Documente Academic

Documente Profesional

Documente Cultură

Data Ir2153

Încărcat de

mdkadryDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Data Ir2153

Încărcat de

mdkadryDrepturi de autor:

Formate disponibile

High Bandwidth Automotive Power Supply for Low-cost PWM Audio Amplifiers

Mikkel C. W. Hyerby

rsted/DTU

Building 325

Dk-2800 Lyngby

Denmark

mcwh@kampsax.dtu.dk

Michael A. E. Andersen

rsted/DTU

Building 325

Dk-2800 Lyngby

Denmark

ma@oersted.dtu.dk

Dennis R. Andersen

rsted/DTU

Building 325

Dk-2800 Lyngby

Denmark

dennis@kampsax.dtu.dk

Abstract - This paper presents the derivation of a practical

solution for constructing a signal tracking power supply for

single-ended switching audio amplifiers, motivated by

requirements for reduced EMI. The cause and effects of

supply pumping in single-ended switching amplifiers are

investigated, and simulation results for a power supply to meet

the specified demands are presented, as well as the results

obtained from the constructed prototype.

Lars Petersen

Bang & Olufsen ICEpower

a/s

Gl. Lundtoftevej 1b

Dk-2800 Lyngby

Denmark

lpe@bang-olufsen.dk

II. SYSTEM SPECIFICATIONS

The following key specifications are to be met by this prototype

tracking power supply:

Input voltage

Output voltages

Output current on +/- Vx50V supplies

Full power tracking

bandwidth

Small-signal tracking

bandwidth (-3dB)

Tracking offset Vx

I. INTRODUCTION

The availability of compact, efficient, high-performance

switching audio power amplifiers [1] in recent years, has only

partially made an impact on the design of automotive power

amplifier systems. The main problem associated with switching

audio power amplifiers for automotive purposes, is EMI from

the switching output stages. This because of very the strict EMI

requirements [2] imposed by car manufacturers on equipment

installed by the factory. Basically, EMI from the power stages

may be reduced either by employing more effective (and costly)

filtering, or by reducing the EMI generated by the power stage

itself. One solution for minimizing EMI, is operating the power

stage at minimum supply voltage, thus minimizing the output

ripple voltage for a given output filter, and minimizing the

inevitable EMI generated by power stage shoot-through. This

however, requires a power supply capable of slewing at audio

frequencies and, as will be seen, capable of reverse energy

transfer if cost-saving single-ended amplifiers are to be used.

9-16V (car battery)

2x +/-12V (fixed), +/- Vx50V (tracking)

0-40A (short term)

Sufficient for 5kHz sine

wave output from amplifiers

Above 30kHz

As low as possible (in the

range of 5-12V)

Tracking supply output voltages and currents are selected to

allow 4 single-ended amplifiers each driving a 4 load to

deliver a total RMS sine wave output power of 4x125W =

500W. The 5kHz full power tracking bandwidth requirement is

set as a compromise between audio performance and practical

limitations imposed by filter component sizes and switching

frequencies. The small signal tracking bandwidth requirement of

more that 30kHz is set to minimize phase lag on the delivered

supply voltages when tracking at 20kHz.

III. MODELING THE SUPPLY PUMPING MECHANISM

Supply pumping is a mechanism that exists in single-ended

(half-bridge) switching amplifiers (as the one shown on Figure

2), which results in energy being transferred from one supply

rail to the other. This has the effect of requiring the supply rail

being pumped to be able to absorb the transferred energy. A

simple average-current model capable of describing this

mechanism has been developed.

The scheme proposed for regulating the supply voltage [3] is

illustrated on Figure 1, where the rail voltages are symmetrical,

and always a fixed offset Vx above the amplifier output voltage.

This scheme has the advantage of providing a fixed minimum

voltage across the amplifier output filter inductor, thus always

securing a minimum slew-rate.

Figure 1 Output signal (magenta), positive (red) and negative (blue) supply

rails for tracking supply with offset voltage Vx = 12V.

Figure 2 Principal single-ended amplifier.

For a sinusoidal output voltage with amplitude A, it can be

shown that the average current in Q1 is:

I Q1,avg =

IV. PROPOSED POWER CONVERSION SCHEME

The tracking power supply for the single-ended amplifiers must

fulfill the following key requirements:

A sin (2 ft ) A sin (2 ft )

1 +

V

2 RL

s

If the supply voltage is controlled so that it follows the output

voltage with a fixed offset Vx, the average current in Q1

becomes:

I Q1,avg =

A sin (2 ft )

A sin (2 ft )

+

1

V + A sin (2 ft )

2 RL

x

High output voltage slew rate (as required by the

audio signal) => High control bandwidth

Ability to deal with supply pumping current

High transient output current capacity

All these requirements can be fulfilled by the 2-stage solution

shown on Figure 4, with an isolated low-bandwidth preconverter for providing fixed high voltage (e.g. +/-50V) rails,

followed by separate high-bandwidth buck converters on each

rail to provide the correct supply voltages for the amplifiers. To

minimize EMI problems, a boost topology is employed for the

pre-converter. A standard single-inductor push-pull boost

converter is chosen over a seemingly advantageous [4] dualinductor boost converter, due to its much lower minimum input

power with a given boost inductor [9].

The buck converters, when implemented with synchronous

rectifiers (Q4 and Q6), have the ability to reverse their output

currents, thus providing a path for the inevitable supply

pumping currents. This is essential, since the filter capacitors

for each Vs rail (C2 and C4) including decoupling for the

amplifiers, may be no more than approximately 10F (with 5H

for L2 and L3) to allow sufficient Vs slew rate.

The found expressions for the positive supply current are

plotted in Figure 3 for various output levels. The load resistance

is set to 1, modeling 4 amplifiers each driving a 4 load,

operated from the same rails, with identical output signals.

Fixed supply (+/-50V)

Tracking supply, Vx =12V

Figure 4 Principal topology for tracking power supply for single ended

amplifier system

Each bulk capacitors (C1 and C3) must be able to store the

energy from the supply pumping, which is maximal for

minimum signal frequencies. It can be shown that the charge

delivered to C1 because of supply pumping during the negative

period with a sinusoidal output voltage waveform, is:

Tracking supply, Vx =5V

Figure 3 Calculated positive supply currents for single-ended amplifier, RL = 1,

f=20Hz, for A=35V (red), A=20V(blue) and A=10V(green).

Q =

The results on Figure 3 show that the supply pumping current

from a +/-50V amplifier can be reduced by employing a

tracking power supply, but low values of Vx are required for

substantial reduction. This will influence the requirements for

control bandwidth and filter component size in the power

supply, in general a low value of Vx will require smaller filter

components and greater closed-loop bandwidth for the power

supply. In addition, low values of Vx impose value restrictions

on the amplifier output filter components, if a minimal amplifier

slew-rate is to be ensured.

AVx

2 fVb RL

Which is useful for finding an appropriate value of C1. Low

values of Vx are seen to reduce the demands on the capacitance

of C1, as expected from results on Figure 3.

V. PROPOSED CONTROL SCHEME

A number of possible schemes exist for realizing highbandwidth controllers for the buck converters [5]. One of the

fastest classes of switching power supply control systems

available is self-oscillating (asynchronous) hysteretic control

2

[5], which can also be employed in amplifiers [6] with excellent

results. When combined with current control, hysteretic control

[7] can provide the high bandwidth and fast transient response

required for the tracking converters. With current control, the

inductor dynamics are avoided in the small-signal design of the

voltage loop, an advantage since the filter frequency is well

within the targeted control bandwidth.

3. Current estimation by inductor sense winding voltage integration

Figure 6 Different methods for obtaining the inductor current in a buck

converter

Feedback of the inductor current estimate, rather than the true

inductor current causes alteration of the closed-loop

characteristics of the current control loop [9]. Specifically, the

inductor current estimate cannot be correct at DC, due to the

input offset voltage of any integrator, resulting in the absence of

current feedback at low frequencies. The model of power stage,

output filter and current loop with current estimation shown on

Figure 7 has been used to assess the effects of limited integrator

DC performance. The parameters in the model shown, with used

values, are:

Figure 5 Principal structure of proposed control scheme for tracking

converters.

Hysteretic current control requires sensing of the inductor

current, where sensing the high-side switch current would

suffice with a standard peak-current mode controller. Relocating

the current sensing resistor to the output side of the filter

inductor results in problems with common-mode rejection in the

sense amplifier, since significant HF (ripple) and LF (audio)

common-mode voltages need rejection. Estimating the inductor

current by integrating the inductor voltage is a different

approach that eliminates the loss and expense of the current

sensing resistor. Again, common-mode rejection of the

differential sense amplifier is critical. An inexpensive sense

winding on the inductor [8] represents a much easier way of

obtaining the differential inductor voltage, as an additional

advantage the sensed voltage is floating, minimizing

measurement noise problems. The discussed methods are

illustrated on Figure 6.

Output

filter

inductance

Output

filter

capacitance

Load resistance

Inductor winding ratio

nsense/ninductor

Integration

time

constant

Lower cut-off time

constant

PWM modulator gain

5H

10H

Rs

nL

Variable

1:12

12s

Variable

Kmod

10

Figure 7 Model of current controlled buck converter with inductor current

estimation.

1. Current measurement using a sensing resistor

The closed-loop transfer function from current reference input

to output voltage, Gcl ( s ) , is:

Rs

,

1 + sRs C

where the transfer function from current reference to average

inductor current, G I (s ) , is given by:

Gcl ( s) = G I ( s)

GI (s) =

2. Current estimation by inductor voltage integration

K mod (1 + s( Rs C + c ) + s 2 Rs C c )

Rs + s( L + Rs c + K mod n L c i ) + s 2 ( L c + LRs C + K mod n L c i Rs C ) + s 3 ( c LRs C )

Bode plots of Gcl(s) with varying Rs and c are shown on Figure

8. The transition from current mode to voltage mode control

when c is shortened is evident.

Figure 9 Simulated Vout (green) and

+/-Vs (red/blue),

Vx = 10V. Full

power 5kHz output signal.

Figure 10 Simulated Vout (green) and

+/-Vs (red/blue),

Vx = 7V. Full

power 5kHz output signal, 1ms decay

time constant.

Figure 11 Simulated Vout (green) and

+/-Vs (red/blue),

Vx = 10V.

Compound 1/3/20kHz signal.

Figure 12 Simulated Vout (green) and

+/-Vs (red/blue),

Vx = 7V, 1ms

decay time constant. Compound

1/3/20kHz signal.

Figure 13 Simulated Vout (green) and

+/-Vs (red/blue), Vx = 7V. Compound

1/3/20kHz signal.

Figure 14 Simulated Vout (green) and

+/-Vs (red/blue), Vx = 7V. Half-wave

5kHz sine wave.

Figure 8 Closed-loop bode plots for current loop in buck converter with inductor

current estimation, with c (top left), c=1s (top right), c=1ms (bottom left)

and c0s (bottom right)

With the information on the frequency characteristics of the

closed current loop, an output voltage controller can be

designed. It is designed around a lag compensator for moving

the output filter pole at Rs=1 from 16kHz to 10kHz, and

incorporates low frequency integration for setting the DC

operating point of the current loop correctly.

VI. SIMULATED RESULTS

A switching simulation model of the tracking converters is

constructed, with the following key parameters:

Buck filter inductor (L2/L3)

Buck filter capacitance

(C2/C3)

Buck supply rails (+/-Vb)

Load type

Switching frequency

(nominal)

Inductor current ripple

5H

10F

+/-60V

Switching amplifier

model, RL = 1

~ 300kHz

a multi-tone input signal, corresponding to an amplifier output

voltage with a 30Vpeak, 1kHz component, and a 10Vpeak 20kHz

component, amplitude modulated with a 10Vpeak 3kHz sine

wave. This is an attempt to model a realistic audio signal. Figure

11 and Figure 12 show the results with this signal, with Vx =

10V, and Vx = 7V, plus 1ms decay time constant, respectively.

With a Vx = 10V, the control system performs excellently, with

minimal phase lag, even when tracking the 20kHz component.

The decay time constant now has a negative influence on

tracking behaviour, because it causes sharp edges on the

reference signal, as seen on Figure 12. If the decay time

constant is removed, the tracking function better with the

compound signal, as Figure 13 shows for Vx = 7V.

4A (peak)

Each converter is fitted with the proposed control system, with

compensator blocks tuned to minimize static and dynamic

errors, while maintaining stability.

Initially, full-power bandwidth is examined. It becomes evident,

as seen on Figure 9, that the required 5kHz can be met with Vx

greater than 10V, if a minimum of difference of 5V between Vs

and Vout is required for the amplifier to function properly.

Limiting the negative slew rate of Vs allows the full-power

bandwidth test to be passed with slightly lower values of Vx.

This is shown on Figure 10, where a 1ms decay time constant is

placed on Vref.

The small-signal bandwidth of the control system is tested using

The tracking power supply is open-load stable, as shown by the

simulation in Figure 14, where both supply rails are stable

during the transition from loaded to unloaded state. This is due

4

to the Zobel networks connected across each Vs rail. Power loss

in the Zobel networks is low, comparable to similar networks

used to ensure open-load stability in switching amplifiers.

With the measured 4mA peak-peak ripple at 120kHz, the

demand for less than 558A peak at 240kHz should be met with

ease. Due to the usage of a 4th order input filter, the following

lower harmonics should also be under control. Examination of

higher frequency EMI performance would require proper EMI

measurement equipment.

VII. ACHIEVED PRACTICAL RESULTS

A functional prototype power supply has been implemented

as shown on Figure 15.

Efficiency of the implemented push-pull boost converter has

been examined, as shown on Figure 17. The real efficiency is

less than the calculated efficiency due to control system power

consumption at low output powers, and probably due to

proximity losses in transformer windings at higher output

powers.

Figure 15 Implemented prototype tracking power supply

Figure 17 Calculated and measured efficiency of implemented push-pull

boost converter

Conducted EMI performance of the push-pull boost section of

the supply has been examined by measurement of the input

current during CCM operation, as shown on Figure 16.

The performance of the current estimation technique employed

in the tracking buck converters is evident from Figure 18. The

estimated current is virtually noiseless, in phase and

proportional to the actual inductor current. This will only occur

as long as the permeability of the core remains constant, which

is ensured through proper inductor core selection.

Figure 16 Measured power supply input current during CCM operation of

push-pull boost converter

The conducted EMI demands imposed by Class 5 of the

CISPR-25 automotive EMC standard are listed for each

harmonic of the switching frequency in Table 1. This standard

imposed no limits below 150kHz, which is the reason for setting

the switching frequency to 120kHz.

Harmonic number

1. (120kHz)

2. (240kHz)

3.-4.(360-480kHz)

5. (600kHz)

6. (720kHz)

7. (840kHz)

8. (960kHz)

9. (1080kHz)

Figure 18 Measured inductor current (below, 500mA/div) and estimated

inductor current (above) in tracking buck converter.

The small-signal closed-loop response of the tracking buck

converters can be examined from the closed-loop gain-phase

measurement shown on Figure 19.

Class 5 maximum limits

Undefined

558Apeak

Undefined

78Apeak

67Apeak

59Apeak

54Apeak

52Apeak

Table 1 Maximum limits for harmonic input currents imposed by CISPR-25

class 5, recalculated from dBV to mApeak.

Figure 19 Measured closed-loop gain-phase characteristics of tracking buck

converter, unloaded (left) and driving 4 (right)

The bandwidth is well above 20kHz, and is in particular

unaffected by loading conditions, while the phase lag at 20kHz

is minimal at 15. The current control loop employs the

maximum practical value of c, so that the transition point from

current to voltage-mode is around 350Hz. Further examination

of control system performance is done by square wave testing,

with an example shown on Figure 20. It is concluded that the

control system is stable and fast, as required.

REFERENCES

[1]

[2]

[3]

[4]

Figure 20 Measured tracking buck converter output voltage, 1kHz square

wave into open load

[5]

The output voltages of the tracking power supply are measured

while driving an amplifier playing a 1kHz sine wave, as shown

on Figure 21. The power supply performs the demanded

function of tracking the amplifier output voltage.

[6]

[7]

[8]

[9]

Figure 21 Measured positive (top) and negative (bottom) tracking supply

voltages, plus amplifier output voltage (middle), 1kHz sine wave into 8.

VIII. CONCLUSION

It has been demonstrated, that the possibility exists for fitting

single-ended switching amplifiers with a high-bandwidth

tracking power supply. Good results have been achieved using

inductor current estimation, minimizing power losses.

Although more complex than a non-tracking supply, the

tracking supply offers the opportunity for utilizing less storage

capacitance per rail, and most probably reduces EMI at low

output levels.

IX. PATENT NOTE

The technique of using tracking supply voltages for PWM audio

amplifiers (as shown on Figure 1), also known as PAWM (Pulse

Amplitude and Width Modulation), is patent pending by Bang

& Olufsen ICEpower a/s.

Karsten Nielsen, Audio Power Amplifier Techniques

with Energy Efficient Power Conversion, Department of

Applied Electronics, DTU, Denmark, May 1998

Ford Motor Company, Electronic Component EMC

Requirements & Test Procedures, April 1999

Karsten Nielsen, Lars Michael Fenger, The Active pulse

modulated Transducer (AT) A novel audio power

conversion system architecture, 115th AES Convention,

New York, October 2003

Wilson C. P. de Arago Filho, Ivo Barbi, A Comparison

Between two Current-Fed Push-Pull DC-DC Converters

Analysis, Design and Experimentation, IEEE

International Telecommunication Energy Conf. Proc.

Rec., pp 313-320, 1996

Rais Miftakhutdinov, An Analytical Comparison of

Alternative Control Techniques for Powering NextGeneration Microprocessors, 2001

Paul van der Hulst, Andr Veltman, Ren Groenberg, An

asynchronous switching high-end power amplifier, 112th

AES Convention, Munich, Germany, May 2002

Robert W. Erickson, Dragan Maksimovic, Fundamentals

of Power Electronics, 2nd ed, p. 657, 2001

Allen F. Rozman, Jeffrey J. Boylan, Band Pass Current

Control Bell Laboratories AT&T Power Systems 1994

Mikkel C. W. Hyerby, Dennis R. Andersen ICEpower

Automotive CarFi System Master Thesis, rsted/DTU,

Denmark April 2004

S-ar putea să vă placă și

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Self Oscillating Class-D Audio Amplifier Circuit DesignDocument29 paginiSelf Oscillating Class-D Audio Amplifier Circuit DesignnicchioÎncă nu există evaluări

- Assembling AC DCPower SupplyDocument51 paginiAssembling AC DCPower SupplyDexter Rogero GumapoÎncă nu există evaluări

- UC3842 Inside SchematicsDocument17 paginiUC3842 Inside Schematicsp.c100% (1)

- Fr-d700 Instruction Manual (Applied)Document308 paginiFr-d700 Instruction Manual (Applied)Thủy TrAnÎncă nu există evaluări

- UC3845 Technical ExplanationDocument15 paginiUC3845 Technical ExplanationankurmalviyaÎncă nu există evaluări

- Uc3842 Provides Low-Cost Current-Mode Control: Application NoteDocument16 paginiUc3842 Provides Low-Cost Current-Mode Control: Application NoteLeonardo Ortiz100% (1)

- Design and Construction of Single Phase Pure Sine Wave Inverter For Photo Voltaic ApplicationDocument4 paginiDesign and Construction of Single Phase Pure Sine Wave Inverter For Photo Voltaic ApplicationRafid Haider ShantonuÎncă nu există evaluări

- An Introduction to Switched Mode Power Supply TopologiesDocument21 paginiAn Introduction to Switched Mode Power Supply Topologiesseahate100% (1)

- Neurophone CompleteDocument9 paginiNeurophone CompleteSimon Benjamin100% (3)

- A Very High Frequency DC-DC Converter Based On A Class Pfi Resonant InverterDocument10 paginiA Very High Frequency DC-DC Converter Based On A Class Pfi Resonant InvertererdemsecenÎncă nu există evaluări

- Capacitor ESR MeterDocument7 paginiCapacitor ESR MeterrubemllÎncă nu există evaluări

- TO Eliminate Common Mode Leakage Current IN Photovoltaic Grid Connected Power SystemDocument11 paginiTO Eliminate Common Mode Leakage Current IN Photovoltaic Grid Connected Power SystemLava KumarÎncă nu există evaluări

- كتاب السر المظروف في علم بسط الحروفDocument30 paginiكتاب السر المظروف في علم بسط الحروفmdkadry83% (65)

- Aplicacion Uc3842Document15 paginiAplicacion Uc3842Gian Mejia100% (1)

- VSC-Based HVDC Link: To Allow Further Modifications To The Original System. This Model ShownDocument38 paginiVSC-Based HVDC Link: To Allow Further Modifications To The Original System. This Model ShownleslyÎncă nu există evaluări

- Yang-Circuit Systems With MATLAB and PSpice-2007Document538 paginiYang-Circuit Systems With MATLAB and PSpice-2007nelsonÎncă nu există evaluări

- Hamza Al-Ali-FinalDocument22 paginiHamza Al-Ali-FinalHamza Mazen100% (1)

- Voltage To Frequency Converter Folosind Ci 555 TimerDocument11 paginiVoltage To Frequency Converter Folosind Ci 555 TimerAl ZanoagaÎncă nu există evaluări

- Analysis and Simulation of Single Phase Inverter Controlled by Neural NetworkDocument14 paginiAnalysis and Simulation of Single Phase Inverter Controlled by Neural NetworknandhakumarmeÎncă nu există evaluări

- Very Wide Input Voltage Range-Flyback (90V To 600V AC)Document12 paginiVery Wide Input Voltage Range-Flyback (90V To 600V AC)senkum812002Încă nu există evaluări

- 3-Phase PFC KolarDocument7 pagini3-Phase PFC KolarJayant SalianÎncă nu există evaluări

- Modeling and Simulation of Frequency Converter Used in Speed Control of Asynchronous MotorDocument6 paginiModeling and Simulation of Frequency Converter Used in Speed Control of Asynchronous MotorLelosPinelos123Încă nu există evaluări

- Low Power Operational Amplifier DesignDocument31 paginiLow Power Operational Amplifier DesignHarish KumarÎncă nu există evaluări

- Switching Power Supply Design Review - 60 Watt Flyback Regulator by Raoji Patel and Glen FRFTZ Slup072Document17 paginiSwitching Power Supply Design Review - 60 Watt Flyback Regulator by Raoji Patel and Glen FRFTZ Slup072Burlacu AndreiÎncă nu există evaluări

- 60W Flyback TIDocument16 pagini60W Flyback TIe_magazin3821Încă nu există evaluări

- 128122-Accelerometer & VelomitorTransducerOperationDocument22 pagini128122-Accelerometer & VelomitorTransducerOperationNorman MoralesÎncă nu există evaluări

- Three phase induction motor using single phase supplyDocument8 paginiThree phase induction motor using single phase supplyhezugÎncă nu există evaluări

- Tidu 174Document16 paginiTidu 174AmyÎncă nu există evaluări

- PWM Strategies For Inverters With Fluctuating DC Link Input: ServedDocument18 paginiPWM Strategies For Inverters With Fluctuating DC Link Input: ServeddaisysheelaÎncă nu există evaluări

- 20 The Essence of ThreePhase INTELEC2011Document28 pagini20 The Essence of ThreePhase INTELEC2011noreuÎncă nu există evaluări

- Cycloconverter UpdateDocument6 paginiCycloconverter Updatesoulfusion85Încă nu există evaluări

- 01413552Document8 pagini01413552Nalin Lochan GuptaÎncă nu există evaluări

- Precision Constant Current Source For Electrical Impedance TomographyDocument4 paginiPrecision Constant Current Source For Electrical Impedance Tomographyjorgeluis.unknownman667Încă nu există evaluări

- IEEE POWER ELECTRONICS 2015 Matlab Projectlist Mtech BeDocument4 paginiIEEE POWER ELECTRONICS 2015 Matlab Projectlist Mtech BeKumar RajÎncă nu există evaluări

- Design and Simulation of PFC Circuit For AC/DC Converter Based On PWM Boost RegulatorDocument5 paginiDesign and Simulation of PFC Circuit For AC/DC Converter Based On PWM Boost RegulatorSEP-PublisherÎncă nu există evaluări

- Applications of Balanced ModulatorDocument5 paginiApplications of Balanced ModulatorSomeshwar GaddalaÎncă nu există evaluări

- High Voltage Power Supply for Electro-Optics ApplicationsDocument5 paginiHigh Voltage Power Supply for Electro-Optics ApplicationsmishithÎncă nu există evaluări

- A Novel Approach For A Sinusoidal Output Inverter: Irfan AlanDocument6 paginiA Novel Approach For A Sinusoidal Output Inverter: Irfan AlanKari Romero GuizasolaÎncă nu există evaluări

- Ieee Current ModeDocument7 paginiIeee Current ModepqqpÎncă nu există evaluări

- IEEE Power System Paper-A 20-KW, 10-KHz, Single-Phase Multilevel ActiveDocument7 paginiIEEE Power System Paper-A 20-KW, 10-KHz, Single-Phase Multilevel ActiveAnoop MathewÎncă nu există evaluări

- Elimination of Harmonics Using Active Power Filter Based On DQ Reference Frame TheoryDocument5 paginiElimination of Harmonics Using Active Power Filter Based On DQ Reference Frame TheoryseventhsensegroupÎncă nu există evaluări

- Mac Int J.Power ElectronicsDocument14 paginiMac Int J.Power Electronicssandeepbabu28Încă nu există evaluări

- PV Inverter System Structure and Control DesignDocument38 paginiPV Inverter System Structure and Control DesignAnggoro Indarto AkbarÎncă nu există evaluări

- Sine Wave GeneratorDocument12 paginiSine Wave GeneratorSorina LupuÎncă nu există evaluări

- Naresh DC Re Injection FinalDocument6 paginiNaresh DC Re Injection FinalRamu ThommandruÎncă nu există evaluări

- A Bidirectional, Sinusoidal, High-Frequency Inverter Design: AbstractDocument7 paginiA Bidirectional, Sinusoidal, High-Frequency Inverter Design: AbstractJoe CkhoÎncă nu există evaluări

- Digital Current Limiting Techniques For Switching Power Supplies PDFDocument9 paginiDigital Current Limiting Techniques For Switching Power Supplies PDFAdolfo A HerreraÎncă nu există evaluări

- Control Strategy For Three Phase PWM Rectifier Using SVM ModulationDocument7 paginiControl Strategy For Three Phase PWM Rectifier Using SVM Modulationeditor_ijtelÎncă nu există evaluări

- EEEN40197 Lecture Notes AJF PDFDocument46 paginiEEEN40197 Lecture Notes AJF PDFAnonymous gVhwdk9ui9Încă nu există evaluări

- An 1162Document36 paginiAn 1162naniknanikÎncă nu există evaluări

- A Complete Narrow-Band Power Line Communication Node For AMRDocument6 paginiA Complete Narrow-Band Power Line Communication Node For AMRSudheer KakaniÎncă nu există evaluări

- Pulse Oximetry CircuitDocument19 paginiPulse Oximetry Circuitنواف الجهنيÎncă nu există evaluări

- L4981Document23 paginiL4981Robert GabrielÎncă nu există evaluări

- DC Ripple Current Reduction On A Single-Phase PWM Voltage-Source RectifierDocument11 paginiDC Ripple Current Reduction On A Single-Phase PWM Voltage-Source RectifierRajni YadavÎncă nu există evaluări

- Dual Current-Sense Amplifi Ers Simplify H-Bridge Load MonitoringDocument2 paginiDual Current-Sense Amplifi Ers Simplify H-Bridge Load MonitoringJorge GuerreroÎncă nu există evaluări

- 500w Power Amplifier Circuit DiagramDocument6 pagini500w Power Amplifier Circuit DiagramJoão Alberto0% (1)

- A 0.55 V 7-Bit 160 MSs Interpolated Pipeline ADC Using Dynamic AmplifiersDocument4 paginiA 0.55 V 7-Bit 160 MSs Interpolated Pipeline ADC Using Dynamic AmplifiersThanos van RamÎncă nu există evaluări

- Bmen3120 Project1 Frequency Selective Circuit 1Document12 paginiBmen3120 Project1 Frequency Selective Circuit 1api-3139933760% (2)

- KK Hpe (PPT) 1Document20 paginiKK Hpe (PPT) 1अभिषेक कुमार उपाध्याय100% (1)

- Low Power High Speed I/O Interfaces in 0.18um CmosDocument4 paginiLow Power High Speed I/O Interfaces in 0.18um Cmosayou_smartÎncă nu există evaluări

- U-93 Application NOTE A New Integrated Circuit For Current Mode ControlDocument9 paginiU-93 Application NOTE A New Integrated Circuit For Current Mode ControlpramodÎncă nu există evaluări

- AppNote03 Uc3842Document14 paginiAppNote03 Uc3842Heriberto Flores AmpieÎncă nu există evaluări

- Slua 143Document15 paginiSlua 143Tonia KataÎncă nu există evaluări

- Steady State Analysis On HVLF-AC Transmission For Offshore Wind Power by Modern XLPE Submarine CableDocument5 paginiSteady State Analysis On HVLF-AC Transmission For Offshore Wind Power by Modern XLPE Submarine CableIJIRAE- International Journal of Innovative Research in Advanced EngineeringÎncă nu există evaluări

- TIP140, TIP141, TIP142, (NPN) TIP145, TIP146, TIP147, (PNP) Darlington Complementary Silicon Power TransistorsDocument8 paginiTIP140, TIP141, TIP142, (NPN) TIP145, TIP146, TIP147, (PNP) Darlington Complementary Silicon Power TransistorsroozbehxoxÎncă nu există evaluări

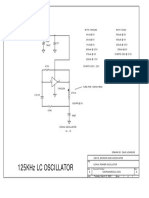

- 125k OscilaterDocument1 pagină125k OscilatermdkadryÎncă nu există evaluări

- LA4628Document9 paginiLA4628jgpbÎncă nu există evaluări

- Self-Oscillating Half-Bridge Driver: Ir2153 (D) (S) & (PBF)Document9 paginiSelf-Oscillating Half-Bridge Driver: Ir2153 (D) (S) & (PBF)Zoltán HalászÎncă nu există evaluări

- Cafene SolventDocument26 paginiCafene SolventmdkadryÎncă nu există evaluări

- Overature Series AN1192Document29 paginiOverature Series AN1192mdkadryÎncă nu există evaluări

- Applications of Op-Amp Circuits: Section 8.2Document8 paginiApplications of Op-Amp Circuits: Section 8.2mdkadryÎncă nu există evaluări

- Latitude-E5420 User's Guide Ar-AeDocument96 paginiLatitude-E5420 User's Guide Ar-AemdkadryÎncă nu există evaluări

- Sloa 133Document4 paginiSloa 133mdkadryÎncă nu există evaluări

- 6 Band Equalizer With One Ic LM741Document4 pagini6 Band Equalizer With One Ic LM741mdkadryÎncă nu există evaluări

- Complementary Transistors Pairs ListingDocument15 paginiComplementary Transistors Pairs ListingAndrea OrtegaÎncă nu există evaluări

- BB5 Natural Label3Document1 paginăBB5 Natural Label3mdkadryÎncă nu există evaluări

- CopigmenDocument87 paginiCopigmenwaterwind666Încă nu există evaluări

- Oxidation of Ethane To Ethylene To AceticDocument31 paginiOxidation of Ethane To Ethylene To AceticmdkadryÎncă nu există evaluări

- Fipronol WikiDocument6 paginiFipronol WikimdkadryÎncă nu există evaluări

- GMX On Irrigation (Sprinklers) : Site: Infosys Technologies MahendracityDocument11 paginiGMX On Irrigation (Sprinklers) : Site: Infosys Technologies MahendracitymdkadryÎncă nu există evaluări

- Loane Potato - Medium Maturity Variety from FranceDocument2 paginiLoane Potato - Medium Maturity Variety from FrancemdkadryÎncă nu există evaluări

- Benzal Thin GrapesDocument8 paginiBenzal Thin GrapesmdkadryÎncă nu există evaluări

- استخلاص الشيحDocument2 paginiاستخلاص الشيحmdkadryÎncă nu există evaluări

- تجمع المواد الصلبةDocument6 paginiتجمع المواد الصلبةmdkadryÎncă nu există evaluări

- Magnetics-Treatment of Fluids and WaterDocument45 paginiMagnetics-Treatment of Fluids and WatermdkadryÎncă nu există evaluări

- ES PROD Active ProductsDocument775 paginiES PROD Active ProductsmdkadryÎncă nu există evaluări

- Composition of GrapesDocument5 paginiComposition of GrapespeepgunÎncă nu există evaluări

- Alcohol Reactions and Oxidation StatesDocument37 paginiAlcohol Reactions and Oxidation Statesfsalgado7Încă nu există evaluări

- GCC Standardization Organization (Gso)Document13 paginiGCC Standardization Organization (Gso)mdkadryÎncă nu există evaluări

- Food Safety Issues Associated With Products From AquacultureDocument68 paginiFood Safety Issues Associated With Products From AquaculturemdkadryÎncă nu există evaluări

- Bacterial Control of Postharvesr DiseasesDocument7 paginiBacterial Control of Postharvesr DiseasesmdkadryÎncă nu există evaluări

- Biocontrol of Citrus Postharvest DiseasesDocument5 paginiBiocontrol of Citrus Postharvest DiseasesmdkadryÎncă nu există evaluări

- Design and Implementation of An Experimental Segway Model: March 2009Document6 paginiDesign and Implementation of An Experimental Segway Model: March 2009SKLÎncă nu există evaluări

- Simulink Collate 290321Document109 paginiSimulink Collate 290321TiniÎncă nu există evaluări

- Aic Lab ManualDocument50 paginiAic Lab ManualVishwanath PetliÎncă nu există evaluări

- 3g3JX InverterDocument262 pagini3g3JX InverterdatdttvuÎncă nu există evaluări

- ACS724 DatasheetDocument27 paginiACS724 DatasheetScott RadÎncă nu există evaluări

- Tinkercad Review For Teachers - Common Sense Education: Passive Filter Low PassDocument1 paginăTinkercad Review For Teachers - Common Sense Education: Passive Filter Low PassAlejandroÎncă nu există evaluări

- TeddyPardo PDFDocument3 paginiTeddyPardo PDFSyste DesigÎncă nu există evaluări

- SQUELCH CircuitDocument5 paginiSQUELCH CircuitZaw Khaing WinÎncă nu există evaluări

- ElectronicsDocument9 paginiElectronicsEstephen EdaÎncă nu există evaluări

- Tda 7340GDocument27 paginiTda 7340GAndrei PetriciÎncă nu există evaluări

- Biosensors 11 00198Document13 paginiBiosensors 11 00198Ramesh kÎncă nu există evaluări

- D Class Audio Amp by TIDocument74 paginiD Class Audio Amp by TIAnonymous DjWqKpZ1Încă nu există evaluări

- Ap3105na BCDDocument9 paginiAp3105na BCDlcd_vinay34Încă nu există evaluări

- 11 November 1986Document60 pagini11 November 1986Monitoring TimesÎncă nu există evaluări

- Amp CA3028 IntersilDocument10 paginiAmp CA3028 IntersilHenry Armando Sivirichi CoronelÎncă nu există evaluări

- The Study of Harmonics and LV Energy Compensation - EEPDocument18 paginiThe Study of Harmonics and LV Energy Compensation - EEPSandro CuetoÎncă nu există evaluări

- Nanotechnology in RF and Microwave ApplicationsDocument10 paginiNanotechnology in RF and Microwave ApplicationssfgavasdfgÎncă nu există evaluări

- Filter Design Report 15 PDFDocument5 paginiFilter Design Report 15 PDFLudy FajardoÎncă nu există evaluări

- Design of Microwave FiltersDocument11 paginiDesign of Microwave FiltersArpit SinghÎncă nu există evaluări

- Single Chip Karaoke Processor: DescriptionDocument28 paginiSingle Chip Karaoke Processor: DescriptionahmedÎncă nu există evaluări

- MC3362 FM ReceiverDocument8 paginiMC3362 FM ReceiverzafarnazÎncă nu există evaluări

- 1.0 Introduction To Filter: RF Engineering - Passive Circuit Microstrip Filter DesignDocument20 pagini1.0 Introduction To Filter: RF Engineering - Passive Circuit Microstrip Filter DesignapecevsbÎncă nu există evaluări

- A Two-Tone Test Method For Continuous-Time Adaptive EqualizersDocument7 paginiA Two-Tone Test Method For Continuous-Time Adaptive EqualizersNidhi GuptaÎncă nu există evaluări

- Ta 0104 ADocument18 paginiTa 0104 AJump DownÎncă nu există evaluări