Documente Academic

Documente Profesional

Documente Cultură

How To Brew - by John Palmer

Încărcat de

zaratustra21Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

How To Brew - by John Palmer

Încărcat de

zaratustra21Drepturi de autor:

Formate disponibile

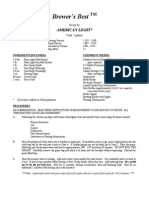

Instructions_Beer#3.

qxd

2/15/07

10:18 AM

Page 1

of sugar into each bottle before filling

it with beer. The amount per bottle is

3/4 tsp. per 1/2 litre, 1 1/2 tsp. per

1 litre, or 1/2 tsp. per 341 ml bottle.

Cap the bottle, invert gently to mix

the sugar, and let stand for 5 to

7 days at room temperature before

transferring to a cool area.

The second method is to prime

the beer in bulk. Take 3/4 to 1 cup

of corn sugar and 1 cup of water,

bring to a boil in a small pot for 1 to

2 minutes. Take the solution and add

it to your primary fermentor (sanitized of course). Gently transfer your

beer from the carboy to the pail with

your syphon equipment. Stir very

gently. Bottle directly from the pail,

cap the bottles, and leave at room

temperature for 5 to 7 days before

transferring to a cool area.

MA

R

K

E

I

E

N

B

G

Remember, the beer is ready when

you think it's ready. Try one every

week and taste the different characteristics as it reaches maturity. Then

when it tastes good to you, it's ready.

Conversion Scale

small glass

beer bottle

= 341 ml.

23 litres

= 5 imp. gallons

19 litres

= 5 U.S. gallons

Instruction

Sheets

Remember, it is important to leave

your beer for at least 5 days at room

temperature or the carbonation will

not develop.

Now, after 5 to 7 days your beer is

ready to drink but it is very young.

You will find that if you let the beer

age for at least 2 to 3 weeks after

bottling, your beer will be much

better.

40 imp. pints = 5 imp. gallons

6 cups of

corn sugar

= 1 kg

Happy

!

g

n

i

w

bre

1. Sanitizing your

equipment

Sanitizing your equipment is the

most important part of beermaking.

In the beer kit you are provided

with Diversol* (pink powder). Mix

1 tsp of Diversol to 1 litre of water.

There are many different methods

of sanitizing your equipment.

Some people partially fill the primary fermentor (plastic pail) with

the sanitizing solution and let the

equipment soak while they attend

to other things and some people

sanitize their equipment individually from a bottle of prepared solution. With practice, you will find

the best method to suit your own

style of beermaking.

Important Suggestions:

Make sure every piece of

equipment that has the

potential to come in contact

with the beer is sanitized.

You should sanitize

immediately before making

your beer.

Do not use high temperatures

when sanitizing equipment.

After sanitizing, rinse well

with cold water.

Remember, at first the sanitizing

procedure may seem tedious. But

once you establish a routine it will

become second nature and the

excellent beer you make will be

worth your effort.

* If you use Diversol for

winemaking, DO NOT use it for

sanitizing corks, wooden barrels

or filter pads.

BELLS CORNERS

613-721-9945

OTTAWA

613-722-9945

ORLEANS

613-590-9946

Check our website

www.defalcowines.com

DeFalcos... for Brewers and Winemakers

Make Your Own Beer and Wine at Home... Naturally!

Instructions_Beer#3.qxd

2/15/07

10:18 AM

2. Getting started

(the instructions)

Page 3

4. Primary

fermentation

5. Temperature

7. Fermentation

(thermometer)

(adding the yeast)

(plastic pail)

All the malt extract kits come

with their own set of instructions.

Some recommend 1 stage brewing

(fermenting in the pail and bottling

right away), while others recommend that you don't boil your beer.

In order to make better beer, we

recommend that you follow our

instructions and ignore the instructions that come with the malt

extract. Remember, you will make

good beer while following the

instructions directly from the can,

but why not make the best beer

possible.

3. Boil your wort

Take your sanitized floating

thermometer and gently place it

into your wort. Ideally, you want

your beer to fall into the temperature range of 18C to 23C (65F

to 73F). Remove the thermometer

from the wort and record the

reading. If it is too warm let it

cool down, if it is too cold let it

warm up.

Fill your sanitized pail with

approximately 9 Litres (2 gallons)

of cold water. Add the hot

malt mixture into the pail

and top up with more cold

water until you reach the

23L (5 imp. gallon) mark

(inside ridge of pail, approx

7 cm from top). (Some malt

kits are intended to make

less than the normal 23L.

If so, pre-mark your primary fermentor accordingly). With a sanitized spoon

(not wooden) make sure

the wort is well mixed.

(wort is the term for

unfermented beer)

*Before starting, you should

determine at what part of your

house or apartment the fermentation is going to take place.

Pick a spot where there is

a consistant temperature

between 18C to 23C

(65F to 73F).

In a large stainless steel or

enamel pot, bring approximately 2 litres of water to a boil.

While stirring constantly, add

the contents of the can of

malt extract and the amount

of sugar the recipe requires

(usually 1 kg). (Instead of

household sugars, we recommend a variety of alternative sugars, - malt, glucose,

corn sugar, etc.). Stir the

pot of hot liquid until the

ingredients are well dissolved

and let boil for 10 to 15 minutes (stir constantly watching

for boil over).

If you have determined that the

temperature of your wort lies within

the 18C to 23C (65F to 73F) range,

it is time to add (pitch) the yeast.

Underneath the lid of the malt extract

you will find a package of dried yeast.

Simply tear open the package and

sprinkle the contents over the surface

of the wort. Now, gently put the lid

of the pail in place (DO NOT

SNAP IT ON) and relax.

Within 8 to 24 hours, you should see

some sign of fermentation (i.e. some

amount of foaming, from small clumps

to a thick head of foam). If you dont

notice any fermentation within

this time, it is CRUCIAL that

another packet of yeast be

added (pitched). More

yeast won't hurt your

beer, but inaction could

prove costly.

Once fermentation

has started, relax. You

neednt continuously

monitor the beer. It's

okay to check it from

time to time but try to

respect its privacy.

6. Hydrometer

reading (stage I)

Syphon a small amount

of wort into your

test jar (about

1 1/2 inches from

the top). Record

your reading from

the specific gravity

scale. (Refer to

the hydrometer

instructions).

T,

RES !

A

E

U

E M YO

GIV OULD

W

After 3 or 4 days of fermentation it

should be time to proceed to the

next step.

8. Hydrometer

reading (Stage II)

Take another specific gravity

reading. (Refer to the hydrometer

instructions).

9. Secondary

fermentation

It is now time to transfer your beer

from the pail into the glass carboy.

With your sanitized syphon tubing and

racking tube, start a syphon and gently

transfer your beer into

the glass carboy.

There is a black

plastic cap at the

end of the racking tube, this

will allow you to

syphon most of

the beer without

disturbing the sediment that has accumulated at the bottom of your

pail. Remember, you might

syphon a little bit of the sediment but

that's okay as long as you try to leave

as much behind as possible.

Once the beer has been transferred,

add water to the air lock (up to the

2 halfway marks) and afix the rubber

stopper with the air lock into

the neck of the carboy.

(Remember, at this point,

do not top up the carboy

or stir the beer.) Now it's

time to relax and let your

beer stand for 1 to 2 weeks

before bottling.

DeFalcos... for Brewers and Winemakers

Make Your Own Beer and Wine at Home... Naturally!

DeFalcos... for Brewers and Winemakers

Important Note: At this point, you may

or may not see action in your

air lock.

10. Bottling

Before bottling, you must be certain

that the beer is completely fermented.

Beermakers usually look for three signs:

1. There is no more gas escaping

through the air lock.

2. The Hydrometer readings remain

unchanged for 2 to 3 days at any

point between 1.000 and 1.010 of

the specific gravity scale (1.008 to

1.015 for Malt and Hi Malt glucose

recipes).

3. The beer is reasonably clear.

Now it is time to bottle your beer.

There are many types of bottles to

choose from in plastic and glass.

Regardless of what type you choose you

should have enough bottles for your

batch of beer (approximately 48 1/2 litre,

24 1 litre, or 65 341 ml bottles) and they

should be cleaned and sanitized very

well. (Do not boil plastic caps or plastic

bottles.)

An amount of corn sugar should be

added to the beer directly before bottling

to ensure that the beer will be carbonated. One way of doing this is the bottle

method: simply add a specific amount

Make Your Own Beer and Wine at Home... Naturally!

Instructions_Beer#3.qxd

2/15/07

10:18 AM

2. Getting started

(the instructions)

Page 3

4. Primary

fermentation

5. Temperature

7. Fermentation

(thermometer)

(adding the yeast)

(plastic pail)

All the malt extract kits come

with their own set of instructions.

Some recommend 1 stage brewing

(fermenting in the pail and bottling

right away), while others recommend that you don't boil your beer.

In order to make better beer, we

recommend that you follow our

instructions and ignore the instructions that come with the malt

extract. Remember, you will make

good beer while following the

instructions directly from the can,

but why not make the best beer

possible.

3. Boil your wort

Take your sanitized floating

thermometer and gently place it

into your wort. Ideally, you want

your beer to fall into the temperature range of 18C to 23C (65F

to 73F). Remove the thermometer

from the wort and record the

reading. If it is too warm let it

cool down, if it is too cold let it

warm up.

Fill your sanitized pail with

approximately 9 Litres (2 gallons)

of cold water. Add the hot

malt mixture into the pail

and top up with more cold

water until you reach the

23L (5 imp. gallon) mark

(inside ridge of pail, approx

7 cm from top). (Some malt

kits are intended to make

less than the normal 23L.

If so, pre-mark your primary fermentor accordingly). With a sanitized spoon

(not wooden) make sure

the wort is well mixed.

(wort is the term for

unfermented beer)

*Before starting, you should

determine at what part of your

house or apartment the fermentation is going to take place.

Pick a spot where there is

a consistant temperature

between 18C to 23C

(65F to 73F).

In a large stainless steel or

enamel pot, bring approximately 2 litres of water to a boil.

While stirring constantly, add

the contents of the can of

malt extract and the amount

of sugar the recipe requires

(usually 1 kg). (Instead of

household sugars, we recommend a variety of alternative sugars, - malt, glucose,

corn sugar, etc.). Stir the

pot of hot liquid until the

ingredients are well dissolved

and let boil for 10 to 15 minutes (stir constantly watching

for boil over).

If you have determined that the

temperature of your wort lies within

the 18C to 23C (65F to 73F) range,

it is time to add (pitch) the yeast.

Underneath the lid of the malt extract

you will find a package of dried yeast.

Simply tear open the package and

sprinkle the contents over the surface

of the wort. Now, gently put the lid

of the pail in place (DO NOT

SNAP IT ON) and relax.

Within 8 to 24 hours, you should see

some sign of fermentation (i.e. some

amount of foaming, from small clumps

to a thick head of foam). If you dont

notice any fermentation within

this time, it is CRUCIAL that

another packet of yeast be

added (pitched). More

yeast won't hurt your

beer, but inaction could

prove costly.

Once fermentation

has started, relax. You

neednt continuously

monitor the beer. It's

okay to check it from

time to time but try to

respect its privacy.

6. Hydrometer

reading (stage I)

Syphon a small amount

of wort into your

test jar (about

1 1/2 inches from

the top). Record

your reading from

the specific gravity

scale. (Refer to

the hydrometer

instructions).

T,

RES !

A

E

U

E M YO

GIV OULD

W

After 3 or 4 days of fermentation it

should be time to proceed to the

next step.

8. Hydrometer

reading (Stage II)

Take another specific gravity

reading. (Refer to the hydrometer

instructions).

9. Secondary

fermentation

It is now time to transfer your beer

from the pail into the glass carboy.

With your sanitized syphon tubing and

racking tube, start a syphon and gently

transfer your beer into

the glass carboy.

There is a black

plastic cap at the

end of the racking tube, this

will allow you to

syphon most of

the beer without

disturbing the sediment that has accumulated at the bottom of your

pail. Remember, you might

syphon a little bit of the sediment but

that's okay as long as you try to leave

as much behind as possible.

Once the beer has been transferred,

add water to the air lock (up to the

2 halfway marks) and afix the rubber

stopper with the air lock into

the neck of the carboy.

(Remember, at this point,

do not top up the carboy

or stir the beer.) Now it's

time to relax and let your

beer stand for 1 to 2 weeks

before bottling.

DeFalcos... for Brewers and Winemakers

Make Your Own Beer and Wine at Home... Naturally!

DeFalcos... for Brewers and Winemakers

Important Note: At this point, you may

or may not see action in your

air lock.

10. Bottling

Before bottling, you must be certain

that the beer is completely fermented.

Beermakers usually look for three signs:

1. There is no more gas escaping

through the air lock.

2. The Hydrometer readings remain

unchanged for 2 to 3 days at any

point between 1.000 and 1.010 of

the specific gravity scale (1.008 to

1.015 for Malt and Hi Malt glucose

recipes).

3. The beer is reasonably clear.

Now it is time to bottle your beer.

There are many types of bottles to

choose from in plastic and glass.

Regardless of what type you choose you

should have enough bottles for your

batch of beer (approximately 48 1/2 litre,

24 1 litre, or 65 341 ml bottles) and they

should be cleaned and sanitized very

well. (Do not boil plastic caps or plastic

bottles.)

An amount of corn sugar should be

added to the beer directly before bottling

to ensure that the beer will be carbonated. One way of doing this is the bottle

method: simply add a specific amount

Make Your Own Beer and Wine at Home... Naturally!

Instructions_Beer#3.qxd

2/15/07

10:18 AM

Page 1

of sugar into each bottle before filling

it with beer. The amount per bottle is

3/4 tsp. per 1/2 litre, 1 1/2 tsp. per

1 litre, or 1/2 tsp. per 341 ml bottle.

Cap the bottle, invert gently to mix

the sugar, and let stand for 5 to

7 days at room temperature before

transferring to a cool area.

The second method is to prime

the beer in bulk. Take 3/4 to 1 cup

of corn sugar and 1 cup of water,

bring to a boil in a small pot for 1 to

2 minutes. Take the solution and add

it to your primary fermentor (sanitized of course). Gently transfer your

beer from the carboy to the pail with

your syphon equipment. Stir very

gently. Bottle directly from the pail,

cap the bottles, and leave at room

temperature for 5 to 7 days before

transferring to a cool area.

MA

R

K

E

I

E

N

B

G

Remember, the beer is ready when

you think it's ready. Try one every

week and taste the different characteristics as it reaches maturity. Then

when it tastes good to you, it's ready.

Conversion Scale

small glass

beer bottle

= 341 ml.

23 litres

= 5 imp. gallons

19 litres

= 5 U.S. gallons

Instruction

Sheets

Remember, it is important to leave

your beer for at least 5 days at room

temperature or the carbonation will

not develop.

Now, after 5 to 7 days your beer is

ready to drink but it is very young.

You will find that if you let the beer

age for at least 2 to 3 weeks after

bottling, your beer will be much

better.

40 imp. pints = 5 imp. gallons

6 cups of

corn sugar

= 1 kg

Happy

!

g

n

i

w

bre

1. Sanitizing your

equipment

Sanitizing your equipment is the

most important part of beermaking.

In the beer kit you are provided

with Diversol* (pink powder). Mix

1 tsp of Diversol to 1 litre of water.

There are many different methods

of sanitizing your equipment.

Some people partially fill the primary fermentor (plastic pail) with

the sanitizing solution and let the

equipment soak while they attend

to other things and some people

sanitize their equipment individually from a bottle of prepared solution. With practice, you will find

the best method to suit your own

style of beermaking.

Important Suggestions:

Make sure every piece of

equipment that has the

potential to come in contact

with the beer is sanitized.

You should sanitize

immediately before making

your beer.

Do not use high temperatures

when sanitizing equipment.

After sanitizing, rinse well

with cold water.

Remember, at first the sanitizing

procedure may seem tedious. But

once you establish a routine it will

become second nature and the

excellent beer you make will be

worth your effort.

* If you use Diversol for

winemaking, DO NOT use it for

sanitizing corks, wooden barrels

or filter pads.

BELLS CORNERS

613-721-9945

OTTAWA

613-722-9945

ORLEANS

613-590-9946

Check our website

www.defalcowines.com

DeFalcos... for Brewers and Winemakers

Make Your Own Beer and Wine at Home... Naturally!

S-ar putea să vă placă și

- CloneBrews 2nd Edition - Marketing BrochureDocument2 paginiCloneBrews 2nd Edition - Marketing BrochureStorey Publishing0% (4)

- Old British Beers PDFDocument31 paginiOld British Beers PDFjavijavier100% (1)

- Coopering 2 PDFDocument23 paginiCoopering 2 PDFtrola666910Încă nu există evaluări

- Brewing Session Beer: Tips for Crafting Lower ABV Beers Under 4.5Document16 paginiBrewing Session Beer: Tips for Crafting Lower ABV Beers Under 4.5Felipe BaronyÎncă nu există evaluări

- BEER-Craft Brew - 50 Homebrew Recipes From The World's Best Craft BreweriesDocument260 paginiBEER-Craft Brew - 50 Homebrew Recipes From The World's Best Craft BreweriesWilliam CI100% (1)

- JamilsRecipeIndexExcel2007. 8Document16 paginiJamilsRecipeIndexExcel2007. 8Culturalmodovar Cultura CucaÎncă nu există evaluări

- The Hop Grower's Handbook: IntroductionDocument12 paginiThe Hop Grower's Handbook: IntroductionChelsea Green PublishingÎncă nu există evaluări

- BeerMalt-Handbook 2017 FINAL 22092017 PDFDocument52 paginiBeerMalt-Handbook 2017 FINAL 22092017 PDFMichel SanchezÎncă nu există evaluări

- Buccaneer Bobs Silver Gold and Black Rum RecipeDocument6 paginiBuccaneer Bobs Silver Gold and Black Rum RecipeJeremy Daniel MeadowsÎncă nu există evaluări

- Gin RecipeDocument18 paginiGin RecipeAnonymous Ov6SPCm100% (2)

- The New Cider Maker's Handbook Press ReleaseDocument1 paginăThe New Cider Maker's Handbook Press ReleaseChelsea Green PublishingÎncă nu există evaluări

- Water Adjustment Key to Unlocking Beer FlavorDocument26 paginiWater Adjustment Key to Unlocking Beer FlavorrarasriwindhuÎncă nu există evaluări

- Yeast Strains ChartDocument26 paginiYeast Strains ChartGastón AguirreÎncă nu există evaluări

- Belgian Beer Experiences tcm24-7788 PDFDocument64 paginiBelgian Beer Experiences tcm24-7788 PDFAlejandro HercenbergÎncă nu există evaluări

- Robo Brew 35 L InstructionsDocument5 paginiRobo Brew 35 L Instructionssteve_milenÎncă nu există evaluări

- Beer RecipesDocument1 paginăBeer Recipes1srafelÎncă nu există evaluări

- BYO - 10 Easiest Beer StylesDocument12 paginiBYO - 10 Easiest Beer StylesduonordesteÎncă nu există evaluări

- Fermentis Tips TricksDocument20 paginiFermentis Tips TricksAntonio Imperi100% (4)

- BrewCrafters Rulebook PDFDocument10 paginiBrewCrafters Rulebook PDFMatthieuDelÎncă nu există evaluări

- The Brew Your Own Big Book of Clone Recipe - Brew Your OwnDocument716 paginiThe Brew Your Own Big Book of Clone Recipe - Brew Your OwnFrederico Ribeiro67% (3)

- Brewing Authentic Bavarian Helles Beer with an Inert ProcessDocument16 paginiBrewing Authentic Bavarian Helles Beer with an Inert ProcessBenson Matthew IshakÎncă nu există evaluări

- Brewing With WheatDocument16 paginiBrewing With WheatGustavo MicheliniÎncă nu există evaluări

- Wikipedia Belgian Beer PDFDocument52 paginiWikipedia Belgian Beer PDFbartekguzikÎncă nu există evaluări

- Dry Hopping A Study of Various ParametersDocument5 paginiDry Hopping A Study of Various Parametersfir3f0xÎncă nu există evaluări

- Designing Belgian Ales: Guidelines for Successful HomebrewingDocument12 paginiDesigning Belgian Ales: Guidelines for Successful Homebrewingzpervan1Încă nu există evaluări

- Malt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupDocument33 paginiMalt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupOleg Burlac100% (1)

- Brew Like A MonkDocument3 paginiBrew Like A MonkSonia Cireaşă0% (1)

- The Scottish Pot Stills - WhiskyDocument22 paginiThe Scottish Pot Stills - Whiskymick100% (1)

- The New Cider Maker's Handbook: Chapter 15 Cider DiverstiyDocument11 paginiThe New Cider Maker's Handbook: Chapter 15 Cider DiverstiyChelsea Green Publishing100% (1)

- Distilling 101: A Complete GuideDocument25 paginiDistilling 101: A Complete Guidemanish.jcus6465100% (1)

- Beer Instruction ManualDocument4 paginiBeer Instruction ManualShaheer MuhammadÎncă nu există evaluări

- American Pale AleDocument2 paginiAmerican Pale AleJustin GarciaÎncă nu există evaluări

- Beer Making ClassDocument5 paginiBeer Making ClassMichael BernierÎncă nu există evaluări

- The Key IngredientsDocument4 paginiThe Key Ingredientsk_168911826Încă nu există evaluări

- Extract Brewing Instructions: Necessary Equipment and SuppliesDocument2 paginiExtract Brewing Instructions: Necessary Equipment and SuppliesHenry Clark TravagliniÎncă nu există evaluări

- Home Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsDe la EverandHome Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsÎncă nu există evaluări

- 1 Gallon Mead Recipe For Beginners - Easy Mead Recipe & KiDocument5 pagini1 Gallon Mead Recipe For Beginners - Easy Mead Recipe & KiRyanÎncă nu există evaluări

- Bulldog Brews InstructionsDocument4 paginiBulldog Brews InstructionsrciobanasuÎncă nu există evaluări

- Midwest Honeybee AleDocument2 paginiMidwest Honeybee AleJesso GeorgeÎncă nu există evaluări

- Killians RED Beer Reciepe 03638Document2 paginiKillians RED Beer Reciepe 03638Joe MoldovanÎncă nu există evaluări

- Mangrove Jack's Craft Series Beer Pouch InstructionsDocument2 paginiMangrove Jack's Craft Series Beer Pouch InstructionsJoao MoreiraÎncă nu există evaluări

- Coopers etc... homebrewing instructionsDocument1 paginăCoopers etc... homebrewing instructionsEric SteenÎncă nu există evaluări

- Homebrew Equipment and Step-by-Step Brewing ProcessDocument2 paginiHomebrew Equipment and Step-by-Step Brewing ProcessDavid SanzÎncă nu există evaluări

- Mangrove Jack's Brewer's Series Kit InstructionsDocument2 paginiMangrove Jack's Brewer's Series Kit InstructionsEsteban Iturra CerónÎncă nu există evaluări

- Beer Brewing For BeginnersDocument5 paginiBeer Brewing For BeginnerspauloadrianoÎncă nu există evaluări

- Brooklyn Brew Shop Punk IPA InstructionsDocument3 paginiBrooklyn Brew Shop Punk IPA InstructionsRamón Farré GómezÎncă nu există evaluări

- Rice BeerDocument8 paginiRice BeerPied7PiperÎncă nu există evaluări

- Brooklyn Brew Shop - Everyday IPA InstructionsDocument3 paginiBrooklyn Brew Shop - Everyday IPA Instructionstecleador10% (1)

- Apple Cider InstructDocument2 paginiApple Cider InstructlegionsixÎncă nu există evaluări

- 1018 American LightDocument2 pagini1018 American LightAhmet MetinÎncă nu există evaluări

- How To Brew Beer at HomeDocument5 paginiHow To Brew Beer at Homelucas.siqueiraÎncă nu există evaluări

- Brew Buddy StarterDocument2 paginiBrew Buddy StarterJuk ArmstrongÎncă nu există evaluări

- 25 L SUPER Reflux Still Ins With Z FilterDocument16 pagini25 L SUPER Reflux Still Ins With Z FiltertoffeloffeÎncă nu există evaluări

- Fantome Saison-Style Ale (16C) - All GrainDocument2 paginiFantome Saison-Style Ale (16C) - All GrainMonitoreo SPERÎncă nu există evaluări

- NEGRA MODELO CLONE ALL-GRAIN RECIPEDocument2 paginiNEGRA MODELO CLONE ALL-GRAIN RECIPEKevin van HollandÎncă nu există evaluări

- Morebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemDocument2 paginiMorebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemTeddy Riaño AlarconÎncă nu există evaluări

- Beginners Guide To Brewing in A Bag, or Biab: WWW - Biabrewer.Info WWW - Forum.Realbeer - Co.NzDocument6 paginiBeginners Guide To Brewing in A Bag, or Biab: WWW - Biabrewer.Info WWW - Forum.Realbeer - Co.Nzerickscribduy321Încă nu există evaluări

- Coopers Yeast CulturingDocument4 paginiCoopers Yeast Culturingmatthendry100% (1)

- Hank'S Hefeweizen: Read All Instructions Before StartingDocument2 paginiHank'S Hefeweizen: Read All Instructions Before StartingBhagavanÎncă nu există evaluări

- A Short Overview of Distilling: - Plus 2 Bonus RecipesDocument4 paginiA Short Overview of Distilling: - Plus 2 Bonus RecipesMatheus Jeronimo MarianÎncă nu există evaluări

- Korean Language Guide (2013) PDFDocument205 paginiKorean Language Guide (2013) PDFAnna Chen100% (1)

- Test Your PrepositionsDocument93 paginiTest Your Prepositionszaratustra21Încă nu există evaluări

- Successful Managerial Behaviour For Farm-Based TourismDocument10 paginiSuccessful Managerial Behaviour For Farm-Based Tourismzaratustra21Încă nu există evaluări

- The Role of Agritourism Farms Characteristics On The Performance A Case Study of Agritourism Farm in South KoreaDocument15 paginiThe Role of Agritourism Farms Characteristics On The Performance A Case Study of Agritourism Farm in South Koreazaratustra21Încă nu există evaluări

- CPE Coursebook Answers PDFDocument47 paginiCPE Coursebook Answers PDFLovereading1582% (17)

- Organic Homemade Cleaning Recipes Your Guide To Safe, Eco-Friendly, and Money-Saving RecipesDocument72 paginiOrganic Homemade Cleaning Recipes Your Guide To Safe, Eco-Friendly, and Money-Saving Recipeszaratustra21100% (5)

- The Influence of Agritourism ExperiencesDocument15 paginiThe Influence of Agritourism Experienceszaratustra21Încă nu există evaluări

- NEW Edition: Four Extra Units Idiom GlossaryDocument193 paginiNEW Edition: Four Extra Units Idiom GlossaryPetar Ilic100% (26)

- Expert Proficiency Audioscripts PDFDocument30 paginiExpert Proficiency Audioscripts PDFAna María Hupan100% (4)

- Agritourism (PDFDrive)Document318 paginiAgritourism (PDFDrive)zaratustra21100% (2)

- Tourism On Organic Farms in South Korea A New Form of EcotourismDocument25 paginiTourism On Organic Farms in South Korea A New Form of Ecotourismzaratustra21Încă nu există evaluări

- Using Data Envelopment Analysis To Measure and Benchmark The Efficiency of Small-Scale Tourism Farms in South KoreaDocument16 paginiUsing Data Envelopment Analysis To Measure and Benchmark The Efficiency of Small-Scale Tourism Farms in South Koreazaratustra21Încă nu există evaluări

- Wine Grape NC 2012Document27 paginiWine Grape NC 2012zaratustra21100% (1)

- Seoul Korean Language 1A (Student Book)Document261 paginiSeoul Korean Language 1A (Student Book)zaratustra21Încă nu există evaluări

- Guide To Red Wine MakingDocument74 paginiGuide To Red Wine MakingSladjan Maslac100% (1)

- The Beer Geek Handbook - Living A Life Ruled by Beer (2016)Document58 paginiThe Beer Geek Handbook - Living A Life Ruled by Beer (2016)zaratustra21Încă nu există evaluări

- BrewingDocument86 paginiBrewingStefanita VlasceanuÎncă nu există evaluări

- How to brew your own beer at home in 5 easy stepsDocument1 paginăHow to brew your own beer at home in 5 easy stepsbathtub2025Încă nu există evaluări

- WebinarSlides WineDocument48 paginiWebinarSlides Winezaratustra21Încă nu există evaluări

- Winegrapes: 2012 Sample Costs To Establish A Vineyard and ProduceDocument19 paginiWinegrapes: 2012 Sample Costs To Establish A Vineyard and Producezaratustra21Încă nu există evaluări

- Draft Copy of A Practical Guide To Developing A Commercial Wine VineyardDocument178 paginiDraft Copy of A Practical Guide To Developing A Commercial Wine Vineyardzaratustra21Încă nu există evaluări

- 2013-11705-01 Brewing Handbook Final SpreadsDocument63 pagini2013-11705-01 Brewing Handbook Final SpreadsCheverry Beer80% (5)

- Craftbeerdotcom Beer StylesDocument86 paginiCraftbeerdotcom Beer StylesSasa NackovicÎncă nu există evaluări

- Lefki&ErithraInopiisi WINE ΟΙΝΟΣDocument16 paginiLefki&ErithraInopiisi WINE ΟΙΝΟΣzaratustra21Încă nu există evaluări

- Growing Table Grapes Ec1639 May 2011 PDFDocument32 paginiGrowing Table Grapes Ec1639 May 2011 PDFzaratustra21Încă nu există evaluări

- Beer 101 - The Basics of BeerDocument19 paginiBeer 101 - The Basics of BeerJúlio Gabriel Queiroz dos SantosÎncă nu există evaluări

- E 2774Document45 paginiE 2774turbo44Încă nu există evaluări

- Grapewine Napa 03Document21 paginiGrapewine Napa 03zaratustra21Încă nu există evaluări

- Getting Started With Wine MakingDocument17 paginiGetting Started With Wine Makingzaratustra21Încă nu există evaluări

- The Properties and Genetics of Barley MaltDocument47 paginiThe Properties and Genetics of Barley MaltJulio SantosÎncă nu există evaluări

- Stone Nixon - Distillation of Alcohol-Professional Guide For Amateur Distillers (2000)Document73 paginiStone Nixon - Distillation of Alcohol-Professional Guide For Amateur Distillers (2000)moreherbsÎncă nu există evaluări

- 1 Dipl. Brew. Module 1: Unit 1.8 - Mashing and Wort Separation - Section 1.8.2Document11 pagini1 Dipl. Brew. Module 1: Unit 1.8 - Mashing and Wort Separation - Section 1.8.2RiyanÎncă nu există evaluări

- Brewer's Saccharomyces Yeast Biomass: Characteristics and Potential ApplicationsDocument8 paginiBrewer's Saccharomyces Yeast Biomass: Characteristics and Potential ApplicationsDavi MouraÎncă nu există evaluări

- The Economics of Beer (Johan F.M. Swinnen) (Z-Library)Document643 paginiThe Economics of Beer (Johan F.M. Swinnen) (Z-Library)kampangfeiÎncă nu există evaluări

- Presto WMFDocument30 paginiPresto WMFKamil SzostokÎncă nu există evaluări

- Grains and Adjuncts ChartDocument2 paginiGrains and Adjuncts ChartJesso GeorgeÎncă nu există evaluări

- Old British Beers and How To Make ThemDocument31 paginiOld British Beers and How To Make ThemJacintoChurriqueÎncă nu există evaluări

- Attachment Report BrewingDocument54 paginiAttachment Report Brewingመቀረ ዮሴፍ50% (2)

- Kosher Beers List Purim 2015Document12 paginiKosher Beers List Purim 2015KosherLawNYÎncă nu există evaluări

- BeerAndFoodCourse LRDocument98 paginiBeerAndFoodCourse LRNathanaelDavidÎncă nu există evaluări

- Bartending NC II Module 3 Alcoholic BeveragesDocument33 paginiBartending NC II Module 3 Alcoholic BeveragesLoraine DocaÎncă nu există evaluări

- Intercontinental Abu Dhabi 7030613385 OriginalDocument20 paginiIntercontinental Abu Dhabi 7030613385 OriginalJannÎncă nu există evaluări

- Production and history of Scotch and Irish whiskiesDocument32 paginiProduction and history of Scotch and Irish whiskiesTaurai ChiwanzaÎncă nu există evaluări

- The Mystery of Lambic Beer PDFDocument7 paginiThe Mystery of Lambic Beer PDFgalagonya222Încă nu există evaluări

- Yeast Management PropagationDocument39 paginiYeast Management PropagationPatricio LazcanoÎncă nu există evaluări

- Business Plan Nepal Breweries Private LimitedDocument71 paginiBusiness Plan Nepal Breweries Private Limitedsubash shresthaÎncă nu există evaluări

- PTE 11 July PredictionDocument447 paginiPTE 11 July Predictionvik.kanavÎncă nu există evaluări

- HayMerchant BottleList1Document2 paginiHayMerchant BottleList1eric_ehouÎncă nu există evaluări

- StoutDocument1 paginăStoutnemfogomÎncă nu există evaluări

- Brewery Construction Guide: Build Your Own Compact Homebrew SystemDocument23 paginiBrewery Construction Guide: Build Your Own Compact Homebrew SystemCesar Diaz100% (6)

- Beer IngredientsDocument17 paginiBeer IngredientsManuel Figueroa AbelicoMcÎncă nu există evaluări

- 5153 Weyermann RecipesDocument8 pagini5153 Weyermann RecipesLaura Marcela Rojas HernandezÎncă nu există evaluări

- BAM-S10-07 CO2 in Beer in Bulk - Zahm Nagel - Feb99aDocument10 paginiBAM-S10-07 CO2 in Beer in Bulk - Zahm Nagel - Feb99aRiyanÎncă nu există evaluări

- BozaDocument5 paginiBozaInn MironÎncă nu există evaluări

- Do Brewers Need A Starch Modification IndexDocument4 paginiDo Brewers Need A Starch Modification IndexGayatri MehtaÎncă nu există evaluări

- Recipes From Make Some Beer: Small-Batch Recipes From Brooklyn To Bamberg by Erica Shea and Stephen ValandDocument12 paginiRecipes From Make Some Beer: Small-Batch Recipes From Brooklyn To Bamberg by Erica Shea and Stephen ValandThe Recipe ClubÎncă nu există evaluări

- Free Book On Ethanol HowtoDocument71 paginiFree Book On Ethanol Howtores06suc100% (6)

- Coors LightDocument53 paginiCoors LightKaren NguyenÎncă nu există evaluări

- BYO 2015 Vol 21-01 Jan-FebDocument100 paginiBYO 2015 Vol 21-01 Jan-FebAndoni MÎncă nu există evaluări