Documente Academic

Documente Profesional

Documente Cultură

Opc Drum Coating

Încărcat de

Louis ChenDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Opc Drum Coating

Încărcat de

Louis ChenDrepturi de autor:

Formate disponibile

Namig, Andrej Janei s.p.

OPC Drum coating explained

FEBRUARY, 2009

DESCRIPTION OF COATING AND INSTRUCTION OF USAGE

Theory

Organic photoconductive

coating is composed

mainly from 2 important

layers. First one is CGL

and second is CTL. Charge-Generation-Layer is the

layer where photoconductive pigment is included.

This is usually TiOPC

pigment in y-shape of

crystals. The second layer

is the most important. It's

called CTL or Charge

Transfer Layer. It's purpose it to transfer electric

charge generated in the

lower layer to the surface.

With transferred charge

the toner powder is picked

up from developer roller.

And this layer must be

recoated in order to protect the CGL layer. I will

try to explain in simple

words how you can easily

do it in your workshop.

During whole process you

shoule take really good

care of clenaliness. I'm not

talking about making

100% cleanroom but you

also shouldn't have toner

and dust particles all over

the place. We installed

normal micron air filter

and recoating is now

much more reliable.

Process:

All parts that come in

contact with coating should be from high quality

staineless steel or

polyamide plastic. Also

silicone tubing is fine. All

parts and also stainless

steel airbrush is available

(costs approx 100 ) from

us. If you use diferent

equipment results may

vary from optimal. Coating should be done from

left to right as shown on

youtube video. And with

newest formulation only 1

pass is enought! If you

have nozzles opened 60%.

In any case you will need

to make your internal

tests. After coating dry the

drum with hot air gun.

Composition of coating

The coating is composed

from different elements.

Most important is the binder. We use same quality

polycarbonate as standard

in industry. This will ensure

full compatibility and endurance for whole cycle. Another ingredient is the heart of

the coatingcharge transfer complex. It's organic

compound that tranfers the

electron to the surface and

pickup the toner particles.

liquid through the series of

filters. It speeds up the

process and help maintain

the quality level.

We add aslo many different

organic solvents and additives to dissolve the binder

and enable fluent and clogfree spraying of the liquid.

R11,R45,R36/37/38,R48/2

0,R63,R65,R67

The last step is filtering the

liquid. We use several filters

with different porosity and

use vacuume to suck the

Since we use toxic solvents

you should use precautions

as : air ventilation, active

carbon filter, safety googles.

Store liquid on safe place.

Away from children and

unauthorized personel.

R-phrases for our coating

are following:

As you can see the coating

is dangerous chemical. It

shouldn't be used without

precautions!

If you are interested we

can provide also all

necessary equipment. We

just need to learn your

quantity requirements.

Coating is

packed in

glass bottles

that will

prevent any

leakage and evaporation.

The storage time

is not

limited.

You need

to keep

coating away from heat

sources and direct sunlight. And it doesn't have

any expiration date. Shipping is only possible via

truck! No air transportation possible!

Svet rnil

Litijska cesta 12a

1000 Ljubljana

SLOVENIJA

EUROPE

Phone: +386 31 204 629

mail: info@svet-crnil.com

Coating procedure:

Use isopropyl alcohol

and clean the drum of

any toner

residue

Coat the

drum

with 1-2

coats of our coating

(depends of cartridge

yield)

Dry the drum with hotair gun for 10-30 sec. at

180C

Why recoat the drums ?

Economy (less then 0,1 )

Ecology

Lower stocks

Quality

S-ar putea să vă placă și

- Operating Instructions Estefold 4210 + 4211Document17 paginiOperating Instructions Estefold 4210 + 4211Alexey KosiyÎncă nu există evaluări

- Ricoh Service Bulletin rfg064463Document6 paginiRicoh Service Bulletin rfg064463Marco Delsalto100% (1)

- Canon Paper Jam CauseDocument3 paginiCanon Paper Jam CauseBrian100% (1)

- Service Manual SCX-6345Document322 paginiService Manual SCX-6345rboborgesÎncă nu există evaluări

- HP Laserjet P1102: Cartridge Remanufacturing InstructionsDocument0 paginiHP Laserjet P1102: Cartridge Remanufacturing InstructionsKevin TateÎncă nu există evaluări

- HP 1020 Laser Printer Service Manual Filetype PDFDocument3 paginiHP 1020 Laser Printer Service Manual Filetype PDFzonelabsmx0% (1)

- Canon Ir2318 Manual PDFDocument2 paginiCanon Ir2318 Manual PDFNazia Ahmed0% (1)

- 7166398-Ricoh Aficio 2232c Color Copier Service ManualDocument580 pagini7166398-Ricoh Aficio 2232c Color Copier Service Manualroblane100% (1)

- Error Codes - Konica-Minolta - Bizhub C654Document4 paginiError Codes - Konica-Minolta - Bizhub C654befremdenÎncă nu există evaluări

- XEROX Work Centre M118 Service ManualDocument564 paginiXEROX Work Centre M118 Service ManualPreduta Monica100% (1)

- WC7556FSM PDFDocument1.436 paginiWC7556FSM PDFPadiparn Sae House100% (3)

- Canon Isensys - mf229dw Service ManualDocument308 paginiCanon Isensys - mf229dw Service ManualFlorin GostianÎncă nu există evaluări

- T08135D ProXL Service ManualDocument271 paginiT08135D ProXL Service ManualAlexandruÎncă nu există evaluări

- E-Studio206-256-306-456 - Mantenimiento PreventivoDocument37 paginiE-Studio206-256-306-456 - Mantenimiento PreventivoRamón Colón100% (3)

- OCE 3121,3122 Service ManualDocument908 paginiOCE 3121,3122 Service Manualclient_escopyÎncă nu există evaluări

- Service Manual ML-551x 651x Ver1.3 111104 PDFDocument258 paginiService Manual ML-551x 651x Ver1.3 111104 PDFBudau RolandÎncă nu există evaluări

- IR3045 Portable ManualDocument170 paginiIR3045 Portable Manualhopala_bgÎncă nu există evaluări

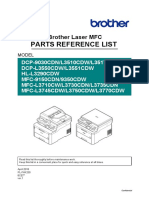

- Parts Reference List: MODEL: DCP-8110DN/ 8150DN/8155DN/8250DN/ MFC-8510DN/8515DN/ 8520DN/8710DW/8910DW/ 8950DW/8950DWTDocument39 paginiParts Reference List: MODEL: DCP-8110DN/ 8150DN/8155DN/8250DN/ MFC-8510DN/8515DN/ 8520DN/8710DW/8910DW/ 8950DW/8950DWTfefotroncitoÎncă nu există evaluări

- Xerox 5018, 5028, 5034 OPC Copier Cartridges: VerviewDocument8 paginiXerox 5018, 5028, 5034 OPC Copier Cartridges: VerviewJaime RiosÎncă nu există evaluări

- Kyocera km-2560 km-3060 SMDocument389 paginiKyocera km-2560 km-3060 SMAnonymous lYwX12hwQÎncă nu există evaluări

- BizHub C452, C552, C652 and Options Theory of OperationDocument580 paginiBizHub C452, C552, C652 and Options Theory of OperationMasło MaślaneÎncă nu există evaluări

- Epson AcuLaser C900 C1900 Parts and Service ManualDocument267 paginiEpson AcuLaser C900 C1900 Parts and Service ManualstopnaggingmeÎncă nu există evaluări

- KIP 7100 User Manual A - 1Document59 paginiKIP 7100 User Manual A - 1Jay TanÎncă nu există evaluări

- Error Code Details for Canon ImageRunner CopiersDocument70 paginiError Code Details for Canon ImageRunner CopiersPadiparn Sae HouseÎncă nu există evaluări

- Manual Service Ricoh FW770 A0Document206 paginiManual Service Ricoh FW770 A0Andreea Iliescu100% (1)

- DCP 6690CW, MFC 6490CW, MFC 6890CDW PDFDocument474 paginiDCP 6690CW, MFC 6490CW, MFC 6890CDW PDFStefanGarnetÎncă nu există evaluări

- Kyocera Taskalfa 180 220 Digital CopiersDocument4 paginiKyocera Taskalfa 180 220 Digital CopiersMuhammedShabeerMAÎncă nu există evaluări

- wcm24 Service ManualDocument1.489 paginiwcm24 Service ManualBlaze Copier100% (2)

- SM 6505ci 7505ci ENG Rev40Document1.286 paginiSM 6505ci 7505ci ENG Rev40mauro_ferrero_Încă nu există evaluări

- Sony PVM-741 Oled ManualDocument36 paginiSony PVM-741 Oled ManualElectra/Off TraxÎncă nu există evaluări

- DCP 9030CDNL3510CDWL3517CDW - DCP L3550CDWL3551CDW - HL L3290CDW - MFC 9150CDN9350CDW - MFC L3710CWL3730CDNL3735CDN - MFC L3745CDWL3750CDWL3770CDW PDFDocument39 paginiDCP 9030CDNL3510CDWL3517CDW - DCP L3550CDWL3551CDW - HL L3290CDW - MFC 9150CDN9350CDW - MFC L3710CWL3730CDNL3735CDN - MFC L3745CDWL3750CDWL3770CDW PDFStefanGarnetÎncă nu există evaluări

- COPYSTAR SRDF-2 Service ManualDocument66 paginiCOPYSTAR SRDF-2 Service ManualChung Kim33% (3)

- Task Alfa 5001i Manual de ServicioDocument1.118 paginiTask Alfa 5001i Manual de ServicioAlfonso Sanchez Verduzco100% (1)

- ECOSYS P6030cdn Service ManualDocument176 paginiECOSYS P6030cdn Service Manualhoem homeÎncă nu există evaluări

- LASER PRINTER SERVICE MANUALDocument131 paginiLASER PRINTER SERVICE MANUALBayardo AguilarÎncă nu există evaluări

- Samsung CLP-610-660 Service ManualDocument180 paginiSamsung CLP-610-660 Service ManualMarco DelsaltoÎncă nu există evaluări

- XEROX WorkCentre Copycentre 123-128-133 Service Manual PagesDocument7 paginiXEROX WorkCentre Copycentre 123-128-133 Service Manual PagesAmr H Fadl HÎncă nu există evaluări

- Toshiba 232 UpdateInstructions For FirmwareDocument6 paginiToshiba 232 UpdateInstructions For FirmwareMarco DelsaltoÎncă nu există evaluări

- Epson Stylus Photo r260 r265 r270Document153 paginiEpson Stylus Photo r260 r265 r270Gary Fabricante100% (1)

- 24 JF1631 - 1610 Maintenance Manual D500325 - Ver3.00Document358 pagini24 JF1631 - 1610 Maintenance Manual D500325 - Ver3.00alex greekÎncă nu există evaluări

- Canon Ir2030 - Series - Service ManualDocument418 paginiCanon Ir2030 - Series - Service Manualariserpl100% (1)

- Panasonic Kx-ft982ls-984ls-988ls (Service Manual Repair)Document194 paginiPanasonic Kx-ft982ls-984ls-988ls (Service Manual Repair)servitecdj100% (2)

- Automobile Body Materials Trim and MechanicsDocument8 paginiAutomobile Body Materials Trim and MechanicsHarshdeepsinh Padhiyar100% (1)

- Car Body Painting ProcessDocument10 paginiCar Body Painting Processviksriram6782100% (1)

- Pub 2010-04 Elements33 WH eDocument7 paginiPub 2010-04 Elements33 WH eSariyyaHeydarovaÎncă nu există evaluări

- Water ProofingDocument30 paginiWater ProofingMuhammad Irfan ButtÎncă nu există evaluări

- CHEM - LEC - PolycarbonateDocument5 paginiCHEM - LEC - PolycarbonateOri SeinÎncă nu există evaluări

- SANYO Semiconductor's Environmental ManagementDocument6 paginiSANYO Semiconductor's Environmental ManagementDeign SeseÎncă nu există evaluări

- Cleaning Pcbs in Electronics: Understanding Today'S NeedsDocument37 paginiCleaning Pcbs in Electronics: Understanding Today'S NeedsDelenzy CinoÎncă nu există evaluări

- Novatex Limited: Internship ReportDocument53 paginiNovatex Limited: Internship ReportMuhammad Ayaz0% (1)

- Materials, Equipments and Fabrication TechniqueDocument17 paginiMaterials, Equipments and Fabrication TechniqueNagarjun CherukuriÎncă nu există evaluări

- Electrolytic Deposition of Paint On Automobiles and Its Removal From Rinse Water by Ultrafiltration - FinalDocument33 paginiElectrolytic Deposition of Paint On Automobiles and Its Removal From Rinse Water by Ultrafiltration - FinalVipul Sharma100% (1)

- ECP TRB - Hassan AhmedDocument9 paginiECP TRB - Hassan AhmedHasan AhmedÎncă nu există evaluări

- Preparing For Coating and Cleaning Procedures The Need For Clean SurfacesDocument3 paginiPreparing For Coating and Cleaning Procedures The Need For Clean Surfacesana_zafÎncă nu există evaluări

- Process DescriptionDocument9 paginiProcess Descriptionsonhai937Încă nu există evaluări

- Universidad Autonóma de Nuevo León Facultad de Ingeniería Mecánica Y EléctricaDocument10 paginiUniversidad Autonóma de Nuevo León Facultad de Ingeniería Mecánica Y EléctricaMaximiliano LarragaÎncă nu există evaluări

- Fiber Polishing Handbook2Document5 paginiFiber Polishing Handbook2Berrezeg MahieddineÎncă nu există evaluări

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsDe la EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsÎncă nu există evaluări

- Modeling, Control, and Optimization of Natural Gas Processing PlantsDe la EverandModeling, Control, and Optimization of Natural Gas Processing PlantsEvaluare: 5 din 5 stele5/5 (1)

- Konica Minolta, Inc. Major Questions and Answers IR Day Long-Term Management Vision and Medium-Term Business Strategy DX2022 Briefing SessionDocument6 paginiKonica Minolta, Inc. Major Questions and Answers IR Day Long-Term Management Vision and Medium-Term Business Strategy DX2022 Briefing SessionLouis ChenÎncă nu există evaluări

- Cru FruDocument1 paginăCru FruLouis ChenÎncă nu există evaluări

- Cru FruDocument1 paginăCru FruLouis ChenÎncă nu există evaluări

- Highlights of Consolidated Results For Fiscal Year Ended March 31, 2015Document6 paginiHighlights of Consolidated Results For Fiscal Year Ended March 31, 2015Louis ChenÎncă nu există evaluări

- 赫比2015年報Document129 pagini赫比2015年報Louis ChenÎncă nu există evaluări

- HP Line-Up Map A3 Printers (Laserjet and Pagewide) : February 2020 EditionDocument3 paginiHP Line-Up Map A3 Printers (Laserjet and Pagewide) : February 2020 EditionLouis ChenÎncă nu există evaluări

- KPM Round Series Miniature Gas Pumps: DC Power, Pressure To 300 MMHG (5.8 Psi)Document1 paginăKPM Round Series Miniature Gas Pumps: DC Power, Pressure To 300 MMHG (5.8 Psi)Louis ChenÎncă nu există evaluări

- 赫比2017年報Document130 pagini赫比2017年報Louis ChenÎncă nu există evaluări

- FF Announcement 20181019 001Document1 paginăFF Announcement 20181019 001Louis ChenÎncă nu există evaluări

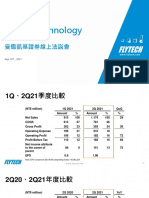

- Flytech TechnologyDocument7 paginiFlytech TechnologyLouis ChenÎncă nu există evaluări

- MicrDocument3 paginiMicrharyy1234567Încă nu există evaluări

- 3M Electronics Vacuum: Model 497AJM, 120 Volt Model 497ABF, 220 VoltDocument2 pagini3M Electronics Vacuum: Model 497AJM, 120 Volt Model 497ABF, 220 VoltLouis ChenÎncă nu există evaluări

- Key Financial Figures (Consolidated) : April 28, 2017 Ricoh Company, LTDDocument4 paginiKey Financial Figures (Consolidated) : April 28, 2017 Ricoh Company, LTDLouis ChenÎncă nu există evaluări

- Xer OgraphyDocument5 paginiXer OgraphyPaula ZorziÎncă nu există evaluări

- KV-S4065CL KV-S4065CW KV-S4065CWCN KV-S4085CL KV-S4085CW KV-S4085CWCNDocument20 paginiKV-S4065CL KV-S4065CW KV-S4065CWCN KV-S4085CL KV-S4085CW KV-S4085CWCNLouis ChenÎncă nu există evaluări

- Bizhub Open PlatformDocument2 paginiBizhub Open PlatformLouis ChenÎncă nu există evaluări

- Preferred Office Companion: Wireless Convenience Automatic Duplex Quick First PrintDocument4 paginiPreferred Office Companion: Wireless Convenience Automatic Duplex Quick First PrintLouis ChenÎncă nu există evaluări

- 4aa7 0138eepDocument6 pagini4aa7 0138eepLouis ChenÎncă nu există evaluări

- HP 1010Document114 paginiHP 1010Louis ChenÎncă nu există evaluări

- 12 139Document12 pagini12 139Louis ChenÎncă nu există evaluări

- Options That Fit Your Deployment Needs.: Xerox Print Driver ComparisonDocument2 paginiOptions That Fit Your Deployment Needs.: Xerox Print Driver ComparisonLouis ChenÎncă nu există evaluări

- Bizhub Open PlatformDocument2 paginiBizhub Open PlatformLouis ChenÎncă nu există evaluări

- 4aa7 0138eepDocument6 pagini4aa7 0138eepLouis ChenÎncă nu există evaluări

- Ar-6020 0Document2 paginiAr-6020 0Louis ChenÎncă nu există evaluări

- KD-X200/KD-X150/KD-X100: Instruction ManualDocument20 paginiKD-X200/KD-X150/KD-X100: Instruction ManualLouis ChenÎncă nu există evaluări

- Ease Your Transition Into Continuous Feed Inkjet Printing.: Xerox Impika Compact Inkjet PressDocument2 paginiEase Your Transition Into Continuous Feed Inkjet Printing.: Xerox Impika Compact Inkjet PressLouis ChenÎncă nu există evaluări

- Corona Wires PDFDocument2 paginiCorona Wires PDFLouis ChenÎncă nu există evaluări

- 端子接觸電阻之自動量測及其相關變因之研究Document74 pagini端子接觸電阻之自動量測及其相關變因之研究Louis ChenÎncă nu există evaluări

- Lec 10Document18 paginiLec 10Phan Nguyen TraÎncă nu există evaluări

- Estudio 907Document36 paginiEstudio 907Louis ChenÎncă nu există evaluări

- Фурнітура електрошаф MESAN-CATALOGUE-2016Document507 paginiФурнітура електрошаф MESAN-CATALOGUE-2016kostyaÎncă nu există evaluări

- Sieve AnalysisDocument3 paginiSieve AnalysisBibhuti B. Bhardwaj100% (1)

- SOP of Maintenance For Ball Mill Including PolycomDocument3 paginiSOP of Maintenance For Ball Mill Including PolycomsantoshÎncă nu există evaluări

- 7. اذرعت التحكم (العصيان)Document14 pagini7. اذرعت التحكم (العصيان)المهندسوليدالطويلÎncă nu există evaluări

- A Chemical Thermodynamics Review Applied To V2O5 ChlorinationDocument16 paginiA Chemical Thermodynamics Review Applied To V2O5 ChlorinationMargarita CaceresÎncă nu există evaluări

- 80 IN 1 Professional Computer Repair ToolDocument5 pagini80 IN 1 Professional Computer Repair ToolCarlos CorreaÎncă nu există evaluări

- Electrical DistributionDocument41 paginiElectrical Distributionjiguparmar1516Încă nu există evaluări

- Amendment No. 1 May 1988 Is: 778-1984 Specification For Copper Alloy Gate, Globe and Check Valves ForDocument2 paginiAmendment No. 1 May 1988 Is: 778-1984 Specification For Copper Alloy Gate, Globe and Check Valves ForThetarunÎncă nu există evaluări

- 500 LPH RO Technical SpecsDocument8 pagini500 LPH RO Technical Specshanif panja0% (1)

- Bleaching Pulp With ChlorineDocument7 paginiBleaching Pulp With ChlorineRaÎncă nu există evaluări

- Pile FoundationDocument17 paginiPile Foundationritam1991Încă nu există evaluări

- Me6301 Engineering Thermodynamics Nov Dec 2011Document3 paginiMe6301 Engineering Thermodynamics Nov Dec 2011BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- Zinoviev 1998Document15 paginiZinoviev 1998Hillman GarnicaÎncă nu există evaluări

- E5 - 50-60Hz - 220-230V - Ing - Rev04Document39 paginiE5 - 50-60Hz - 220-230V - Ing - Rev04ValdasÎncă nu există evaluări

- Smart Prep Cibacron On SlavosDocument4 paginiSmart Prep Cibacron On SlavosagnberbcÎncă nu există evaluări

- Pre Stressed Concrete Is A Method For Overcoming The ConcreteDocument7 paginiPre Stressed Concrete Is A Method For Overcoming The ConcreteNurhamizah MeskamÎncă nu există evaluări

- Pigging Valves Safety - Interlock System - Plant SafetyDocument11 paginiPigging Valves Safety - Interlock System - Plant SafetyRenukhaRangasamiÎncă nu există evaluări

- OHL-25-002 OHL PTE Earths & NeutralsDocument6 paginiOHL-25-002 OHL PTE Earths & NeutralsFranÎncă nu există evaluări

- Corrosion of RC StructuresDocument5 paginiCorrosion of RC StructuresvigneshwarimahamuniÎncă nu există evaluări

- Pressure Drop Chart Y StrainersDocument1 paginăPressure Drop Chart Y StrainersAshimÎncă nu există evaluări

- Silane Coupling Agent GuideDocument20 paginiSilane Coupling Agent GuidePathik ShahÎncă nu există evaluări

- Q Railing KatalogDocument416 paginiQ Railing KatalogТомић ЕминаÎncă nu există evaluări

- Shell Thermia Oil B Heat Transfer Fluid PropertiesDocument3 paginiShell Thermia Oil B Heat Transfer Fluid PropertiesBoon Kuan LimÎncă nu există evaluări

- ACEMATT® TS 100/20: Characteristic Physico Chemical Data )Document2 paginiACEMATT® TS 100/20: Characteristic Physico Chemical Data )Fadi MagdyÎncă nu există evaluări

- Modul EkstraksiDocument11 paginiModul EkstraksiBayu Octavian PrasetyaÎncă nu există evaluări

- Brochure MarineDocument16 paginiBrochure MarineKriz Hor Jiunn ShyangÎncă nu există evaluări

- GEO PUB 1/93 - Review of Granular and Geotextile FiltersDocument133 paginiGEO PUB 1/93 - Review of Granular and Geotextile FiltersaescarameiaÎncă nu există evaluări

- Impco Engine Catalog 2008Document137 paginiImpco Engine Catalog 2008Maria Fernanda Bonilla Salas100% (1)

- CNC Sewing and Embroidery MachineDocument5 paginiCNC Sewing and Embroidery MachineniltoncesÎncă nu există evaluări

- Dynamic Response of Structural MachineDocument10 paginiDynamic Response of Structural MachineRudyÎncă nu există evaluări