ( 4/b12 ) +

(7)

which is a equation of straight line y= yo + ax, where

(4)

yo = ln ( 4/b12 )

(8)

a = -De ( b12/r2 )

or

= (RMSE) *N/N-m

(5)

Where, RMSE: Root mean square error

N: No. of observations

m: No. of constants used in the thin layer models (Newton,

Page, Logarithmic, Henderson and Pabis)

MRpre,iis the ith predicted moisture ratio, MRexp, iis theith

experimental value of moisture ratio.

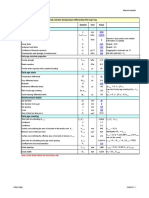

Table.1: Empirical models for drying kinetics

S.NO MODEL

TYPE

REFERENCE

NAME

1

Newton

MR=exp(Mujumdar25

kt)

2

Page

MR=exp(Diamante and

ktn)

Munro26

3

Logarithmic MR=aexp(- Yagciogluet

kt+c)

al.27

4

Henderson

MR=aexp(- Zhang

and

and Pabis

kt)

Litchfleld28

2.4 Moisture Diffusivity and Activation Energy

According to Ficks second law for unsteady-state

diffusion, assuming that the samples used can be

approximated to cylinders,the diffusion is expressed as

follows:

W 1

W

W

= De r

+ De r

t

r r

r z

r

(6)

whereDe is the effective moisture diffusivity (m2/s), ris

thecylinder radius (m), z is the height (m) and t is the

time,expressed in seconds.

Assuming uniform initial moisture content and constant

diffusivity throughout the sample, the solution of eq. (6)

becomes

www.ijaers.com

(9)

From the graph plotted between ln (MR) versus time, for

each of the temperatures, value of

De and b1 was calculated.

The diffusivity varies with temperature according to

Arrhenius equation as

De= Deoexp ( -E/RT)

(10)

Where Deo is the effective diffusivity at infinite

temperature (m2/s), E is the activation energy for molecular

diffusion (J/mol), R is the universal gas constant (R= 8.314

J/ (mol) K) and T is the drying temperature expressed in

Kelvin29.

Eq. (10) can be written as

ln(De) = ln(Deo) + ( -E/R) 1/T

(11)

Which is a straight line , y= yo + ax,

Thus by plotting ln(De) versus ( 1/T), y and a were

calculated as

y = ln(Deo)

(12)

a = - E/R

(13)

From eq. 12 & 13, values of Deo and E were calculated.

III.

RESULTS & DISCUSSION

3.1 Drying kinetics

Temperature of drying is the most important factor of

drying rate20. Hence the drying kinetics of sandgewas

studied at three different air temperatures 45, 50 & 55C.

The drying rate was plotted against time and the drying

rate curves for the three drying temperatures have been

shown in Fig.1.The drying rate in the first hour of drying

was 0.034, 0.048 and 0.055kg of moisture removed/hr. at

45, 50 and 55C respectively, which implied that air

temperature has been a very important factor of drying rate

for sandge. As seen from the graph, although the initial

moisture content of the samples was quite high (92.43%),

Page | 60

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.12

a constant drying rate period was not observed under the

experimental conditions and the drying of sandge took

place in the falling rate period which showed that diffusion

phenomenon controlled the drying of sandge. Similar

results were observed during the air-convective drying of

potato, carrot, green pepper, red pepper, yellow pepper,

garlic, mushroom, onion, leek, pea, corn, celery, pumpkin

and tomato20.The graph indicated that the loss of moisture

was at its highest in the first half of drying; however it

slowed down in the subsequent drying period. The drying

rate of sandgeduring the first hour was highest at 55C,

followed by 50C and 45C drying temperatures. After2

hrs.of drying, the values of drying rate of sandge dried at

45, 50 & 55C were almost similar. After a period of 4

hrs.,the drying rate slowed down for all the three drying

temperatures, but the drying was faster at 55C.

Fig.1: Drying rate curves for Sandge at 45, 50 & 55C

Fig.2 explains the drying curves for moisture content (kg/kg

db) versus time of drying (hrs.) for the three drying

temperatures. The curve was plotted to see the influence of

temperature on the time required for drying. The drying

time for sandge was 13hrs., 17hrs.and 22hrs. at 55, 50 and

45C.As expected, there was an acceleration of drying

process due to the increase in drying temperatures from 45

to 55C.

www.ijaers.com

ISSN: 2349-6495(P) | 2456-1908(O)

Fig.2: Drying curve of Sandge at 45,50& 55C

3.2 Fittings of the experimental data to empirical

models

The drying kinetics data obtained for the three different

temperatures, 45, 50 & 55C, in the form of moisture ratio

(MR) versus time (hrs.) has been shown in Table2 . The

data was fitted to four different empirical models: Newton,

Page, Logarithmic, Henderson& Pabis. The results of such

fittings, obtained with the software XLSTAT, 2016.02 for

the three temperatures and for each model have been

presented in Table 3-5, which show the values of the

estimated parameters along with the statistical information,

coefficient of determination (R2), root mean square error

(RMSE) and chi-square (2).

Table.2: Moisture ratio and time at three drying

temperatures (45, 50 & 55C) for Sandge

S.No.

Time

MR ( MR

MR

(hrs.)

45 C) (50

(55

C)

C)

1

0

1

1

1

2

1

0.88

0.86

0.77

3

2

0.76

0.75

0.62

4

3

0.65

0.66

0.49

5

4

0.56

0.58

0.39

6

5

0.48

0.51

0.31

7

6

0.42

0.43

0.25

8

9

10

11

7

8

9

0.36

0.32

0.28

0.38

0.33

0.28

0.2

0.15

0.11

10

0.25

0.23

0.08

12

11

0.22

0.19

0.07

13

14

12

13

0.2

0.17

0.16

0.14

0.07

-

Page | 61

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.12

15

16

14

0.15

0.11

15

0.14

0.1

17

18

19

16

17

18

0.12

0.11

0.1

0.09

0.08

0.08

ISSN: 2349-6495(P) | 2456-1908(O)

20

0.09

20

0.08

22

21

The MR values are an average of triplicates

19

21

Table.3: Results of fitting to empirical models for 45C drying temperature (n=21)

Henderson &

Newton

Page

Logarithmic

Pabis

k=0.138

k=0.154

k=0.138

Estimated

k=0.139

a=0.996

parameters

n=0.951

a=0.992

c= -0.004

2

R

0.998

0.999

0.998

0.998

RMSE

0.013

0.010

0.013

0.013

2

0.000177

0.000111

0.000197

0.00018

Parameters/

Models

Parameters/

Models

Estimated

parameters

R2

RMSE

2

Parameters/

Models

Estimated

parameters

R2

RMSE

2

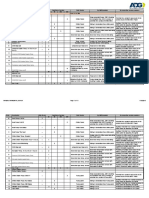

Table.4: Results of fitting to empirical models for 50C drying temperature (n=19)

Newton

Page

Logarithmic

Henderson

Pabis

k=0.144

k=0.128

k=0.145

k=0.145

n=1.057

a=1.004

a=1.009

c= 0.005

0.998

0.999

0.998

0.998

0.013

0.011

0.014

0.013

0.00017

0.00013

0.00023

0.00018

Table.5: Results of fitting to empirical models for 55C drying temperature (n=13)

Newton

Page

Logarithmic

Henderson

Pabis

k=0.237

k=0.244

k=0.235

k=0.235

n=0.981

a=0.997

a=0.992

c= -0.005

0.999

0.999

0.999

0.999

0.009

0.009

0.009

0.009

0.00008

0.00009

0.0001

0.00009

Table 3-5 revealed that all the fittings were good, with high

values of coefficient of determination (R2) between 0.998 to

0.999, low values of root mean square error (RMSE)

between 0.009 to 0.014 and chi-square (2) between

0.00008 to 0.0001. For the drying temperatures of 45 &

50C, although goodness of fit was obtained for the Page

model, with high values of R2 of 0.999 each, low values of

RMSE 0.010 and 0.011, 2 of 0.00011and 0.00013

respectively, the Newtons model was selected to be the

perfect fit, since the values of n were nearly equal to 1. For

55C, the goodness of fit was obtained for the Newtons

model, with high value of R2 of 0.999, low value of RMSE

www.ijaers.com

&

&

of 0.009 and value of 2 of 0.00008. The very low values of

2 and RMSE indicated that the values predicted by the

model were very close to the experimental values. Reyes et

al. (2008) studied the drying kinetics for carrot, dried using

different drying methods such as tunnel drying, vacuumfreeze drying, with or without assisted infrared radiation,

fluidized bed drying assisted by microwave radiation and a

combination of these methods and found that the Pages

model fitted adequately to the drying process with specific

parameters for each drying zone30. Vazquez-Vila et al.

(2009) studied the drying kinetics of carrots in osmotic and

air-convective drying processes. Experimental drying

Page | 62

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.12

ISSN: 2349-6495(P) | 2456-1908(O)

kinetics werefitted satisfactorily to a first order (simple

model) kinetics and to the Pages model in order to

determine the kinetic constants during drying31.

3.3 Diffusion coefficient and activation energy

Fig. 3-5 and Table6 show the results of the fitting to

equation y= yo+ ax, where y= ln(MR), yo = ln(4/b12) and a

= - De (b12/r2) and x= time. The equation was used to

estimate the values of effective diffusivity, De at the three

drying temperatures, 45, 50 & 55C. The high value of

coefficient of determination, R2 (0.996-0.997) and F value

(3264.34 - 4759.38) indicated that the quality of fitting was

good. Diffusivity increased from 1.75 x 10-6m2/s at 45C to

17.5 x 10-6 m2/s at 55C.

0

ln (MR)

0 2 4 6 8 10 12 14 16 18 20

-1

ln(MR) at 45C

-2

Linear (ln(MR) at

45C)

y = -0.126x + 0.052

-3

Time (hrs.)

Fig. 3: Plot of ln (MR) vs. Time (hrs.) at 45C

ln (MR)

1

0

-1

ln (MR) at 50C

0

8 10 12 14 16

-2

-3

y = -0.154x + 0.207

Time (hrs.)

Linear (ln (MR)

at 50C)

Fig.4: Plot of ln (MR) vs. Time (hrs.) at 50C

1

ln (MR)

0

-1

0 1 2 3 4 5 6 7 8 9 1011

-2

-3

-4

y = -0.244x + 0.268

ln (MR) at 55C

Linear (ln (MR)

at 55C)

Time (hrs.)

Fig.5 : Plot of ln (MR) Vs. Time (hrs.) at 55C

Table.6: Estimation of diffusion coefficients at three drying temperatures (45,50& 55C) for Sandge

Parameters/ Drying

45C

50C

55C

temperatures

R2

0.996

0.997

0.997

yo

0.052

0.2077

0.2688

A

-0.1266

-0.1543

-0.2447

b1

5.33

2.66

2.34

r(m)

0.0198

0.0198

0.0198

De (m2/s)

1.75 x 10-6

8.54 x 10-6

17.5 x 10-6

RMSE

0.051

0.049

0.051

F value

4704.67

4759.38

3264.34

Pr>F

<0.0001

<0.0001

<0.0001

www.ijaers.com

Page | 63

International Journal of Advanced Engineering Research and Science (IJAERS)

https://dx.doi.org/10.22161/ijaers/3.10.12

The values of the diffusion coefficients were used to fit Eq.

y= yo + ax, where y= ln(De), yo= ln(De), a= -E/R and x=

1/T. The graph was plotted between ln(De) versus 1/T and

has been shown in Fig.6. The results from the graph have

been presented in Table 7. The average radius of the

samples was found to be 0.0198m. The high value of R2

(0.976) and F-value (40.12) indicated that the fitting was

good. The molecular diffusivity at infinite temperature,

Deand the activation energy for moisture diffusion, E were

determined from the graph. De was estimated to be

0.038m2/s and E to be 9.57kJ/mol. Doymaz (2007) reported

the values of effective diffusivity of pumpkin slices to be

3.88 1010 to 9.38 1010 m2/s for the thin-layer drying

carried out under three air temperatures of 50, 55 and 60C,

whereas the activation energy was found to be

78.93 kJ/mol. The values of De for onion slices dried at 30,

50 and 60C were 3.65401009m2/s at the lowest

temperature and

9.53241009m2/sat the highest

temperature whereas the Dewas1.16791004m2/s, and the

activation energy for moisture diffusion,E, was found to be

26.4 kJ/mol31.

Fig.6: Plot of ln (De) vs. 1/T

Table.7: Estimation of parameters to determine diffusivity

at infinite temperature,De0 and activation energy, E

Parameter

Value

2

R

0.976

yo

-9.6574

a

-1.1543

De0 (m2/s)

0.038

E (J/mol)

9.57

F value

40.12

P value

www.ijaers.com

~0

[Vol-3, Issue-10, Oct- 2016]

ISSN: 2349-6495(P) | 2456-1908(O)

IV.

CONCLUSION

The drying kinetics of Sandge, a traditional food adjunct in

India was studied for air convective drying at 45, 50 and

55C. The drying rate curve and the drying curve were

plotted. The drying rate increased with temperature and the

drying time lowered. From the drying curve, it was seen

that the drying took place in falling rate period and

diffusion controlled the drying process. The experimental

data was fitted to four different empirical models for thin

layer drying, Newton, Page, Logarithmic, Henderson &

Pabis. From the results, it could be verified that the models

used in this study showed good predicting capacity and

performance for all the three temperatures, over the entire

duration of the drying process. With the selectioncriteria of

high values of coefficient of determination (R2), low values

of root mean square error (RMSE) between and chi-square

(2), Newtons model was selected as perfect fit.Applying

the model of Fickian unsteady state diffusion, effective

moisture diffusion coefficient (De) was calculated.The

diffusivity varied from 17.5 x 10-7m2/s to 1.75 x 10-5m2/s

within the temperature range and fitted the Arrhenius

equation. The molecular diffusivity at infinite temperature,

De was estimated to be 0.038m2/s and the activation energy

for moisture diffusion, E to be 9.57k J/mol.

REFERENCES

[1] Brennan J.G., In: Food Dehydration: A Dictionary and

Guide, Oxford: Butterworth-Heinemann Ltd., 1994.

[2] Mujumdar,A. S., New Dehydration Technologies for

Dairy and Food Products,Indian Dairyman, 60: 3, 2008.

[3] Bartz, J.A., Brecht, J.K., Postharvest physiology and

pathology of vegetables, Series: Food Science and

Technology (second ed.), CRC Press, 2002.

[4] Kader, A.A. (ed.), In: Postharvest Technology of

Horticultural Crops (3rd Edition),UC Publication 3311,

University of California, Division of Agriculture and

Natural Resources, Oakland, California 94608, 535,

2002.

[5] Tindal, H.D. and Proctor, F.J., Loss Prevention of

Horticultural Crops in the Tropics,ProgFd Nat Sci, 4 (34): 25-39, 1980.

[6] Kitinoja, L. and Gorny, J.R., In: Postharvest

Technology for Small-Scale Produce Marketers:

Economic Opportunities, Quality and Food Safety, UC

PTRIC Horticultural Series No. 21, 1999.

[7] Grabowski, S., Marcotte, M. and Ramaswamy, H.S.,

Drying of fruits, vegetables, and spices. In: Handbook

of Postharvest Technology: Cereals, Fruits, Vegetables,

Tea, and Spices, Chakraverty, A., Mujumdar, A.S.,

Page | 64

International Journal of Advanced Engineering Research and Science (IJAERS)

https://dx.doi.org/10.22161/ijaers/3.10.12

Raghavan, G.S.V., Rawaswamy, H.S. (ed), Marcel

Dekker, New York, 23:653695, 2003.

[8] Wankhede, P.K., Sapkal, R.S. and Sapkal, V.S., Drying

characteristics of okra slices using different drying

methods by comparative evaluation, In: Proceedings of

the World Congress on Engineering and Computer

Science, October 24-26, San Francisco, USA, 2012.

[9] Alibas, I., Microwave, air and combined microwaveair-drying parameters of pumpkin slices, LWT-Food

SciTechnol, 40: 14451451,2007.

[10] Maskan, M., Microwave/air and microwave finish

drying of banana, J Food Eng, 44(2): 71-78, 2000.

[11] Banga,J.R., Balsa-Canto, E., Moles, C.G., Alonso,

A.A., Improving food processing using modern

optimization methods,Trends Food Sci Tech ,14(4):

131-144, 2003.

[12] Marinos-Kouris, D. andMaroulis, Z.

B.,Thermophysical properties of the Drying of Solids.

In A. Mujumdar (Ed.),Handbook of Industrial Drying.

NY: Marcel Dekker, 1995.

[13] Vazquez- Vila, M.J.,Chenlo-Romero, F., MoreiraMartinez, R. and Pacios-Penelas, B., Dehydration

kinetics of carrrots (Daucuscarota L.) in osmotic and

air convective drying processes, Span J Agric Res, 7(4):

869-875, 2009.

[14] Mazza, G., Dehydration of carrots, Effects of predrying treatments on moisture transport and product

quality, IntJ Food SciTech, 18:113123, 1983.

[15] Bakal S.B., Sharma G.P., Sonawane S.P., and Verma

R.C., Kinetics of potato drying using fluidized bed

dryer, J Food Sci Tech,49(5):608-13,2011.

[16] Lee, J.H. and Kim, H.J., Vacuum drying kinetics of

Asian white Radish (Raphanussativus L.) slices, LWTFood SciTechnol, 42: 180-186, 2009.

[17] Abbasi, S. and Azari S., Novel microwavefreeze

drying of onion slices,Int J Food SciTechnol, 44: 974

979, 2009.

[18] Doymaz, I., The kinetics of forced convective air-drying

of pumpkin slices, J Food Eng, 79 (1):243-248, 2007.

[19] Akpinar, E.K., Determination of suitable thin layer

drying curve model for some vegetables and fruits, J

Food Eng,73(1): 75-84, 2006.

[20] Krokida M.K., Karathanos V.T., Marinos-Kuris, D. and

Maroulis Z.B., Drying kinetics of some vegetables, J

Food Eng, 59: 391-403, 2003.

[21] Ahmed, J., Shivaghare, U.S. and Singh, G. , Drying

characteristics and product quality of coriander

leaves,Transactions of the Institution of Chemical

www.ijaers.com

[Vol-3, Issue-10, Oct- 2016]

ISSN: 2349-6495(P) | 2456-1908(O)

Engineers, Part C, Food BioProd Process, 79: 103-106,

2001.

[22] Kayamak-Ertekin, F., Drying and rehydrating kinetics

of green and red peppers, J Food Sci, 67(1): 168-175,

2002.

[23] Aghbashlo, M., Kianmehr, M. H. and SamimiAkhljahani, H., Influence of drying conditions on the

effective moisture diffusivity, energy of activation and

energy consumption during the thin-layer drying of

barberries fruit (Berberidaceae), Energ Convers

Manage,49: 28652871, 2008.

[24] Demir, V., Gunhan, T., Yagcioglu, A. K. and

Degirmencioglu, A., Mathematical modeling and the

determination of some quality parameters of air-dried

bay leaves, Bio systems Eng,88:325335, 2004.

[25] Mujumdar, A.S., In: Handbook of industrial drying,

MarckelDekker,New York, 437-562, 1987.

[26] Diamente, L. M. and Munro, P. A., Mathematical

modeling of the thin layer solar drying of sweet potato

slices,Solar Energy,51(4):271276, 1993.

[27] Yagcioglu A., Degirmencioglu A. and Cagatay F.,

Drying characteristic of laurel leaves under different

conditions. In: A. Bascetincelik (ed.), In: Proceedings of

the 7th international congress on Agricultural

Mechanization and Energy, Adana, Turkey: Faculty of

Agriculture, Cukurova University, 565569, 1999.

[28] Zhang, Q.andLitchfleld, J. B.,An optimization of

intermittent corn drying in a laboratory scale thin layer

dryer,Drying Technol,9:383395, 1991.

[29] Akpinar, E. K., Midilli, A. and Bicer, Y.,Single layer

drying behavior of potato slices in a convective cyclone

and

mathematical

modeling,Energ

Convers

Manage,44:16891705, 2003.

[30] Reyes ,A., Vega ,R., Bustos, R. and Araneda, C., Effect

of Processing Conditions on Drying Kinetics and

Particle Microstructure of Carrot, Drying Technol,

26(10): 1272-1285, 2008.

[31] Guine,R.P.S., Barroca, M.J., Dias, A., Luciano, C. and

Mota, C.L.,Convective drying of onion: Kinetics and

nutritional evaluation, Food Bioprod Process, 88(2-3):

115-123, 2010.

Page | 65

S-ar putea să vă placă și

- Impacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicDocument7 paginiImpacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicIJAERS JOURNALÎncă nu există evaluări

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocument4 paginiThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALÎncă nu există evaluări

- Climatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninDocument8 paginiClimatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninIJAERS JOURNALÎncă nu există evaluări

- Beef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaDocument7 paginiBeef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaIJAERS JOURNALÎncă nu există evaluări

- Facing Dengue and Malaria As A Public Health Challenge in BrazilDocument6 paginiFacing Dengue and Malaria As A Public Health Challenge in BrazilIJAERS JOURNALÎncă nu există evaluări

- Enhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionDocument6 paginiEnhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionIJAERS JOURNALÎncă nu există evaluări

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocument4 paginiThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALÎncă nu există evaluări

- Analysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingDocument11 paginiAnalysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingIJAERS JOURNALÎncă nu există evaluări

- Breastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewDocument16 paginiBreastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewIJAERS JOURNALÎncă nu există evaluări

- Business Logistics and The Relationship With Organizational SuccessDocument4 paginiBusiness Logistics and The Relationship With Organizational SuccessIJAERS JOURNALÎncă nu există evaluări

- Associativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMDocument9 paginiAssociativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMIJAERS JOURNALÎncă nu există evaluări

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocument9 paginiMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALÎncă nu există evaluări

- Childhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationDocument12 paginiChildhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationIJAERS JOURNALÎncă nu există evaluări

- Water Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaDocument11 paginiWater Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaIJAERS JOURNALÎncă nu există evaluări

- VCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodDocument6 paginiVCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodIJAERS JOURNAL100% (1)

- Constructed Wetlands: Technology For Removing Drug Concentration From WaterDocument12 paginiConstructed Wetlands: Technology For Removing Drug Concentration From WaterIJAERS JOURNALÎncă nu există evaluări

- Study of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractDocument8 paginiStudy of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractIJAERS JOURNALÎncă nu există evaluări

- Komla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)Document9 paginiKomla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)IJAERS JOURNALÎncă nu există evaluări

- Design and Building of Servo Motor Portable Coconut Peller MachineDocument5 paginiDesign and Building of Servo Motor Portable Coconut Peller MachineIJAERS JOURNALÎncă nu există evaluări

- Multiprofessional Care For A Patient With Gestational DiabetesDocument12 paginiMultiprofessional Care For A Patient With Gestational DiabetesIJAERS JOURNALÎncă nu există evaluări

- Process Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47Document5 paginiProcess Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47IJAERS JOURNALÎncă nu există evaluări

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocument9 paginiMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALÎncă nu există evaluări

- Sociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilDocument9 paginiSociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilIJAERS JOURNALÎncă nu există evaluări

- Association of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixDocument15 paginiAssociation of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixIJAERS JOURNALÎncă nu există evaluări

- Modeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilDocument5 paginiModeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilIJAERS JOURNALÎncă nu există evaluări

- Humanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveDocument12 paginiHumanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveIJAERS JOURNALÎncă nu există evaluări

- The Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsDocument8 paginiThe Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsIJAERS JOURNALÎncă nu există evaluări

- Does Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyDocument12 paginiDoes Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyIJAERS JOURNALÎncă nu există evaluări

- Assessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsDocument13 paginiAssessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsIJAERS JOURNALÎncă nu există evaluări

- Mining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaDocument7 paginiMining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaIJAERS JOURNALÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Calculate Capacity of Room Air Conditioner: Room Detail Unit Electrical Appliances in The RoomDocument2 paginiCalculate Capacity of Room Air Conditioner: Room Detail Unit Electrical Appliances in The Roomzmei23Încă nu există evaluări

- Supersedes DIN V 18599-1:2005-07Document66 paginiSupersedes DIN V 18599-1:2005-07LBÎncă nu există evaluări

- TransducerDocument8 paginiTransducerTeoh Chia Yang100% (1)

- Development of Ice Abrasive Waterjet PDFDocument10 paginiDevelopment of Ice Abrasive Waterjet PDFPrapto PraptÎncă nu există evaluări

- Seresco Natatorium Design Guide 2011Document32 paginiSeresco Natatorium Design Guide 2011Tariq AsgharÎncă nu există evaluări

- Early Thermal CrackingDocument5 paginiEarly Thermal CrackingSravanthi Mehar100% (1)

- Board Exam - Attempt Review (Page 4 of 10) 1Document4 paginiBoard Exam - Attempt Review (Page 4 of 10) 1LEANDRO LAHINDOÎncă nu există evaluări

- ASTM C 680 - 03 Estimate of The Heat Gain or Loss and The Surface Temperatures of Insulated Flat, Cylindrical, and Spherical SystemsDocument15 paginiASTM C 680 - 03 Estimate of The Heat Gain or Loss and The Surface Temperatures of Insulated Flat, Cylindrical, and Spherical SystemsFu_JohnÎncă nu există evaluări

- BS 1881-Part 5-70-Dropbox PDFDocument14 paginiBS 1881-Part 5-70-Dropbox PDFNidDou100% (1)

- DesuperheaterDocument5 paginiDesuperheaterKrishna KumarÎncă nu există evaluări

- TEDOM Tri Generation enDocument2 paginiTEDOM Tri Generation enAnna DruzbovaÎncă nu există evaluări

- Paper-3/1995: T, As Shown in Fig. 1.1Document11 paginiPaper-3/1995: T, As Shown in Fig. 1.1Lawrence Lim Ah KowÎncă nu există evaluări

- M0712101104 - Ktra Do Nong ChayDocument4 paginiM0712101104 - Ktra Do Nong ChayTịch MịchÎncă nu există evaluări

- Ics e Science Class 7Document31 paginiIcs e Science Class 7Pooja RÎncă nu există evaluări

- Chapter 4Document7 paginiChapter 4Mohamed Ayman MoshtohryÎncă nu există evaluări

- Full Text FTHDocument3 paginiFull Text FTHBaadsha BanerjeeÎncă nu există evaluări

- Final 2 - States of Matter Lab Assessment PacketDocument22 paginiFinal 2 - States of Matter Lab Assessment Packetapi-112724521Încă nu există evaluări

- Maker Final DWG & Inst. Manual For Plate Heat ExchangerDocument35 paginiMaker Final DWG & Inst. Manual For Plate Heat ExchangeralexanderÎncă nu există evaluări

- 69NT40-541-001 To 199 OSDocument112 pagini69NT40-541-001 To 199 OSDavid Pereira AquinoÎncă nu există evaluări

- Molar Mass of A Volatile LiquidDocument16 paginiMolar Mass of A Volatile LiquidJoaquin MoulicÎncă nu există evaluări

- Teac Unit 03Document17 paginiTeac Unit 03Vaidika GoldieÎncă nu există evaluări

- Daikin - Paquetes Enfriados Por AguaDocument96 paginiDaikin - Paquetes Enfriados Por AguaAlexandra SerratoÎncă nu există evaluări

- Tecumseh 2003Document18 paginiTecumseh 2003willcarl obandoÎncă nu există evaluări

- Refrigerant Reference ChartDocument2 paginiRefrigerant Reference ChartMarMaryantoÎncă nu există evaluări

- HELMER DH8 User ManualDocument30 paginiHELMER DH8 User ManualSamson AyalewÎncă nu există evaluări

- Industrial Plant DesignDocument5 paginiIndustrial Plant DesignMarvin BayanayÎncă nu există evaluări

- Construction Issue: Qty. (Nos) AI DI AO DO Hvac System I Water Chilling Units 3Document11 paginiConstruction Issue: Qty. (Nos) AI DI AO DO Hvac System I Water Chilling Units 3Al Amin Hossain Srabon100% (1)

- STM 003 Sas Module #24Document8 paginiSTM 003 Sas Module #24Kriztel Andrei NavajaÎncă nu există evaluări

- HT17X Datasheet V1d-WebDocument2 paginiHT17X Datasheet V1d-WebFawziyyah AgboolaÎncă nu există evaluări

- Gasdecom Paper 1Document10 paginiGasdecom Paper 1JuanÎncă nu există evaluări