Documente Academic

Documente Profesional

Documente Cultură

UFT Specifications

Încărcat de

abduDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

UFT Specifications

Încărcat de

abduDrepturi de autor:

Formate disponibile

UFT Guide Specification and Technical Description

ISI

UFT Series

GUIDE SPECIFICATIONS

And

TECHNICAL DESCRIPTION

For 1.5, 2.25, 3.0, 3.75, 4.8, 6.0, 8.0, 10.0, 12.5 or 16.7kVA

Single-Phase Uninterruptible Power System

This description contains all the necessary functional and technical information for the UFT series

of uninterruptible power supplies.

This specification also provides electrical and mechanical characteristics and an overall description

of the typical operation of an UFT system.

For any further information, please contact our Authorized Sales Representative or Inverter

Systems, Inc. directly.

Inverter Systems, Inc. reserves the right to modify at any time, without notice, the technical

characteristics, illustrations and weights indicated in this document.

Inverter Systems, Inc.

329 Otter Street

Bristol, PA 19007

U.S.A.

Tel: 215-788-8870

Fax: 215-788-8873

Toll Free: 1-800-967-5540

SECTION 1.0 GENERAL

1

113681 rev 04/02

UFT Guide Specification and Technical Description

1.1 SPECIFICATION

This specification defines the electrical and mechanical characteristics and requirements for a standby, single-phase, solid-state uninterruptible power supply, hereafter referred to as the UPS system.

The UPS shall provide high quality, computer grade AC power for todays electronic lighting loads

(power factor corrected and self-ballast fluorescent, incandescent, quartz re-strike or halogen and

HID) during emergency backup.

The UPS shall incorporate a high frequency pulse width modulated (PWM) inverter utilizing IGBT

technology, a microprocessor controlled inverter and a temperature compensating battery charger, a

user friendly control panel with audible and visual alarms.

1.2 DESIGN STANDARDS

The UPS shall be designed in accordance with the applicable sections of the current revision of the

following documents. Where a conflict arises between these documents and statements made

herein, the statements in this specification shall supersede.

UL 924 Standard Emergency Lighting and Power Equipment

ANSI C62.41 (IEEE 587)

ANSI C62.42.45 (Cat. A & B)

National Electrical Code

NFPA- 101

OSHA and Life Safety Code

1.3 SYSTEM DESCRIPTION

1.3.1 Design Requirements - Electronics Module

A. Nominal input/output Voltage

The Input and Output voltage of the UPS shall be pre-configured to match the user

specified input and load requirements. Available voltages are 120, 208, 240, 277 or 480

Vac.

Input: _____ Vac, 1-phase, ___ -wire-plus-ground

Output: _____ Vac, 1-phase, ___ -wire-plus-ground

B. Output Load Capacity

The output load capacity of the UPS shall be rated in kVA at unity power factor. The

UPS shall be able to supply the rated kW from .5 lagging to .5 leading.

Rating: _____ kVA

1.3.2 Design Requirement - Battery System

A. Battery Cells

The UPS shall be provided with sealed, valve regulated lead acid batteries.

2

113681 rev 04/02

UFT Guide Specification and Technical Description

B. Reserve Time

The battery system shall be sized to provide the necessary reserve time to feed

the inverter in case of a mains failure.

Battery Reserve time: ___ minutes

C. Recharge Time

The battery charger shall recharge the fully discharge batteries within a 24 hour period. The

charger shall be an integrated 3 step with equalize, microprocessor controlled and

temperature compensating.

1.3.2 Design Requirement - Transformer Module

For systems with input main voltages (208, 240, 480VAC) the use of an isolation transformer is

required. The transformer is housed in the electronics enclosure. The isolation transformer is not

bypassed when optional maintenance bypass circuit is activated.

1.3.3 Modes of Operation

The UPS shall be designed to operate with less than a 2-millisecond transfer time:

A. Normal

The UPS Inverter is normally off and the commercial AC power continuously supplies the

critical load. The input converter (bi-directional transformer) derives power from the

commercial AC power source and supplies to the inverter while simultaneously providing

floating charge to the batteries.

B. Emergency

Upon failure of the commercial AC power the inverter instantaneously with a maximum of a

2-millisecond break, switches its power supply from the input converter to the battery

system. There shall be no loss of power to the critical load upon failure or restoration of the

utility source.

C. Recharge

Upon restoration of commercial AC power after a power outage, the input converter shall

automatically restart and start charging the batteries. The critical loads are powered by the

commercial AC power again.

1.3.4 Performance Requirements

1.3.4.1 AC Input to UPS

A. Voltage Configuration for Standard Units: 1-phase, 2-wire-plus-ground.

B. Voltage Range:

3

(+10%, -15%)

113681 rev 04/02

UFT Guide Specification and Technical Description

C. Frequency:

60 Hz. (+/- 3Hz)

D. Power Factor:

. 5 lagging / leading

E. Inrush Current: 1.25 times nominal input current, 10 times 1 line cycle for

incandescent loads

F. Current Limit:

125% of nominal input current

G. Current Distortion:

10% THD maximum from 50% to full load

H. Surge Protection:

Sustains input surges without damage per standards set in

ANSI C62.41 (IEEE 587) & ANSI C62.42.45 (Cat. A&B)

1.3.4.2 AC Output, UPS Inverter

A. Voltage Configuration for Standard Units: 1-phase, 2-wire-plus-ground

B. Static Voltage Stability: Load current changes +/- 2%, battery discharge +/- 12.5%

C. Dynamic Voltage Stability:

+/- 2% (25% step load), +/- 3% (50% step load)

D. Dynamic Recovery Time to within 1% of nominal: 3 cycles (0-100% load step)

E. Output Harmonic Distortion:

< 3% (with linear load)

F. Frequency:

60 Hz (+/- .05Hz during emergency mode)

G. Load Power Factor Range:

0.5 lagging to 0.5 leading

H. Output Power Rating:

kVA = kW

I. Overload Capability:

to 100% continuous rating

to 125% for 5 minutes

to 150% for 12 line cycles

J. Crest Factor:

<= 2.8

1.4 ENVIRONMENTAL CONDITIONS

The UPS shall be capable to operate within the specified design and performance criteria provided

that the following environmental conditions are met:

A. Storage/Transport Temperature:

-4 to 158 deg. F (-20 to 70 deg. C) without batteries

0 to 104 deg. F (-18 to 40 deg. C) with batteries*

4

113681 rev 04/02

UFT Guide Specification and Technical Description

* Maximum recommended storage temperature for batteries is 25 deg. C for up to six

months. Storage at up to 40 deg. C is acceptable for a maximum of three months.

B. Relative Humidity:

0 to 95% non-condensing

C. Altitude:

Operating: to 10,000 ft. (3,000 m) above sea level

De-rated 5% per Km above 3 Km

Storage/Transport: to 40,000 ft. (12.2 Km) above sea level

D. Audible Noise:

45 dBA @ 1 meter from surface of the UPS

1.5 SUBMITTALS

1.5.1 Proposal Submittals

Submittals with the proposal shall include the following:

A. System configuration with single-line diagrams

B. Functional relationship of equipment including weights dimensions and heat

Dissipation

C. Descriptions of equipment to be furnished, including deviations from these

specifications

D. Size and weight of units to be handled by installing contractor

E. Detailed layouts of customer power and control connections

F. Detailed installation drawings including all terminal locations

1.5.2 UPS Delivery Submittals

Submittals upon UPS delivery shall include:

1. A complete set of submittal drawings

2. One set of instruction manuals. Manuals shall include a functional description of the

equipment, installation, safety precautions, instructions, step-by-step

operating procedures and routine maintenance guidelines, including illustrations.

1.6 WARRANTY

1.6.1 UPS Module

The UPS manufacturer shall warrant the UPS module against defects in materials and workmanship

for 12 months after initial start-up or 18 months after ship date, whichever occurs first.

1.6.2 Battery

The battery manufacturers standard warranty shall be passed through to the end user.

Sealed Lead Calcium VRLA, 10-year life expectancy one-year full replacement warranty plus an

additional nine years pro-rata.

5

113681 rev 04/02

UFT Guide Specification and Technical Description

1.7 QUALITY ASSURANCE

1.7.1 Manufacturer Qualifications

A minimum of 35 years experience in the design, manufacture, and testing of emergency power

systems is required.

1.7.2 Factory Testing

Before shipment, the manufacturer shall fully and completely test the system to assure compliance

with the specification.

SECTION 2.0 PRODUCT

2.1 FABRICATION

All materials of the UPS shall be new, of current manufacture, high grade, free from all defects and

shall not have been in prior service except as required during factory testing.

The UPS module shall be housed in a single freestanding NEMA type 1 enclosure. Battery cabinets

are designed to allow stacking to minimize the overall systems footprint. Front access only shall be

required for installation, adjustments and expedient servicing (MTTR: < 15 minutes). All

components shall have a modular design and quick disconnect means to facilitate field service.

The UPS shall be powered painted with the manufacturers standard color. The UPS shall be

constructed of replaceable subassemblies. Like assemblies and like components shall be

interchangeable.

Cooling of the UPS shall be forced-air in emergency mode with internally mounted fans to minimize

audible noise. Fans shall not operate in the battery charge / standby mode. Fan power shall be

provided by the UPS.

2.2 COMPONENTS

The UPS shall be comprised of the following components:

A. UPS Module - The UPS module shall contain an inverter, an AC distributions with an

input circuit breaker, control, and monitoring subsystems.

B. Battery Module - The battery module shall contain the battery plant required to

produce the reserve energy to supply the inverter during abnormal AC mains conditions.

The battery module may be contained in an external cabinet(s) depending on the system

VA.

2.2.1 Battery Charger

A. General

In the standard configuration the charger converts ac voltage to dc voltage. With commercial power

present, the inverter power transformer is powered and the IGBT modules are microprocessor

controlled to recharge the batteries. The temperature compensated battery charger circuit supplies

6

113681 rev 04/02

UFT Guide Specification and Technical Description

constant voltage and constant current to the batteries. Once the batteries have received a full

recharge, a constant trickle charge maintains batteries at maximum level. Recharge time is 24 hours

maximum at nominal ac input voltage. The ac ripple current of the dc output meets the battery

manufacturer specification, thus ensuring the maximum battery lifetime.

B. AC Input Current

The charger unit is provided with an ac input current limiting circuit whereby the maximum input

current shall not exceed 125% of the output full current rating.

C. Automatic Restart

Upon restoration of utility AC power, after a utility AC power outage and after a full UPS

automatic end-of-discharge shutdown, the UPS will automatically restart, performing the normal

UPS start up.

D. DC Filter

The charger shall have and output filter to minimize AC ripple voltage into the battery.

Under no conditions shall ripple voltage into the battery exceed 2% RMS.

E. Battery Recharge

The charger is capable of producing battery-charging current sufficient enough to recharge the fully

discharge battery bank within a 24-hour period. After the battery is recharged, the charger shall

maintain full battery charge until the next emergency operation.

F. Over-voltage Protection

The charger is equipped with a DC over-voltage protection circuit so that if the DC voltage rises

above the pre-set limit, the charger is to shut down automatically and initiate an alarm condition.

2.2.2 Inverter

A. General

The inverter converts dc voltage supplied by the battery to ac voltage of a precisely stabilized

amplitude and frequency that is suitable for powering most sophisticated electrical equipment.

The inverter output voltage is generated by sinusoidal pulse width modulation (PWM). The use of a

high carrier frequency for PWM and a dedicated ac filter circuit consisting of a transformer and

capacitors, ensure a very low distortion of the output voltage (THD<3% on linear loads).

B. Overload Capability

The inverter during emergency modes shall be capable of supplying current and voltage for

overloads exceeding 100% and up to 150% of full load current for 12 line cycles, 125% for 5

minutes and 110% for 10 minutes.

7

113681 rev 04/02

UFT Guide Specification and Technical Description

C. Output Power Transformer

A dry type power transformer provides the inverter AC output. The transformer is built

with copper wiring exclusively. The hottest winding temperature of the transformer shall not

exceed the temperature limit of the transformer insulation class of material at ambient temperature.

2.2.3 Display and Controls

A. Monitoring and Control

The UPS system provides operation monitoring and control, audible alarms, LED indicators, and

diagnostics. The front-mounted control panel includes a 2-line 40-character LED display, a keypad

to control and monitor the internal operation of the system. This allows the operator to easily

watch system functions as they occur and check on virtually any aspect of the systems operation.

Monitoring and control are microprocessor-based for accuracy and reliability. To ensure only

authorized personnel can operate the unit, the system is multi-level password protected for all

control functions and parameter changes.

B. Metering

Scrolling through the meter functions can monitor the following measurements:

- Utility input voltage

- System output voltage

- Battery voltage

- Battery current

- System output current

- System output VA

- Inverter wattage

- System temperature

- Date & time

C. LED Indication

The front panel with integrated LEDs, allows a quick check of the UPS operating status.

- AC Present (Green)

- System Ready (Green)

- Battery Charging (Yellow)

- Battery Power (Yellow)

- Fault (Red)

D. Audible Alarm

Audible alarm will activate with any of the following conditions and automatically store the 50 most

recent events.

- High battery charger voltage

- Low battery charger voltage

- High AC input voltage

- Low AC input voltage

- Near low battery voltage

- Low battery voltage

8

113681 rev 04/02

UFT Guide Specification and Technical Description

Load reduction fault

High Ambient temperature

Inverter fault

Output fault

Output overload

2.2.4 RS-232 Interface

The system shall be equipped with an RS-232 serial port (DB9) for remote communications.

2.2.5 Manual and Programmable Testing

The system shall incorporate a manual test function and two automatic test modes. The system will

perform a programmable, self-diagnostic monthly test for 5 minutes which is preset for the 15th of

every month and the user can program the event time of day. The yearly self-diagnostic test is for

90 minutes and the user can program the time of the day the event is to take place. The

microprocessor automatically records the last 75 test events in its own separate test result log.

2.2.6 Battery Assembly

The batteries are sealed, lead-acid valve regulated battery cells with a ten year prorated warranty.

Precut cable wires are included to provide easy installation. A disconnect means shall be included

for isolation of battery assembly from the UPS module.

2.2.7 System Options

-

Output Circuit Breakers:

Distribution circuit breakers are for output load protection. Protection for the normally on

and/or for the optional normally off loads. A maximum of 12 unsupervised 1-pole and a

maximum of 8 supervised 1-pole circuit breakers are available for all systems. A maximum of

6 unsupervised 2-pole and a maximum of 4 supervised 2-pole circuit breakers are available for

all systems. All circuit breakers are rated for 10,000 AIC.

Output Circuit Breaker Trip Alarm:

An audible and visual alarm activates when an output distribution circuit breaker is open or

has tripped.

Summary Form C Contacts:

Form C contacts rated at 5 amps maximum at 250VAC/30VDC. Dry contacts will change

state when any system alarm activates. Contacts change states with the following alarms:

High/low battery charger fault, near low battery, low battery, load reduction fault, output

overload, high/low AC input volts, high ambient temperature, inverter fault, and with optional

circuit breaker trip alarm.

Fast Charge:

This is a battery charger upgrade, which decreases the time to recharge a fully discharged

battery bank to a full charge. The recharge time is decreased from the standard 24-hour period

to a 12-hour period.

Maintenance Bypass Switch:

9

113681 rev 04/02

UFT Guide Specification and Technical Description

This device is internally mounted in the system and permits maintenance personnel to easily

bypass the protected equipment directly to the AC utility power. The make before break

switch isolates the system to perform routine maintenance or servicing.

-

Normally Off Output:

This output circuit is dedicated for the emergency equipment only. Emergency equipment only

operates during power outages and when the system is on battery back up. This option leaves

the load circuits off during normal utility power conditions.

Long Life Sealed Lead Calcium, VRLA Battery:

Maintenance free battery that requires no addition of water over the life of the battery. The

battery cells are housed in protective, modular steel trays. Life expectancy is designed for 20years at 77F (25C). Warranty is one-year full replacement plus an additional fourteen years

pro-rata.

Wet Nickel Cadmium Battery:

Cell containers are made of translucent, heavy-duty polypropylene, making it easy to check the

electrolyte level. The battery cells are housed in cabinets with step shelves. Life expectancy is

designed for 25-years at 77F (25C). Warranty is one-year full replacement plus an additional

fourteen years pro-rata.

2.2.8 Accessories

-

Remote Meter Panel:

This allows greater flexibility to monitor all the system parameters from a remote location. Up

to 300 feet away from the system. This allows the user to remotely monitor the status of the

inverter. Also allows user to control and program the inverter from a remote location.

Modem:

Modems are devices that boost the signal level of the RS-232 diagnostic interface

communications to a remote location that is more than 100 feet away from the system.

External Maintenance Bypass Switch:

This maintenance bypass switch is mounted in a NEMA 1 enclosure with a hinged door

measuring 20 high by 16 wide by 7 deep and permits maintenance personnel to easily

bypass the protected equipment directly to the AC utility power. The make before break

switch isolates the system to perform routine maintenance or servicing. This accessory cannot

be used in conjunction with more than one output circuit breaker in the system and the output

circuit breaker must be sized for the total system current.

SECTION 3.0 EXECUTION

3.1 WIRING

All wiring shall be installed in conduit. Input and output wiring shall enter the cabinet in separate

conduits.

3.2 UNIT START-UP and SITE TESTING

10

113681 rev 04/02

UFT Guide Specification and Technical Description

Site start-up and testing shall be provided by the manufacturers field service representative during

normal working hours (Mon. - FRI. 8 a.m. - 5 p.m.). Individual scheduling requirements

can usually be met with 7 working days advance notice. Site testing shall consist of a complete

test of the UPS and accessories by the UPS manufacturer in accordance with manufacturers

standards. Manufacturers approved service representative must perform commissioning for twoyear warranty applies.

3.3 REPLACEMENT PARTS

Parts shall be available through Field Service Centers throughout the country. Recommended spare

parts shall be fully stocked by local field service personnel with back up available from

manufacturing location.

3.4 MAINTENANCE CONTRACTS

A complete offering of preventive and full-service maintenance contracts for both the UPS

system and batteries shall be available. An extended warranty and preventive maintenance

package shall be available. Factory-trained service personnel shall perform warranty and preventive

maintenance service. A five-year maintenance contract will include a unit start-up and site testing.

11

113681 rev 04/02

S-ar putea să vă placă și

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 paginiITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemÎncă nu există evaluări

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 paginiITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemÎncă nu există evaluări

- Liebert NPower Guide SpecsDocument18 paginiLiebert NPower Guide SpecstwobruinsÎncă nu există evaluări

- Guide Specifications Symmetra 96 160kVADocument8 paginiGuide Specifications Symmetra 96 160kVAAugusto Francisco Diaz LaraÎncă nu există evaluări

- APC by Schneider Electric: APC Symmetra PX Guide Specifications 96/160 KW Uninterruptible Power SystemDocument8 paginiAPC by Schneider Electric: APC Symmetra PX Guide Specifications 96/160 KW Uninterruptible Power SystemAugusto Francisco Diaz LaraÎncă nu există evaluări

- Liebert Npower Guide SpecificationsDocument16 paginiLiebert Npower Guide SpecificationsJOSE MIGUEL AYALA DURANÎncă nu există evaluări

- Symmetra PX 48kW - Guide SpecificationDocument11 paginiSymmetra PX 48kW - Guide SpecificationAugusto Francisco Diaz LaraÎncă nu există evaluări

- UPS Specification CSI 263353 03LPDocument18 paginiUPS Specification CSI 263353 03LPJuvencio MolinaÎncă nu există evaluări

- Liebert Exm 50 250kva Single Module Guide Specifications - 00Document18 paginiLiebert Exm 50 250kva Single Module Guide Specifications - 00naveedfndÎncă nu există evaluări

- Eaton 9155 Ups Guide SpecDocument12 paginiEaton 9155 Ups Guide SpecFernando Joan Ramos RojasÎncă nu există evaluări

- Galaxy VX 300 To 1500kW 400 V Guide Specification 12nov2019 PDFDocument17 paginiGalaxy VX 300 To 1500kW 400 V Guide Specification 12nov2019 PDFkargayasnowÎncă nu există evaluări

- Liebert NX Ups Guide SpecsDocument16 paginiLiebert NX Ups Guide SpecstwobruinsÎncă nu există evaluări

- CONVENTIONNAL UPS - 100kva To 800kva - Tender Technical SpecificationsDocument8 paginiCONVENTIONNAL UPS - 100kva To 800kva - Tender Technical SpecificationsMuhammad Qumar NazeerÎncă nu există evaluări

- APC Symmetra LX UPS Guide SpecDocument14 paginiAPC Symmetra LX UPS Guide SpecRenato Maillo100% (1)

- SchneiderDocument18 paginiSchneideruddinnadeemÎncă nu există evaluări

- 40-80 kVA 3-Phase UL924 Guide SpecificationDocument16 pagini40-80 kVA 3-Phase UL924 Guide SpecificationDiegoJoseMorenoMoralesÎncă nu există evaluări

- UPS Guide SpecsDocument13 paginiUPS Guide SpecsONILEDA1970100% (1)

- Galaxy PW Muti Module Technical SpecsDocument30 paginiGalaxy PW Muti Module Technical SpecsRUBEN LOZANOÎncă nu există evaluări

- Inter Plant Standard - Steel Industry: 3.1.1 Ambient Temperature - The Reference Ambient Temperature Shall Be 50Document7 paginiInter Plant Standard - Steel Industry: 3.1.1 Ambient Temperature - The Reference Ambient Temperature Shall Be 50Velu SamyÎncă nu există evaluări

- CONVENTIONNAL UPS - 10kva To 120 - Tender Technical SpecificationsDocument8 paginiCONVENTIONNAL UPS - 10kva To 120 - Tender Technical SpecificationsMuhammad Qumar NazeerÎncă nu există evaluări

- 93E 15-80 KVA Guide SpecificationDocument11 pagini93E 15-80 KVA Guide SpecificationHafiz SafwanÎncă nu există evaluări

- 401985Document82 pagini401985Julio Cesar Garcia ReyesÎncă nu există evaluări

- GE VH UPS Guide Spec TemplateDocument12 paginiGE VH UPS Guide Spec TemplateJohn CollinsÎncă nu există evaluări

- UpsDocument18 paginiUpsVan Phuong PhamÎncă nu există evaluări

- CONVENTIONNAL UPS - 1KVA To 10KVA - Tender Technical SpecificationsDocument6 paginiCONVENTIONNAL UPS - 1KVA To 10KVA - Tender Technical SpecificationsMuhammad Qumar NazeerÎncă nu există evaluări

- 15-90 kW Modular UPS Tender SpecsDocument11 pagini15-90 kW Modular UPS Tender SpecsdhruvÎncă nu există evaluări

- Marine Three-Phase UPS Guide SpecificationDocument12 paginiMarine Three-Phase UPS Guide SpecificationJosephine Wong Sian CheeÎncă nu există evaluări

- 500 kW UPS Guide SpecificationDocument14 pagini500 kW UPS Guide Specificationnn rajeshÎncă nu există evaluări

- Eaton 93e 20 60 Kva Guide SpecDocument15 paginiEaton 93e 20 60 Kva Guide SpecMMM ManoÎncă nu există evaluări

- Vertiv Liebert gxt5 500 3000 Va Rack Tower Guide Specifications SL 71027Document13 paginiVertiv Liebert gxt5 500 3000 Va Rack Tower Guide Specifications SL 71027Dendy PurnamaÎncă nu există evaluări

- Guide Spec 9395P 200-600kW UPS PDFDocument19 paginiGuide Spec 9395P 200-600kW UPS PDFabual3ezÎncă nu există evaluări

- GXT3-10000RT230 Guide Spec PDFDocument12 paginiGXT3-10000RT230 Guide Spec PDFAlan BartlettÎncă nu există evaluări

- GXT2-10000T230 Service ManualDocument33 paginiGXT2-10000T230 Service ManualMilton Mejia80% (10)

- REM HR8022 001 - A User ManualDocument31 paginiREM HR8022 001 - A User Manualwaqkhan0% (1)

- AHC Static UPS SystemDocument8 paginiAHC Static UPS SystemsallammohamedÎncă nu există evaluări

- UPS SPEC TECHNICAL SPECDocument26 paginiUPS SPEC TECHNICAL SPECengrrafÎncă nu există evaluări

- Solid State UPS Provides Reliable PowerDocument7 paginiSolid State UPS Provides Reliable PowerMuhammad Qumar NazeerÎncă nu există evaluări

- Mge Galaxy 5000 PDFDocument17 paginiMge Galaxy 5000 PDFNgoy mulundaÎncă nu există evaluări

- 20 - 80 kVA UPS User's and Installation ManualDocument40 pagini20 - 80 kVA UPS User's and Installation ManualediÎncă nu există evaluări

- 9305_20-80_kVA_Users_and_Installation_manual_1015543D_GBDocument40 pagini9305_20-80_kVA_Users_and_Installation_manual_1015543D_GBkraguz5Încă nu există evaluări

- Galleon 2-3KVA Service Manual-20090730Document28 paginiGalleon 2-3KVA Service Manual-20090730EDWARD TUTA67% (3)

- 46 TMSS 03 R0Document0 pagini46 TMSS 03 R0renjithas2005Încă nu există evaluări

- Eaton Connected Datacenter UPS and LV DistributionDocument9 paginiEaton Connected Datacenter UPS and LV DistributionGustavo GamezÎncă nu există evaluări

- QCS 2010 Section 21 Part 18 Uninterruptible Power Supply SystemsDocument5 paginiQCS 2010 Section 21 Part 18 Uninterruptible Power Supply Systemsbryanpastor106Încă nu există evaluări

- Powerware 9305 20-80 Kwa PDFDocument520 paginiPowerware 9305 20-80 Kwa PDFalex80% (5)

- UPS SpecificationDocument15 paginiUPS Specificationpreetam100% (1)

- Eum HR9002-001 - A (2009.7.2)Document29 paginiEum HR9002-001 - A (2009.7.2)waqkhanÎncă nu există evaluări

- sl-26158 Rev2 09-21Document13 paginisl-26158 Rev2 09-21ldiipahmedÎncă nu există evaluări

- Manual USM - 2 - 5 PDFDocument28 paginiManual USM - 2 - 5 PDFJuan Carlos Zapata BuilesÎncă nu există evaluări

- Ups-0003 Ups-Um 0621-En Rv00 Kgk-2k User ManualDocument45 paginiUps-0003 Ups-Um 0621-En Rv00 Kgk-2k User Manualjuan.rodriguez.youutubeeÎncă nu există evaluări

- Chloride LINEAR MK II - Service ManualDocument32 paginiChloride LINEAR MK II - Service Manualfabio.perazzoloÎncă nu există evaluări

- 7011B SERIES: UNINTERRUPTED Peace of MindDocument11 pagini7011B SERIES: UNINTERRUPTED Peace of MindJuan CastañedaÎncă nu există evaluări

- LADS Modular 2-3K Online UPS ManualDocument27 paginiLADS Modular 2-3K Online UPS ManualAllamÎncă nu există evaluări

- Qcs 2014 - Sec21 p18 - Uninterruptible Power SupplyDocument6 paginiQcs 2014 - Sec21 p18 - Uninterruptible Power Supplychandra100% (1)

- 7011a 6-10kva SpecsDocument10 pagini7011a 6-10kva SpecsOscar MorenoÎncă nu există evaluări

- Optimize your PV system with the OK4-100 AC inverterDocument4 paginiOptimize your PV system with the OK4-100 AC inverterdavidmc6375Încă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Arcam A70 Amplifier Amplificateur Arcam A70 Arcam-Verstärker A70 Arcam-Versterker A70Document52 paginiArcam A70 Amplifier Amplificateur Arcam A70 Arcam-Verstärker A70 Arcam-Versterker A70Ella MariaÎncă nu există evaluări

- Metal Shark® 2 Metal Shark® 2 Metal Shark® 2 Metal Shark® 2Document88 paginiMetal Shark® 2 Metal Shark® 2 Metal Shark® 2 Metal Shark® 2RAFLY SYAHÎncă nu există evaluări

- Goldmedal Common Price List - 2022Document98 paginiGoldmedal Common Price List - 2022Tasbeeh EleÎncă nu există evaluări

- ELEC9713 Lecture Notes 6IN1Document90 paginiELEC9713 Lecture Notes 6IN1smart jamesÎncă nu există evaluări

- MD 602 MD 612 GBDocument76 paginiMD 602 MD 612 GBCleiver MaasÎncă nu există evaluări

- Combined Searchable Employer Requirement)Document389 paginiCombined Searchable Employer Requirement)Ahmad ButtÎncă nu există evaluări

- FMT18 Conventional Room DrawingDocument2 paginiFMT18 Conventional Room DrawingMr. AlegríaÎncă nu există evaluări

- Fdd60s (TNK JKT) 2020Document1 paginăFdd60s (TNK JKT) 2020hareudangÎncă nu există evaluări

- Technical Specification For 20 KVA GeneratorDocument3 paginiTechnical Specification For 20 KVA GeneratorNurye NigusÎncă nu există evaluări

- 100 Series Microchip Petporte Smart Flap Manual en FR NL de IT ESDocument125 pagini100 Series Microchip Petporte Smart Flap Manual en FR NL de IT ESJuan Fernandez GarciaÎncă nu există evaluări

- EasYgen-1000 Series InstallationDocument53 paginiEasYgen-1000 Series InstallationRavi KumarÎncă nu există evaluări

- MP 3VFMAC Dip SWDocument20 paginiMP 3VFMAC Dip SWthanggimme.phanÎncă nu există evaluări

- 4we10 .. Serie 5XDocument24 pagini4we10 .. Serie 5XDanilo BrunelloÎncă nu există evaluări

- Contactor by EE Controls PDFDocument10 paginiContactor by EE Controls PDFPaul MendozaÎncă nu există evaluări

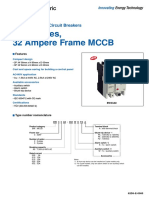

- BW0 Series, 32 Ampere Frame MCCB: Fuji Molded Case Circuit BreakersDocument4 paginiBW0 Series, 32 Ampere Frame MCCB: Fuji Molded Case Circuit BreakersAutomation Engineering & Controls Ltd.Încă nu există evaluări

- ElectricalDocument44 paginiElectricalRachitÎncă nu există evaluări

- Melag Vacu 23-31 - Fault DiagnosisDocument25 paginiMelag Vacu 23-31 - Fault DiagnosisFrepa_AL100% (3)

- Nabertherm Manuale B150Document20 paginiNabertherm Manuale B150So Nic0% (2)

- Product data sheet for Lexium 23 motion servo driveDocument9 paginiProduct data sheet for Lexium 23 motion servo drivePablo OrricoÎncă nu există evaluări

- Preventive MaintenanceDocument31 paginiPreventive MaintenanceNeeraj Singh100% (1)

- VFD-convertidor Chino PDFDocument69 paginiVFD-convertidor Chino PDFvaronibericoÎncă nu există evaluări

- VtsDocument4 paginiVtsPe MorÎncă nu există evaluări

- LF - DPS 600B 48 4 19IN - enDocument2 paginiLF - DPS 600B 48 4 19IN - enchipuwaÎncă nu există evaluări

- WinnerPro 6 10KVA - ManualDocument26 paginiWinnerPro 6 10KVA - ManualevanilsonsantanaÎncă nu există evaluări

- FlygtDocument40 paginiFlygtAbdo MawjoudÎncă nu există evaluări

- Adjustable electronic timer accessories kitDocument2 paginiAdjustable electronic timer accessories kitgerardo floresÎncă nu există evaluări

- Technical Specifications for Master MPS UPSDocument36 paginiTechnical Specifications for Master MPS UPSCarlucho15Încă nu există evaluări

- Wbs Binder PDFDocument49 paginiWbs Binder PDFKuncoro Arry MochaaÎncă nu există evaluări

- The Case of The Floating Neutral-EC&MDocument4 paginiThe Case of The Floating Neutral-EC&MJOSE LUIS FALCON CHAVEZÎncă nu există evaluări

- Catalogo KondorDocument138 paginiCatalogo KondorSEBASTIAN PEREZ100% (1)