Documente Academic

Documente Profesional

Documente Cultură

DSFGDF

Încărcat de

nidheeshDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DSFGDF

Încărcat de

nidheeshDrepturi de autor:

Formate disponibile

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-9, September- 2016]

Robot Navigation System with RFID and Ultrasonic Sensors

A.Seshanka Venkatesh1, K.Vamsi Krishna2, N.K.R.Swamy3, P.Simhachalam4

B.Tech., Student, Dept. Of EEE, Pragati Engineering College,Surampalem, Andhra Pradesh, India

seshank28@gmail.com, 2vamsikrishna1133@gmail.com, 3rajesh20dhoni@gmail.com, 4simhachalam456@gmail.com

Abstract This Paper proposed a new navigation method for indoor mobile robots. The robot system is composed of a

Radio Frequency Identification (RFID) tag sensor and Ultrasonic sensors. The RFID tags are used as landmarks for global

path planning and the topological relation map which shows the connection of scattered tags through the environment is

used as course instructions to a goal. The robot automatically moves along hallways using the scanned range data until a tag

is found and then refers to the topological map for the next movement. Our proposed technique would be useful for realworld robotic applications such as intelligent navigation for motorized wheelchairs, surveillance and security purposes and

in Nuclear power plants where humans are prone to harmful radiations.

Keywords RFID Cards, Ultrasonic Sensor, Motor, Driver, Micro Controller.

I.

INTRODUCTION

Navigation services which usually depend on GNSS are limited to use in open areas with satellite signals. If the users or

robots are about to move in buildings, another approach must be used to navigate accurately. In our approach Radio

Frequency Identification (RFID) is used to determine the location indoors. In RFID positioning there are two common

approaches to estimate the location. One method is based on signal strength. We take received signal strength indication

(RSSI) which presents the power of received signal as the measurement. Then the position is computed with certain methods

based on the measurements. Several methods have been studied, such as RFID location fingerprinting, cell-based positioning

and the way using ranges to the tags calculated with RSSI. Another particular method to estimate the location is based on the

landmarks. In the landmark-based navigation, landmarks are required to be set in the building, usually on certain doors and

corners. A topological map with nodes corresponding to the landmarks is used to do the navigation.[1]

II.

HARDWARE REQUIRED

A basic RFID system consists of three components

a) An antenna or coil

b) A transceiver (with decoder)

c) A transponder (RF tag)

RFID uses electromagnetic fields to automatically identify and track tags attached to objects. The tags contain electronically

stored information. Passive tags collect energy from a nearby RFID reader's interrogating radio waves. Active tags have a

local power source such as a battery and may operate at hundreds of meters from the RFID reader. Unlike a barcode, the tag

need not be within the line of sight of the reader, so it may be embedded in the tracked object.[2]

Chip less RFID tags are RFID tags that do not require a microchip in the transponder. The robot system is composed of a

Radio Frequency Identification (RFID) tag sensor, The RFID tags are used as landmarks for global path planning and the

topological relation map which shows the connection of scattered tags through the environment is used as course instructions

to a goal. The robot automatically moves along hallways using the scanned range data until a tag is found and then refers to

the topological map for the next movement. Our proposed technique would be useful for real-world robotic applications.[3]

FIG.1. RFID CARDS

Page | 92

International Journal of Engineering Research & Science (IJOER)

III.

ISSN: [2395-6992]

[Vol-2, Issue-9, September- 2016]

HARDWARE IMPLEMENTATION

A microcontroller is a small computer (SoC) on a single integrated circuit containing a processor core, memory, and

programmable input/output peripheral. Some microcontrollers may use four-bit words Other microcontrollers may serve

performance critical roles, where they may need to act more like a digital signal processor (DSP), with higher clock speeds

and power consumption.

Motor driver is one of the important components to drive the motor. Here we are going to use L293D motor driver. The

L293D motor driver is available for providing User with ease and user friendly interfacing for embedded application. L293D

motor driver is mounted on a good quality, single sided non-PTH PCB. The pins of L293D motor driver IC are connected to

connectors for easy access to the driver ICs pin functions. The L293D is a Dual Full Bridge driver that can drive up to

1Amp per bridge with supply voltage up to 24V.

There are two Enable pins on L293D. Pin 1 (left H-bridge) and pin 9 (right H-bridge). To drive the corresponding motor, pin

1 or 9 need to be set to HIGH. If either pin 1 or pin 9 goes low then the motor in the corresponding section will suspend

working.

The four Input pins for the L293D are pin 2 and 7 on the left and pin 15 and 10 on the right. Left input pins will regulate the

rotation of motor connected on the left side and right input for motor on the right hand side. The motors are rotated on the

basis of the inputs provided at the input pins as LOGIC 1 or LOGIC 0[4]

FIG.2.ULTRASONIC SENSOR

FIG.3 HARDWARE IMPLEMENTATION SCHEMATIC DIAGRAM

Page | 93

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-9, September- 2016]

Ultrasonic sensors are devices that use electricalmechanical energy transformation, the mechanical energy being in the form

of ultrasonic waves, to measure distance from the sensor to the target object. Ultrasonic waves are longitudinal mechanical

waves which travel as a succession of compressions and rarefactions along the direction of wave propagation through the

medium. Any sound wave above the human auditory range of 20,000 Hz is called ultrasound.

When ultrasonic waves are incident on an object, diffused reflection of the energy takes place over a wide solid angle which

might be as high as 180 degrees. Thus some fraction of the incident energy is reflected back to the transducer in the form of

echoes and is detected. The distance to the object (L) can then be calculated through the speed of ultrasonic waves (v) in the

medium by the relation wheret is the time taken by the wave to reach back to the sensor. If the object is in motion,

instruments based on Doppler shift are used.[5]

The input to the circuit is applied from the regulated power supply. The a.c. input i.e., 230V from the mains supply is step

down by the transformer to 12V and is fed to a rectifier. The output obtained from the rectifier is a pulsating d.c voltage. So

in order to get a pure d.c voltage, the output voltage from the rectifier is fed to a filter to remove any a.c components present

even after rectification. Now, this voltage is given to a voltage regulator to obtain a pure constant dc voltage. According to

the layout features of a building, the whole space is divided into a number of rooms and hallways The doors and intersection

of hallways are important places for a robot, at which the robot must do the choice to go straight, turn left, turn right or stop

if it is the destination.

To mark the special places it uses RFID tags pasted in the centre of the route at the mentioned place. When it detected the tag

and get its unique ID, computer inside the robot will figure out where the robot is. With the topological map the robot is

going to find out the next node to go on the route. Since the robot may access every place in every direction, turn left or

right orders do not seem to work well enough. Therefore, it uses directions as North (N), South (S), East (E), West (W) for

robot movement control. We should first assign directions when making a map. With the topological map and the directions,

the total route of robot is easy to set up.

IV.

PROPOSED SYSTEM

The robot is consisting of the mechanical part, a computer, a RFID reader and an antenna, and ultrasonic sensors. The

mechanical part is a platform with wheels and motors which is controlled by the microcontroller. The RFID interrogator is

connected to the computer via RS-232 serial port. The ultrasonic sensors are attached to the sides of the robot and used to

measure the distance to walls. Since the area where tags can be detected at intersections is quite large, the robot has to use

ultrasonic sensors to determine when to turn without collision to the wall. And the sensors will keep robot out of collision

when the hallway is not straight.[5]The computer is in charge of processing the data from the RFID interrogator and

ultrasonic sensors via serial ports and sending orders to the microcontroller to impact on the movement of the robot.[6]

FIG.4. ROBOT CANNOT TURN

FIG.5. ROBOT CAN TURN

WITHOUT COLLISION

FIG.6. BLOCK DIAGRAM OF ROBOT

NAVIGATION

Page | 94

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-9, September- 2016]

FIG.7. FLOW CHART SHOWING FUNCTIONING OF KIT

Skilled navigation in mobile robotics usually requires solving two problems pertaining to the knowledge of the position of

the robot, and to a motion control strategy. When no prior knowledge of the environment is available, the problem becomes

even more challenging, since the robot has to build a map of its surroundings as it moves. These three tasks ought to be

solved in conjunction due to their interdependency.[7] The present manuscript proposes a novel mobile robot navigation

technique using a customized RFID reader with two receiving antennas mounted on the robot and a number of standard

RFID tags attached in the robots environment to define its path. Here, in this implementation it is showed that using the RF

signal from the RFID tags as an analog feedback signals can be a promising strategy to navigate a mobile robot within an

unknown or uncertain indoor environment [8,9].

V.

FIG.8.FRONT VIEW OF ULTRASONIC SENSORS

RESULTS

FIG.9. TOP VIEW OF OVERALL KIT

Page | 95

International Journal of Engineering Research & Science (IJOER)

ISSN: [2395-6992]

[Vol-2, Issue-9, September- 2016]

FIG.10. RUNNING SNAPSHOT

VI.

CONCLUSION

A novel RFID based robot navigation system is proposed in this paper. This system makes the robot able to navigate around

the building and records in indoor environment. The core part of the system is the RFID system and the ultrasonic sensors,

which enable the robot to locate itself and move without mistakes. This also uses a topological map of the building plan,

which makes the robot to move in proper route quickly. This paper brings a new product to the world of industry to increase

speed and efficiency. This approach is a practical and feasible way to create a smart security robot with navigation function.

For future extension of this paper the robot may use different materials to its designing process, based on different functional

operations of it. More number of IR sensors can be used to avoid obstacles from different sides. And also the robot may

increase RFID ranges.

REFERENCES

[1] L. Armesto, J. Tornero Automation of Industrial Vehicles: A Vision-based Line Tracking Application IEEE Conference on

Emerging Technologies & Factory Automation, 2009, pp 1-7.

[2] L. Kneip, F. Tache and et al. Characterization of the compact Hokyo URG-04LX 2D laser range scanner Proc. of IEEE Int. Cof. On

Robotics and Automation pp.1447-1454, 2009.

[3] O. Kubitz, M. O. Berger, and et al. Application of Radio Frequency Identification Devices to Support Navigation of Autonomous

Mobile Robots Proc. of IEEE Conf. On Vehicular Technology Vol. 1, pp. 126-130, 1997.

[4] C.P.Urmson, M.B.Dias and R.G.Simoms Stereo Vision Based Navigation for Sun-Synctoonous Exploration Proc. of IROS, pp. 805810, 2002.

[5] M. Ogaz, R. Sandoval and M. Chacon Data Processing from a Laser Range Finder Sensor for the Construction of Geometric Maps of

an Indoor Environment Proc. of IEEE 52nd Midwest Symposium on Circuits and Systems pp. 306-313, 2009.

[6] I. Hallmann and B. Siemiatkowska, Artificial landmark navigation system ,in Proc. Int. Symp. Intell. Robot. Syst., Jul. 2001, pp.

219228.

[7] A.K.Ray, M.Gupta, and et al. Sonar Based Autonomous Automatic Guided Vehicl (AGV) Navigation Proc. Of IEEE Int. Conf. on

System of Systems Engineering pp.1-8, 2008

[8] Emily M. Harwoo. Digital CCTV: A Security Professional's Guide

[9] Vision Based Autonomous Robot Navigation Algorithms and Implementations, authors:Amitava Chatterjee, Anjan Rakshit, N.

Nirmal Singh. ISBN: 978-3-642-33964-6 (Print) 978-3-642-33965-3 (Online)

[10] Emily M. Harwoo. Digital CCTV: A Security Professional's Guide

Page | 96

S-ar putea să vă placă și

- Robot Navigation System With RFID and Ultrasonic SensorsDocument5 paginiRobot Navigation System With RFID and Ultrasonic SensorstarezuÎncă nu există evaluări

- 30.IJAEST Vol No 7 Issue No 2 An Intelligent Mobile Robot Navigation Technique Using RFID Technology 356 364Document10 pagini30.IJAEST Vol No 7 Issue No 2 An Intelligent Mobile Robot Navigation Technique Using RFID Technology 356 364helpdesk9532Încă nu există evaluări

- P L M B Rssi U Rfid: Osition Ocation Ethodology Ased ON SingDocument6 paginiP L M B Rssi U Rfid: Osition Ocation Ethodology Ased ON SingInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Warehouse Management BOT Using ArduinoDocument6 paginiWarehouse Management BOT Using ArduinoIJRASETPublicationsÎncă nu există evaluări

- Intelligent Mobile ROBOT Navigation Technique Using RFID TechniqueDocument29 paginiIntelligent Mobile ROBOT Navigation Technique Using RFID TechniquenehakolheÎncă nu există evaluări

- Intelligent Smart Zone Based Vehicle Speed Control System Using RFDocument5 paginiIntelligent Smart Zone Based Vehicle Speed Control System Using RFSANGAVI SÎncă nu există evaluări

- IOT Asset Tracking System Using Android ApplicationDocument5 paginiIOT Asset Tracking System Using Android ApplicationBhaskar Rao PÎncă nu există evaluări

- RFID Based Auto-Navigation Robot: Chandan Raj S, Dinesh K. Anvekar and Sudhakar KNDocument6 paginiRFID Based Auto-Navigation Robot: Chandan Raj S, Dinesh K. Anvekar and Sudhakar KNDynamic gamingÎncă nu există evaluări

- A Low Cost Localization Algorithm For An Autonomous LawnmowerDocument6 paginiA Low Cost Localization Algorithm For An Autonomous LawnmowerabdallahlotfylÎncă nu există evaluări

- Matlab Colour Sensing RobotDocument5 paginiMatlab Colour Sensing Robotwaqas67% (3)

- Low Cost AvDocument5 paginiLow Cost AvrahulsundaresanÎncă nu există evaluări

- RFID-based Mobile Robot Guidance To A Stationary Target: Myungsik Kim, Nak Young ChongDocument13 paginiRFID-based Mobile Robot Guidance To A Stationary Target: Myungsik Kim, Nak Young ChongJayendra SharmaÎncă nu există evaluări

- Irjet V3i10104Document4 paginiIrjet V3i10104Shoshka AshÎncă nu există evaluări

- A Real-Time Multi-Antenna SAR-Based Method For 3D Localization of RFID Tags by A Moving RobotDocument15 paginiA Real-Time Multi-Antenna SAR-Based Method For 3D Localization of RFID Tags by A Moving RobotAlexis TÎncă nu există evaluări

- Design & Analysis of Vehicle Speed Control Unit Using RF TechnologyDocument7 paginiDesign & Analysis of Vehicle Speed Control Unit Using RF TechnologyVrushabh Madanlal JainÎncă nu există evaluări

- RFID-Based Mobile Robot Positioning - Sensors and TechniquesDocument5 paginiRFID-Based Mobile Robot Positioning - Sensors and Techniquessurendiran123Încă nu există evaluări

- JB Institute of Engineering and Technology: Home Service RobotDocument12 paginiJB Institute of Engineering and Technology: Home Service RobotNKNEELAMÎncă nu există evaluări

- Advance Line Following Robot: Shivam Singh, Prashant KumarDocument3 paginiAdvance Line Following Robot: Shivam Singh, Prashant Kumaranil kasot100% (1)

- Phase II Batch10Document22 paginiPhase II Batch10S SREENATHÎncă nu există evaluări

- Density Based Traffic Light ControlDocument6 paginiDensity Based Traffic Light ControlVIVA-TECH IJRIÎncă nu există evaluări

- Design and Implementation of Line Follower and Obstacle Detection Robot PDFDocument9 paginiDesign and Implementation of Line Follower and Obstacle Detection Robot PDFVINH Nhan ĐứcÎncă nu există evaluări

- Department of Computer Science EngineeringDocument16 paginiDepartment of Computer Science EngineeringmohitÎncă nu există evaluări

- BE ProjectDocument53 paginiBE ProjectDhruv GowdaÎncă nu există evaluări

- Department of Electronic Engineering: "Design of An Arduino Based Radar System"Document8 paginiDepartment of Electronic Engineering: "Design of An Arduino Based Radar System"Meer Zafarullah Noohani0% (1)

- Design For Visually Impaired To Work at Industry Using RFID TechnologyDocument5 paginiDesign For Visually Impaired To Work at Industry Using RFID Technologyilg1Încă nu există evaluări

- Autonomous Mobile Robot Navigation Using Passive RFID in Indoor EnvironmentDocument8 paginiAutonomous Mobile Robot Navigation Using Passive RFID in Indoor EnvironmentGunasekar R ErÎncă nu există evaluări

- Autonomous Robots PDFDocument8 paginiAutonomous Robots PDFEduard FlorinÎncă nu există evaluări

- Presented By: Group No:8Document16 paginiPresented By: Group No:8Priyanka TrivediÎncă nu există evaluări

- RFID Based Human Following Load Carrier ChangedDocument9 paginiRFID Based Human Following Load Carrier ChangedmunugotisumanthraoÎncă nu există evaluări

- Electronics and Communication EngineeringDocument12 paginiElectronics and Communication Engineeringgokul_rajÎncă nu există evaluări

- The Line Follower - And-Pick and Place Robot.: International Research Journal of Engineering and Technology (IRJET)Document6 paginiThe Line Follower - And-Pick and Place Robot.: International Research Journal of Engineering and Technology (IRJET)VASANTHKUMAR M SÎncă nu există evaluări

- On - Automotive Rail Track Crack Detection SystemDocument17 paginiOn - Automotive Rail Track Crack Detection SystemHuxtle RahulÎncă nu există evaluări

- Parking Management in Shopping MallsDocument12 paginiParking Management in Shopping MallsadÎncă nu există evaluări

- Design and Implementation of RGB Color Line Following RobotDocument5 paginiDesign and Implementation of RGB Color Line Following RobotpaishkepengÎncă nu există evaluări

- Traffic Data Vertical of Geospatial Data CenterDocument4 paginiTraffic Data Vertical of Geospatial Data CenterVIVA-TECH IJRIÎncă nu există evaluări

- AM 8th Sem Solution 17.05.19 in CourseDocument16 paginiAM 8th Sem Solution 17.05.19 in CourseRaj PatelÎncă nu există evaluări

- Infrared Range Sensor Array For 3D Sensing in Robotic ApplicationsDocument9 paginiInfrared Range Sensor Array For 3D Sensing in Robotic Applicationshabib_archillaÎncă nu există evaluări

- Fundamentals of RoboticsDocument5 paginiFundamentals of RoboticsFranklin Jara MoncayoÎncă nu există evaluări

- Spying Swarm Robots For Military ApplicationsDocument39 paginiSpying Swarm Robots For Military ApplicationsRishi ChawlaÎncă nu există evaluări

- Obstacle Avoiding Robot Using Arduino: AbstractDocument5 paginiObstacle Avoiding Robot Using Arduino: AbstractWarna KlasikÎncă nu există evaluări

- Active RFID Positioning of Vehicles in Road Traffic: Enzhan Zhang Weili JiangDocument6 paginiActive RFID Positioning of Vehicles in Road Traffic: Enzhan Zhang Weili JiangGautam KunalÎncă nu există evaluări

- Defence Surveillance Robot Based On RF and DTMF TechnologyDocument7 paginiDefence Surveillance Robot Based On RF and DTMF TechnologyGowtham SakthiÎncă nu există evaluări

- 3 Din SAR2016Document8 pagini3 Din SAR2016chaker AdrianoÎncă nu există evaluări

- Localization and Navigation For Aoutonomous Mobile RobotDocument12 paginiLocalization and Navigation For Aoutonomous Mobile RobotEkky Yonathan GunawanÎncă nu există evaluări

- RFID Blind Navigation Final PDFDocument4 paginiRFID Blind Navigation Final PDFNaveen LalÎncă nu există evaluări

- Participation of Disability People To Working and Learning Envıronments With The Help of RobotsDocument10 paginiParticipation of Disability People To Working and Learning Envıronments With The Help of RobotsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Rfid BunDocument7 paginiRfid BunSimona NicoletaÎncă nu există evaluări

- Advanced Military Spying and Bomb Disposal Robot: Senthamizh.R1, Subbu Lakshmi.P1, Subhashree.P1, Prof. M.Priyadarshini2Document3 paginiAdvanced Military Spying and Bomb Disposal Robot: Senthamizh.R1, Subbu Lakshmi.P1, Subhashree.P1, Prof. M.Priyadarshini2xoxoÎncă nu există evaluări

- Smart Bus Tracker: K.V. Nagalakshmi, Monisha M, Puja Kaul, Sumaya Bhat, Revathy C Kattepur, Sneha Sara JacobDocument5 paginiSmart Bus Tracker: K.V. Nagalakshmi, Monisha M, Puja Kaul, Sumaya Bhat, Revathy C Kattepur, Sneha Sara Jacobankush belkarÎncă nu există evaluări

- StarliteDocument4 paginiStarliteSundar C EceÎncă nu există evaluări

- Paper 26Document5 paginiPaper 26vivekgorasiya32Încă nu există evaluări

- 7 RemoteMonitoring PDFDocument7 pagini7 RemoteMonitoring PDFIjaems JournalÎncă nu există evaluări

- Progress in Electromagnetics Research C, Vol. 11, 213-228, 2009Document16 paginiProgress in Electromagnetics Research C, Vol. 11, 213-228, 2009Karloz CondeÎncă nu există evaluări

- Train Collision Avoiding SystemDocument7 paginiTrain Collision Avoiding SystemIJRASETPublicationsÎncă nu există evaluări

- Restaurant BOTSDocument8 paginiRestaurant BOTSSaudin TantriÎncă nu există evaluări

- SPY Night Vision Robot With Moving Wireless Video Camera & Ultrasonic SensorDocument6 paginiSPY Night Vision Robot With Moving Wireless Video Camera & Ultrasonic SensorrajeshÎncă nu există evaluări

- Development of An Autonomous Vehicle at A 1:8 ScaleDocument13 paginiDevelopment of An Autonomous Vehicle at A 1:8 ScaleAriel BogadoÎncă nu există evaluări

- University of Trento: Department of Information and Communication TechnologyDocument17 paginiUniversity of Trento: Department of Information and Communication TechnologyjebileeÎncă nu există evaluări

- Radio Frequency Identification and Sensors: From RFID to Chipless RFIDDe la EverandRadio Frequency Identification and Sensors: From RFID to Chipless RFIDÎncă nu există evaluări

- Chipless Radio Frequency Identification Reader Signal ProcessingDe la EverandChipless Radio Frequency Identification Reader Signal ProcessingÎncă nu există evaluări

- Free Paris Walking Tour: Contemporary ArchitectureDocument14 paginiFree Paris Walking Tour: Contemporary ArchitectureInvisibleParis100% (2)

- Kleist - On The Marionette TheaterDocument6 paginiKleist - On The Marionette TheaterAlejandro AcostaÎncă nu există evaluări

- Microstrip Antennas PDFDocument85 paginiMicrostrip Antennas PDFKeviinCarrillo100% (1)

- Company ProfileDocument11 paginiCompany ProfileJose Leonardo Gomez0% (1)

- Blues BrosDocument14 paginiBlues Brossandrovergara100% (4)

- Ink GSM Coverage Determination: Quality Control Lab Report - SAKATA INKDocument1 paginăInk GSM Coverage Determination: Quality Control Lab Report - SAKATA INKMATTHEW MUNGAIÎncă nu există evaluări

- English Literature MCQs Solved From Past PapersDocument33 paginiEnglish Literature MCQs Solved From Past PapersJohn Faustus100% (1)

- A High-Capacity Transmission Technique Using A Wide Range of Frequencies, Which Enables A Large Number of Messages To Be Communicated SimultaneouslyDocument1 paginăA High-Capacity Transmission Technique Using A Wide Range of Frequencies, Which Enables A Large Number of Messages To Be Communicated Simultaneouslymukhtar omerÎncă nu există evaluări

- Reading Strategies ActivitiesDocument3 paginiReading Strategies ActivitiesXiv NixÎncă nu există evaluări

- Contoh Lain Text SpoofDocument7 paginiContoh Lain Text SpoofSigit51Încă nu există evaluări

- CHP 2 Updated Literature ReviewDocument38 paginiCHP 2 Updated Literature ReviewBhaumik NayakÎncă nu există evaluări

- Megalovania From Undertale For Percussion EmsembleDocument6 paginiMegalovania From Undertale For Percussion EmsembleGerben BuijzeÎncă nu există evaluări

- UMTS Protocol Stack - UMTS TutorialDocument3 paginiUMTS Protocol Stack - UMTS TutorialBiswajit MohantyÎncă nu există evaluări

- Triton-Ocean Bottom Seismometer-001Document2 paginiTriton-Ocean Bottom Seismometer-001Furio RuggieroÎncă nu există evaluări

- A Tu Vera 2 by Paco de LuciaDocument7 paginiA Tu Vera 2 by Paco de LuciaAdrián Vázquez AlfonsoÎncă nu există evaluări

- Projector Epson EB-980WDocument5 paginiProjector Epson EB-980WVajar Ramdan ZaoldyeckÎncă nu există evaluări

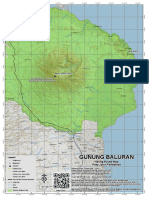

- Peta Jalur Pendakian Gunung BaluranDocument1 paginăPeta Jalur Pendakian Gunung BaluranKindi SienaÎncă nu există evaluări

- High-Resolution Frequency-Wavenumber Spectrum Analysis: OF NODocument11 paginiHigh-Resolution Frequency-Wavenumber Spectrum Analysis: OF NONelson YaltaÎncă nu există evaluări

- FEYNMAN, Richard. What-Do-You-Care-What-Other-People-Think PDFDocument111 paginiFEYNMAN, Richard. What-Do-You-Care-What-Other-People-Think PDFFELLINIERS100% (2)

- Sandi Chadwick StoryDocument1 paginăSandi Chadwick Storyapi-242886250Încă nu există evaluări

- 5-4. SCHEMATIC DIAGRAM - TUNER SECTION - Refer To Page 13 For IC Block DiagramDocument2 pagini5-4. SCHEMATIC DIAGRAM - TUNER SECTION - Refer To Page 13 For IC Block DiagramAndre BaezÎncă nu există evaluări

- VAASA WILDLIFE FESTIVAL - Official Selection 2018Document58 paginiVAASA WILDLIFE FESTIVAL - Official Selection 2018Wildlife Vaasa Festival / Ilias MissyrisÎncă nu există evaluări

- The Trojan Women Greek Tragedy in New TranslationsDocument120 paginiThe Trojan Women Greek Tragedy in New TranslationsHogla Marín Pabon100% (5)

- WAP HS LectureDocument33 paginiWAP HS LectureEdison C. TiczonÎncă nu există evaluări

- Indian Traditional Musical InstrumentsDocument3 paginiIndian Traditional Musical InstrumentsPiriya94Încă nu există evaluări

- Dunsby, Schoenberg's Op. 22 No. 4 Premonition (JASI 1-3, 1977)Document7 paginiDunsby, Schoenberg's Op. 22 No. 4 Premonition (JASI 1-3, 1977)Victoria ChangÎncă nu există evaluări

- Cultivation Theory by George GerbnerDocument3 paginiCultivation Theory by George GerbnerLyne Caguisa100% (1)

- Henry IV Part1 Teacher's GuideDocument24 paginiHenry IV Part1 Teacher's GuideShirley Samuel100% (1)

- Nigel Pennick - Woden's Swastika (1979)Document9 paginiNigel Pennick - Woden's Swastika (1979)Various TingsÎncă nu există evaluări

- 09007Document53 pagini09007Jagadesh KumarÎncă nu există evaluări