Documente Academic

Documente Profesional

Documente Cultură

M 2548 M 2558 Brochure

Încărcat de

Ravinder KadianTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

M 2548 M 2558 Brochure

Încărcat de

Ravinder KadianDrepturi de autor:

Formate disponibile

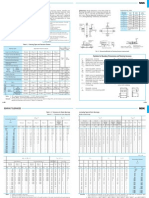

Turret Layout

INDEX

GHJ

B

C

C

B

D

D

X

X

B

B

B

X

B

X

B

B

B

C

BX

XB

C

B

X

B

X

B

B

B

X

X

54 Stations

2 Index

D

B

X

X

B

B

INDEX

B

X

B

D

D

CNC Servo Motor Driven Ram Turret Punch Press

B

EF

EF

XB

44 Stations

4 Index

X

BX

B

X

B

Floor Plan

INDEX

X

X

MOTORUM 2548

D

D

Machine weight

26,400 lbs

EF

GHJ

C

INDEX

CNC Servo Motor Driven Ram Turret Punch Press

52.76"

GHJ

C

INDEX

Round punch

X

B

C

D

E

F

G

H

J

INDEX

VT

VM

0.5"

1.0"

1.5"

2.0"

2.5"

3.0"

3.5"

4.0"

4.75"

3.0"

12,18 Stations

20,40 Characters

No. of Stations

54ST/2 I/T

10

28

6

4

44ST/4 I/T

10

16

6

4

98.43"

7' 5"

Range

16' 7"

Tooling range

* With Auto-index stations, Index tool (I/T), VARITOOL (VT) or VARIMARK (VM) can be selected as

options in desired combination.

Option

Varitool

Varimark

Brush table

4-Station Tapping

8-Station Tapping

Retractable Die-holder function

Programmable up forming

In turret bending

Slug suction unit

Downward extrusion protection

Programmable positioning workholder

Cell ready

Safety Specification

Machines built CE-safety conformity is available as option.

17' 1"

Floor Plan

MOTORUM 2558

Machine weight

33,000 lbs

63.78"

MOTORUM 2548 MOTORUM 2558

27.5 tons (245 KN)

0.25" (Steel ball table)

63.0"

75.0"

100.4"

49.21" 98.43"

60.04" 98.43"

49.21" 196.85"

60.04" 196.85"

52.76"

63.78"

0.984"

330 lbs

X: 400 HPM / Y: 300 HPM

X: 800 HPM / Y: 700 HPM

4.920"/min

0.004"

40 rpm

180 rpm

35 ft3/min

71 PSI

23 KVA

18' 6"

Punching capacity

Maximum sheet thickness

Y-axis stroke

X-axis stroke

Maximum sheet size Without repositioning

(Yx X)

With one reposition

Throat depth

Feed clearance

Maximum allowable sheet weight

Hit rate

Punching: 25 mm pitch

Nibbling: 1 mm pitch

Simultaneous axis speed

Punching accuracy

Turret index speed

Index tool speed

Quantity

Compressed air

Pressure

Power supply

98.43"

7' 5"

Specifications

60.04"

EF

72.04"

38.58"

INDEX

17' 1"

38.58"

B

GHJ

* Machine appearance may differ to that shown in the catalogue pictures.

* All specifications are subject to change without advanced notice.

CAT. NO.92P1062 B 08-01-2(X-TU)

CNC Servo Motor Driven Ram Turret Punch Press

Servo Drive Pioneer Motorum has evolved to a new level

Functionality !

Power !

Speed !

Process Integration

Downward extrusion up to 0.079"

Servo controlled upward forming

In turret bending height as high as 0.787"

Increased power delivers

higher processing stability

Servo motor with 27.5 tons punching capacity

Increased speed raises productivity

Higher auto-index speed, to 180 rpm

Faster punching rate, to 400 hpm

Note: Photographs in this catalogue include some options.

Ram Operation Patterns

The Servo Motor Driven Punching Mechanism

Toggle Link

Crank Arm

Ram

Punch Holder

Cam Drive

Cylinder

The servo motor drive mechanism delivers precise RAM control. Combined with Muratec application,

Motorum 2548/2558 enables Ram Operation Patterns ideal for a wide range of processes.

Nibbling Operation

Forming Operation

Low Noise Operation

RAM Stroke

RAM Stroke

RAM Stroke

High Speed Punching

RAM Stroke

The MURATEC ram drive technology

incorporates a toggle mechanism driven by

an AC servo motor. This innovative

technology has resulted in achieving higher

productivity, an environment friendly

operation, and energy efficient production. A

single rotation of the crank arm gives two

punching strokes.

By utilizing a mechanical advantage, the

servo driven ram technology provides greater

punching force while generating less heat

and using less energy.

Punch-in, Pull-Out Type Wiedemann Tooling

Energy Conservation & Low Running Cost

The positive Punch-in and Pull-out design of the

ram, which is mechanically linked to the punch

holder during the punching cycle, guarantees

positive punching. This design has already been

field proven for its high strength, precision and

simplicity of tooling.

By combining this feature with the newly

innovated servo motor driven ram, the reliability

of the machine has been greatly enhanced.

An environment-friendly eco-machine, Motorum

uses the energy it needs only at the time of

punching, thanks to the servo motor drive

mechanism.

Power Consumption Comparison

(%)

Time

The servo motor is driven

alternately in clockwise and

counter clockwise directions

to swing the toggle

mechanism between two top

dead centers and a bottom

dead center. The two top

dead centers are

automatically adjusted to suit

the sheet thickness data to

achieve the shortest ram

stroke and thus high speed

punching and productivity.

Time

The servo motor is driven

continuously in one

direction to swing the toggle

between two top dead

centers and bottom dead

center repeatedly for high

speed nibbling operation.

Time

By swinging the toggle mechanism

between first top dead center and

bottom dead center positions and

by adjusting the length of stroke, the

top and bottom dead centre can be

controlled to obtain the best results

in forming tool operations. The most

important benefit of this operation in

MOTORUM-2548/2558 punch press

is that you can set the length of

dwell time at bottom dead center

that will allow the form tools to be

kept together allowing material flow,

filling the form tool cavities. Precise

control over ram operation enables

excellent forming repeatability.

Time

Power consumption

during punching

100

Full control of the ram speed

is maintained within one

punching cycle to achieve the

ultimate reduction in noise

and vibration.

70% Reduction

Standby power

consumption

30% Reduction

50

43

30

VECTRUM-3046

MOTORUM 2548/2558 CENTRUM-3000

The Key to Reduced Lead Time

In Turret Bending

Process types

L bend

C bend

T

Tapping

apping

(Option)

Stations used:

Auto-index (F-Station)

The servo drive allows precise stop

positioning of the RAM punch, which

in turn gives accurate angle control,

for Z-bending via index-station

processing. Increase in turret feed

clearance takes the in turret bending

height to a maximum of 0.787".

Motorum 2548/2558 provides high speed processing with reliability and accuracy. This machine also raises overall productivity through process integration

of bending, forming, tapping and other processes, together with reduction of time needed to setup and program.

Z bend

Sheet thickness: 0.02"- 0.06" (Mild Steel)

8-Station Tapping Unit (Option)

A full-scale rigid tapping unit using with

synchronization of RPM and feed speed

by the servo motor.

Tap size: M2 10

Tapping methods:

Machine thread / Rolling thread

Max. sheet thickness: 0.25"

*Specifications vary, depending on type of material,

hole diameter, etc.

Z bend

Designed for higher productivity,

quality and operating ease

Brush Table (Option)

8-Station Tapping Unit

(Option)

L bend

C bend

4-Station Tapping Unit (Option)

This tapping unit uses the floating

method with dual cylinder feeding for a

preset RPM.

Tap size: M2.6 M8

Tapping methods:

Machine thread / Rolling thread

Max. sheet thickness: 0.125"

Forming

Optimum control of RAM speed leads to fast and accurate forming of the

highest quality, with minimal distortion of the workpiece.

*Specifications vary, depending on type of material,

hole diameter, etc.

Retractable Repositioning Pad Buttons

4-Station Tapping Unit

(Option)

Retractable forming die function

Upward forming tool dies are

retracted to die height when not in

use. This is to avoid interference of

the forming die with the workpiece

and workholders. This allows free

movement of the sheet without any

restrictions and improves quality.

Not in use

In use

While reducing scratching on

the back of the worksheet, the

brush table also gives stable

movement of the worksheet.

The brush table reduces noise

during worksheet movement

and eliminate scratches to the

back of worksheet.

High-Speed Auto-Index Mechanism

Index tool speed has been raised to 180RPM. Reduction of positioning time for index tool

angles, multi-tools and marking tools shortens production time.

Retractable repositioning pad buttons

are raised automatically for clamping

the worksheet during the repositioning

operation only. During normal

punching when the worksheet is

moving over the repositioning pad

buttons, the buttons are retracted

downward which

eliminates scratches on

the under side of the

UP

worksheet. This

DOWN

enhances the quality of

the finished worksheet.

Programmable up forming (Option)

Varitool (Option)

Conventional turret punch presses have

long had difficulty with downward

extrusion. As the formed work is lifted off

the upper surface of the die during

table/sheet movement, this option

eliminates degradation of the form

stemming from interference with the die.

0.079"

Downward extrusion protection (Option)

Varitool

12-station type

(Option)

Varimark (Option)

Varimark

(Option)

The VARIMARK is built-in with 20 or 40

standard alphanumeric and punctuation

characters for stamping on the worksheet.

Stamping Character Size:

0.083" x 0.125" (40 characters)

0.125" x 0.197" (20 characters)

Ball transfers

Repositioning

pad buttons

The slug suction unit enables better punching quality and minimizes

slug pull-back problem for thin worksheets. This function is extremely

useful while processing worksheets having scratch prevention films.

The air suction helps to detach cut films from the workpiece.

Fast indexing any angle shortens

production of needed for complex forms.

The VARITOOL is available in 12 and 18

tool configurations. Using VARITOOL in

the Auto-index station increases the turret

tool capacity. The 12-station tool

configuration has tool sizes up to 0.5"

dia., while the 18-station has a maximum

tool size of 0.354" dia.

Workpiece

Slug Suction Unit (Option)

High-Speed Indexing

After lowering the punch onto the

material, the servo controlled upward

forming stroke will not lift the material.

This improves accuracy on extrusion and

other high precision forming processes.

Repositioning pad

Built-in Turret Parts Chute

A part chute is provided

underneath the inner track punch

centre for efficient discharge of

small parts, to enable micro

jointless parts production. The parts

discharge port is located at CNC

control side of the press frame.

Maximum part size:

7.9" (X) x 5.9" (Y)

Minimum part size :

1.2" (X) x 3.1" (Y)

Sheet Metal Processing Expertise

Optional Automated Cell Systems

The operator should be able to output a high level of processing know-how without having to

think about how to do it, and this is the control concept of MOTORUM.

Applying the rich delivery results and expertise of sheet metal FMS, Muratec offers automated

cell systems ideal for client needs.

Skeleton

Features

Micro jointless parts production

Flexible stacking system reduces

Post-process operations and parts handling

Manual blank sheet loading operation is possible

Effective parts handling of small size and hole intensive parts

NC-type loader unit control & scheduler

Blank sheet

18' 9"

FG-1250/FG-1500

[22' 4"]

Tool Life Monitor Function

9' 3"

Tool Alignment Confirmation Function

[9' 3"]

Conversational NC Programming and Editing

Parts

35' 2"

Program Creation & Background Editing

Programs can be created using the

conversational mode.

Background editing of programs is also possible.

The MOTORUM servo ram control features a ram

motor torque monitoring system that enables the

operator to detect punch and die nonalignment,

avoiding damages to the punch and die.

The MOTORUM incorporates a programmable

auto tool life monitor function, that when tool

life has reached a set hit number the "Tool Life

Caution" message is displayed to capture the

operator's attention to carry out the punch and

die regrinding.

FG-1250

FG-1500

49.2" x 98.4" 60.0" x 120.0"

[41' 0"]

Sheet Size: Max.

(Y x X)

Min. [Nested Layout] 39.4" x 59.0"

[Single Part]

11.8" x 19.7"

Blank Sheet Thickness:

0.024" to 0.125"

*Stocker type is also available

[ ]:FG-1500

Benchmark

Worksheet example

F1G-1250/F1G-1500

Mild Steel 0.05" thick. 4 x 8

42% Reduction

5 min 45 s

CENTRUM-3000

19' 9"

Space saving compact design

Increased productivity through reduced loading cycle time

Quieter system operation

Manual blank sheet loading operation is possible

NC-type loader unit control & scheduler

[23' 6"]

Features

58

Blank Sheet

100

21' 5"

Compact design to store and handle full size blank sheets

and finished parts

Side panel reinforcement lip

Dowel fastening

Slotting into half-moon dowels

Unmanned operation over extended periods for variety of

production schedules

Quieter system operation

Manual blank sheet loading operation is possible

NC-type loader unit control & scheduler

Perfect-fit bottoming

In turret bending by turret punch

[25' 1"]

Features

Slit

In turret bending by press brake

Blank Sheet

32' 7"

Want to reduce the number of parts ?

Want to reduce

the"site

number

of actual

parts ?

eliminate

matching"

work

FFG-1250

FFG-1500

49.2" x 98.4" 60.0" x 120.0"

11.8" x 29.5"

0.024" to 0.177"

25 seconds 29 seconds

17' 0"

Sheet Size: Max.

(Y x X)

Min.

Blank Sheet Thickness:

Loading / Unloading Cycle Time:

Downward bridge formation

[17' 0"]

[36' 9"]

Want to decrease the number of welded

parts

raise

efficiency ?

weld parts

andand

raise

efficiency

improve

production

processes ?

Want to revise

thethe

production

mechanism

Completed Sheet

14' 11"

Want to consolidate processes and

reduce holding time for work-in-process ?

Air bends

&

bottoming

In turret bending by turret punch

Do you

Want to raise production speed ?

FFG-1250/FFG-1500

Muratec endeavors to increase overall processing speed for sheet metal products

Upper panel stop

11.8" x 29.5"

0.024" to 0.177"

22 seconds 29 seconds

[ ]:F1G-1500

Examples of suggestions

for process integlation

In addition to improving processing ability,

Muratec works with customers in revising

production processes for sheet metal products

and offers suggestions for improvement of

industrial techniques.

29' 11"

[34' 1"]

[14' 11"]

Process Innovation

F1G-1250

F1G-1500

49.2" x 98.4" 60.0" x 120.0"

7' 3"

9 min 55 s

Sheet Size: Max.

(Y x X)

Min.

Blank Sheet Thickness:

Loading Cycle Time:

[7' 3"]

MOTORUM-2548

Completed Sheet

Fitting inner bend into slit

Slotting into a bottoming formation

(Downward)Embossed fittings

6-shelf type

8-shelf type

[ ]:FFG-1500

S-ar putea să vă placă și

- Centrum &magnum C-3000Document12 paginiCentrum &magnum C-3000ศูนย์เครื่องจักรบางบอนโดยวงศ์ธนาวุฒิÎncă nu există evaluări

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 paginiTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- Catalogo Holders TungaloyDocument156 paginiCatalogo Holders Tungaloyabsalon_jarvÎncă nu există evaluări

- Cincom L12Document8 paginiCincom L12asilka68Încă nu există evaluări

- Apostila PowerMILL 5.5 - 5 EixosDocument126 paginiApostila PowerMILL 5.5 - 5 EixosRoberto SilvaÎncă nu există evaluări

- Handbook Prototyp Threading UsDocument124 paginiHandbook Prototyp Threading UsRobotÎncă nu există evaluări

- ToolingDocument12 paginiToolingPuneet SharmaÎncă nu există evaluări

- Davi-MCA - FOUR ROLLDocument8 paginiDavi-MCA - FOUR ROLLبازرگانی راهیان کار و دانشÎncă nu există evaluări

- Design Considerations With Powder MetallurgyDocument15 paginiDesign Considerations With Powder MetallurgyTagaytayan MaritesÎncă nu există evaluări

- Design and Fabrication of Fixture For Labyrinth RingDocument6 paginiDesign and Fabrication of Fixture For Labyrinth RingAkhilesh KumarÎncă nu există evaluări

- 650Document25 pagini650Eldori1988Încă nu există evaluări

- 1 ToleranceDocument8 pagini1 ToleranceRaymond LO OtucopiÎncă nu există evaluări

- Creo Manufacturing 4 0 PDFDocument26 paginiCreo Manufacturing 4 0 PDFtwo-1Încă nu există evaluări

- 26 Punch Press ToolingDocument10 pagini26 Punch Press ToolingAntoine LaurentÎncă nu există evaluări

- Introduction To CNC MachineDocument4 paginiIntroduction To CNC MachineRamanujam O SÎncă nu există evaluări

- News Room Services Products Sales Network Manufacturing Units Corporate Profile Financial DataDocument1 paginăNews Room Services Products Sales Network Manufacturing Units Corporate Profile Financial DataVarun PatelÎncă nu există evaluări

- Frame Cad-Self Tapping Screw SpecDocument2 paginiFrame Cad-Self Tapping Screw Specersivaraj100% (1)

- TaegoTech - PG BroshureDocument11 paginiTaegoTech - PG Broshurealexl5892Încă nu există evaluări

- 1405 Katalog eDocument232 pagini1405 Katalog eAnonymous YdCOaQTÎncă nu există evaluări

- Ewag RS 15 en PDFDocument16 paginiEwag RS 15 en PDFMARCO.S.X7952Încă nu există evaluări

- Rolleri Scule Abkant - Press Brake Tooling Catalogue SM PDFDocument134 paginiRolleri Scule Abkant - Press Brake Tooling Catalogue SM PDFDamir HadzicÎncă nu există evaluări

- WEG Roller Table 50040456 Brochure EnglishDocument12 paginiWEG Roller Table 50040456 Brochure EnglishjmartinezmoÎncă nu există evaluări

- ISO Powertap 2014 UK InternetDocument8 paginiISO Powertap 2014 UK Internetm_najmanÎncă nu există evaluări

- Hydraulic Rod Bending MachineDocument14 paginiHydraulic Rod Bending Machinek.santhosh kumar50% (2)

- Fastening &joiningDocument45 paginiFastening &joiningboschir100% (1)

- Mechanical Fasteners - Part IIDocument24 paginiMechanical Fasteners - Part IIsaded05Încă nu există evaluări

- 1325 Portable CNC Cutting MachineDocument9 pagini1325 Portable CNC Cutting MachineJorge Ligeti LandersÎncă nu există evaluări

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De la EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonÎncă nu există evaluări

- Position Measurement On Machine ToolsDocument13 paginiPosition Measurement On Machine ToolsAriel GermainÎncă nu există evaluări

- Yaskawa Siemens CNC Series: Programming Manual FundamentalsDocument517 paginiYaskawa Siemens CNC Series: Programming Manual FundamentalsStanko RadovanovicÎncă nu există evaluări

- Cadcam Module 2Document433 paginiCadcam Module 2Ahsan IftikharÎncă nu există evaluări

- 14 StipperDocument33 pagini14 Stippermahdi sakhaeeÎncă nu există evaluări

- High Speed Z Purlin MachineDocument6 paginiHigh Speed Z Purlin MachineChris RishbinÎncă nu există evaluări

- Deep Hole SolutionsDocument28 paginiDeep Hole SolutionsyatinbhatÎncă nu există evaluări

- PRO E LibraryDocument11 paginiPRO E LibrarygokulahbÎncă nu există evaluări

- Claw Pole Forging ProcessDocument8 paginiClaw Pole Forging ProcessBhagat SinghÎncă nu există evaluări

- Cone Tolerance PDFDocument21 paginiCone Tolerance PDFsosu_sorin3904Încă nu există evaluări

- Kroeplin - Katalog - 202110 ENDocument24 paginiKroeplin - Katalog - 202110 END.T.Încă nu există evaluări

- SheetCam TNG Manual - LetterDocument160 paginiSheetCam TNG Manual - LetterSergio BricellaÎncă nu există evaluări

- IMI Norgren CatalogueDocument252 paginiIMI Norgren CatalogueAdverÎncă nu există evaluări

- Recent Trends in ManufacturingDocument13 paginiRecent Trends in ManufacturingAmbarish100% (2)

- Display 30 Pinos B140XTN02.4-AUODocument33 paginiDisplay 30 Pinos B140XTN02.4-AUOBobÎncă nu există evaluări

- Deep Hole Drlling On Maching Centres BOTEKDocument2 paginiDeep Hole Drlling On Maching Centres BOTEKmapalptsÎncă nu există evaluări

- A-313 - 98Document7 paginiA-313 - 98José Ramón GutierrezÎncă nu există evaluări

- Engineering ServicesDocument2 paginiEngineering ServiceszeeÎncă nu există evaluări

- Permaglide Glijlagers LRDocument76 paginiPermaglide Glijlagers LRVitor GodoyÎncă nu există evaluări

- Chapter (5) Di Fsidl Dsidls T Design of Spindles and Spindle SupportsDocument16 paginiChapter (5) Di Fsidl Dsidls T Design of Spindles and Spindle Supportsabdullah 3mar abou reashaÎncă nu există evaluări

- Nps - NPSM - NPSC TapsDocument1 paginăNps - NPSM - NPSC TapsCarlos Murguia PerezÎncă nu există evaluări

- Sprintcut PDFDocument5 paginiSprintcut PDFpruthiviraj13100% (1)

- Tebis 4.0 R3 A4 2016Document8 paginiTebis 4.0 R3 A4 2016Paul VeramendiÎncă nu există evaluări

- Bearing CatalogueDocument12 paginiBearing CatalogueSandeep MatetiÎncă nu există evaluări

- The Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalDocument1 paginăThe Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalSM TECH SRLÎncă nu există evaluări

- AE NT Series BrochureDocument6 paginiAE NT Series Brochureramkisnak100% (1)

- Japan South Asia Korea Taiwan China Europe-Germany Citizen Machinery Europe GMBH Europe-Uk AmericaDocument8 paginiJapan South Asia Korea Taiwan China Europe-Germany Citizen Machinery Europe GMBH Europe-Uk AmericaRaghav ZyoÎncă nu există evaluări

- Amada Turret PunchDocument9 paginiAmada Turret PunchPriyansh Tiwari100% (1)

- VMC 4020Document11 paginiVMC 4020Arul SakthiÎncă nu există evaluări

- TP TP: Turret Punch Turret PunchDocument20 paginiTP TP: Turret Punch Turret PunchMaly AliÎncă nu există evaluări

- Blohm Planomat HP CNC 10 05Document8 paginiBlohm Planomat HP CNC 10 05hamedadibiÎncă nu există evaluări

- Eng - DNM Ii - 1401 - Su - E20Document20 paginiEng - DNM Ii - 1401 - Su - E20Nikolat840% (1)

- AC Resistance and Impedance in An AC Circuit PDFDocument20 paginiAC Resistance and Impedance in An AC Circuit PDFKamal CharbelÎncă nu există evaluări

- Datasheet Solis 110K 5GDocument2 paginiDatasheet Solis 110K 5GAneeq TahirÎncă nu există evaluări

- 2014oct FE PM QuestionDocument34 pagini2014oct FE PM QuestionShwe Yee Win ThantÎncă nu există evaluări

- QuestionsDocument9 paginiQuestionsPlutoÎncă nu există evaluări

- Modbus RegisterDocument7 paginiModbus RegisterZuniiga AndersonÎncă nu există evaluări

- IptablesDocument3 paginiIptablessoomalikÎncă nu există evaluări

- SimulatorHW MidSize dSPACE Catalog 2008Document4 paginiSimulatorHW MidSize dSPACE Catalog 2008Ram Krishan SharmaÎncă nu există evaluări

- Prosthetic Arm For AmputeesDocument6 paginiProsthetic Arm For AmputeesPratik ParsewarÎncă nu există evaluări

- CV Bilal Ur Rehman RF EngineerDocument4 paginiCV Bilal Ur Rehman RF Engineermudassar2k4Încă nu există evaluări

- Switchgear Manufacturing Company Pvt. LTD Smc-454-Rev-0Document62 paginiSwitchgear Manufacturing Company Pvt. LTD Smc-454-Rev-0Suvendu Sekhar SabatÎncă nu există evaluări

- LectureEKC216 CH7Document38 paginiLectureEKC216 CH7Siva SangaryÎncă nu există evaluări

- Coca Cola Potentiometric TitrationDocument5 paginiCoca Cola Potentiometric TitrationDaniela Delgadillo RestrepoÎncă nu există evaluări

- BS Iso 21573-1-2014Document32 paginiBS Iso 21573-1-2014Salafi MhmdÎncă nu există evaluări

- Thanh Huyen - Week 5 - Final Test AnswerDocument3 paginiThanh Huyen - Week 5 - Final Test AnswerNguyễn Sapphire Thanh HuyềnÎncă nu există evaluări

- Wyatt, ASTRA V Software User's Guide PDFDocument372 paginiWyatt, ASTRA V Software User's Guide PDFR YÎncă nu există evaluări

- Minimization of Blast Furnace Fuel Rate by Optimizing Burden and Gas DistributionsDocument1 paginăMinimization of Blast Furnace Fuel Rate by Optimizing Burden and Gas DistributionsOsama AlwakkafÎncă nu există evaluări

- SanternoDocument468 paginiSanternoFrank DicksonÎncă nu există evaluări

- Nutanix OverviewDocument33 paginiNutanix OverviewDeepak JainÎncă nu există evaluări

- Finishing EnglDocument49 paginiFinishing EnglSalim NgaosÎncă nu există evaluări

- Assign N LabDocument4 paginiAssign N LabMtende MosesÎncă nu există evaluări

- Transformer Health IndicesDocument12 paginiTransformer Health IndicesIngenieria APAÎncă nu există evaluări

- As-St300 - Day 1 - PLC WorkingDocument16 paginiAs-St300 - Day 1 - PLC Workingashutosh123Încă nu există evaluări

- Kitchen Improvised FertilizerDocument68 paginiKitchen Improvised Fertilizerjohn smith100% (1)

- C Programming StringDocument5 paginiC Programming StringJohn Mark CarpioÎncă nu există evaluări

- System Flyer PROSLIDE 32 B - V5.0 - 2020-03-09 PDFDocument10 paginiSystem Flyer PROSLIDE 32 B - V5.0 - 2020-03-09 PDFeduardoÎncă nu există evaluări

- Jadual Seminar 1 0910Document24 paginiJadual Seminar 1 0910ScalperÎncă nu există evaluări

- Basics of Robotics 24.06.2020Document25 paginiBasics of Robotics 24.06.2020prabhaÎncă nu există evaluări

- US6362718 Meg Tom Bearden 1Document15 paginiUS6362718 Meg Tom Bearden 1Mihai DanielÎncă nu există evaluări

- Quarter I Subject: GENERAL Mathematics Date: - Content Standard Performance Standard Learning Competency M11GM-Ia-4Document4 paginiQuarter I Subject: GENERAL Mathematics Date: - Content Standard Performance Standard Learning Competency M11GM-Ia-4PatzAlzateParaguyaÎncă nu există evaluări

- ACC20 Engine Safety UnitDocument2 paginiACC20 Engine Safety UnitVictor EugenÎncă nu există evaluări