Documente Academic

Documente Profesional

Documente Cultură

Surs PDF

Încărcat de

saeed65Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Surs PDF

Încărcat de

saeed65Drepturi de autor:

Formate disponibile

SURFACE SAFETY SYSTEMS

PRODUCT NUMBER INDEX

GENERAL INFORMATION INDEX

Page

Number

Product

Number

Overview of Surface Safety Equipment ...................................... 4

Typical Safety System ................................................................ 5

Bonnets and Actuators ................................................................ 6

Bonnet Design ............................................................................ 7

Surface Safety System Ordering Example ............................... 27

876-53

877-36

877-37

877-51

877-52

877-53

877-55

884-62

884-63

884-64

885-06

885-07

885-09

885-10

885-11

885-12

885-13

885-14

885-15

885-16

885-19

885-21

885-23

885-27

885-30

885-37

885-38

885-39

885-59

ALPHABETICAL INDEX

Product

Number

Description

Page

Number

Actuator, Dia-Flex Pneumatic Diaphragm ................. 9

Actuator, Dia-Flex Pneumatic w/Integral Bonnet .... 10

Actuator, Model C Hydraulic ................................. 12

Actuator, Model CSWC Coil Spring Wire-Cutting . 17

Actuator, Model E Hydraulic ................................. 13

Actuator, Model HWC Hydraulic ...............................

Wire-Cutting .............................................................. 18

885-83 Actuator, Model J Hydraulic .................................. 14

886-41 Actuator, Model RV Hydraulic .............................. 15

884-63 Actuator, Model SH Hydraulic .............................. 16

885-06 Actuators, Pneumatic Piston-Type .............................. 8

Actuator Accessories ........................................... 24-26

885-30

Block-and-Bleed Fusible Plug .............................. 26

885-38

Clear Stem Protector ........................................... 24

885-21

Control Line Blowout Preventer ........................... 25

885-64/66 Electric Limit Switches ......................................... 26

885-37

Heat-Sensitive Lock-Open Device, High-Thrust .. 25

885-39

Heat-Sensitive Lock-Open Device, Stanard ........ 25

885-16

High Pressure Fusible Plug ................................. 26

885-14

Hydraulic Opener ................................................. 24

885-15

Low Pressure Fusible Plug .................................. 26

885-13

Mechanical Opener .............................................. 24

885-63

Pneumatic Limit Switch ........................................ 26

885-62

Screw Jack ........................................................... 24

885-19

Sensing Line Blowout Preventer .......................... 25

886-23 Gate Valve, DAV Reduced Port

Diaphragm Actuated ................................................. 11

885-59 LPO (Line Pressure Operated)

Surface Safety System ............................................. 19

876-53 Pilot, Helix I High-Low Pilot System .......................... 22

877-53 Pilot, High Hydraulic .................................................. 21

877-52 Pilot, Low Hydraulic .................................................. 21

877-55 Pilots, Hydraulic High or Low .................................... 20

877-51 Pilots, High-Pressure High-Low Hydraulic ................ 21

Quick-Disconnect System ......................................... 6

877-36 Relay, BPR Pneumatic ......................................... 23

885-92

885-92

885-10

884-64

885-79

884-62

Description

Page

Number

Helix I High-Low Pilot System ................................... 22

"BPR" Pneumatic Relay f/Standard, H2S - CO2 ...... 23

"BPR" Pneumatic Relay f/Arctic Service ................. 23

High Pressure High-Low Hydraulic Pilots ................. 21

Low Hydraulic Pilot ................................................... 21

High Hydraulic Pilot ................................................... 21

Hydraulic High or Low Pilots ..................................... 20

Model HWC Hydraulic Wire-Cutting Actuator ....... 18

Model SH (Short) Hydraulic Actuator ................... 16

Model CSWC Coil Spring Wire-Cutting Actuator .. 17

Pneumatic Piston Actuator for Standard Service. ....... 8

Pneumatic Piston Actuators for H2S - CO2 Service ..... 8

Pneumatic Piston Actuators for Arctic H2S Service. .... 8

Model C Hydraulic Actuator for Standard Service 12

Model C Hydraulic Actuator for H2S Service. ....... 12

Model C Hydraulic Actuator f/Arctic H2S Service .. 12

Mechanical Opener ................................................... 24

Hydraulic Opener for Standard Service .................... 24

Low Pressure Fusible Plug ....................................... 26

High Pressure Fusible Plug ...................................... 26

Sensing Line Blowout Preventer ............................... 25

Control Line Blowout Preventer ................................ 25

Hydraulic Opener for Arctic Service. ......................... 24

Hydraulic Opener for H2S - CO2 Service ................... 24

Block-and-Bleed Fusible Plug ................................... 26

Heat-Sensitive Lock-Open Device ............................ 25

Clear Stem Protector ................................................ 24

Heat-Sensitive Lock-Open Device f/Std. Actuators .. 25

"LPO" (Line Pressure Operated) Surface

Safety System ........................................................... 19

885-62 Screw Jack ................................................................ 24

885-63 Pneumatic Limit Switch ............................................. 26

885-64/66 Electric Limit Switch ................................................ 26

885-79 Model E Hydraulic Actuator f/Standard Service ... 13

885-80 Model E Hydraulic Actuator for H2S Service ......... 13

885-83 Model J Hydraulic Actuator ................................... 14

885-92 Dia-Flex Pneumatic Diaphragm Actuators ................ 9

885-92 Dia-Flex Pneumatic Diaphragm Actuators

w/Integral Bonnet ...................................................... 10

886-23 Model DAV Reduced Port Diaphragm ......................

Actuated Gate Valve f/Standard Service .................. 11

886-36 Model DAV Reduced Port Diaphragm ......................

Actuated Gate Valve for Mechanical Override .......... 11

886-41 Model RV Hydraulic Actuator ............................... 15

SURFACE SAFETY SYSTEMS

OVERVIEW OF SURFACE

SAFETY EQUIPMENT

3

MASTER SSV

HYDRAULIC

OR

PNEUMATIC

ACTUATOR

1 SCSSSV

1) Subsurface Safety Valve

Tubing or Wireline Valves

2) Surface Safety Valve

Upper Master Valve

3) Surface Safety Valve

Outer Wing Valve

WING SSV

HYDRAULIC

OR

PNEUMATIC

ACTUATOR

Safety Systems is comprised of two

applications: Subsurface Safety Valves

and Surface Safety Systems. The Surface Safety equipment (bonnet /actuators/ pilots) compliments the Subsurface

Safety equipment to provide complete

control of the wells. Baker Oil Tools has

long been recognized as a world leader

in wellhead, production, pipeline, and

process safety control systems.

Surface Safety Systems manufactures actuators for applications including

Christmas tree master and wing valve

locations, shut down valves, header

manifolds, and pipeline control valves.

The tradition of excellence began over

75 years ago and reflects Bakers approach to innovative products and services. Baker's Surface Safety Systems

are backed up by experienced professionals including field and shop personnel. Five major service centers located

in the Far East, Middle East, Europe,

South America and the USA provide

technical service support and house

spare parts inventories.

Safety Systems' primary manufacturing facilities are in Broken Arrow, Oklahoma and Aberdeen, Scotland. Each

plant operates under strict quality control

procedures to insure the highest possible quality is built into every product.

In addition to modern manufacturing

facilities and a broad product line, Baker

also offers the experience required to

analyze a particular application and recommend the most appropriate equipment for the service condition of a well.

All safety system requirements can be

satisfied through the extensive Baker Oil

Tools network of contacts located

worldwide.

SURFACE SAFETY SYSTEMS

TYPICAL SAFETY SYSTEM

The subsurface and surface safety valves control the flow of the well and are fail-safe closed upon loss of their control signal.

The safety system has two main parts: the end devices, such as the safety valves; and, the control devices, such as the pilots

and control panels. These devices monitor and detect the flowing conditions of the well. Under normal operating conditions, the

panel sends the signal to the subsurface and surface safety valves, holding them in the open position. Should an abnormal

operating condition occur, the panel blocks and bleeds the control signal allowing the safety valves to return to their fail-safe closed

position.

Baker Oil Tools manufactures the bonnets, actuators and pilots. A complete surface safety system, tailored to specific

applications, can be supplied.

Below is an example of typical offshore safety systems components.

Typical Safety System

SURFACE SAFETY SYSTEMS

BONNETS AND ACTUATORS

Two-Piece Quick-Disconnect

The two-piece Quick-DisconnectTM

(U.S. Patent No. 4,135,547), Baker Oil

Tools unique bonnet and actuator design, totally isolates the actuator from

the bonnet without compromise of safety.

Since the bonnet and the actuator

are two distinct products, it is possible to

remove the actuator from the bonnet

without depressurizing or isolating the

valve. A substitute actuator may be

installed on the bonnet while the original

actuator is being serviced; or, a larger or

smaller actuator may be installed to accommodate a change in production pressures. It is even possible to substitute a

hydraulic actuator for a pneumatic actuator providing the adequate control

pressure is available.

We specifically design each valve

bonnet to adapt to one of the many

commonly used gate valves. Bonnet

selection is simple and specific for each

valve manufacturer and model. Actuator

choice is entirely a matter of available

control pressure and desired characteristics.

The bonnet features both a metal-tometal back-seat seal and a state-of-theart sealing system. The sealing system

is designed for the pressure range and

service of the valve and is interchangeable with others in its size and pressure

range.

Because of their individual, completely self-contained sealing systems,

a sour service bonnet may be used in

conjunction with a standard service actuator, providing the control medium is

acceptable. This Quick-Disconnect is an

exclusive Baker advantage targeted at

saving the customer time, space and

money.

SURFACE SAFETY SYSTEMS

BONNET DESIGN

The bonnet is an integral part of the

patented Quick-Disconnect system for

actuators. The bonnets are easy to maintain and feature an advanced sealing

system and a metal-to-metal fire seal

that guarantees seal integrity even if the

elastomeric seals are damaged by high

temperatures. Bonnets are designed and

rated for the reverse-acting or directacting gate valve on which they will be

mounted. The bonnet and actuator assembly utilizes a two- piece stem design

that completely isolates all the corrosive

fluids in the valve body and bonnet.

Because of their individual, completely

self-contained sealing systems, a sour

service bonnet may be used in conjunction with a standard service actuator,

providing the control medium is acceptable. This Quick-Disconnect adds value

to the Baker safety system equipment

and provides savings in the short and

long term.

FEATURES/BENEFITS

Patented Quick-Disconnect design

isolates all process fluids in the valve

body

Rated to match the valve specifications for service environment and

applications

Two-piece stem design makes

actuator selection a matter of control

pressure required and operating

characteristics

The Quick-Disconnect design provides

easy access to critical seal areas for

quick valve maintenance

Wide selection of packing cartridges

are available for every service

environment

Bonnets adapt to all popular gate

valves with permanent drift setting

capability

Stem and packing cartridge are made

of 17-4PH stainless steel as a

standard

CRA materials are available on

request

Actuator

Connector

Mounting

Bolts

Sealing

Cartridge

Drift

Adjustment

Spacers

Fire Seal

Gate

Attachment

(Typical)

Typical Bonnet Design

SURFACE SAFETY SYSTEMS

PNEUMATIC PISTON-TYPE

ACTUATORS

Product Nos. 885-06, 885-07,

and 885-09

For opening and closing any of the popular direct or reverse acting gate valves,

this actuator supplies a downward thrust

upon application of pneumatic pressure

from an external source. When control

pressure is relieved, a compression

spring, aided by pressure in the valve

body, returns the piston to its normal, or

up, position. The loss of control pressure

causes the actuator to act as a fail-safe

closed device when adapted to reverse

acting gate valves.

The Baker numbering system for actuators describes the required piston diameter and valve stroke. For example,

an 885-06-1703 is a Pneumatic Piston

Type Actuator for standard service with

a 17" diameter piston that operates a 3"

or smaller reverse acting gate valve.

Typical Pneumatic Actuator

Product No. 885-06

SPECIFICATION GUIDE

Product No.

Service

Operating Temperature Range

885-06

Standard

-20F to 250F

-29C to 121C

885-07

H2S-CO2

-20F to 250F

-29C to 121C

885-09

Arctic H2S

-75F to 180F

-59C to 82C

FEATURES/BENEFITS

Available in piston sizes 8" - 20" for

1-13/16" through 16" gate valves, direct or reverse acting, for all pressures

and service environments

Compact design, removable within its

own working space

Universal adaptability

Visual indication produced by rising

stem

Dual-wound opposed springs

One-piece lock ring (stainless steel)

External safety relief device

Fail-safe design

Quick-Disconnect design that allows

intelligent troubleshooting

M series available with high thrust

spring package for low pressure backseat valves

SURFACE SAFETY SYSTEMS

DIA-FLEX PNEUMATIC

DIAPHRAGM ACTUATOR

Product No. 885-92

Designed to the industrys highest

standards, the Dia-Flex Pneumatic

Diaphragm Actuator incorporates the

exclusive interchangeability, ease of

maintenance, and durability that are built

into other Baker actuators. The Dia-Flex

is lighter in weight than the piston actuator. It will accept most of the same

accessories as other Baker Oil Tools

actuators.

The first diaphragm type actuator to

eliminate the o-rings from moving

surfaces, the Dia-Flex features an easily

renewed poly-pak seal around the rising

stem. Additionally, it does not require

disassembly for dynamic seal

replacement.

The Dia-Flex actuator may be

interchanged with Baker Oil Tools

pneumatic or hydraulic actuators of

comparable rating, with no need for

change-out of bonnet parts or adapter

kits.

FEATURES/BENEFITS

Eliminates the dynamic o-ring

problems with a diaphragm

Utilizes an easily renewed poly-pak

seal that provides easy seal replacement

Lighter in weight than the piston type

designs

Universal adaptability to any Baker

bonnet assembly without bonnet

adapter kits

Dual-wound opposed springs

External safety relief device

Fail-safe design

Patented Quick-Disconnect design

Available for sizes 1-3/16" to 4" valves

with 12", 14", & 18" diaphragm

M series with high thrust spring package for low pressure back-seat valves

Tandems also available

Dia-Flex Pneumatic Diaphragm Actuator

Product No. 885-92

Nominal Valve

Size (In.)

Commodity No.

885-92-1203

885-92-1403

885-92-143M *

885-92-1803

885-92-M403 *

885-92-M803 *

885-92-T123

885-92-T143

885-92-1204

885-92-1404

885-92-1804

885-92-M84T *

885-92-T144

1-3/16

2-1/16

2-9/16

3-1/16

* M series for low pressure back-seat valves. Requires special bonnet.

SPECIFICATION GUIDE

Maximum Control Pressure

Production Test Pressure

Operating Temperature Range

Product No. 885-92

150 psi

10 bars

225 psi

15.5 bars

-20F to 180F

-29C to 82C

Standard Service

SURFACE SAFETY SYSTEMS

DIA-FLEX PNEUMATIC

ACTUATOR WITH

INTEGRAL BONNET

Product No. 885-92

For use on land or offshore installations,

the Dia-Flex Pneumatic Actuator with

Integral Bonnet delivers reliable fail-safe

performance on gate valves. It is ideal for

both wellhead and shut-down valves.

Designed and built to the industrys

highest standards, this fail-safe gate valve

actuator delivers simplicity, low weight,

durability, and ease of maintenance.

Integrated with a Baker Oil Tools

valve bonnet, and incorporating dual polypak seal technology, this actuator is designed to operate any of the popular

direct or reverse-acting gate valves.

Because the Dia-Flex actuator is

lighter than standard piston-type actuators, it is particularly useful on tensionleg platforms and other weight-sensitive

applications.

FEATURES/BENEFITS

Eliminates the dynamic o-ring

problems with a diaphragm

Visual indication of position provided

by the rising stem

Lighter in weight than piston-type

design

External safety relief device

Fail-safe design

Available for sizes 1-3/16" to 4" valves

with 12", 14", & 18" diaphragm

Tandems also available

Dia-Flex Pneumatic Actuator

with Integral Bonnet

Product No. 885-92

SPECIFICATION GUIDE

Maximum Operating Pressure

150 psi

10 bars

Maximum Valve Working Pressure

5000 psi

345 bars

Production Test Pressure

248 psi

15 bars

-20F to +250F

-29C to +121C

Operating Temperature Range

Product No. 885-92

10

Standard Service

SURFACE SAFETY SYSTEMS

MODEL DAV REDUCED

PORT DIAPHRAGM

ACTUATED GATE VALVE

Product No. 886-23 f/Standard

Service, 886-36 Mechanical

Override f/ Standard Service

The DAV (Diaphragm Actuated Valve)

is a simple, reliable, all-in-one safety

valve designed to minimize the cost and

size of safety systems. It provides protection of energy resources, life, property and the environment. The DAV is

pneumatically actuated and available with

an optional mechanical override. Applications include wellhead wing valve, shutdown, casing relief, gas lift process, and

other similar applications. The DAV is

a 2", 1-1/4" reduced port, bi-directional

flow safety valve. It utilizes two floating

seats and a slab gate of hardened steel

to provide a durable complete seal. The

spring return diaphragm actuator assures

a positive fail-close operation.

The valve working pressure is 3000

psi (207 bars). It requires a maximum of

60 psi (4 bars) control pressure to operate the actuator, depending on valve

body pressure.

FEATURES/BENEFITS

Screwed or flanged end connections

Metal-to-metal fire seals

Tapered reduced port design to protect seats from flow erosion

Repairs can be made without removing valve from flowline

Bi-directional flow

Mechanical override option available

Model DAV Reduced Port Diaphragm

Actuated Gate Valve

Product No. 886-23

SPECIFICATION GUIDE

Maximum Control Pressure

Maximum Valve Working Pressure

Operating Temperature Range

60 psi

3000 psi

-29F to 250F

4 bars

207 bars

-29C to 121C

SPECIFICATION GUIDE

Operation Mode

Pneumatically Actuated

Pneumatically Actuated

Manual Override

Manual Override

End Connection

Screwed

Flanged

Screwed

Flanged

Commodity Number

866-23-1200

866-23-1202

866-36-1200

866-36-1202

11

SURFACE SAFETY SYSTEMS

HYDRAULIC ACTUATORS

Application is the key to determining

which actuator to select. Safety valves

operate on pneumatic or hydraulic pressure; when pneumatic supply pressure

is not available, then hydraulic pressure

is utilized. Baker manufactures several

different versions of hydraulic actuators

to meet specific requirements. Baker

hydraulic actuators use the same twopiece Quick-Disconnect design as the

pneumatic actuators with the bonnet

being a separate component, which isolates all the process fluids in the valve

and bonnet assembly. The Quick-Disconnect feature allows actuator choice

to be entirely a matter of available control

pressure and desired operating

parameters. Hydraulic actuator selection is also based on valve size, pressure

requirements and service environment

conditions.

MODEL C HYDRAULIC

ACTUATOR, Product Nos.

885-10 f/Standard Service

885-11 f/H2S Service

885-12 f/Arctic H2S

The Model C is one of the most widely

used hydraulic actuators. Once mounted

on the bonnet, it becomes the power unit

assuring complete valve closure or open-

ing upon loss of control pressure. Like all

of Bakers actuators, it incorporates the

female portion of the patented QuickDisconnect on the shaft assembly. The

Model C Hydraulic Actuator operates

valves from the 1-13/16" to 4-1/16" range

with operating pressures up to 10,000

psi and 6-3/8" range with operating pressure up to 5000 psi. The Model C

piston assembly is located in the bottom

of the actuator, which allows the spring

to be totally immersed in oil for protection

from corrosion. The piston assembly is

available in 3" and 4" sizes. The actuator

shaft, in the fail-safe position, serves as

a visual indicator. The actuator is protected from over-pressurization by an

external safety relief device, which is

rated for the working pressure and temperature service of the actuator. The

Model C is available in standard, H2S

and Arctic* services, with temperature

ranges from -75F to +250F.

SPECIFICATION GUIDE

H2S Service, 14D Class 1-2-3S-4/

Standard Service, 14D Class 1-2

Service for 3" Piston

Maximum Control Pressure

Mounted on 2" Valve (0303)

Mounted on 2-1/2" Valve (0303)

Mounted on 3" Valve (0303)

Mounted on 4" Valve (0304)

Maximum Operating Pressure

Test Pressure

Temperature Range (Standard Service)

Product Weight

(0.362 x Valve Pressure) + 140 psi

(0.416 x Valve Pressure) + 140 psi

(0.570 x Valve Pressure) + 140 psi

(0.827 x Valve Pressure) + 140 psi

7500 psi

517 bars

11,250 psi

776 bars

-20F to 250F

-29C to 121C

130 lbs

59 kg

SPECIFICATION GUIDE

Service for 4" Piston

Model C Hydraulic Actuator

Product No. 885-10

12

Maximum Control Pressure

Mounted on 2" Valve (0403)

Mounted on 2-1/2" Valve (0403)

Mounted on 3" Valve (0403)

Mounted on 4" Valve (0404)

Mounted on 6" Valve (0406)

Maximum Operating Pressure

Test Pressure

Temperature Range (Standard Service)

Product Weight

* Arctic service temperature is -75F to 180F.

H2S Service, 14D Class 1-2-3S-4/

Standard Service, 14D Class 1-2

(0.195 x Valve Pressure) + 75 psi

(0.224 x Valve Pressure) + 75 psi

(0.306 x Valve Pressure) + 75 psi

(0.450 x Valve Pressure) +75 psi

(0.890 x Valve Pressure) + 75 psi

7500 psi

517 bars

11,625 psi

801 bars

-20F to 250F

-29C to 121C

238 lbs

108 kg

SURFACE SAFETY SYSTEMS

MODEL E HYDRAULIC ACTUATOR

Product Nos. 885-79 f/Standard Service

and 885-80 f/H2S Service

The Model E Hydraulic Actuator is short

in profile and intended for valves from

2-1/2" through 6-5/8". It is designed for

applications with line pressures up to

10,000 psi and with control pressures of

6000 psi. The piston assembly is located

in the top of the actuator and is available

in 5" and 7" sizes. This larger piston area

permits the use of control pressures lower

than that of the Model C. The actuator

shaft houses the female portion of the

patented Quick-Disconnect system. In

the fail-safe position, the shaft serves as

a visual indicator. The actuator is pro-

tected from over-pressurization by an

external safety relief device. Each safety

relief device is rated for the working

pressure and service of the actuator.

The Model E is available in standard

and H2S-CO2 service with temperature

ranges from -20F to +250F.

The Model E is available with sidemount magnetic limit switches. These

switches provide valve position indication to a remote control station. The

Model E is also available for 2500 psi

maximum control pressure applications.

SPECIFICATION GUIDE

Service for 5" Piston

H2S Service, 14D Class 1-2-3S-4

Maximum Control Pressure

Mounted on 2-1/2" Valve (0503)

Mounted on 3" Valve (0503)

Mounted on 4" Valve (0504)

Mounted on 4" 15K Valve (8A54)*

Temperature Range

Product Weight

(0.18 x Valve Pressure) + 100 psi

(0.24 x Valve Pressure) + 100 psi

(0.36 x Valve Pressure) + 100 psi

(0.33 x Valve Pressure) + 75 psi

-18C to 121C

-20F to 250F

86 kg

190 lbs

SPECIFICATION GUIDE

Service for 7" Piston

H2S Service, 14D Class 1-2-3S-4

Maximum Control Pressure

Mounted on 6" Valve (0706)

Mounted on 6-3/8" 10K Valve (8SA6)*

Maximum Operating Pressure

Safety Head Maximum Working Pressure

Test Pressure

Temperature Range

Product Weight

(0.28 x Valve Pressure) + 50 psi

(0.42 x Valve Pressure) + 50 psi*

406 bars

6000 psi

422 bars

6200 psi

632 bars

9300 psi

-29C to 121C

-20F to 250F

182 kg

400 lbs

Model E Hydraulic Actuator

Product No. 885-79

* Requires 8 bolt hole bonnet assembly.

13

SURFACE SAFETY SYSTEMS

MODEL J HYDRAULIC ACTUATOR

Product No. 885-83

The Model J Hydraulic Actuator is designed for long stroke applications, valves from

5" to 10" with control pressures up to 6000 psi. The Model J utilizes a translating

cylinder to obtain a compact profile for long stroke operation. The piston is located in

the top of the actuator and is available in 5" and 7" piston sizes. A rising stem feature

is available for visual indication. The Model J employs a coil spring to return the gate

valve to the closed position upon loss of control pressure. Additional model options

include the RV with one-piece stem and mechanical opener, and the RV with heatsensitive lock-open device.

SPECIFICATION GUIDE

Service

Standard Service 14D Class 1,2

Maximum Control Pressure for 5" Piston

Mounted on 5" Valve (0506)

Mounted on 6" Valve (0506)

Mounted on 8" Valve (0508)

(0.4157 x Valve Pressure) + 75 psi

(0.477 x Valve Pressure) + 75 psi

(0.798 x Valve Pressure) + 75 psi

Mounted on 10" Valve (0510)

Maximum Operating Pressure

Test Pressure

Temperature Range

Product Weight (0506)

(0508)

(0510)

Model J Hydraulic Actuator

Product No. 885-83

14

(1.34 x Valve Pressure) + 68 psi

6000 psi

414 bars

9300 psi

-20F to 250F

340 lbs

352 lbs

364 lbs

641 bars

-29C to 121C

154 kg

160 kg

165 kg

SURFACE SAFETY SYSTEMS

MODEL RV (REDUCED VOLUME)

HYDRAULIC ACTUATOR

Product No. 886-41

The Model RV (Reduced Volume) Hydraulic Actuator is designed to minimize

the cost and size of safety systems. The RV operates 2" to 4" valves and

accommodates pressures up to 5000 psi. The Model RV utilizes the patented

translating cylinder design, which makes maintenance of the single T-seal very

simple. The inspection window provides visual indication of the gate valve

position and allows a side-mount magnetic limit switch to be installed. The

external safety relief device protects the actuator from over-pressurization.

Additional model options include the RV with one-piece stem and mechanical

opener, and the RV with heat-sensitive lock-open device.

SPECIFICATION GUIDE

Service

Standard and H2S-CO2 Service

14D Class 1-2-3S-4

Maximum Control Pressure for 3" Piston

Mounted on 2" Valve

(0.54 x Valve Pressure) + 210 psi

Mounted on 3" Valve

(0.86 x Valve Pressure) + 210 psi

Mounted on 4" Valve

Contact Engineering Department

Maximum Operating Pressure

5000 psi

345 bars

Maximum Working Pressure

5200

359 bars

Test Pressure

7800 psi

538 bars

Temperature Range

0F to 250F

-18C to 121C

Product Weight

75 lbs

34 kg

Model RV Hydraulic Actuator

Product No. 886-41

15

SURFACE SAFETY SYSTEMS

MODEL SH (SHORT) HYDRAULIC ACTUATOR

Product No. 884-63

The Model SH (Short) Hydraulic Actuator is a compact design for space conservation. The compact design is achieved with the patented translating cylinder. The SH

actuator operates valves within a 3" to 6" range and accommodates operating

pressures up to 15,000 psi, with a maximum control pressure of 6000 psi. The piston

assembly is available in 3" and 5" sizes and has only one dynamic T-seal. An

inspection window is provided for visual gate valve position indication. An external

safety relief device and breather protect the actuator from over-pressurization. The

SH is also available with side-mount magnetic limit switches.

SPECIFICATION GUIDE

Service

Maximum Control Pressure for 3" Piston

Mounted on 3" Valve

Mounted on 4" Valve

Model SH Hydraulic Actuator

Product No. 884-63

16

Maximum Control Pressure for 5" Piston

Mounted on 4" Valve

Mounted on 5" Valve

Mounted on 6" Valve

Maximum Operating Pressure

Test Pressure

Temperature

Product Weight

Standard and H2s-Co2 Service

14D Class 1-2-3S-4

(0.36 x Valve psi) + 1300 psi

(0.48 x Valve psi) + 1300 psi

(0.22 x Valve psi) + 80 psi

(0.38 x Valve Pressure) + 80 psi

(0.45 x Valve Pressure) + 80 psi

6000 psi

9300 psi

-20F to 250F

900 lbs

414 bars

641 bars

-29C to 121C

406 kg

SURFACE SAFETY SYSTEMS

HYDRAULIC HIGH-THRUST

WIRE-CUTTING

ACTUATORS

The Hydraulic High-Thrust Wire-Cutting

Actuators help offset the inherent risk associated with wireline operations. In the event

of a wireline accident, these actuators deliver fail-safe shut-in by providing sufficient

force to cut a 7/32" logging cable, 3/16"

stainless steel line, or coiled tubing. The

models offered are the CSWC CoiledSpring Wire-Cutter and the HWC Hydraulic Wire-Cutter.

MODEL CSWC COIL SPRING

WIRE-CUTTING ACTUATOR

Product No. 884-64

The Model CSWC Coil-Spring Wire-Cutter is widely used for fail-safe shut-in during

extended wireline operations. The CSWC

utilizes a patented translating cylinder and

is available in 5" or 7" piston sizes. The

pistons operate gate valves in the 4" to 6"

range and accommodate operating pressures up to 15,000 psi with 6000 psi control

pressure. The translating cylinder contains

all control pressure inside the piston area,

which is sealed by a single T-seal and backup ring arrangement. This simplifies maintenance. The CSWC design incorporates

Bakers patented Quick-Disconnect, permitting installation or removal of the actuator without depressurizing the gate valve. In

addition, the gate valve or Christmas tree

may be handled, shipped, or installed without the actuators in place to provide user

convenience.

The CSWC design offers many options. They include side-mounted limit

switches for valve position indication, a

remote control station, and a rising stem for

visual indication of valve position. A variety

of accessories is available to extend the

utility of this actuator.

Baker also offers a Pneumatic WireCutting Actuator, Product No. 885-06-17m4,

for use on valves up to 4" with operating

pressures to 5000 psi.

Model CSWC Coil Spring Wire-Cutter Actuator

Product No. 884-64

SPECIFICATION GUIDE

Service for 3" Piston

Maximum Control Pressure

Mounted on 4" Valve (0304)

Maximum Operating Pressure

Test Pressure

Temperature Range

Product Weight

Standard and H2S-CO2 Service

14D Class 1-2-3S-4

(0.48 x Valve Pressure) + 1300 psi

6000 psi

9300 psi

-20F to 250F

410 lbs

414 bars

641 bars

-29C to 121C

408 kg

SPECIFICATION GUIDE

Service for 5" Piston

Maximum Control Pressure

Mounted on 5" Valve (0506)

Mounted on 65" Valve (0506)

Maximum Operating Pressure

Test Pressure

Temperature Range

Product Weight

Standard and H2S-CO2 Service

14D Class 1-2-3S-4

(0.38 x Valve Pressure) + 800 psi

(0.45 x Valve Pressure) + 800 psi

6000 psi

9300 psi

-20F to 250F

900 lbs

414 bars

641 bars

-29C to 121C

408 kg

17

SURFACE SAFETY SYSTEMS

HIGH-THRUST ACTUATORS

MODEL HWC HYDRAULIC WIRE-CUTTING ACTUATOR

Product No. 884-62

The HWC Hydraulic Wire-Cutting Actuator is designed to provide fail-safe gate valve

closure during extended wireline work. The HWC operates valves in the 2" to 6"

range and accommodates operating pressures up to 10,000 psi with maximum control

pressures of 6000 psi. The HWC is available with a 5" piston, and it utilizes disc

springs located below the piston assembly. The actuator shaft houses the female

portion of the Quick-Disconnect and in the fail-safe position, serves as a valve position

indicator. The actuator is protected from over-pressurization by an external safety

relief device. Each safety relief device is rated for working pressure and service of the

actuator.

SPECIFICATION GUIDE

Service

Maximum Control Pressure for 5" Piston

Mounted on 3" Valve (0503)

Mounted on 4" Valve (0504)

Maximum Operating Pressure

Test Pressure

Temperature Range

Product Weight

Model HWC Hydraulic

Wire-Cutting Actuator

Product No. 884-62

18

Standard 14D Class 1-2

(0.194 x Valve psi) + 690 psi

(0.194 x Valve psi) + 690 psi

6000 psi

9300 psi

-20F to 250F

410 lbs

414 bars

641 bars

-29C to 121C

185 kg

SURFACE SAFETY SYSTEMS

LPO (LINE PRESSURE

OPERATED) SURFACE

SAFETY SYSTEM

Product No. 885-59

The LPO (Line Pressure Operated)

Surface Safety System is designed for

precision well control in situations where

local supervision is minimal and external

power sources are not available. The

system is compact and utilizes flowline

pressure as the surface safety valve

control medium.

Flowline pressure, within predetermined limits, maintains the surface safety

valve in the open position. When a high

or low flowline pressure condition exists,

the respective pilot vents pressure from

the actuator and closes the surface safety

valve. The pressure differential in the

actuators control line closes the velocity

check valve, blocking flowline pressure

to the actuator. The surface safety valve

then remains closed until the high or low

pressure condition is corrected and the

LPO system is manually reset.

*The reverse acting gate valve can

be provided by Baker or other

manufacturers.

FEATURES/BENEFITS

Configured for gate valve sizes from

1-13/16" through 8" with working pressures up to 5000 psi

Alleviates need for an external power

source

Minimizes system monitoring

High/low pilots and components are

externally mounted for ease of calibrating and servicing

Stainless steel wetted parts provide

years of reliable service for Model

SS-4 high-pressure pilot and lowpressure pilot

External safety relief device protects

actuator from over-pressurization

Pilot design includes interchangeable

spools, allowing easy field conversion

from high-to-low or low-to-high

pressure

Interchangeable springs allow fast

field conversion of sensor ranges

SS-4 Pilot System

Actuator

Bonnet

Gate Valve*

Velocity

Check Valve

Isolation

Valve

Line Pressure Operated Surface Safety System

Product No. 885-59

Sensor Ranges

Spring Codes (Colors)

Standard

Spring

Inconel

Spring

Spring Ranges

PSI (Bar)

B (blue)

G (green)

100-1200 (6.9-83)

R (red)

Y (yellow)

1000-2500 (69-173)

S (silver)

P (purple)

2000-5000 (137-345)

Switch Specifications

Valve Type

Set Point Deviation

Deadband

2 Way

3%

10% of Range

Max Operating Pressure 5000 psi (345 bar)

Burst Pressure

10,000 psi (690 bar)

Cv Factor

1.1

Temperature Range

-20 to 250 F

-29 to 122C

19

SURFACE SAFETY SYSTEMS

HYDRAULIC HIGH

OR LOW PILOTS

Product No. 877-55

Hydraulic High or Low Pilots for high

system pressures are hydraulic power

controllers which monitor flowline pressure conditions. The pilots will automatically block and bleed from 75 psi to 5500

psi control pressure when preset line

pressure limits are violated. The unique

pressure handling capability of the high

pressure exhaust pilot permits direct

monitoring and control of high pressure

fluids. This allows the high pressure

control system to reduce in size and

complexity. Since use of this type pilot

can eliminate the need for field gas supply, separators and scrubbers, pressure

regulators and pneumatic pilots, it is

possible to operate an entire safety sys-

tem using unregulated flowline fluids of

5500 psi and below.

The high pressure exhaust type pilot

is ideal for line break systems application where supervision is minimal or external power sources are not available.

This type of pilot is capable of being

tripped by a fusible plug, which indicates

fire safe applications. High Pressure

Exhaust Type Pilot, Product No. 877-55,

must be used in conjunction with a velocity check valve. This allows the system

to be charged up and on line as soon as

the well is ready for test or production.

Product No. 877-55 exhaust type pilot is

field convertible from high to low or vice

versa.

SPECIFICATION GUIDE

Sensing Pressure Ranges

Maximum Control Pressure

Operating Temperature Range

Repeatability of Set Point

PSI

75-300

250-900

750-2200

2000-5500

3000

-20F to 250F

Hysteresis or Deadband

Design Meets

Weight

Bars

5-20

17-62

52-152

138-380

206

-29C to 121C

1% Set Pressure Maximum

Less than 10% of Full Range

NACE MR-01-75 Standards

12 lbs

5.5 kg

RANGE CHART

Sensing Range (PSI)

75-300

High Pressure Exhaust Pilot

Manifold Assembly

Product No. 877-55

20

750-2200

250-900

Commodity No.

2000-5500

High Pilot

877-55-0003

877-55-0009

877-55-0022

877-55-0055

Low Pilot

877-55-0300

877-55-0900

877-55-2200

877-55-5500

SURFACE SAFETY SYSTEMS

HIGH PRESSURE HIGH-LOW

HYDRAULIC PILOTS

Product No. 877-51

The High Pressure Pilot incorporates the

functions of a complete system.

The high-low pilot assembly consists

of four major components: control valve,

low pressure sensing unit, high pressure

sensing unit, and mechanical operator,

all of which are packaged in a single

compact cylinder. This assembly can be

utilized for sensing pressures up to 9000

psi. Within the preset high-low pressure

set points, the pilot will transmit a high

pressure control signal (9000 psi maximum). When the sensed pressure falls

below or exceeds the high-low set point

range, the assembly will automatically

block and bleed the control pressure. On

either a high or low trip condition, the pilot

will automatically lock itself out and must

be manually reset.

This assembly includes a low pressure bypass detent mechanism which

can be used to override the low pressure

pilot for start-up sequence. Once the

flowline pressure reaches the low set

point, the detent assembly will automatically clear and arm the pilot assembly.

This high-low pilot also has a manual

control which provides start-up or shutdown control regardless of the pilotsensed pressure. The high pressure

hydraulic pilot design is also available

individually for either low or high pressure sensing.

FEATURES/BENEFITS

Simplicity Because this is a simple

control system, it is inherently reliable

and serviceable. Installation, maintenance, and calibration are easy, even

for beginning control technicians.

Reliability This pilot eliminates the

maze of control tubing, relays, and

interface valves found in conventional

control consoles, and replaces them

with one simple, reliable component.

Trip point accuracy Incorporation

of a snap-acting adjustable valve assures the accuracy of trip-point

setting.

Repeatable set point Powerful

springs and permanently lubricated

seal bores assure set-point reliability

better than +3 percent of the set

pressure.

Manual control The safety system

may be manually shut down or started

up at any time, regardless of the pilot

set point or line pressure conditions.

Automatic start-up bypass A

spring-loaded detent pin can be used

to override the low pilot for start-up.

When flow-line pressure rises above

the set point, the detent automatically

retracts. This feature makes it easy for

a single operator to start up a large

number of wells simultaneously.

High Pressure

Sensing Unit

LOW HYDRAULIC PILOT

Product No. 877-52

When pressure falls below the pilotsensed set point, the pilot blocks and

bleeds the hydraulic control pressure.

Low Pressure

Sensing Unit

HIGH HYDRAULIC PILOT

Product No. 877-53

When pressure exceeds the pilot-sensed

set point, the pilot blocks and bleeds the

hydraulic control pressure.

High-Low Hydraulic Pilot

Product No. 877-51

SPECIFICATION GUIDE

Sensing Pressure Ranges

Repeatability of Set Point

Maximum Operating Pressure

Control Valve

Pilot

Production Test

Control Valve

Pilot

Operating Temperature Range

Design Meets

PSI

100-300

250-900

750-2000

1900-5500

3300-9000

Bars

7-21

18-62

52-138

131-380

227-620

Within +3% of Set Pressure

7500 psi

517 bars

9000 psi

620 bars

6000 psi

420 bars

1.5 x Maximum Range

-40F to 250F

-20C to 121C

NACE MR-01-75 Standards

21

SURFACE SAFETY SYSTEMS

DIRECT-DIAL PILOTS

HELIX 1 HIGH-LOW

PILOT SYSTEM

Product No. 876-53

The Helix 1 High-Low Pilot System utilizes coil-type stainless steel Bourdon

tubes to open and close snap-acting

block-and-bleed valves in response to

either high or low changes in sensed

pressure. The typical system contains

one Helix 1 Pilot set to high pressure

sensitivity, one Helix 1 Pilot set to low

pressure sensitivity, and a manifold for

mounting both to a control panel.

The Helix 1 Pilot can be supplied as

an individual product (Product No. 87648). This compact pilot is easily installed,

insensitive to harsh environment and

vibration, and is packaged in a stainless

steel case. Changing the set point is as

simple as changing the trip point setting

on the adjustable dial on the face of the

pilot. The pilot can easily be shop or field

converted from high to low, or vice versa,

by a simple interchange of parts.

Helix 1 Pilot System

Product No. 876-53

SPECIFICATION GUIDE

Over Pressure Capacity of Sensing Element

Repeatability of Set Point

1%, Full Scale

Deadband (Trip to Reset)

Accuracy of Dial Setting

Less than 5%, Full Scale

+ 3 Percent

2 times for all ranges to 5000 psi; 1.8 times for 0-10,000 psi; 1.5 times for 0-15,000 psi ranges

Pressure Sensing Element

316 Stainless Steel

Operating Temperature Range

Body Construction

Pneumatic Supply Pressure

PSI

0-150

0-250

0-500

Bars

0-10

0-17

0-34

High Low

N150

150H 150L

High

Low

N250

250H 250L

High

Low

N500

500H 500L

Pilot System (876-53)

Individual Pilot (876-48)

0-1500

Stainless Steel

30 psi 2,07 bars

Pressure Ranges

0-2500

0-103

0-172

Commodity No. 876-53

High Low

High

Low

N15C

N25C

15DH 15DL 25CH 25CL

-20F to 250F

-29C to 121C

0-5000

0-10,000

0-15,000

0-345

0-689

0-1034

High

Low High

Low

N05K

N10K

05KH 05KL 10KH 10KL

Each Helix 1 Pilot System or individual pilot is assigned a nine digit commodity number.

The four digit numbers above would follow the five digit product number to specify the various versions offered.

22

High

Low

N15K

15KH 15KL

SURFACE SAFETY SYSTEMS

BPR PNEUMATIC RELAY

Product No. 877-36 f/Standard and H 2S-CO2 Service

Product No. 877-37 f/Arctic Service

The BPR is a pilot-operated, three-way, spring-return, pneumatic relay. It can be

used as a normally closed or normally open logic valve, with or without automatic reset.

It is commonly used as an actuator control valve, but may be panel mounted for other

uses. Designed to quickly exhaust control pressure from any actuator to permit rapid

emergency closure, this normally closed, pilot-operated pneumatic device transmits

125 to 150 psi pressure. A signal from the pilot causes the relay spool to shift to the

open position, thus supplying the actuator with control pressure.

SPECIFICATION GUIDE

Commodity Number

Service

Operating Temperature

Minimum Control Pressure Air Latch

Minimum Control Pressure Automatic Reset

Maximum Control Pressure

Maximum Working Pressure

Weight

877-36-2000

Standard and H2S-CO 2

877-37-2000

Arctic

-20F to 250F (-28C to 121C) -75F to 120F (-60C to 49C)

30 psi for 125 psi output (1,7 bars for 8,6 bars output)

40 psi for 125 psi output (2,8 bars for 8,6 bars output)

30 psi for 125 psi output (4,1 bars for 17,2 bars output)

250 psi (17,2 bars)

4.3 lbs (1,9 kg)

BPR Pneumatic Relay

Product No. 877-36

23

SURFACE SAFETY SYSTEMS

ACTUATOR ACCESSORIES

MECHANICAL OPENER

Product No. 885-13

The Mechanical Opener is typically employed to open low

pressure gate valves when actuator control pressure is

unavailable. This accessory is offered in sizes suitable for

valves to 7".

885-13-0003 . . . . for 1-13/16" valves (with pressures to 10,000 psi),

and 2", 2-1/2", and 3" valves (with pressures to 5000 psi)

885-13-0006 . . . . for 4", 6", 6-1/2" and 7" valves (with no valve body

pressure)

SCREW JACK

Product No. 885-62

Mechanical Opener

Product No. 885-13

The Screw Jack is used to mechanically stroke a valve

before the actuator is installed. This device mounts directly

on a Baker bonnet assembly. Small (to 4") valves may be

operated while pressurized.

Screw Jack

Product No. 885-62

885-62-0103 . . . . for 2", 2-1/2", and 3" valves (to 2000 psi)

885-62-0004 . . . . for 4" valves (to 2000 psi)

HYDRAULIC OPENER

Product No. 885-14

Hydraulic Openers are used when a mechanical opener is

incapable of doing the work. This hydraulic opener will

open pressurized gate valves when the actuator is out of

service. It opens 2" to 12" gate valves with valve body

pressures of up to 5000 psi (345 bars). A 5000 psi control

pressure is required and may be obtained from a hand

pump.

885-14.....for standard service

885-23.....for arctic service

885-27......for H2S-CO2 service

CLEAR STEM PROTECTOR

Product No. 885-38

The Clear Stem Protector is available in two accessory

thread sizes to fit most Baker gate valve actuators. The

clear stem protector permits the rising stem of the actuator

to be seen, while preventing damage to the stem.

Hydraulic Opener

Product No. 885-14

24

885-38-0304....2.75 thread, for

885-38-0608....2.75 thread, for

885-38-1012....2.75 thread, for

885-38-1416....2.75 thread, for

885-38-0004....2.87 thread, for

885-38-0005....4.56 thread, for

885-38-2012....4.65 thread, for

885-38-2016....4.65 thread, for

4 valve, overall height 10.78

8 valve, overall height 14.70

12 valve, overall height 17.86

16 valve, overall height 21.86

6 valve, overall height 10.87

6 valve, overall height 13.12

12 valve, overall height 19.10

16 valve, overall height 23.22

Clear Stem Protector

Product No. 885-38

SURFACE SAFETY SYSTEMS

ACTUATOR ACCESSORIES (Cont.)

SENSING LINE

BLOWOUT PREVENTER

Product No. 885-19

Mounted between a flowline and a line sensing device

(usually a pilot or relay), the Sensing Line Blowout

Preventer unit reacts to the volume-velocity relationship of fluids in the sense line. When the velocity

component exceeds a predetermined rate, the Sensing Line Blowout Preventer shuts in, removing control

pressure from the end device (usually an actuator).

The actuator is thus permitted to close the valve,

preventing a blowout.

U.S. Patent No. 4,479,506

885-19.....for standard and H2S-CO2 service, 10,000 psi working

pressure (689 bars)

CONTROL LINE

BLOWOUT PREVENTER

Product No. 885-21

Sensing Line Blowout Preventer

Product No. 885-19

Control Line Blowout Preventer

Product No. 885-21

The Control Line Blowout Preventer is a safety device

that prevents excessive control line flow due to seal

failures. This product operates as a velocity check

valve that incorporates a volume delay. When control

line flow exceeds a rate of 0.1 GPM for a total of 35

cubic inches, the Control Line Blowout Preventer

automatically resets reestablishing control line

pressure.

U.S. Patent No. 4,202,368.

885-21.. for standard and H2S-CO2 service

HEAT-SENSITIVE

LOCK-OPEN DEVICE

Product No. 885-37

Specific thread and valve pressure requirements are

necessary for proper application of these accessories. The device is used to hold a reverse acting gate

valve open. It mounts on top of an actuator and

permits the actuator to close the valve only in the

event of a fire. HSLODs are used only during extended wireline work and are not designed to override

a safety system.

Heat-Sensitive

Lock-Open Device

Product No. 885-37

885-37-S283 HSLOD, HI THRST, F/6" SWC, 212F

885-37-2283 HSLOD, HI THRST, 2.75 THD., 212F

885-37-2350 HSLOD, HI THRST, 2.75N THD., 350F

885-37-4L28 HSLOD, HI THRST, QIK. DISC., 4.656 ACME, 212F

885-37-4283 HSLOD, HI THRST, 4.656 ACME, 212 F

885-37-4350 HSLOD, HI THRST, 4.656 ACME, 350F

885-37-5283 HSLOD, HI THRST, 5.00 ACME, 212F

885-37-6J28 HSLOD, HI THRST, A506 MOD. J 212F

885-37-J283 HSLOD, HI THRST, F/0508 MOD J, 212F

Heat-Sensitive Lock-Open Device

Product No. 885-39-370P

f/Standard Model Actuators

212F Eutectic

25

SURFACE SAFETY SYSTEMS

FUSIBLE PLUGS/LIMIT SWITCHES

LOW PRESSURE FUSIBLE PLUG

Product No. 885-15

HIGH PRESSURE FUSIBLE PLUG

Product No. 885-16

Specifically designed to act as fire sensors on pressure control

lines, these plugs contain a low-melting alloy that vents control

line pressure when ambient temperature exceeds a specified

value. Body construction is of 316 stainless steel or brass with

standard 1/4", 1/2", or 3/8" NPT male threads available. A range

of eutectic melting temperatures is offered.

SPECIFICATION GUIDE

High Pressure Fusible Plug

Product No. 885-16

Low

Pressure

Max Pressure (psi)

Service

Melting Points (F)

High

Pressure

300

10,000

Standard & H2S-CO2

Standard & H2S-CO2

162, 205, 281, 449

168, 210, 283

BLOCK-AND-BLEED FUSIBLE PLUG

Product No. 885-30

Designed for use on high pressure control lines, the block-andbleed fusible plugs will melt at fire temperatures and bleed control

fluids downstream, blocking upstream pressure. Constructed of

17-4PH and 300 series stainless steel for resistance to corrosive

environments, they are available with 1/4", 3/8", and 1/2" NPT

female connections. A range of eutectic melting temperatures is

offered.

SPECIFICATION GUIDE

Max Pressure (psi)

Service

Melting Points (F)

10,000

Standard & H2S-CO2

210, 283, 350

ELECTRIC LIMIT SWITCH

Product Nos. 885-64 & 885-66

PNEUMATIC LIMIT SWITCH

Product No. 885-63

Electric Limit Switch

Product No.s 885-64 & 885-66

26

Limit switches permit remote indication of gate valve position (full

open or closed) by electrical contact during actuator shaft movement, or by pneumatic movement due to actuator piston travel.

Limit switches are typically used on large production platforms or

automated leases. The Pneumatic Limit Switch is also applied in

hazardous areas where electrical devices are undesirable.

Block-and-Bleed Fusible Plug

Product No. 885-30

SURFACE SAFETY SYSTEMS

SURFACE SAFETY SYSTEMS

ORDERING EXAMPLE

BAKER OIL TOOLS SURFACE SAFETY SYSTEMS

CUSTOMER

END USER

CONTACT/PHONE

CONTACT/PHONE

VALVE BONNET DETAILS

VALVE BORE SIZE

API 6A PSL

PRESSURE RATING

API 6A TEMP CLASS

K, L, P, S, T, U, X

VALVE MODEL

API 6A MATL CLASS

BB, CC, EE, FF, HH

COMMODITY CODE

FIRESAFE 6FC

YES/NO

API 14D CLASS

1, 2, 3S, 3C, 4

1, 2, 3

ACTUATOR DETAILS

HYDRAULIC

YES/NO

PSI

WIRELINE-CUTTING

YES/NO

PNEUMATIC

YES/NO

PSI

MANUAL OVERRIDE

YES/NO

LIMIT SWITCH

YES/NO

MODEL

TYPE

COMMODITY CODE

ACTUATOR MODEL

API 6A PSL

1, 2, 3

API 6A TEMP CLASS

API 6A MATL CLASS

AA, DD

API 14D

API 6A PR2

YES/NO

K, L, P, S, T, U, X

YES/NO

CLASS

YES/NO

CLASS

PSI

MAXIMUM CONTROL PRESSURE

OTHER INFORMATION

OTHER Q.A. SPECS

BONNET COMM. #

VALVE INTERFACE W/REVISION LEVEL

SCREW JACK

YES/NO

SENSE LINE BLOWOUT PREVENTER

YES/NO

CONTROL LINE BLOWOUT PREVENTER

YES/NO

HEAT- SENSITIVE LOCK-OPEN DEVICE

YES/NO

MECHANICAL OPENER

CLEAR STEM PROTECTOR

QTY BONNETS

QTY ACTUATORS

VALIDITY

30, 60, 90 DAYS

DATE REQUIRED

DELIVERY TERMS

ACCESSORIES

C & F / EX-WKS

HSLOD

27

S-ar putea să vă placă și

- Maternity and Pediatric Nursing 3rd EditionDocument347 paginiMaternity and Pediatric Nursing 3rd EditionTaylor Talley80% (15)

- 0 BOSH FrameworkDocument18 pagini0 BOSH Frameworkharold fontiveros100% (1)

- Gastronomia 10 Competition GuideDocument21 paginiGastronomia 10 Competition Guidefpvillanueva100% (1)

- Product Catalogue - 0417ST (Print)Document54 paginiProduct Catalogue - 0417ST (Print)Ivan GutierrezÎncă nu există evaluări

- Catálogo Cameron Bop Novo 2004-2005Document162 paginiCatálogo Cameron Bop Novo 2004-2005Edmo Virgens100% (1)

- BALON Floating Valve - Installation and Repair Manual 2Document13 paginiBALON Floating Valve - Installation and Repair Manual 2Rudi Syarif Hidayat HarahapÎncă nu există evaluări

- Hydra Jar ProceduresDocument3 paginiHydra Jar Proceduresice_PLÎncă nu există evaluări

- API 6A Valve Parts CatalogDocument144 paginiAPI 6A Valve Parts CatalogAnggi SujiwoÎncă nu există evaluări

- Model D Tech Unit Stripper Packer SpecsDocument14 paginiModel D Tech Unit Stripper Packer SpecsДудла Станіслав100% (1)

- Drilling ProblemsDocument7 paginiDrilling ProblemsMEUBROÎncă nu există evaluări

- Human Persons As Oriented Towards Their Impendeing DeathDocument28 paginiHuman Persons As Oriented Towards Their Impendeing DeathMaxwell LaurentÎncă nu există evaluări

- Operating and Service Manual For Hyd. Act. Series 4000,5000,6500Document24 paginiOperating and Service Manual For Hyd. Act. Series 4000,5000,6500Mehdi Norouzi100% (1)

- HMH KFDJ Diverters r1Document9 paginiHMH KFDJ Diverters r1budygmoodÎncă nu există evaluări

- Oilfield Union Color Code GuideDocument5 paginiOilfield Union Color Code Guidelalberto96Încă nu există evaluări

- DHSV TestDocument7 paginiDHSV TestRonald Lucas Silva Lefundes OliveiraÎncă nu există evaluări

- Pumptools - BOP CanDocument1 paginăPumptools - BOP Cancasda73Încă nu există evaluări

- List of API Monogram LicensesDocument5 paginiList of API Monogram LicensesGopi SelvarajÎncă nu există evaluări

- Te ValveDocument30 paginiTe Valvecrni roko100% (2)

- General Catalog 2016Document64 paginiGeneral Catalog 2016Jamal100% (1)

- BPV Specification and Drawings PDFDocument4 paginiBPV Specification and Drawings PDFParag PadoleÎncă nu există evaluări

- Grade 3 Science: PlantsDocument5 paginiGrade 3 Science: PlantsMauie Flores100% (3)

- API 6A Gate ValvesDocument12 paginiAPI 6A Gate ValvesLee Sweningson100% (1)

- WPX Plug and WXN Lock Mandrel SizesDocument21 paginiWPX Plug and WXN Lock Mandrel Sizesu2006262918Încă nu există evaluări

- Difference Between PSL1 and PSL2Document1 paginăDifference Between PSL1 and PSL2samkarthik47100% (1)

- Introduction To The Philosophy of The Human PersonDocument17 paginiIntroduction To The Philosophy of The Human Personrovie andes100% (1)

- IQ3 RangeDocument44 paginiIQ3 Rangerizky efrinaldoÎncă nu există evaluări

- DSQ4 10M SidedoorDocument15 paginiDSQ4 10M SidedoorДудла СтаніславÎncă nu există evaluări

- Hydril Annular BOP1Document2 paginiHydril Annular BOP1Abde EsselamÎncă nu există evaluări

- CMD Civil Shaft Construction Capability Statement 2015Document20 paginiCMD Civil Shaft Construction Capability Statement 2015aecom2009Încă nu există evaluări

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 paginiTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanÎncă nu există evaluări

- D601005184 Man 001Document17 paginiD601005184 Man 001Riski Kurniawan100% (1)

- Valveworks USA 7-1/16Document30 paginiValveworks USA 7-1/16LeandroÎncă nu există evaluări

- Oilfield Processing Measurement and Control Oil and Gas SeparationDocument8 paginiOilfield Processing Measurement and Control Oil and Gas SeparationAnonymous 8te2h1Încă nu există evaluări

- 01 Bolt Tightening ToolDocument30 pagini01 Bolt Tightening ToolabdulfetahÎncă nu există evaluări

- Custom Pipe Handlers Brochure Feb 27 2013Document6 paginiCustom Pipe Handlers Brochure Feb 27 2013Alejandro Gomez100% (1)

- 980 Catwalk Broch 2014 v10 FINALDocument6 pagini980 Catwalk Broch 2014 v10 FINALtictacalÎncă nu există evaluări

- 7.0625 10000 Shaffer Bolted Annular Bop Spec SheetDocument1 pagină7.0625 10000 Shaffer Bolted Annular Bop Spec SheetJoel SÎncă nu există evaluări

- Case Study VR Lubricator ToolDocument2 paginiCase Study VR Lubricator ToolVictorÎncă nu există evaluări

- D391000177-MKT-001 Rev 06 WISE Catalog PDFDocument28 paginiD391000177-MKT-001 Rev 06 WISE Catalog PDFHumberto GonçalvesÎncă nu există evaluări

- Downhole Instrumentation Qualification RPDocument4 paginiDownhole Instrumentation Qualification RPabinadi1230% (1)

- SH Shandong Kerui Petroleum Equipment Co., LTD.: 1, Crown BlockDocument7 paginiSH Shandong Kerui Petroleum Equipment Co., LTD.: 1, Crown BlockCleevh MabialaÎncă nu există evaluări

- Tailrod Hydraulic Gate ValveDocument2 paginiTailrod Hydraulic Gate ValveTopoilServ100% (1)

- 012 +FMC+Technologies+-+Arno+Vissers PDFDocument21 pagini012 +FMC+Technologies+-+Arno+Vissers PDFmalikscribdÎncă nu există evaluări

- 7.6 SingleDocument226 pagini7.6 Singlewuillian barretoÎncă nu există evaluări

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 paginiTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopPastor VelasquezÎncă nu există evaluări

- Parker HTR ActuatorDocument22 paginiParker HTR ActuatorYorkistÎncă nu există evaluări

- Catcus Annual Report 2020 PDFDocument214 paginiCatcus Annual Report 2020 PDFMichael DasÎncă nu există evaluări

- SSV Control System SHUT DOWN VALVEDocument12 paginiSSV Control System SHUT DOWN VALVEglobal3tÎncă nu există evaluări

- KF Series Ball Valve PDFDocument20 paginiKF Series Ball Valve PDFbloggerparthiÎncă nu există evaluări

- Operation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enDocument108 paginiOperation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enPeter RhoadsÎncă nu există evaluări

- Mj-1645-Us Expanding Gate Valve MJDocument16 paginiMj-1645-Us Expanding Gate Valve MJgm_revankar3942Încă nu există evaluări

- Shandong Kerui Petrochemical Equipment CO.-business AnalysisDocument1 paginăShandong Kerui Petrochemical Equipment CO.-business Analysis911targaÎncă nu există evaluări

- M60eh44 Man 001Document40 paginiM60eh44 Man 001Riski KurniawanÎncă nu există evaluări

- FSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes ReliabilityDocument2 paginiFSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes Reliabilitymehmet sait öztürkÎncă nu există evaluări

- CamesaEMC Catalog 12-2013 7Document1 paginăCamesaEMC Catalog 12-2013 7Gerardo LizardoÎncă nu există evaluări

- Stripper TOT 2.50 10M DS34 TechMan1146Document13 paginiStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaÎncă nu există evaluări

- Wireline Depth CountersDocument1 paginăWireline Depth CounterssitaÎncă nu există evaluări

- Fail Safe or TR RegulatorDocument2 paginiFail Safe or TR RegulatorYeit HauÎncă nu există evaluări

- Caja de Cambio John DeereDocument52 paginiCaja de Cambio John Deerenelson.oyanadel21Încă nu există evaluări

- Test Pump WindlassDocument40 paginiTest Pump WindlassMd.farman Ali AhmedÎncă nu există evaluări

- National Oilwell Varco: Distributed by EESDocument2 paginiNational Oilwell Varco: Distributed by EESG MahendraÎncă nu există evaluări

- B+V General Catalog 2010Document32 paginiB+V General Catalog 2010Leonardo Faria Bueno100% (1)

- Packer Cup Testing - 9-5-8 Packer Cup LineDocument2 paginiPacker Cup Testing - 9-5-8 Packer Cup LineFerney FonsecaÎncă nu există evaluări

- 350 Direct Pump Setting tool-DPSTDocument2 pagini350 Direct Pump Setting tool-DPSTAdarsh HegdeÎncă nu există evaluări

- Model fm4Document25 paginiModel fm4LeandroÎncă nu există evaluări

- Uztel OrizontalDocument5 paginiUztel OrizontalDorin RaduÎncă nu există evaluări

- Grove g4n Gate Valve BrochureDocument24 paginiGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- SL Manual Lock 13 58 Shaffer Ram Bop Page-11-15Document5 paginiSL Manual Lock 13 58 Shaffer Ram Bop Page-11-15Richard EVÎncă nu există evaluări

- CT WKM Powrseal GateDocument28 paginiCT WKM Powrseal GatemoonanbuÎncă nu există evaluări

- BHDecat072013_bu0930Lexar_From080607 10/3/14 12:15 Am Page 12Document1 paginăBHDecat072013_bu0930Lexar_From080607 10/3/14 12:15 Am Page 12Prime Energy Warehouse-YemenÎncă nu există evaluări

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDe la EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- Safety Relief Valve General InformationDocument85 paginiSafety Relief Valve General InformationShridharBadamiÎncă nu există evaluări

- پدیده های مخرب در شیرهای کنترل و راه کارهای مقابله با انهاDocument25 paginiپدیده های مخرب در شیرهای کنترل و راه کارهای مقابله با انهاsaeed65Încă nu există evaluări

- Api 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim MccabeDocument11 paginiApi 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim Mccabesaeed65Încă nu există evaluări

- Well Head Sealing Guide PDFDocument4 paginiWell Head Sealing Guide PDFQaiser Hafeez100% (1)

- Basic Equation of DrillingDocument4 paginiBasic Equation of Drillingsaeed65Încă nu există evaluări

- Comparison of Analytical and Numerical Models On Torque and Hookload CalculationDocument7 paginiComparison of Analytical and Numerical Models On Torque and Hookload Calculationsaeed65Încă nu există evaluări

- Article1379511666 - Kutasov and Eppelbaum PDFDocument8 paginiArticle1379511666 - Kutasov and Eppelbaum PDFsaeed65Încă nu există evaluări

- 4th 120316074120 Phpapp02Document27 pagini4th 120316074120 Phpapp02Ahmed ghÎncă nu există evaluări

- Multivariate Probability DistributionDocument55 paginiMultivariate Probability Distributionrnjan321Încă nu există evaluări

- Study of The Interaction Model of PDC Cutters With RockDocument5 paginiStudy of The Interaction Model of PDC Cutters With Rocksaeed65Încă nu există evaluări

- Arma 10 407 PDFDocument7 paginiArma 10 407 PDFsaeed65Încă nu există evaluări

- Fann Model 35Document4 paginiFann Model 35Mahardhyka PrakashaÎncă nu există evaluări

- Liner Equipment: Class Code: 1539Document1 paginăLiner Equipment: Class Code: 1539saeed65Încă nu există evaluări

- Casing-Running Challenges For Extended-Reach WellsDocument2 paginiCasing-Running Challenges For Extended-Reach Wellssaeed65Încă nu există evaluări

- 3.5, 13.3 - G Grade NC38 5-2.438 PDFDocument1 pagină3.5, 13.3 - G Grade NC38 5-2.438 PDFsaeed65Încă nu există evaluări

- Quantum Shear Type Anchor LatchDocument1 paginăQuantum Shear Type Anchor Latchsaeed65Încă nu există evaluări

- Sulphide Scavengers in Oil and Gas Industry - A ReviewDocument8 paginiSulphide Scavengers in Oil and Gas Industry - A ReviewMartín Diego MastandreaÎncă nu există evaluări

- Iran student SPE presentation contest rulesDocument1 paginăIran student SPE presentation contest rulessaeed65Încă nu există evaluări

- Tools Diagram Run 2 PDFDocument2 paginiTools Diagram Run 2 PDFsaeed65Încă nu există evaluări

- Aade 22 PDFDocument8 paginiAade 22 PDFsaeed65Încă nu există evaluări

- Subject:: TKC Mms 8 Round Ancillary SpecificationsDocument2 paginiSubject:: TKC Mms 8 Round Ancillary Specificationssaeed65Încă nu există evaluări

- Positive Displacement Motor Increases Drilling Power, Rate of PenetrationDocument2 paginiPositive Displacement Motor Increases Drilling Power, Rate of PenetrationRFVÎncă nu există evaluări

- Drilling EquationDocument1 paginăDrilling Equationsaeed65Încă nu există evaluări

- Spe 5906 MSDocument13 paginiSpe 5906 MSsaeed65Încă nu există evaluări

- Petroleum Transactions: Spectral Gamma-Ray LoggingDocument6 paginiPetroleum Transactions: Spectral Gamma-Ray Loggingsaeed65Încă nu există evaluări

- Spwla 1961 JDocument15 paginiSpwla 1961 Jsaeed65Încă nu există evaluări

- 631 500seriesvalves PDFDocument2 pagini631 500seriesvalves PDFsaiful_tavipÎncă nu există evaluări

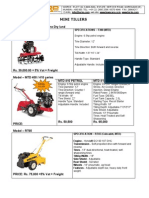

- Optimize soil preparation with a versatile mini tillerDocument2 paginiOptimize soil preparation with a versatile mini tillerRickson Viahul Rayan C100% (1)

- Epreuve LV 2 Anglais Premiere L Composition 2e Semestre 2023Document2 paginiEpreuve LV 2 Anglais Premiere L Composition 2e Semestre 2023Thierno ousmane DialloÎncă nu există evaluări

- B Fire BehaviorDocument39 paginiB Fire BehaviorDon VitoÎncă nu există evaluări

- Forced Retirement - Government Retirement AccountsDocument3 paginiForced Retirement - Government Retirement AccountsMark HarrisonÎncă nu există evaluări

- Final Final PosterDocument1 paginăFinal Final Posterapi-486056653Încă nu există evaluări

- Deck Damage and Penetrations: Prepared by Richard B. Heagler, P.EDocument9 paginiDeck Damage and Penetrations: Prepared by Richard B. Heagler, P.ENelzon MamaniÎncă nu există evaluări

- Ketamine Drug Study for AnesthesiaDocument1 paginăKetamine Drug Study for AnesthesiaPRINCESS MARIZHAR OMARÎncă nu există evaluări

- Caffeine's Effect on Daphnia Heart RateDocument2 paginiCaffeine's Effect on Daphnia Heart RateMianto NamikazeÎncă nu există evaluări

- PDI Quality Manual Rev 4 - 1.0 Table of ContentsDocument1 paginăPDI Quality Manual Rev 4 - 1.0 Table of ContentslouieÎncă nu există evaluări

- AHG-003 Guideline On GHG Accounting and Reporting 1junDocument16 paginiAHG-003 Guideline On GHG Accounting and Reporting 1junbagjabuktiÎncă nu există evaluări

- Using Casts For ImmobilizationDocument17 paginiUsing Casts For Immobilizationmpmayer2Încă nu există evaluări

- NPD High Level Status: Concept Development FeasibilityDocument22 paginiNPD High Level Status: Concept Development FeasibilityRaviÎncă nu există evaluări

- ZCT ZCT ZCT ZCT: 40S 60S 80S 120S 210SDocument1 paginăZCT ZCT ZCT ZCT: 40S 60S 80S 120S 210SWilliam TanÎncă nu există evaluări

- Bio Project-Polymerase Chain ReactionDocument21 paginiBio Project-Polymerase Chain ReactionS.AbiniveshÎncă nu există evaluări

- Medray Letterhead TemplateDocument5 paginiMedray Letterhead TemplateSteve NjugiÎncă nu există evaluări

- The Human Excretory System: A 40-Character GuideDocument3 paginiThe Human Excretory System: A 40-Character GuideMelvel John Nobleza AmarilloÎncă nu există evaluări

- 2 - Electrical Energy Audit PDFDocument10 pagini2 - Electrical Energy Audit PDFPrachi BhaveÎncă nu există evaluări

- Makalah Silverius Simatupang A24050072Document5 paginiMakalah Silverius Simatupang A24050072Maul MaulanaÎncă nu există evaluări

- Presentation On: Perfetti Van MelleDocument20 paginiPresentation On: Perfetti Van MelleAkash RaiÎncă nu există evaluări

- Ib Items: PotionsDocument8 paginiIb Items: PotionsZeNoWTFÎncă nu există evaluări

- Everything You Want To Know in ChennaiDocument428 paginiEverything You Want To Know in ChennaiBalamuruganÎncă nu există evaluări

- Chapter 1 EconomicsDocument5 paginiChapter 1 Economicsjordan cedeñoÎncă nu există evaluări