Documente Academic

Documente Profesional

Documente Cultură

YTC-H-ENV-MPL-162 Waste Rock Management Plan PDF

Încărcat de

Chairul Wahyu AdhaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

YTC-H-ENV-MPL-162 Waste Rock Management Plan PDF

Încărcat de

Chairul Wahyu AdhaDrepturi de autor:

Formate disponibile

Waste Rock Management Plan

Author

Approved

YTC-H-ENV-MPL-162

S Haures

S Pearce

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Environmental Department

Environmental Management Plan

Waste Rock

Edition

1

2

Revision

Rev 0

Rev 1

Author

S. Haures

R W Corkery & Co

Pty Limited

Kay Oxley

Document Control

Comment

Initial document

Peer review and

update

Date

22/11/2012

Authorised by

S Haures

DISTRIBUTION: YTC Resources Hera Site records & YTC Resources Orange Office.

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 1 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

This page was intentionally left blank

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 2 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Page Number

CONTENTS

Introduction ......................................................................................................................................... 5

1.

Approved activities ................................................................................................................... 5

2.

Consultation .............................................................................................................................. 8

3.

Environmental management..................................................................................................... 8

4.

3.1

legal and other requirements.......................................................................................... 9

3.2

objectives and outcomes .............................................................................................. 10

3.3

roles and responsibilities ............................................................................................. 10

3.4

competence and awareness training ........................................................................... 11

Implementation of waste rock management measures ......................................................... 11

4.1

introduction ................................................................................................................... 11

4.2

waste rock balance ....................................................................................................... 11

4.3

waste rock management ............................................................................................... 13

4.3.1 waste rock characterisation procedures ............................................................ 13

4.3.2 stockpiling of waste rock .................................................................................... 16

4.3.3 management of acid-formation ........................................................................... 17

4.3.4 placement of potential acid-forming waste rock placement underground ....... 19

4.3.5 non acid-forming waste rock .............................................................................. 20

5.

Monitoring of acid-forming material ....................................................................................... 20

6.

Review and compliance .......................................................................................................... 21

7.

6.1

evaulation of compliance .............................................................................................. 21

6.2

corrective and preventative measures ......................................................................... 21

6.3

incident reporting .......................................................................................................... 22

6.4

review ............................................................................................................................ 22

References .............................................................................................................................. 23

Figures

Figure 1

Locality ............................................................................................................................ 6

Figure 2

Approved Activities......................................................................................................... 7

Figure 3

Underground Material Handling Flowsheet ................................................................. 15

Figure 4

Proposed Design for the Waste Rock Emplacement Area .......................................... 18

Figure 5

Cross Section of Potentially Acid Forming Waste Rock Emplacement Area ............. 19

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 3 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Tables

Table 1

Project Approval Conditions .......................................................................................... 9

Table 2

Objectives and Outcomes............................................................................................. 10

Table 3

Roles and Responsibilities ........................................................................................... 10

Table 4

Waste rock balance ...................................................................................................... 12

Table 5

Waste Rock Classification ........................................................................................... 16

Table 6

Parameters and Frequency for Monitoring of Sulfides in Core and Rock-chip

Samples ................................................................................................................................... 20

Table 7

Parameters and Frequency for Monitoring of Water Quality in the Leachate Dam ... 21

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 4 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

INTRODUCTION

The Hera Mine site (Mine) is located approximately 100km southeast of Cobar and approximately 4km south of the

village of Nymagee (Figure 1). The Mine is an underground mine with an expected operational life of nine years.

This Waste Rock Management Plan (WRMP) has been prepared to comply with Condition 3(43) of Project Approval

10_0191 which was granted on 31 July 2012 by the Director-General of the Department of Planning and

Infrastructure in accordance with the Environmental Planning and Assessment Act 1979. The purpose of this

WRMP is to:

Provide employees and contractors with a clear and concise description of their responsibilities in

relation to waste rock management during the operations of the mine.

1.

Address the relevant commitments made within the environmental assessment.

APPROVED ACTIVITIES

Hera Resources is to establish an underground mine, processing plant, run-of-mine (ROM) pad, temporary waste

rock emplacement, tailings storage facility, mine camp, site offices and ancillary infrastructure for mining and related

activities.

The operational life of the mine is expected to total nine years, comprising 1.5 years of site establishment activities,

5.5 years of mining and processing operations and 2 years of rehabilitation operations.

The following activities have approval under the Project Approval (Figure 2).

Extraction of a maximum of 355 000t per annum of ore using an underground sublevel open stope

mining method.

Construction and use of a surface facilities area that would incorporate a range of approved

infrastructure including expanded Hera Resources and contractors site offices, ablutions facilities,

vehicle parking, power station, fuel storage, refuelling area, workshop and laydown areas.

Construction and use of a processing plant within the surface facilities area comprising crushing

and grinding, gravity, separation, flotation, leach and gold recovery circuits and ancillary

infrastructure.

Construction and use of a tailings storage facility.

Construction of a mine camp to house up to 80 personnel.

Construction and use of a surface water harvesting system, including expansion of an existing dam

(Pete's Tank) to 20ML capacity and construction of a new 90ML capacity dam (Back Tank East).

Construction of a water reticulation system that would connect the surface water storage dams and

existing production bores with the raw water dam and the mine camp.

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 5 of 25

Waste Rock Management Plan

Author

Approved

Figure 1

YTC-H-ENV-MPL-162

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Locality

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 6 of 25

Waste Rock Management Plan

Author

Approved

Figure 2

YTC-H-ENV-MPL-162

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Approved Activities

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 7 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Construction and use of the mine site access road and the associated intersection to allow site

access from Burthong Road.

Transportation of bulk concentrate from the Mine site to customers using the surrounding public

road network.

Construction and use of ancillary infrastructure, including soil stockpiles, core storage yards,

internal roads and tracks, and sediment and erosion management structures not already approved.

In addition, YTC Resources holds approval under Exploration Licence 6162 to construct a range of infrastructure,

including an exploration decline and ancillary infrastructure (the Part 5 Approval). Those works are fully described in

the Review of Environmental Factors (REF) titled Exploration Decline at the Hera Deposit within Exploration

Licence 6162, via Nymagee dated December 2006 and approved by the Department of Primary Industries on

2 April 2007.

That document includes a range of approved management plans that are to apply to all work

undertaken under the Part 5 Approval.

Condition 2 (13) of the Project Approval states the following:

Until they are replaced by an equivalent strategy, plan or program approved under this approval, the

Proponent shall implement the existing strategies, plans or programs for the site that have been approved

under the approved exploration activities described in Review of Environmental Factors (REF) entitled

Exploration Decline at the Hera Deposit within Exploration Licence 6162.

This WRMP replaces the existing waste rock management strategies documented in the REF and approved under

the Part 5 Approval.

2.

C O N S U LTAT I O N

Condition 3 (43)(a) of Project Approval requires this WRMP to be prepared in consultation with the Environmental

Protection Authority (EPA) and the NSW Office of Water (NOW) prior to being submitted to the Director-General of

the Department of Planning and Infrastructure (DP&I) for approval.

st

An initial draft of this WRMP was provided to the EPA and NOW for their comment and review on 21 November

2012.

st

In a letter received from the EPA on the 21 December 2012 EPA stated that they reviewed the Waste Rock

Management Plan and had identified the Waste Rock Management Plan met the information requirements.

On the 21st June 2013 NOW responded that they are satisfied that the consultation requirements have been met in

respect of the preparation of the Waste Rock Management Plan.

3.

E N V I R O N M E N TA L M A N A G E M E N T

This section describes the legal requirements, objectives and outcomes, the Hera Resources personnel roles and

responsibilities and the necessary training and awareness required to ensure the management of waste rock.

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 8 of 25

Waste Rock Management Plan

Author

Approved

3.1

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

LEGAL AND OTHER REQUIREMENTS

The Project Approval stipulates the required criteria that the construction and operational activities of the Mine must

comply with and sets out the core requirements of this WRMP. Relevant conditions associated with this approval

are reproduced in (Table 1).

Table 1 Project Approval Conditions

Page 1 of 2

Waste Rock Management Plan

3(43)

Section

The Proponent shall prepare and implement a Waste Rock Management Plan to the

satisfaction of the DirectorGeneral. The Plan must:

(a) Be developed in consultation with the EPA and NOW;

(b) Submitted for the approval of the Director-General within six months of this

approval;

(c) Include a detail description of the procedures to be implemented to monitor and

manage potential acid forming material;

(d) Reflect the groundwater and surface water monitoring programs to monitor the

potential acid-forming waste rock and any leachate generated, including

appropriately designed detection and response systems for acid generation

(covering monitoring methods, trigger levels and proposed management actions);

(e) Ensure effective isolation of potential acid forming material in rock dumps;

(f) Include procedures for appropriate testing of potentially acid forming waste rock

prior to it being bought to the surface;

(g) Include a procedure for prioritising the relocation of potential acid forming material

to a suitable underground location prior to oxidation;

(h) Include procedures to ensure that material relocated underground does not, to the

extent reasonable and feasible, further oxidise or cause impact to groundwater;

(i) Notwithstanding (e) above, trigger levels for any material that has been oxidised to

the extent that it cannot be placed underground without impacting groundwater

quality and procedures for adequate capping and sealing of such material at the

surface;

(j) Detail proposed neutralising options to be implemented for oxidising material stored

or encapsulated aboveground; and

(k) Where there is unlikely to be an extended time between placement of potential acid

forming material underground, details of proposed methods to prevent oxidation of

the material underground or to otherwise manage acid drainage to prevent impacts

on groundwater.

3

3

6

6, 7

5.3

5.3

5.3.4

5.3.5

5.3.5

5.3.5

5

Management Plan Requirements

5(2)

The Proponent shall ensure that the management plans required under this approval are

prepared in accordance with any relevant guidelines, and include:

(a) detailed baseline data;

(b) a description of:

the relevant statutory requirements (including any relevant approval, licence or

lease conditions);

any relevant limits or performance measures/criteria;

the specific performance indicators that are proposed to be used to judge the

performance of, or guide the implementation of, the project or any management

measures;

(c) a description of the measures that would be implemented to comply with the

relevant statutory requirements, limits, or performance measures/criteria;

(d) a program to monitor and report on the:

impacts and environmental performance of the project;

effectiveness of any management measures (see c above);

Management Plan Requirements

YTC-H-ENV-MPL-162

6

5

6, 7

Section

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 9 of 25

Waste Rock Management Plan

Author

Approved

5(2)

(Contd)

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

(e) a contingency plan to manage any unpredicted impacts and their consequences;

(f) a program to investigate and implement ways to improve the environmental

performance of the project over time;

(g) a protocol for managing and reporting any:

incidents;

complaints;

non-compliances with statutory requirements; and

exceedances of the impact assessment criteria and/or performance criteria; and

(h) a protocol for periodic review of the plan.

7

6

7

Note: The Director-General may waive some of these requirements if they are unnecessary or unwarranted for

particular management plans.

3.2

OBJECTIVES AND OUTCOMES

The ooverriding oobjective is to prevent production and escape of acid leachate form the stockpiled waste rock.

Table 2 lists the objectives and outcomes for the WRMP.

Table 2 Objectives and Outcomes

Objective

Outcome

Procedures are developed to ensure that potential acid

forming waste rock is identified during ongoing

underground mining operations and is stockpiled in the

appropriate designed temporary potentially acid

forming waste rock emplacement cell.

Procedures for ongoing classification, storage and

disposal of waste rock implemented to prevent acid

mine drainage.

Competence training has been implemented to ensure

relevant employees and contractors manage potentially

acid forming waste rock material appropriately.

Employees and contractors competently trained in

managing potentially acid forming waste rock material.

To ensure that the temporary waste rock cell is

designed to contain and manage any potential acid

rock drainage.

Impact on surface and groundwater is negligible.

To ensure that potentially acid forming material is

relocated to underground voids as soon as available to

prevent further oxidisation of the material.

Potentially acid forming waste rock material is

relocated underground in the shorter term to prevent

ongoing oxidisation of the material.

3.3

ROLES AND RESPONSIBILITIES

Table 3 lists the roles and responsibilities for the WRMP.

Table 3 Roles and Responsibilities

Position

YTC-H-ENV-MPL-162

Accountable Task

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 10 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

General Manager

Must ensure adequate resources are available to enable implementation of

this WRMP.

Accountable for the overall environmental performance of the Mine, including

the outcomes of this Waste Rock Management Plan.

Environmental Officer

Ensure the implementation of this WRMP.

Ensure all site personnel are competent through training and awareness

programs.

Conduct surface and ground water monitoring as specified in this

management plan.

Investigate any exceedances in groundwater and surface water quality and

implement the relevant trigger responses if required.

Project Geologist

Ensure potential acid forming waste rock is identified using appropriate

standards.

Ensure the relevant employees and contractors transport and store

potentially acid forming material to the designated storage areas.

3.4

COMPETENCE AND AWARENESS TRAINING

Waste rock awareness training shall be a component of the competency based site induction program. All

personnel will be inducted on the significance of acid mine drainage in the Mine area including the following.

Procedures for identifying and classifying potential acid forming material.

Procedures for temporarily storing potential acid forming material at surface.

Awareness of monitoring requirements.

Procedures for relocating potential acid forming material underground as soon as a designated void

area is available.

The Environmental Officer shall be responsible for ensuring the appropriate waste rock training is included in the

induction.

4.

I M P L E M E N TAT I O N O F W A S T E R O C K

MANAGEMENT MEASURES

4.1

INTRODUCTION

Condition 3(43) required this WRMP to include procedures for identification of potentially acid forming waste rock,

isolation during storage in a temporary waste rock emplacement and procedures for relocating back underground.

The following sections provide a description of these procedures to ensure potentially acid forming material is

managed effectively.

4.2

WASTE ROCK BALANCE

The waste rock balance during the life of the Hera mine is presented in Table 4. Hera Resources has updated the

mine plan following submission of the Environmental Assessment document. The current estimates indicate that

3

some 250 000m of waste rock would be generated during the life of the mine. Approximately 195 000m of waste

rock would be used during stope backfilling operations. The remainder will be used in construction of the ROM pad,

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 11 of 25

Waste Rock Management Plan

Author

Approved

YTC-H-ENV-MPL-162

S Haures

S Pearce

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

access roads and the TSF. As a result, there would be no waste rock surplus during the life of the mine and no

waste rock material excess to construction requirements would remain on the surface at the completion of the

mining activities.

Table 4

Waste rock balance

Volume (m 3)

Item

Source

Usage (Approx)

Box cut, portal and decline

20 000

Underground waste rock Trucked to Surface

160 000

Underground waste rock Used Underground

70 000

Site access roads

25 000

ROM pad

20 000

Tailings storage facility

10 000

Stope backfill Trucked back into the Mine

125 000

Stope backfill Direct from Underground

Total

70 000

250 000

250 000

The mine plan generated for the Hera deposit results in all waste excess to construction requirements being sent

back underground as part of the fill cycle. The detailed Back Fill Model indicates that during the first 30 months of

the operation all underground waste rock will be transported to the surface. From 30 months 45 months there is a

requirement to fill underground stopes and this will be done using waste generated underground with only

intermittent transport to the surface, preference will be given to using PAF waste rock over NAF waste rock. Post 45

months from the commencement of mining there will be a requirement to progressively truck the waste rock stored

on the surface back underground. In total it is estimated that of the Underground Mine waste rock generated some

3

160,000 m will be truck to the surface the remainder will be placed into back fill stope directly from the source

underground

Rock and samples from drill core in the vicinity of the proposed exploration decline, boxcut, ventilation rise and the

ore body have been analysed and characterised for acid rock drainage (ARD) potential, specifically to determine the

Net Acid Production Potential (NAPP) and Net Acid Generation (NAG) characteristic (Geoterra (2006); Triako

Resources Limited (2006)).

Conclusions reached on the acid rock generation characteristics from the assessments conducted to date are as

follows.

Samples tested showed low acid neutralisation potential.

Waste rock from the boxcut, ventilation rises and exploration decline, being predominantly

unweathered siltstone, have low NAPP and NAG values and have been characterised as non-acid

forming to uncertain.

The ore body samples or samples acquired close to the ore body are potentially acid forming due to

the sulfide contents of these samples.

Using the ARD assessment of all samples previously analysed it was estimated (Triako Resources Limited 2006)

that approximately 30% of the waste rock recovered during various activities would be Potentially Acid Forming

(PAF) and the remaining approximately 70% would be non-acid Forming. For this management plan Hera

Resources have adopted a more conservative view and have planned to be able to manage up to 60% of the waste

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 12 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

rock trucked to the surface designated as PAF material. Thus there will be sufficient contingency in the plan to

ensure stockpiling capacity available on the surface to appropriately manage PAF waste rock.

4.3

WASTE ROCK MANAGEMENT

4.3.1

Waste Rock Characterisation Procedures

A mine PAF/NAF model will be developed from existing drilling programs to identify potential high sulphur waste

zones within the designated underground mining area. Additional samples to those collected and analysed by

previous owners Triako Resources have been collected and submitted for NAG Testing (Static Testing).

Net acid generation (NAG) testing determines the balance between the acid producing and acid consuming

components of tailings/waste rock samples. NAG results provide the acid rock drainage characteristics based on

the complete oxidation of the samples sulfide content (as well as ferrous iron from siderite dissolution). Acid that is

produced by oxidation is consumed by carbonates and/or other acid consuming components of the material. The pH

of the solution is measured (NAG pH). The acid remaining after the reaction is titrated with standardized NaOH to

determine the net acid generated.

The methodology for characterising the waste rock following the NAG Testing is provided in Table 5.

The dominant sulphide minerals at Hera are as follows:

Within Ore Zones are dominantly Galena, Sphalerite with pyyrhotite and minor chalcopyrite

Waste zones adjacent the Ore Body (Ore Halo) pyrrhotite, minor galena and sphalerite Chalcopyrite

Decline Waste Zones are dominantly devoid of sulphides however local fault structures and minor

mineralised zones will be encountered. Locally we may encounter fault zones with minor pyrite.

It should also be noted that sphalerite is non-acid producing, galena is acid consuming. There is a lower relative

acid production potential for arsenopyrite, pyrrhotite and chalcopyrite compared to pyrite. For this reason Hera

Resource will utilise the Static Test results from the additional drillhole samples submitted for analysis combined

with the existing information to enable development of a more definitive Mine PAF/NAF model. This will enable

geological personnel to calibrate the relationship between sulphide species and content of the waste rock and

potential for acid generation on oxidation enabling better visual control on classification of waste rock

Using Kinetic NAG tests on selected samples Hera Resources will quantify the rate at which the different waste

types may begin to oxidise within the stockpile. As the dominant sulphide species at Hera exclude pyrite the rate of

oxidation of the waste rock is expected to be quite slow. The Kinetic Test program will enable Hera Resources to

model waste types based on the rate at which the PAF material is likely to oxidise so as to make more appropriate

stockpile management decisions in respect of how this material is treated to prevent the onset of oxidation.

The process for determining how waste rock mined will be classified and ultimately where the waste rock will be

stored will be the function of the Mine Geological personnel. They will classify material on a mining block basis and

issue instructions to the underground operators was to where this material is to be tipped onto the stockpile

Project Geologists will be trained to identify sulphide zones within the waste material. This process will be validated

by completing Static Tests (NAG) on underground rock chip samples where appropriate. This process of visual

inspection supported by validation through sampling will ensure the Project Geologist will be familiar with the rock

type characterisation techniques for identifying NAF and PAF waste material.

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 13 of 25

Waste Rock Management Plan

Author

Approved

YTC-H-ENV-MPL-162

S Haures

S Pearce

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

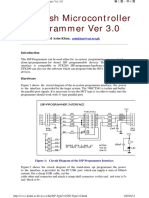

The decision tree that will be followed by the Mine Geological Personnel is as shown in Figure 3.

Hera Mining Material Handling Flow Sheet

Start

Yes (PAF)

Yes

Is the Rock

Yes Is the

From

Rock

Development

Ore

Yes

No

Stope

Material

Mill Feed

End

YTC-H-ENV-MPL-162

Waste Stockpile

(Cell 2) or

Use Around Site

No (NAF)

Does the Rock

Contain Sulfides

No

Is the

Rock

Possible

Ore

No

Rehandle

Stockpile

PAF Stockpile

Sample

and Assay

Low Grade

Stockpile

Activities Within The PAF

Stockpile Area (Cell 1)

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 14 of 25

Waste Rock Management Plan

Author

Approved

Figure 3

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Underground Material Handling Flowsheet

A Mine Fill Schedule has been developed to determine the timeframe of the availability of underground void areas

for permanent storage of PAF waste rock. It is on the basis of this model that PAF material located in surface

stockpiles will be preferentially used as fill material in underground stopes. Where practicable underground stopes

will be capped with NAF material and compacted with underground mining equipment. PAF material generated

underground that is not ore bearing will be immediately placed into empty stopes where available although it is

anticipated that for at least the first 2 years of mining this material will need to be hauled to the surface. If no space

is available in stopes the PAF material will be placed in temporary stockpiles underground or transported to the

surface and placed in the WREA as per this management plan.

Table 5 presents the classification of waste rock and the relevant procedures and mitigation measures for location

of temporary storage above ground and the relocation of potentially acid forming material underground when

possible.

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 15 of 25

Waste Rock Management Plan

Author

Approved

Table 5

YTC-H-ENV-MPL-162

S Haures

S Pearce

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Waste Rock Classification

Waste Rock Classification

Management Procedures

Coded: Green Material

Stored in temporary waste rock emplacement Cell No. 2

for general construction, fill and rehabilitation works.

Non Acid Forming l (NAF)

pH>4 from Static Tests for NAPP.

No sulphide reactivity.

Coded: Yellow Material

Potentially Acid Forming Low Capacity (PAF LC)

pH<4 but not lower than pH3 from Static Tests for

NAPP.

Low Risk

Stored in temporary waste rock emplacement Cell No. 1

on outer edge area. Relocate underground in area

(when available) that will be saturated by groundwater

1

following completion of mining .

Coded: Red Material

Stored in the centre of temporary waste rock

emplacement Cell No. 1. Relocate underground in area

(when available) that will be saturated by groundwater in

the early years following completion of mining1.

This material may be covered by NAF material while in

the aboveground temporary storage facility to minimise

oxidation rate

Potentially Acid Forming (PAF)

pH<3.

High Risk

1.

Storing of potential and acid forming material below waterline in an anaerobic environment eliminates the

potential for further oxidisation.

Source:

Environment Australia, Managing Sulphidic Mine Wastes and Acid Drainage.

Following the completion of mining activities the groundwater level will be allowed to inundate the mine workings.

This will eliminate the availability of oxygen preventing oxidisation of the potential acid forming material for the long

term.

4.3.2

Stockpiling of Waste Rock

The temporary waste rock emplacement will be designed and constructed to contain the estimated volumes of PAF

and NAF material and enable appropriate sorting as required. The design will aim to minimise acid generation and

prevent the discharge of any low pH leachate formed.

The waste rock emplacement for all material stored from underground will have the following design components:

Area of approximately 2.6ha divided into two cell areas, Cell No. 1 (PAF) and Cell No. 2 (NAF),

ROM pad and Low Grade Stockpile

Capacity approximately 200 000m3.

Maximum elevation approximately 10m higher than the existing surface.

Outer slope approximately 45o.

Additionally, the potentially acid-forming Cell No. 1 area will be constructed in a manner that would prevent

potentially acidic leachate from being discharged. In summary, this would include the following design parameters

(see Figure 3, Figure 4 and Figure 5).

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 16 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

The footprint of the cell will graded and compacted to between 1 to 2% slope towards the WREA

leachate dam to ensure no pooling of water internally and to minimise infiltration into soils within the

waste rock emplacement footprint.

The footprint of the Stockpile area will have the topsoils and subsoil removed

The footprint of the PAF cell will be made from compacted NAF material to an appropriate depth

A bund will be constructed around the perimeter of the PAF cell to capture and divert any potentially

acidic leachate to the WREA leachate dam and to divert any other surface water away from the cell.

4.3.2.1

The low-grade and rehandle stockpiles will be located within Cell 1

PAF WREA Leachate Dam and Internal Drains

A WREA Leachate Dam and perimeter drains will be constructed and maintained to ensure any potential acid

leachate is contained within the PAF WREA footprint as follows.

To ensure no discharge from the dam during heavy rainfall events, the maximum filling point for the

dam is 870mm below the top of the dam wall, comprising an allowance of 170mm for incident

rainfall1 and 700mm freeboard. The maximum filling point will be marked by a peg and water

levels, in the absence of rainfall input, will not be permitted to rise above this point.

The WREA Leachate Dam will be constructed to hold 1.2ML of runoff from the PAF WREA, which

will cater for a 1 in a 100 year rainfall event.

The WREA Leachate Dam will be lined with High Density Polyethylene (HDPE)

The WREA Leachate Dam will be inspected monthly and after significant rainfall (>12mm). If any

remedial action is required (e.g. pumping, repair) it will be logged and recorded in the Annual

Environmental Management Report.

Water from the Leachate Dam will be transferred to the PWD and used for processing.

Water levels will be measured and recorded in the Annual Environmental Management Report.

Water will be tested on field for pH and Electrical Conductivity (EC) on a monthly basis

Water samples will be collected on a monthly basis or prior to being pumped to the PWD, and sent

to the laboratory for analysis (Parameters listed in Table 7).

Figure 5 shows a cross section of the PAF WREA.

4.3.3

Management of acid-formation

As discussed in Section 5.3.1 potentially acid forming material will be graded either as Yellow Material with a NAF

pH less than 4 but not lower than pH 3 or Red Material that has potentially a NAF pH of less than 3. These

materials will be stored within Cell No 1 of the designated WREA. Red material will be stored in the centre of the

cell encompassed by the Yellow material to minimise the surface area that will be exposed to air.

1

The 72-hour 100 year rainfall depth

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 17 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

The rehandle stockpile and the low-grade stockpile will be located within the PAF Cell. The approximate locations of

these stockpiles are shown in Figure 4.

During the storage phase, prior to backfill underground requirements and the transport of these materials

underground, the following mitigation measures will be implemented.

Minimise infiltration of water within the WREA stockpiles by levelling and track rolling the surface of the

stockpiles on a regular basis.

If required grading the surface may be undertaken to ensure water runs of the surface and does not pool

on the PAF material

Covering with compacted NAF waste rock in completed stockpile areas to reduce infiltration of water and

oxygen.

Monitoring of sulphur oxidation will be undertaken prior to underground emplacement to determine rate of

oxidation. The primary method will be via the visual inspection and monitoring of acidity of any runoff or

leachate from the PAF cell

Preferential placement underground will be given to Red material, or as a result of monitoring, other

material that has been identified with potential higher sulphur reactivity.

The management of highly oxidised PAF waste rock is discussed in the following section.

YTC-H-ENV-MPL-162

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 18 of 25

Waste Rock Management Plan

Author

Approved

Figure 4

YTC EMP 015

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Proposed Design for the Waste Rock Emplacement Area

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 18 of 25

Waste Rock Management Plan

Author

Approved

Figure 5

4.3.4

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Cross Section of Potentially Acid Forming Waste Rock Emplacement Area

Placement of Potential acid-forming waste rock placement underground

As previously described in Section 5.3.1 potentially acid forming material will be backfilled into underground void

areas that will be saturated with ground water following the completion of mining. It is anticipated that these areas

will become available within the third year of mining.

Placement underground will be in stopes that are to be filled with loose rock fill and cemented rock fill. The

cemented rockfill stopes will utilise waste rock that has up to 8% cement added as a binder to make the fill stable to

enable extraction of adjacent panels. The addition of the cement to the rock material will act in two ways. Firstly it

will act as a buffer to any acid produced form the material and secondly to act as a coating to the rocks to prevent

further oxidation. The cement has inherent neutralising capacity on PAF material (Department of Industry and

resources, 2007). Hera Resources will conduct leach column tests on PAF material to confirm that the additions of

cement are sufficient to buffer any potential net acid generation from varying waste types.

Prior to the placement of material underground, inspection of the waste rock will be made to estimate the

degree of oxidation that may have occurred. Preference for PAF material that is showing signs of oxidation

will to place within the cemented backfill stopes

In the event that significant oxidation has occurred then a risk assessment will be completed to ensure

appropriate remediation of the material is made by treating with crushed limestone prior to placement or by

encapsulating in compacted NAF or oxidised fill in the surface stockpile. The risk assessment will consider

the implications of both surface and underground disposal and the implications on groundwater.

If required, potential surface PAF wasterock emplacements may include storage within the existing Tailings

Storage Facility following drying of tailings.

YTC EMP 015

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 19 of 25

Waste Rock Management Plan

Author

Approved

4.3.5

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Non acid-forming waste rock

Waste rock material excavated and placed within the temporary waste rock emplacement will initially be paddock

dumped in the Cell No. 2 in layers of approximately 3m high. Once the initial waste rock material has been

emplaced, further material will be emplaced using either paddock dumping or face tipping methods.

Where appropriate, non-acid forming waste rock will be transported directly to other sections of the Hera Mine for

infrastructure establishment including the TSF, site access roads and tracks and, if required, proposed hard stand

areas. The waste rock may be crushed prior to use in construction activities.

Waste rock not required for surface infrastructure or for rehabilitation purposes will be reclaimed and transported

back underground.

5.

M O N I T O R I N G O F A C I D - F O R M I N G M AT E R I A L

Monitoring of surface water and groundwater will be undertaken in order to determine whether mine activities are

causing adverse impacts upon the surrounding environment. Water will be sampled for specific parameters (Refer

to Table 7) and assessed over time and reported in the Annual Environmental Management Report.

In summary, monitoring for the WREA and potential leachate includes the following.

Water quality monitoring and visual inspections for the WREA leachate dam will be undertaken

monthly during the life of the emplacement to identify any issue with the proposed management

measures.

Visual inspections of underground PAF emplacement cells and water quality monitoring if seepages

are detected.

Water quality in the nearby groundwater bores is monitored monthly for pH and EC and water samples are collected

on a quarterly basis and analysed in a NATA Accredited Laboratory. If water is present in the Leachate Dam a

water sample will be collected prior to the water being pumped to the Process Water Dam (PWD) and sent to a

NATA accredited laboratory.

The initial drilling program into the ore body will identify potential high sulphur waste zones within the designated

underground mining area; this will be confirmed via chip-rock samples collected from the underground wall face.

The core from the drilling program and the chip-rock samples will be analysed using Static Tests for the compounds

in Table 6.

Table 6

Parameters and Frequency for Monitoring of Sulfides in Core and Rock-chip

Samples

Parameter / Test

NAG Static Test,

Kinetic NAG

YTC EMP 015

Frequency

As required during the drilling

program

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 20 of 25

Waste Rock Management Plan

Author

Approved

Table 7

YTC-H-ENV-MPL-162

S Haures

S Pearce

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

As required at the Underground

face wall

Parameters and Frequency for Monitoring of Water Quality in the Leachate Dam

Physical and Chemical Stressors

Frequency

pH

Electrical conductivity

Total Suspended Solids

Metals

aluminium

arsenic

zinc

Monthly or prior to water

being pumped to the PWD

copper

lead

silver

nickel

boron

manganese

cadmium

6.

REVIEW AND COMPLIANCE

6.1

EVAULATION OF COMPLIANCE

Hera Resources will conduct periodic evaluation of compliance with the following reported within the Annual

Environmental Management Report.

An overview of waste rock extracted from the underground mine.

On overview of the amount of potential acid-forming waste rock extracted and the procedures

implemented to ensure emplacement in designated areas.

Results from waste rock and water samples.

Actions undertaken, if required, to ensure potential acid-forming waste rock material does not

impact on water quality in the surrounding area.

6.2

CORRECTIVE AND PREVENTATIVE MEASURES

YTC will implement the necessary surface water and groundwater trigger responses in the event that water quality

criteria are exceeded. Full details of the responses are described in the Water Management Plan.

In summary, the following will be implemented.

Arrange for further sampling to confirm initial monitoring results.

If exceedances are confirmed and in consultation with the relevant government agency, implement

the necessary containment and neutralising measures to ensure impacts are minimised.

YTC EMP 015

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 21 of 25

Waste Rock Management Plan

Author

Approved

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

Re-evaluate the containment of potentially acid forming material and determine the measures to be

implemented to further prevent any potential discharges of acid leachate.

6.3

INCIDENT REPORTING

All reports associated with contamination of groundwater will be provided within 7 days to the EPA and other

agencies as required and will be retained for a minimum of four years.

All incidents will be reported in the Annual Environmental Management Report.

6.4

REVIEW

In accordance with Condition 5 (5) of Project Approval, this WRMP will be reviewed and, if required, revised within 3

months of:

the submission of an annual review under Condition 5(4);

the submission of an incident report under Condition 5(7);

the submission of an independent audit report under Condition 5(9); and

any modification to the conditions of Project Approval.

This review will include the adequacy of strategies, plans and programs as required under the Project Approval.

Recommendation for appropriate measures or action to improve the environmental performance of the Mine and or

any assessment, plan or program will be incorporated into this WRMP.

YTC EMP 015

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 22 of 25

Waste Rock Management Plan

Author

Approved

7.

S Haures

S Pearce

YTC-H-ENV-MPL-162

Created

Version

Review

15/7/2013

V 1.0

15/7/2014

REFERENCES

Department of Industry Tourism and Resources, Leading Practice Sustainable Development program for the Mining

Industry, Managing Acid and Metalliferous Drainage, 2007

YTC EMP 015

Uncontrolled Copy When Printed

Tuesday, 16 July 2013

Page 23 of 25

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- A CMOS Current-Mode Operational Amplifier: Thomas KaulbergDocument4 paginiA CMOS Current-Mode Operational Amplifier: Thomas KaulbergAbesamis RanmaÎncă nu există evaluări

- STM Series Solar ControllerDocument2 paginiSTM Series Solar ControllerFaris KedirÎncă nu există evaluări

- Sacmi Vol 2 Inglese - II EdizioneDocument416 paginiSacmi Vol 2 Inglese - II Edizionecuibaprau100% (21)

- Effects of Organic Manures and Inorganic Fertilizer On Growth and Yield Performance of Radish (Raphanus Sativus L.) C.V. Japanese WhiteDocument5 paginiEffects of Organic Manures and Inorganic Fertilizer On Growth and Yield Performance of Radish (Raphanus Sativus L.) C.V. Japanese Whitepranjals8996Încă nu există evaluări

- Chapter 1: Investment Landscape: Financial GoalsDocument8 paginiChapter 1: Investment Landscape: Financial GoalsshubhamÎncă nu există evaluări

- Time-Dependent Deformation of Shaly Rocks in Southern Ontario 1978Document11 paginiTime-Dependent Deformation of Shaly Rocks in Southern Ontario 1978myplaxisÎncă nu există evaluări

- CBC Building Wiring Installation NC IIDocument72 paginiCBC Building Wiring Installation NC IIFaysbuk KotoÎncă nu există evaluări

- TQM BisleriDocument27 paginiTQM BisleriDishank ShahÎncă nu există evaluări

- Flow Chart For SiFUS Strata Title ApplicationDocument5 paginiFlow Chart For SiFUS Strata Title ApplicationPhang Han XiangÎncă nu există evaluări

- Alternator: From Wikipedia, The Free EncyclopediaDocument8 paginiAlternator: From Wikipedia, The Free EncyclopediaAsif Al FaisalÎncă nu există evaluări

- ELC Work DescriptionDocument36 paginiELC Work DescriptionHari100% (1)

- Crawler Base DX500/DX600/DX680/ DX700/DX780/DX800: Original InstructionsDocument46 paginiCrawler Base DX500/DX600/DX680/ DX700/DX780/DX800: Original InstructionsdefiunikasungtiÎncă nu există evaluări

- Frigidaire Parts and Accessories CatalogDocument56 paginiFrigidaire Parts and Accessories CatalogPedro RuizÎncă nu există evaluări

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDocument4 paginiISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićÎncă nu există evaluări

- In Comparison With Oracle 8i, 9i Is Have Lot Many New Features. Important IsDocument241 paginiIn Comparison With Oracle 8i, 9i Is Have Lot Many New Features. Important IsBalaji ShindeÎncă nu există evaluări

- Quality in CRDocument10 paginiQuality in CRkaushikcrÎncă nu există evaluări

- AutoCAD Dinamicki Blokovi Tutorijal PDFDocument18 paginiAutoCAD Dinamicki Blokovi Tutorijal PDFMilan JovicicÎncă nu există evaluări

- White Button Mushroom Cultivation ManualDocument8 paginiWhite Button Mushroom Cultivation ManualKhurram Ismail100% (4)

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Document3 paginiAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraÎncă nu există evaluări

- Application of ARIMAX ModelDocument5 paginiApplication of ARIMAX ModelAgus Setiansyah Idris ShalehÎncă nu există evaluări

- 87 - Case Study On Multicomponent Distillation and Distillation Column SequencingDocument15 pagini87 - Case Study On Multicomponent Distillation and Distillation Column SequencingFranklin Santiago Suclla Podesta50% (2)

- Amel Forms & Logging SheetsDocument4 paginiAmel Forms & Logging SheetsisaacÎncă nu există evaluări

- PW Unit 8 PDFDocument4 paginiPW Unit 8 PDFDragana Antic50% (2)

- CNG Fabrication Certificate16217Document1 paginăCNG Fabrication Certificate16217pune2019officeÎncă nu există evaluări

- Week 7 Apple Case Study FinalDocument18 paginiWeek 7 Apple Case Study Finalgopika surendranathÎncă nu există evaluări

- Sealant Solutions: Nitoseal Thioflex FlamexDocument16 paginiSealant Solutions: Nitoseal Thioflex FlamexBhagwat PatilÎncă nu există evaluări

- CEA 4.0 2022 - Current Draft AgendaDocument10 paginiCEA 4.0 2022 - Current Draft AgendaThi TranÎncă nu există evaluări

- Sales Manager Latin AmericaDocument3 paginiSales Manager Latin Americaapi-76934736Încă nu există evaluări

- Canopy CountersuitDocument12 paginiCanopy CountersuitJohn ArchibaldÎncă nu există evaluări

- Computer System Architecture: Pamantasan NG CabuyaoDocument12 paginiComputer System Architecture: Pamantasan NG CabuyaoBien MedinaÎncă nu există evaluări