Documente Academic

Documente Profesional

Documente Cultură

NT 664Y6400 B E-Tech-S EN

Încărcat de

Hugo CarvalhoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

NT 664Y6400 B E-Tech-S EN

Încărcat de

Hugo CarvalhoDrepturi de autor:

Formate disponibile

EN

FR

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

For the Installer and the User

NL

ES

E-Tech S

IT

160 - 240 - 380

DE

PL

RU

664Y6400 B

EN

TABLE OF CONTENTS

FR

RECOMMENDATIONS......................................................................................................3

Power Supply wiring diagram : E-Tech S 160....................................................................................................................14

Instructions for the end user.....................................................................................................................................................3

Control wiring diagram : E-Tech S 160.................................................................................................................................15

Periodic checks...............................................................................................................................................................................3

Power Supply wiring diagram : E-Tech S 240....................................................................................................................16

APPLIANCE DESCRIPTION...............................................................................................4

NL

Models : E-Tech S 160 - 240 - 380.............................................................................................................................................4

Control panel : E-Tech S 160 - 240............................................................................................................................................4

Control panel : E-Tech S 380......................................................................................................................................................4

TECHNICAL CHARACTERISTICS.....................................................................................6

ES

STARTING UP..................................................................................................................20

Tools required for starting up................................................................................................................................................ 20

Checks before starting up....................................................................................................................................................... 20

Filling the system........................................................................................................................................................................ 20

Starting up the Boiler.................................................................................................................................................................21

Recommandations for the prevention of corrosion and scaling in Heating Systems.........................................7

INSTALLATION.................................................................................................................8

MAINTENANCE...............................................................................................................22

Tools required for maintenance............................................................................................................................................ 22

Boiler shut down for maintenance....................................................................................................................................... 22

Periodic boiler maintenance tasks....................................................................................................................................... 23

Safety instructions for the installation..................................................................................................................................8

Restarting after maintenance................................................................................................................................................ 23

Clearance..........................................................................................................................................................................................8

Draining the boiler..................................................................................................................................................................... 23

Dimensions : E-Tech s 160 - 240................................................................................................................................................9

Dimensions : E-Tech s 380...........................................................................................................................................................9

PL

Control wiring diagram : E-Tech S 380.................................................................................................................................19

Hydraulic characteristics.............................................................................................................................................................6

Maximum Operating Conditions.............................................................................................................................................6

DE

Power Supply wiring diagram : E-Tech S 380....................................................................................................................18

Electrical Characteristics.............................................................................................................................................................6

DHW Performance.........................................................................................................................................................................6

IT

Control wiring diagram : E-Tech S 240.................................................................................................................................17

DECLARATION OF CONFORMITY................................................................................24

Package Contents........................................................................................................................................................................10

Tools required for the installation.........................................................................................................................................10

Boiler preparation before installation : E-tech S 160 - 240...........................................................................................10

DHW connection..........................................................................................................................................................................11

RU

Heating connection....................................................................................................................................................................11

Electrical Connection.................................................................................................................................................................12

Sizing of power supply wires..................................................................................................................................................12

Electrical Connection : E-Tech S 160.....................................................................................................................................12

Electrical Connection : E-Tech S 240.....................................................................................................................................13

Electrical Connection : E-Tech S 380.....................................................................................................................................13

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

RECOMMENDATIONS

INSTRUCTIONS FOR THE END USER

NOTE

This manual contains important information with respect to the installation, the starting up and the

maintenance of the appliance.

Essential recommendations for safety

This manual must be provided to the user, who will read it carefully and keep it in a safe place.

We accept no liability should any damage result from the failure to comply with theinstructions

contained in this technical manual.

Essential recommendations for safety

It is prohibited to carry out any modifications to the appliance without the

manufacturers prior and written agreement.

The product must be installed by a qualified engineer, in accordance with

applicable local standards and regulations.

The installation must comply with the instructions contained in this manual and

with the standards and regulations applicable to heating systems.

Failure to comply with the instructions in this manual could result in personal

injury or a risk of environmental pollution.

The manufacturer declines all liability for any damage caused as a result of

incorrect installation or in the event of the use of appliances or accessories that are

not specified by the manufacturer.

In order to ensure that the appliance operates correctly, it is essential to have it

serviced by a certified installer or maintenance contractor every year.

In case of anomaly, please call your service engineer.

Faulty parts may only be replaced by genuine factory parts.

The availability of certain models as well as their accessories may vary according to

markets.

The manufacturer reserves the right to change the technical characteristics and

features of its products without prior notice.

In spite of the strict quality standards that ACV applies to its appliances during

production, inspection and transport, faults may occur. Please immediately notify

your approved installer of any faults.

Hot water can cause scalding!

I n the event of small amounts of hot water repeatedly being drawn off, a stratification

effect can develop in the tank. The upper hot water layer may then reach very high

temperatures.

Water heated to wash clothes, dishes and for other uses can cause serious burns.

I n order to avoid exposure to extremely hot water that can cause serious burns, never

leave children, old people, disabled or handicapped people in the bath orshower alone.

Never allow young children to turn on the hot water or fill their own bath.

This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge,

only if they have been given supervision or instruction concerning use of the appliance

in a safe way and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children unless they are aged from

8 years and above and supervised.

he risk of developing bacteria exists, including Legionella pneumophila, ifaminimum

T

temperature of 60C is not maintained in both the DHW tank and the hot water

distribution network.

FR

NL

ES

IT

DE

Essential recommendations for the correct operation of the appliance

General remarks

Do not store any corrosive products, paint, solvents, salts, chloride products and other

detergent products near the appliance.

PERIODIC CHECKS

Essential recommendations for the correct operation of the appliance

heck regularly that the system water pressure is at least 1 bar when cold. If the pressure

C

drops below 0.5 bar, the built-in pressure sensor blocks the appliance until the pressure

exceeds 0.8 bar.

If it is required to top up the system to maintain the minimum recommended water

pressure, always turn the appliance off and only add small amounts of water at a time.

If a large amount of cold water is added in a hot boiler, the boiler can be damaged

definitively.

If the system needs to be refilled repeatedly with water, please contact your installer.

Regularly check that there is no water on the floor under the boiler. If there is, please call

your service engineer.

PL

RU

General remark

hecking the boiler settings can only be carried out by an ACV-trained installer or by

C

ACV's maintenance department.

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

APPLIANCE DESCRIPTION

CONTROL PANEL : E-TECH S 380

MODELS : E-TECH S 160 - 240 - 380

This floor electric boiler is available in 4 models :

FR

The E-Tech S 160 single phase model is supplied 230 Volt.

The E-Tech S 160 / 240 / 380 three-phase models are supplied 400 Volt.

The maximum power can be adjusted for all models by acting on the control panel switches.

NL

Models

E-Tech S 160 single phase and three-phase

E-Tech S 240 three-phase

E-Tech S 380 three-phase

Level 1

9,6 (66%)

14,4 (50%)

14,4 (50%)

kW

kW

kW

4

6

Level 2

4,8 (33%)

14,4 (50%)

14,4 (50%)

2

7

ES

3

The maximum power can be limited for this model by acting on the terminal bridges

S8 or TB2.

Models

E-Tech S 160 single phase and three-phase

E-Tech S 240 three-phase

E-Tech S 380 three-phase

IT

DE

Min

7,2

14,4

7,2

kW

kW

kW

Max

14,4

28,8

28,8

60

85

CONTROL PANEL : E-TECH S 160 - 240

1

Description

PL

1. ON/OFF switch

2. Power switch level 1

3. Power switch level 2

4. Summer/Winter switch

RU

5. On peak indicator light

6. Booster indicator light

Description

1. Thermo-manometer

7. Booster switch

8. Thermo-manometer

9. Two-stage control thermostat adjustable from 60 at 85C

2. Two-stage control thermostat

3. Manual reset hight limit thermostat [103C]

Control thermostat

4. Alarm indicator light

1 = 25C

5. ON/OFF switch

2 = 40C

6. Power switch level 1

3 = 55C

7. Power switch level 2

4 = 70C

8. Summer/Winter switch

5 = 85C

10. Manual reset hight limit thermostat [103C]

11. Alarm indicator light

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

10

11

EN

APPLIANCE DESCRIPTION

E-Tech S 160 - 240

E-Tech S 380

1.

Auxiliary connection DHW or for an optional T&P valve.

10. Cold water inlet

1.

Safety valve (3 bar)

10. Cold water inlet

2.

Electrical support

11. Heating pump

2.

Auxiliary connection DHW or for an optional T&P valve.

11. Heating pump

3.

Control panel

12. Heating circuit outlet

3.

12. Heating circuit outlet

4.

Dry well for limit thermostats [90C max] and

thermometer bulbs

13. DHW outlet

Dry well for limit thermostats [90C max] and

thermometer bulbs

13. DHW outlet

14. Safety valve (3 bar)

4.

Control panel

5.

Low-water pressure switch

14. Thermal insulation

15. Primary expansion vessel

5.

Low-water pressure switch

6.

Thermal insulation

15. Dip tube

16. Stainless steel tank [DHW]

6.

Primary expansion vessel

7.

Dip tube

16. Stainless steel tank [DHW]

17. Heating circuit return

7.

Electrical support

8.

Dry well for control thermostat, safety thermostat

[103C] and bulbs.

17. Heating circuit return

18. Drain valve

8.

Dry well for control thermostat, safety thermostat

[103C] and night load thermostat [95C] bulbs.

18. Primary circuit

9.

Primary circuit

9.

Drain valve

1

2

19. Electrical heating elements

10

11

19. Electrical heating elements

10

11

ES

12

IT

13

14

13

NL

12

FR

14

DE

15

6

PL

15

6

16

7

7

17

18

19

16

RU

17

18

19

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

TECHNICAL CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

DHW PERFORMANCE

E-TECH S

FR

160

Main Characteristics

NL

380

Operating conditions at 80 C

160

240

380

Tri

Mono

Tri

Tri

Constant flow at

40 C [T = 30 K]

L/h

413

827

827

kW

14,4

14,4

28,8

28,8

Peak flow at

40 C [T = 30 K]

L/10

356

545

875

min

kW

7,2

7,2

14,4

7,2

Peak flow at

40 C [T = 30 K]

L/60

700

1234

1564

21

63

42

42

Tank refill time at 60 C

Rated voltage

3 x 400 + N

2 x 230

3 x 400 + N

3 x 400 + N

Initial heating time

minutes

36

41

67

Rated frequency

Hz

50

50

50

50

After drawing off 140 litres at 45 C

minutes

16

12

12

Ohm

22

22

22

22

kW

2 x 2,4

2 x 2,4

2 x 2,4

2 x 2,4

Ohmic resistance of heating elements

Heating element type

IT

240

E-TECH S

max

Power

ES

Domestic hot water performance (cold drink water at 10C)

Number of heating elements

DE

MAXIMUM OPERATING CONDITIONS

Maximum Service Pressure

- Primary circuit : ............................................................................................................................................ 3 bar

PL

- DHW circuit : .............................................................................................................................................. 8,6 bar

HYDRAULIC CHARACTERISTICS

- Recommended pressure relief valve (central heating) : ................................................... 3 bar

- Recommended pressure relief valve (DHW) : .......................................................................... 7 bar

E-TECH S

RU

Main Characteristics

160

240

380

Mains supply pressure

Capacity (primary)

68

86

131

- Max 6 bar, without a pressure reducing valve being required (to avoid discharge of the safety pressure valve)

Capacity (DHW)

99

164

263

Total capacity

167

250

394

Primary circuit expansion vessel volume

12

12

2X8

Heating connection

1 [F]

1 [F]

1 [F]

DHW connection

3/4 [M]

3/4 [M]

11/2 [M]

Auxiliary connection

3/4 [F]

3/4 [F]

11/2 [M]

Maximum Operating Conditions

- Maximum temperature (primary) : .................................................................................................. 85C

- Maximum temperature (DHW) : ........................................................................................................ 85C

Water Quality

See "Recommendations for the Prevention of Corrosion and Scaling in Heating Systems".

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

TECHNICAL CHARACTERISTICS

RECOMMENDATIONS FOR THE PREVENTION OF CORROSION AND

SCALING IN HEATING SYSTEMS

How oxygen and carbonates can affect the heating system

Oxygen and dissolved gasses in the water of the primary circuit contribute to the

oxidation and the corrosion of the system components that are made of ordinary steel

(radiators, ...). The resulting sludge is then deposited in the boiler.

4. Limit the carbonate concentration in the water

- The fill water must be softened if its hardness is higher than 20 fH (11,2 dH).

- Check regularly the water hardness and enter the values in the service log.

- Water hardness table :

The combination of carbonates and carbon dioxide in the water results in the formation of scale

on the hot surfaces of the installation.

These deposits on the heating element thermally insulate the surface of the which may cause

damage elements.

Sources of oxygen and carbonates in the heating circuit

The primary circuit is a closed circuit; the water it contains is therefore isolated from the mains

water. When maintaining the system or filling up the circuit, water renewal results in the addition

of oxygen and carbonates in the primary circuit. The larger the water volume in the system, the

larger the addition.

Hydraulic components without an oxygen barrier (PE pipes and connections) admit oxygen into

the system.

fH

dH

mmolCa(HCO3)2 / l

Very soft

0-7

0 - 3.9

0 - 0.7

Soft

7 - 15

3.9 - 8.4

0.7 - 1.5

Fairly hard

15 - 25

8.4 - 14

1.5 - 2.5

Hard

25 - 42

14 - 23.5

2.5 - 4.2

> 42

> 23.5

> 4.2

Conductivity

Clean the existing system before installing a new boiler

- Before the system is filled, it must be cleaned in accordance with standard EN14336.

Chemical cleaning agents can be used.

- If the circuit is in bad condition, or the cleaning operation was not efficient, or the volume of

water in the installation is substantial (e.g. cascade system), it is recommended to separate

the boiler from the heating circuit using a plate-to-plate exchanger or equivalent. In that

case, it is recommended to install a hydrocyclone or magnetic filter on the installation side.

NL

ES

Control the water parameters

- In addition to the oxygen and the water hardness, other parameters of the water must be

checked.

- Treat the water if the measured values are outside the range.

Acidity

Prevention Principles

1.

Water hardness

Very hard

5.

FR

IT

6,6 < pH < 8,5

< 400 S/cm (at 25C)

Chlorides

< 125 mg/l

Iron

< 0,5 mg/l

Copper

< 0,1 mg/l

DE

PL

2. Limit the fill frequency

- Limit fill operations. In order to check the quantity of water that has been added into the

system, a water meter can be installed on the filling line of the primary circuit.

- Automatic filling systems are not recommended.

- If your installation requires frequent water refilling, make sure your system is free of water

leaks.

- Inhibitors may be used in accordance with standard EN 14868.

RU

3. Limit the presence of oxygen and sludge in the water

- A deaerator (on the boiler flow line) combined with a dirt separator (upstream of the boiler)

must be installed according to the manufacturer's instructions.

- ACV recommends using additives that keep the oxygen in solution in the water, such as

Fernox (www.fernox.com) and Sentinel (www.sentinel-solutions.net) products.

- The additives must be used in accordance with the instructions issued by the manufacturer

of the water treatment product.

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

INSTALLATION

SAFETY INSTRUCTIONS FOR THE INSTALLATION

General remarks

FR

NL

The connections (electrical, hydraulic) must be carried out in accordance with

current standards and regulations in force.

If the water drawing off point is far from the tank, installing an auxiliary DHW loop

can allow to get hot water more quickly at all times.

Essential recommendations for the correct operation of the appliance

ES

IT

The boiler must be installed in a dry and protected area, with an ambient

temperature comprised between 0 and 45C.

Install the appliance to ensure easy access at all times.

To avoid any risk of corrosion, connect the stainless steel DHW production tank

directly to the earth.

Make sure that the mains water used to fill the boiler has a minimum pressure of

1.2 bar.

Make sure to install a pressure reducing valve set at 4.5 bar if the mains supply

pressure is in excess of 6 bar.

The DHW circuit must be fitted with an approved safety group, comprised of a 7

bar safety valve, a check valve and a shut-off valve.

CLEARANCE

The boiler room must be large enough to allow proper access to the boiler. The following minimum

distances around the boiler are required :

At the front

500 mm

Above

300 mm

On the heating circuit

connections side

150 mm

This boilers can be connected to the heating circuit in any one of three directions.

Essential recommendations for safety

DE

PL

RU

Install the boiler on base made of non-combustible materials.

ACV recommends using a pre-set thermostatic mixing valve in order to provide

hot water at a maximum of 60C.

The DHW circuit must be fitted with an approved safety group, comprised of a 7

bar safety valve, a check valve and a shut-off valve.

The temperature of the domestic hot water can be adjusted up to 85C in the boiler.

However, the temperature of the domestic hot water at the drawing off point must

comply with local regulations. (E.g. in Belgium, the maximum DHW water temperature

at a drawing off point must be 75C for boilers < 70 kW).

The risk of developing bacteria exists, including Legionella pneumophila,

ifaminimum temperature of 60C is not maintained in both the DHW tank andthe

hot water distribution network.

This appliance is not constructed for installation in zone 3.

Essential recommendations for the electrical safety

Only an approved installer is authorized to carry out the electrical connections.

Install a 2-way switch and a fuse or circuit breaker of the recommended rating

outside the appliance, so as to be able to shut power down when servicing the

appliance or before performing any operation on it.

Isolate the external electrical supply of the appliance before performing any

operation on the electrical circuit.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless supervised or unless they have been given instruction concerning the use

of the appliance by a person responsible for their safety.

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

INSTALLATION

DIMENSIONS : E-TECH S 160 - 240

360

220

220

590

260

NL

E-Tech S 160 : 1150

E-Tech S 240 : 1630

220

E-Tech S 160 : 1135

E-Tech S 240 : 1610

E-Tech S 160 : 1170

E-Tech S 240 : 1645

220

E-Tech S 160 : 1140

E-Tech S 240 : 1615

295

295

135

250

250

ES

280

1

3/4

1/2

1/2

155

E-Tech S 160 : 1140

E-Tech S 240 : 1615

1

3/4

1/2

1/2

115

280

Kg

240

E-Tech S 160 : 1170

E-Tech S 240 : 1645

Heating connection [F]

DHW connection [M]

Safety valve connection [M]

Drain valve connection [F]

Drained weight

160

250

E-TECH S

E-Tech S 160 : 1345

E-Tech S 240 : 1820

730

FR

295

IT

270

DIMENSIONS : E-TECH S 380

720

100

320

100

810

DE

2005

2010

2005

1

11/2

1/2

1/2

230

360

400

Kg

400

Heating connection [F]

DHW connection [M]

Safety valve connection [M]

Drain valve connection [F]

Drained weight

RU

380

400

E-TECH S

2005

2140

PL

360

360

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

INSTALLATION

PACKAGE CONTENTS

The E-Tech S boilers are delivered assembled and packaged.

FR

At product reception and after removal of packaging, check the package contents and that

the appliance is free of damages.

Contents of the E-Tech S 160 - 240 - 380

NL

1. Electrical boiler

2. Check valve *

3. Safety valve *

4. Drain valve *

ES

5. Installation, Operation and Maintenance Instructions

* Installed in factory on E-Tech S 380 model

TOOLS REQUIRED FOR THE INSTALLATION

IT

6

DE

BOILER PREPARATION BEFORE INSTALLATION : E-TECH S 160 - 240

PL

Essential recommendations for the correct operation of the system

The drain valve (7) and the safety valve (5) must be connected to the sewer.

he boiler is fitted with a primary expansion volume of :

T

- 12 litres for the E-Tech S 160 and 240.

- 2 x 8 litres for the E-Tech S 380.

I f the expansion vessel volume is not sufficient for your needs, it is possible to install an

additional expansion vessel.

The boiler is fitted with a safety valve set to 3 bar.

RU

2x

en

10

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

INSTALLATION

DHW CONNECTION

OPTIONAL ACCESSORIES

Description

General remark

The circuit illustrations are basic principle diagrams only.

Essential recommendation for safety

The hot water output may reach temperatures in excess of 60C, which can cause

scalding! It is therefore necessary to install a thermostatic mixing valve after the

appliance.

The installation must be fitted with an approved safety group, comprised of a 7 bar

safety valve, a check valve and a shut-off valve.

Essential recommendations for the correct operation of the appliance

Flush the system before connecting the domestic hot water circuit. Refer to the

installation instructions.

Make sure to install a pressure reducing valve set at 4.5 bar if the mains supply

pressure is in excess of 6 bar.

It is recommended to install an expansion vessel in the DHW circuit to prevent the

safety valve from opening constantly and reduce the water hammer effect in the

system.

If the appliance is used as a domestic hot water preparation tank, a primary

expansion vessel of at least 16 litres must be fitted in the heating circuit, if there is

no built-in expansion vessel.

Typical installation

Description

1. Isolating valve

2. Pressure reducing valve

3. Check valve

4. DHW expansion vessel

5. Safety valve

6. Drain valve

7. Draw-off tap

8. Grounding

9. Thermostatic mixing valve

3

4

9

1

Code

DHW safety valve (7bar) - 3/4 [F]

557A1500

DHW safety group (7bar) - 3/4 [F]

55211400

Thermostatic mixing valve - 3/4 [M]

55212000

DHW expansion vessel - 5 litres - 3/4 [M]

55301300

DHW expansion vessel - 8 litres - 3/4 [M]

55301400

DHW expansion vessel - 12 litres - 3/4 [M]

55301500

DHW expansion vessel - 18 litres - 3/4 [M]

55301600

FR

NL

ES

IT

HEATING CONNECTION

Typical connection - high temperature

DE

Description

1. Isolating valve

2. Heating pump

3. Filling valve

4. Check valve

5. Safety valve

6. Expansion vessel

7. Drain valve

PL

1

5

6

7

RU

3

4

Cold water

Hot water

Cold water

Hot water

Typical connection - low temperature

Description

1. Isolating valve

E-Tech S 160 - 240 - 380 : 664Y6400 B

en

11

EN

INSTALLATION

ELECTRICAL CONNECTION

FR

ELECTRICAL CONNECTION : E-TECH S 160

CONNECTING THE ACCESSORIES

The electrical accessories are connected to the numbered terminals shown on the diagram below.

Essential recommendations for the electrical safety

NL

ES

The wiring connections must be carried out by a competent person, in accordance with

the current IEE Wiring Regulations.

The boiler must be effectively earthed.

box fitted with a magneto-thermal circuit breaker must be fitted on the outside of

A

the boiler to protect the boiler and allow the power supply to be switched off during

servicing or other work on the boiler.

o avoid any risk of electrocution, the electrical circuit must be fitted with a differential

T

circuit breaker.

The control circuit is protected by a 3A magneto-thermal circuit breaker.

he boiler is protected against overheating even if one or more power switches

T

malfunction, by means of a magnetic power switch placed in series with the power

switches.

E-Tech S 160

SIZING OF POWER SUPPLY WIRES

The power supply wires are sized according to the type and current of the main circuit breaker (MCB).

The latter is sized according to the nominal current of the boiler. The admissible current of the power

supply wires depends on the ambient temperature, the section and length of the wires, the wires

insulation, the wiring system construction, the installation type and the environment.

The following values are given for information only, for an ambient temperature of 30C and a maximum

length of 5 meters. In all cases, the system must be set up in accordance with the current IEE Wiring

Regulations.

PL

RU

1-2 :

3-4 :

5-6 :

7-8 :

10-11 :

12-13 :

14-15-16 :

17-18 :

IT

DE

Nominal section

(mm)

Nominal current of the MCB

(A)

1.5

16

2.5

25

32

40

10

63

16

80

10 11 12 13 14 15 16 17 18 19 20 21 22

Phase (230V ~ 50Hz)

Neutral

Time clock or controller supply (optional)

Safety switch

Stop Bridge or time clock switch control (optional)

Room thermostat (optional)

Heating pump

Relay K3 deactivated

CONNECTING THE POWER SUPPLY

E-Tech S 160 Three-phase : the power circuit must be connected using three phases (3 x 400 V ) +

neutral.

E-Tech S 160 Mono Phase : the power circuit must be connected using one phase (1 x 230 V) + neutral.

E-Tech S 160

Three-phase

TB1

E-Tech S 160

Mono Phase

N L3 L2 L1

400 V ~ 50 Hz

POWER

en

12

TB2

E-Tech S 160 - 240 - 380 : 664Y6400 B

TB1

PE N

230 V ~ 50 Hz

POWER

EN

INSTALLATION

ELECTRICAL CONNECTION : E-TECH S 240

ELECTRICAL CONNECTION : E-TECH S 380

CONNECTING THE ACCESSORIES

The electrical accessories are connected to the numbered terminals shown on the diagram below.

CONNECTING THE ACCESSORIES

The electrical accessories are connected to the numbered terminals shown on the diagram below.

E-Tech S 240

E-Tech S 380

1-2 :

3-4 :

5-6 :

7-8 :

9-10 :

11-12 :

13-14 :

15-16 :

1

1

10 11 12 13 14 15 16 17 18 19 20 21 22

FR

TB2

3

4

5

6

7

NL

Time clock or controller supply (optional)

Stop Bridge or time clock switch control (optional)

day / night signal

Room thermostat (optional)

Relay K1 deactivated

Relay K3 deactivated

Relay K2 deactivated

Relay K4 deactivated

ES

1-2 :

3-4 :

5-6 :

7-8 :

10-11 :

12-13 :

14-15-16 :

17-18 :

19-20 :

Phase (230V ~ 50Hz)

Neutral

Time clock or controller supply (optional)

Safety switch

Stop Bridge or time clock switch control (optional)

Room thermostat (optional)

Heating pump

Relay K3 deactivated

Relay K4 deactivated

CONNECTING THE POWER SUPPLY

E-Tech S 240 Three-phase : the power circuit must be connected using three phase (3 x 400 V ) +

neutral.

10

IT

11

12

13

14

15

DE

16

TB2

CONNECTING THE POWER SUPPLY

E-Tech S 380 Three-phase : the power circuit must be connected using three phases (3 x 400 V ) +

neutral.

PL

E-Tech S 240

Three-phase

L2

L3

N

RU

E-Tech S 380

Three-phase

L1

400 V ~ 50 Hz

POWER

L1

400 V ~ 50 Hz

POWER

L2

L3

TB1

N

TB1

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

13

EN

INSTALLATION

POWER SUPPLY WIRING DIAGRAM : E-TECH S 160

B

FR

Or

Bk

NL

Or

Bk

Or

Bk

DE

K4

B

B

Or

Or

Or

K3

Or

B

B

B

B

Bk

Bk

Bk

Bk

B

B

K2

Bk

Or

IT

K1

ES

S8

B

Bk

E-Tech S 160

TB1

PL

L1

L2

L3

14,4 kW

12 kW

9,6 kW

7,2 kW

PE

S8

Three

Phase

TB2

3 4 5

L1 L2 L3

17 18

9,6 kW

3 4 5

L1 L2 L3

17 18

17 18

12 kW

3 4 5

L1 L2 L3

17 18

17 18

14,4 kW

3 4 5

L1 L2 L3

17 18

17 18

E-Tech S 160

17 18

TB2

RU

7,2 kW

TB1 : Terminal of power supply

TB2 : Terminal of control circuit

S8 : Power selector

K1 : Power relay 1 - level 1

B : Blue

3 4 5

L1 L1 L1

17 18

E-Tech S 160 - 240 - 380 : 664Y6400 B

17 18

en

14

3 4 5

L1 L1 L1

17 18

TB2

R : Red

17 18

3 4 5

L1 L1 L1

17 18

K4 : Safety switch

17 18

Or : Orange

3 4 5

L1 L1 L1

17 18

Bk : Black

S8

17 18

K2 : Power relay 1 - level 2

K3 : Power relay 2 - level 1

Mono

Phase

EN

INSTALLATION

S2 : Manual reset safety thermostat [103C max.]

Br

PS : Low-water pressure switch

DS1 : Alarm indicator light

PS

P

S4 : Two-stage control thermostat

[15-22C / 78-85C]

Bk

Bk

Bk

R

R

NL

S3 : Limit thermostat [90C max.]

1

Bk

FR

S1 : ON/OFF switch + lamp

CB : Circuit breaker

Bk

S2

Bk

Bk

CONTROL WIRING DIAGRAM : E-TECH S 160

S5 : Power switch level 1 + lamp

10

K1 : Power relay 1 - level 1

ES

Bk

K3 : Power relay 2 - level 1

T1 : Timer

S6 : Power switch level 2 + lamp

K2 : Power relay 1 - level 2

11

IT

S7 : Summer / winter switch + lamp

S3

K4 : Safety switch

11

Or

T1

7-8 : Safety switch power supply

10-11 : Stop Bridge or time clock switch control

(optional)

12

A2

12-13 : Room thermostat (optional)

1.1

17-18 : Relay K3 deactivated

13

S6

Or

1.2

2.2

S5

1.2

Bk

18

Or

L1

1-1

1-1

6

B

9

B

K2

B

K3

B

K1

B

DS1

PE

8

B

B

B

Br

Br

15

16

RU

Br : Brown

K4

Pk

CB

B : Blue

Bk : Black

Br

17

Br

14

2

PL

14-15 : Heating pump

2.2

1.1

DE

5-6 : Time clock or controller supply (optional)

1.2

2.1

Br

1.1

S7

1

A1

2.2

3-4 : Neutral

1.1

2.2

Pk

12

Bk

1.2

S1

P1

Or

S4

1-2 : Phase

P2

21

22

G : Grey

Or : Orange

Pk : Pink

R : Red

V : Violet

W : White

Y : Yellow

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

15

EN

INSTALLATION

POWER SUPPLY WIRING DIAGRAM : E-TECH S 240

B

FR

Or

Bk

NL

Bk

Bk

Bk

B

B

Or

R

R

K4

Or

Bk

B

B

Bk

R

R

Or

Bk

Bk

K3

Or

Or

B

B

K2

Or

Bk

Bk

Or

K1

Or

ES

Bk

Bk

Or

Or

K5

DE

Bk

Bk

IT

S8

B

Bk

PL

TB1

7

L1

L2

L3

PE

TB2

RU

E-Tech S 240

TB1 : Terminal of power supplu

28,8 kW

24 kW

21,6 kW

14,4 kW

S8

TB2 : Terminal of control circuit

S8 : Power selector

5

L3

3

L2

5

L3

3

L2

5

L3

17 18

17 18

17 18

17 18

17 18

19 20

19 20

19 20

19 20

19 20

19 20

R : Red

3

L2

17 18

19 20

K5 : Safety switch

TB2

5

L3

17 18

Or : Orange

19 20

K4 : Power relay 2 - level 2

3

L2

17 18

B : Blue

19 20

Bk : Black

5

L3

17 18

19 20

K2 : Power relay 1 - level 2

K3 : Power relay 2 - level 1

3

L2

Three

Phase

17 18

K1 : Power relay 1 - level 1

en

16

26,4 kW

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

INSTALLATION

S2 : Manual reset safety thermostat [103C max.]

Br

PS : Low-water pressure switch

DS1 : Alarm indicator light

PS

P

S4 : Two-stage control thermostat

[15-22C / 78-85C]

Bk

Bk

Bk

S5 : Power switch level 1 + lamp

10

K1 : Power relay 1 - level 1

7

Bk

Y

T1 : Timer

S6 : Power switch level 2 + lamp

K2 : Power relay 1 - level 2

11

Y

S7 : Summer / winter switch + lamp

K5 : Safety switch

11

Or

T1

S7

5-6 : Time clock or controller supply (optional)

7-8 : Safety switch power supply

12

A2

10-11 : Stop Bridge or time clock switch control

(optional)

W

R

1.1

14-15 : Heating pump

13

S6

17-18 : Relay K3 deactivated

Or

1.2

2.2

S5

1.2

Pk

19-20 : Relay K4 deactivated

Or

L1

1-1

1-1

6

B

9

B

8

B

B

B

15

B

16

K4

B

K2

B

K3

B

K1

B

DS1

PE

B : Blue

Bk : Black

B

B

K5

20

21

22

Br : Brown

G : Grey

Or : Orange

Pk : Pink

Br

Br

RU

Bk

18

Pk

CB

19

Br

17

Br

14

2

PL

12-13 : Room thermostat (optional)

2.2

1.1

DE

3-4 : Neutral

1.2

1

A1

2.2

1-2 : Phase

1.1

2.2

Pk

12

2.1

Br

1.1

P1

Bk

P2

Or

S4

1.2

IT

K4 : Power relay 2 - level 2

S3

S1

ES

K3 : Power relay 2 - level 1

NL

S3 : Limit thermostat [90C max.]

1

Bk

FR

S1 : ON/OFF switch + lamp

CB : Circuit breaker

Bk

S2

Bk

Bk

CONTROL WIRING DIAGRAM : E-TECH S 240

R : Red

V : Violet

W : White

Y : Yellow

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

17

EN

INSTALLATION

POWER SUPPLY WIRING DIAGRAM : E-TECH S 380

B

FR

Or

Bk

B

B

Bk

R

R

Bk

Bk

Bk

K4

Or

Or

B

B

Or

Bk

Bk

Or

Or

R

R

Bk

Bk

K3

L2

L3

Or

Bk

Or

L1

K2

PE

Bk

Bk

TB1

Or

B

B

IT

Or

K1

ES

Or

Bk

Or

K6

NL

TB2

DE

PL

TB1 : Terminal of power supply

TB2 : Terminal of control circuit

K1 : Power relay 1 - level 1

RU

K2 : Power relay 1 - level 2

K3 : Power relay 2 - level 1

K4 : Power relay 2 - level 2

E-Tech S 380

K6 : Safety switch

B : Blue

Bk : Black

Or : Orange

R : Red

28,8 kW

9

Three

Phase

7,2 kW

9

10

10

10

12

12

12

12

11

13

13

14

14

15

15

16

16

en

18

14 kW

10

11

TB2

21,6 kW

E-Tech S 160 - 240 - 380 : 664Y6400 B

11

13

14

15

16

11

13

14

15

16

EN

INSTALLATION

CONTROL WIRING DIAGRAM : E-TECH S 380

CB : Circuit breaker

S1 : ON/OFF switch + lamp

S2 : Manual reset safety thermostat [103C max.]

Br

Br

R

S2

PS

1

Bk

K3 : Power relay 2 - level 1

Bk

S6 : Night load thermostat [95C max.]

Or

Bk

Or

K2 : Power relay 1 - level 2

K4 : Power relay 2 - level 2

T1 : Booster timer preset at one hour

K5 : Reverse current relay

4

V

DS3 : Booster indicator light

PB : Booster switch

S3

S8 : Summer / winter switch + lamp

1

W

32

22

Bk

Bk

Bk

14

Pk

18

3-4 : Stop Bridge or Time clock switch control

(optional)

7-8 : Room thermostat (optional)

12

9-10 : Relay K1 deactivated

11-12 : Relay K3 deactivated

S5

Bk

Y1

K6

B

B : Blue

Bk : Black

2

Bk

B

A2

Pk

Br

Bk

A1

K5

K4

B

DS3

Bk

Bk

DS2

Br

16

K2

B

Bk

15

14

K3

B

K1

DS1

PE

B

12

Or

13

Or

11

Br

10

15-16 : Relay K4 deactivated

Pk

Pk

CB

RU

13-14 : Relay K2 deactivated

S7

1.2

Br

2.2

1.1

Br

Or

2.2

1.1

PL

5-6 : Day / night signal

Or

24

2.1

1

Br

11

Bk

21

16

1-2 : Time clock or controller supply (optional)

S8

1.2

31

2.2

T1

1.1

2.2

PB

15

Bk

Br

1

W

11

2

R

12

1.2

L1

Bk

6

P

S6

34

Br

P1

DE

B : Heating pump

K6 : Safety switch

P2

S4

Br

IT

DS2 : On Peak indicator light

V

1.1

ES

S7 : Power switch level 2 + lamp

S1

NL

K1 : Power relay 1 - level 1

S3 : Limit thermostat [90C max.]

S5 : Power switch level 1 + lamp

Or

DS1 : Alarm indicator light

S4 : Two-stage control thermostat

[15-22C / 78-85C]

Br

Or

1.2

FR

PS : Low-water pressure switch

Br : Brown

G : Grey

Or : Orange

Pk : Pink

R : Red

V : Violet

W : White

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

19

EN

STARTING UP

SAFETY INSTRUCTIONS FOR STARTING UP

FR

FILLING THE SYSTEM

First put the DHW tank under pressure before pressurizing the heating (primary)

circuit.

Essential recommendations for safety

NL

The components inside the control panel may only be accessed by an approved

installer.

Set the water temperature in accordance with usage and local plumbing codes.

1.

Open the isolating valves (1) and the

draw-off tap (2).

2.

Once the water flow rate has stabilized

and the air is totally evacuated from

the system, close the draw-off tap (2).

3.

Check all the connections for leaks.

TOOLS REQUIRED FOR STARTING UP

ES

Filling the domestic hot water circuit

1

1

IT

Cold water

DE

Hot water

CHECKS BEFORE STARTING UP

PL

Essential recommendation for the correct operation of the appliance

RU

Control the tightness of the hydraulic circuit connections.

Filling of the heating circuit

1.

Open the isolating valves (1).

2.

Make sure that the drain valve (3) is

tightly closed.

3.

Open the filling valve (2).

4.

Open the air bleed valve (4).

5.

Once the system is bled from air,

bring the pressure to the static

pressure + 0.5 bar: 1.5 bar = 10m - 2

bar = 15m

1

2

en

20

E-Tech S 160 - 240 - 380 : 664Y6400 B

However, the temperature of the domestic hot water at the drawing off point must

STARTINGcomply

UP with local regulations. (E.g. in Belgium, the maximum DHW water temperature

EN

at a drawing off point must be 75C for boilers < 70 kW).

The risk of developing bacteria exists, including Legionella pneumophila,

temperature of 60C is not maintained in both the DHW tank andthe

STARTINGifaminimum

UP THE BOILER

hot water distribution network.

This appliance is not constructed for installation in zone 3.

FR

Essential recommendations for the electrical safety

Only an approved installer is authorized to carry out the electrical connections.

Install a 2-way switch and a fuse or circuit breaker of the recommended rating

outside the appliance, so as to be able to shut power down when servicing the

appliance or before performing any operation on it.

Isolate the external electrical supply of the appliance before performing any

operation on the electrical circuit.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless supervised or unless they have been given instruction concerning the use

of the appliance by a person responsible for their safety.

NL

ES

Set-up conditions

IT

All electric connections made.

Power supply.

DHW and heating circuits full of water.

Procedure

DE

1.

Place the ON/OFF master switch on the ON position (

).

2.

If a room thermostat is installed, possibly increase the temperature set-point to generate a demand.

If the boiler heating pump does not work, the boiler can be damaged and its life reduced.

3.

Set the central heating and domestic hot water temperatures to the required values using the

control panel.

4.

After 5 minutes of operation, bleed the heating circuit until all air is evacuated and restore a 1.5

bar pressure.

5.

Bleed the central heating circuit once again and top it up with water to get the required pressure,

if necessary.

6.

Make sure that the central heating system is properly balanced and, if needed, adjust the valves to

prevent certain circuits or radiators from getting a flow rate that is far above or below the set rate.

PL

RU

Follow-up tasks

7.

Check that there are no leaks.

8.

Check all electric connections.

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

21

EN

MAINTENANCE

SAFETY INSTRUCTIONS FOR THE BOILER MAINTENANCE

Essential recommendation for the electrical safety

FR

NL

Isolate the external power supply of the appliance before performing any

operation, unless it is required to take measurements or perform system setup.

Essential recommendation for safety

ES

Water flowing out of the drain valve may be extremely hot and could cause severe

scalding.

Essential recommendations for the correct operation of the appliance

IT

DE

It is recommended to have the boiler serviced at least once a year. More frequent

servicing may be required depending on boiler use. Please consult your installer

for advice.

The boiler maintenance will be carried out by a qualified engineer, and the

defective parts may only be replaced by genuine factory parts.

Control the tightness of the hydraulic circuit connections.

Make sure to replace the gaskets of the removed items before reinstalling them.

TOOLS REQUIRED FOR MAINTENANCE

PL

RU

BOILER SHUT DOWN FOR MAINTENANCE

1. Switch the boiler off using the ON/OFF master switch and isolate the external power supply.

2. Remove the front panel and the top cover of the boiler.

en

22

E-Tech S 160 - 240 - 380 : 664Y6400 B

EN

MAINTENANCE

PERIODIC BOILER MAINTENANCE TASKS

DRAINING THE BOILER

Essential recommendations for safety

Frequency

Tasks

1.

2.

Periodic inspection

1 year

End-user

Professional

Make sure that the system water pressure is at least 1 bar

when cold. Top up the system if necessary, adding small

quantities of water at a time. In case of repeated fills, call

your installer.

Check that there is no water on the floor next to the boiler.

Call your installer if there is.

Boiler switched off using the ON/OFF

master switch.

Power supply isolated from the external

electrical box.

4.

Check that all hydraulic connections are correctly fastened

and tight.

5.

Inspect the wiring and the heating elements looking for any

sign of overheating.

6.

7.

1.

Close the isolating valves (1).

2.

Connect the drain valve (2) to the sewer

with a hose.

3.

Open the drain valve (2) to empty the

heating circuit of the boiler.

4.

Open the circuit air bleed valve (3) to

accelerate the draining process.

Check that the screws on the connection terminal block are

properly tightened.

5.

Check visually the heating body: no evidence of corrosion,

overheating or damages. Carry out all required cleaning

tasks, repairs and replacements that might be required.

Close the drain valve (2) and the air bleed

valve (3) once the heating circuit of the

boiler is empty.

1

IT

1

DE

Cold water

Hot water

DHW circuit draining procedure

Before draining the DHW tank, make

sure that the heating (primary) circuit

pressure is null.

RESTARTING AFTER MAINTENANCE

Set-up conditions

1.

2.

3.

2. Check the correct operation of the charging pump.

ES

Heating circuit draining procedure

X

1. Switch the appliance on using the ON/OFF master switch.

Check that the thermostats and safety devices are working

properly.

Procedure

NL

Set-up conditions

3.

All removed components reinstalled

All connections made

Power supply

DHW and heating circuits full of water

FR

Before draining the DHW tank, drain the heating (primary) circuit or bring its

pressure to 0 bar.

Water flowing out of the drain valve may be extremely hot and could cause severe

scalding. Keep people away from the hot water discharge.

4.

5.

6.

PL

Open fully a draw-off tap (3) for about 60

minutes to make sure that the DHW tank

has cooled down.

Close the isolating valves (1).

Connect the drain valve (2) to the sewer

with a hose.

Open the drain valve (2) and drain the

DHW tank water to the sewer.

Open the draw-off tap (3) to accelerate the

draining process. If it is located lower than

the tank connection, open a draw-off tap

located higher in the system.

RU

Close the drain valve (2) and the draw-off

tap (3) once the DHW tank of the boiler is

empty.

en

E-Tech S 160 - 240 - 380 : 664Y6400 B

23

EN

DECLARATION OF CONFORMIT Y

FR

NL

ES

IT

DE

PL

RU

en

24

E-Tech S 160 - 240 - 380 : 664Y6400 B

S-ar putea să vă placă și

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDe la EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideEvaluare: 4.5 din 5 stele4.5/5 (8)

- Practical Process Control for Engineers and TechniciansDe la EverandPractical Process Control for Engineers and TechniciansEvaluare: 5 din 5 stele5/5 (3)

- ACV Smart 240 Hot Water TankDocument36 paginiACV Smart 240 Hot Water Tankkyle wetherillÎncă nu există evaluări

- Model U-C1 Copier Manual FINALDocument487 paginiModel U-C1 Copier Manual FINALMichał SzweminÎncă nu există evaluări

- Minas Servo Drive AMplifierDocument155 paginiMinas Servo Drive AMplifierScott Veckler0% (1)

- Whirlpool 30â FREESTANDING SELF-CLEANING ELECTRIC RANGE 8178042Document72 paginiWhirlpool 30â FREESTANDING SELF-CLEANING ELECTRIC RANGE 8178042Rich Foster0% (1)

- Instruction Manual: Modular Crescent CuberDocument41 paginiInstruction Manual: Modular Crescent CuberSamuelÎncă nu există evaluări

- Rsag7 820 6589Document67 paginiRsag7 820 6589Sergio AibarÎncă nu există evaluări

- Sega Lindbergh Universal CabinetDocument88 paginiSega Lindbergh Universal CabinetMartin FeÎncă nu există evaluări

- Combo KM MId Modular J ServDocument63 paginiCombo KM MId Modular J ServAngel BajanaÎncă nu există evaluări

- Manual-Heater Installation and Operation 115V ULDocument96 paginiManual-Heater Installation and Operation 115V ULmichel782011Încă nu există evaluări

- Eberspacher Airtronic D2 Technical ManualDocument52 paginiEberspacher Airtronic D2 Technical ManualDardan HusiÎncă nu există evaluări

- Operator'S Manual: Original Operating InstructionsDocument42 paginiOperator'S Manual: Original Operating InstructionsReymundo ChanÎncă nu există evaluări

- Service Manual: Plate Processor 85Document90 paginiService Manual: Plate Processor 85Andres Perez0% (1)

- EBA 20 User Manual - Bahasa EnglisDocument18 paginiEBA 20 User Manual - Bahasa EnglisYap's TechÎncă nu există evaluări

- BC440-6 & BC450-6 DIGITAL DC Speed Control: Installation and Operating ManualDocument32 paginiBC440-6 & BC450-6 DIGITAL DC Speed Control: Installation and Operating ManualFredy Padilla IglesiasÎncă nu există evaluări

- Hisense 40h5Document40 paginiHisense 40h5The Rod Of CorrectionÎncă nu există evaluări

- Frigidaire Affinity Dryer Service ManualDocument91 paginiFrigidaire Affinity Dryer Service ManualLyle Weischwill100% (13)

- Model J-P2: (Machine Code: G080)Document419 paginiModel J-P2: (Machine Code: G080)Dariusz BaranÎncă nu există evaluări

- Model A-C3: (Machine Code: B079/B082) Service ManualDocument254 paginiModel A-C3: (Machine Code: B079/B082) Service ManualDen ZaytsevÎncă nu există evaluări

- Service KlimaDocument50 paginiService Klimaspirittotti100% (1)

- 504615e - RRS6 7 10 16 22 35 GBDocument29 pagini504615e - RRS6 7 10 16 22 35 GBSaadiÎncă nu există evaluări

- Manual Instalación PBO 85 PDFDocument26 paginiManual Instalación PBO 85 PDFWilson ValladaresÎncă nu există evaluări

- RTSYQ-PY1 Installation Manual PDFDocument27 paginiRTSYQ-PY1 Installation Manual PDFZlatko HuićÎncă nu există evaluări

- BROILLER MPB94 NIECO Manual TécnicoDocument44 paginiBROILLER MPB94 NIECO Manual TécnicoJoão Vitor Cordeiro ManhãesÎncă nu există evaluări

- Manual Operacion Hoshizaki Modelo KM-650 - InstDocument42 paginiManual Operacion Hoshizaki Modelo KM-650 - Instchristopher menesesÎncă nu există evaluări

- GlasStile Manual NeuDocument34 paginiGlasStile Manual NeuDanÎncă nu există evaluări

- LCD Television Service Manual: MTK5655EPDJDocument55 paginiLCD Television Service Manual: MTK5655EPDJyoregistradoÎncă nu există evaluări

- Installation and Servicing Manual: R 18 - C 18 - R 24 - C 24 R 28 - C 28 - R 35 - C 35Document44 paginiInstallation and Servicing Manual: R 18 - C 18 - R 24 - C 24 R 28 - C 28 - R 35 - C 35Anastasia KazaÎncă nu există evaluări

- LHD32D77US 32D77 MT5305 Service Manual 20121213Document45 paginiLHD32D77US 32D77 MT5305 Service Manual 20121213Vicky MoralesÎncă nu există evaluări

- Service Manual: Modular Crescent Cuber WithDocument55 paginiService Manual: Modular Crescent Cuber WithWellington CamargoÎncă nu există evaluări

- Lorentz Pump ManualDocument16 paginiLorentz Pump ManualGirish OniyilÎncă nu există evaluări

- S Af2035Document247 paginiS Af2035dieubimatÎncă nu există evaluări

- S Af2035Document254 paginiS Af2035liviumaraÎncă nu există evaluări

- Aermec Toplotna Pumpa Anl - SeriesDocument72 paginiAermec Toplotna Pumpa Anl - SeriesdjezeracÎncă nu există evaluări

- Gts-150 Operation Manual 08 VerDocument329 paginiGts-150 Operation Manual 08 VersunhuynhÎncă nu există evaluări

- LTDN39K310US 39K310 MT5320 Service Manual 20121212Document44 paginiLTDN39K310US 39K310 MT5320 Service Manual 20121212Vicky Morales0% (1)

- MTK5660 US ATSC Service Manual Ver1.0 2018-5-28Document49 paginiMTK5660 US ATSC Service Manual Ver1.0 2018-5-28Ross RebelÎncă nu există evaluări

- Model MT Service Manual: (Machine Code: B064/B065)Document490 paginiModel MT Service Manual: (Machine Code: B064/B065)Mr DungÎncă nu există evaluări

- Installation and Operation Manual: PIKO MP PlusDocument48 paginiInstallation and Operation Manual: PIKO MP PlusAhsan ShabbirÎncă nu există evaluări

- 575 Electrolux Washer Front Load 5995523536Document90 pagini575 Electrolux Washer Front Load 5995523536Técnicos Diversos100% (3)

- Service Manual Af2035e PDFDocument273 paginiService Manual Af2035e PDFCristian BobaruÎncă nu există evaluări

- Master Controller Manual Legacy 1 0 SystemsDocument31 paginiMaster Controller Manual Legacy 1 0 SystemsBernieÎncă nu există evaluări

- Pellet Stove 25-PDVCDocument37 paginiPellet Stove 25-PDVCsjaved786Încă nu există evaluări

- DB68-03812A-11 IM DVM S Outdoor AA EN 200929Document110 paginiDB68-03812A-11 IM DVM S Outdoor AA EN 200929jlrlÎncă nu există evaluări

- Service Manual: Quartz Supreme CTP 85-125-150-165Document124 paginiService Manual: Quartz Supreme CTP 85-125-150-165SergeyÎncă nu există evaluări

- BR-900CD Owner ManualDocument232 paginiBR-900CD Owner ManualMerolÎncă nu există evaluări

- Olxe PDFDocument19 paginiOlxe PDFJohn GarnetÎncă nu există evaluări

- Installation and Programming Instructions: EnglishDocument68 paginiInstallation and Programming Instructions: EnglishEmílio BeckerÎncă nu există evaluări

- Instruction Manual For AC Generators EnglishDocument76 paginiInstruction Manual For AC Generators EnglishAtlas SEÎncă nu există evaluări

- 369 Motor Management Relay - MULTILIN PDFDocument280 pagini369 Motor Management Relay - MULTILIN PDFMario Guzman100% (1)

- Yokogawa Temperature TransmitterDocument64 paginiYokogawa Temperature Transmittermarco007_84Încă nu există evaluări

- SM 7056i 8056i Rev00 PDFDocument1.614 paginiSM 7056i 8056i Rev00 PDFmauro_ferrero_Încă nu există evaluări

- The Red Jacket Submersible Turbine Pump FE Petro Conversion KitDocument18 paginiThe Red Jacket Submersible Turbine Pump FE Petro Conversion KitsyahabdulrizalÎncă nu există evaluări

- Eberspacher Heater D3LC Installation ManualDocument34 paginiEberspacher Heater D3LC Installation ManualMario BalijaÎncă nu există evaluări

- Airtronic L: Technical Description, Installation, Operation and Maintenance InstructionsDocument52 paginiAirtronic L: Technical Description, Installation, Operation and Maintenance InstructionsevgenyÎncă nu există evaluări

- Cooper F6Document48 paginiCooper F6BEAMS32Încă nu există evaluări

- Small Block Chevrolet: Stock and High-Performance RebuildsDe la EverandSmall Block Chevrolet: Stock and High-Performance RebuildsEvaluare: 4 din 5 stele4/5 (6)

- 1-Introduction To Soil Mechanics (Introduction)Document57 pagini1-Introduction To Soil Mechanics (Introduction)Farhat Iqbal Malik100% (1)

- Smart Phone: An Embedded System For Universal InteractionsDocument12 paginiSmart Phone: An Embedded System For Universal InteractionsraghueshÎncă nu există evaluări

- Eero SaarinenDocument16 paginiEero SaarinenSaunokÎncă nu există evaluări

- Terostat Ms 930-EnDocument4 paginiTerostat Ms 930-Enken philipsÎncă nu există evaluări

- Drop BoxDocument78 paginiDrop BoxRoberto RosasÎncă nu există evaluări

- Tashkent Seismic Modernism BuildingsDocument8 paginiTashkent Seismic Modernism BuildingsЭльёрбек ФайзуллаевÎncă nu există evaluări

- Color in VMDocument39 paginiColor in VMShubham GoleÎncă nu există evaluări

- Conseal 250Document2 paginiConseal 250Rabih GergesÎncă nu există evaluări

- BS en 13561-2004Document48 paginiBS en 13561-2004balakumar12362100% (1)

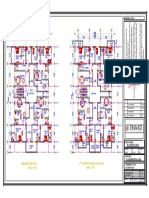

- D C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Document1 paginăD C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Ahmed Daahir AdenÎncă nu există evaluări

- 2011 Edition Handbook For Green Housing ENGDocument68 pagini2011 Edition Handbook For Green Housing ENGDaisyÎncă nu există evaluări

- RC17 Column1Document20 paginiRC17 Column1lavyÎncă nu există evaluări

- Proposal FINALDocument23 paginiProposal FINALGaming with cristineÎncă nu există evaluări

- Graduate Trainee Monthly Report SummaryDocument2 paginiGraduate Trainee Monthly Report Summarymichael100% (1)

- BOCW ActDocument41 paginiBOCW ActSai KiranÎncă nu există evaluări

- ACPA City Street Pavement DesignDocument8 paginiACPA City Street Pavement DesignFelipe Fernández100% (1)

- 1 Introduction (Compatibility Mode)Document45 pagini1 Introduction (Compatibility Mode)Steven KuaÎncă nu există evaluări

- Weblogic Portal JSF WhitepaperDocument152 paginiWeblogic Portal JSF WhitepaperwangpchomebuyÎncă nu există evaluări

- Presentation 2Document18 paginiPresentation 2api-505506312Încă nu există evaluări

- PCH Install Guide Extras PackDocument2 paginiPCH Install Guide Extras PackFrancisco ValdiviaÎncă nu există evaluări

- Drafting Module 10 Ab 2nd QDocument20 paginiDrafting Module 10 Ab 2nd QKC JaymalinÎncă nu există evaluări

- As 2192-2002 Sterilizers - Steam - Downward-DisplacementDocument8 paginiAs 2192-2002 Sterilizers - Steam - Downward-DisplacementSAI Global - APACÎncă nu există evaluări

- Hawar HighwayDocument31 paginiHawar HighwayantogsÎncă nu există evaluări

- Dokras Wada Part IIIDocument17 paginiDokras Wada Part IIIUday DokrasÎncă nu există evaluări

- Combination Wall Oven Installation GuideDocument2 paginiCombination Wall Oven Installation Guidejulio ariasÎncă nu există evaluări

- Debug 1214Document16 paginiDebug 1214Salceanu Ioana AndreeaÎncă nu există evaluări

- Transformer Sizing CalculationDocument6 paginiTransformer Sizing CalculationAvijnan Mitra100% (3)

- Ccaaguide2003 t49 Res Floors Web TBRDocument47 paginiCcaaguide2003 t49 Res Floors Web TBRLaura KinnearÎncă nu există evaluări

- Design Proforma AmdDocument5 paginiDesign Proforma AmdsantkabirÎncă nu există evaluări

- Understanding The Impact of Multi-Core Architecture in Cluster Computing: A Case Study With Intel Dual-Core SystemDocument8 paginiUnderstanding The Impact of Multi-Core Architecture in Cluster Computing: A Case Study With Intel Dual-Core SystemhfarrukhnÎncă nu există evaluări