Documente Academic

Documente Profesional

Documente Cultură

SL03 415 PDF

Încărcat de

econmechTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SL03 415 PDF

Încărcat de

econmechDrepturi de autor:

Formate disponibile

MAN B&W Diesel A/S

SL03-415/CSH

January 2003

Service Letter

60-98MC/MC-C Engines

Radial Type Starting Air Distributors

Action Code: WHEN CONVENIENT

Dear Sirs

The radial type starting air distributor was introduced for the large bore MC/MC-C

engines in the early 1990s, and later for the medium bore MC/MC-C engines.

As impurities in the starting air, in a few cases, have caused starting air distributors of

this type to fail, we take this opportunity to describe the nature of these few failures

and, at the same time, state our recommendations for precautions to be taken to

avoid such inconveniences.

Almost all the starting difficulties encountered have been caused by sticking of the

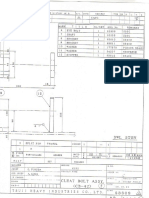

piston valve slide, see, by way of example, Item 129 of the enclosed Plate 907030086, which is for an S70MC-C engine.

Insufficient cleaning of pipes and air bottles before their installation on board may

cause seizure and sticking of the piston valve slides. The foreign particles are

gradually carried by the air, through the pipe system, ending up in the distributor, thus

creating seizure and sticking of the piston valve slides.

In addition, we have experienced cases where a high air humidity level at the

compressor air intake has created heavy condensation of water, which is carried with

the air through the system, causing corrosion of the steel and iron components. The

rust scales resulting from such corrosion have, when entering the distributor, also

contributed to seizure and sticking of the piston valve slides.

HEAD OFFICE (& Postal address)

Teglholmsgade 41

DK-2450 Copenhagen SV

Telephone: +45 33 85 11 00

Telex: 16592 manbw dk

Telefax: +45 33 85 10 30

E-mail: manbw@manbw.dk

http://www.manbw.dk

DIESEL SERVICE

Teglholmsgade 41

DK-2450 Copenhagen SV

Telephone: +45 33 85 11 00

Telex: 31197 manbw dk

Telefax: +45 33 85 10 49

E-mail: diesel-service@manbw.dk

PRODUCTION

Teglholmsgade 35

DK-2450 Copenhagen SV

Telephone: +45 33 85 11 00

Telex: 19023 manfw dk

Telex: 19042 manfw dk

Telefax: +45 33 85 10 17

E-mail: manufacturing/copenhagen@manbw.dk

FORWARDING

Teglholmsgade 35

DK-2450 Copenhagen SV

Telephone: +45 33 85 11 00

Telex: 19023 manfw dk

Telex: 19042 manfw dk

Telefax: +45 33 85 10 16

MAN B&W Diesel A/S

Denmark

CVR.No.: 39 66 13 14

In the cases experienced, the foreign particles entering the distributor have caused

the coefficient of friction to increase, leading to seizure of the running surfaces

between the liners (Items 130 and 274) and the piston valve slide (Item 129), and also

between the cam follower of the piston valve slide (Item 129) and the running surface

of the starting cam (Item 058). The seizures furthermore contribute to an increase of

the friction, thus aggravating the situation. This increase in the frictional resistance

has, in a few cases, become so high that the piston valve slide has become selflocking and caused the piston valve slide or the starting cam to break.

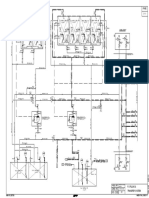

In order to improve the distributors resistance to damage caused by the ingress of

foreign particles from the air, the profile of the starting cam for ahead has been

slightly modified. The pitch of the ahead cam has been reduced, thereby also

reducing the guide and friction forces.

For plants that have suffered from problems with broken piston valve slides/damaged

starting cams, it is recommended that the new modified starting cam is installed in

connection with the replacement of damaged piston valve slides.

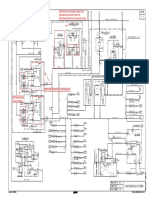

In addition to following the overhaul procedure for the starting air distributor

(Instruction book, Volume II, Chapter 907-1), we also find it appropriate to extend the

recommended inspections with the following points:

1. During port stays, when the engine is stopped, we recommend checking

whether the piston valve slide (Item 129) and the liners (Items 130 and 274)

have become seized. Check, with stopped engine, that the piston valve slide

can be pushed up and down by hand just overcoming the force of the spring. If

this is not possible, it is recommended that the piston valve slide (Item 129)

and liners (Items 130 and 274) are disassembled for inspection.

2. When the distributor parts are assembled, the parts should be lubricated with

Molybdenum Disulphide (MoS2). The starting cam and the cam followers

should be lubricated with grease containing MoS2.

When operating in areas with a high humidity level, it is recommended to check that

the automatic venting valves are functioning properly, otherwise manual draining of

condensate water from the air bottles is recommended.

Questions or comments regarding this SL should be directed to our Dept. 2300.

Yours faithfully

MAN B&W Diesel A/S

Carl-Erik Egeberg

Encl.

Mikael C Jensen

S-ar putea să vă placă și

- 6S 50 MC-C, Vol. III - Component, DescriptionDocument184 pagini6S 50 MC-C, Vol. III - Component, DescriptionAbsar Mamun100% (8)

- S35MC 01Document782 paginiS35MC 01cengiz kutukcu50% (2)

- MAN B&W 6S50MC - Components DescriptionDocument182 paginiMAN B&W 6S50MC - Components DescriptionHải Nguyễn Văn67% (3)

- L70MC-C Vol. 2 PDFDocument658 paginiL70MC-C Vol. 2 PDFPaul Lucian VentelÎncă nu există evaluări

- A Guide to Ship Repair Estimates in Man-hoursDe la EverandA Guide to Ship Repair Estimates in Man-hoursEvaluare: 4.5 din 5 stele4.5/5 (5)

- MAN B&W Diesel A/S: Licence LetterDocument3 paginiMAN B&W Diesel A/S: Licence Letterbhaswath2000Încă nu există evaluări

- SL2001-394 Manoeuvring Systems PneumaticDocument4 paginiSL2001-394 Manoeuvring Systems Pneumaticcengiz kutukcuÎncă nu există evaluări

- SL96-339 B&W Service LetterDocument5 paginiSL96-339 B&W Service LetterkamalÎncă nu există evaluări

- Oil Record Book Entries: Machinery Space OperationsDocument8 paginiOil Record Book Entries: Machinery Space Operationsrafael_camacho_15Încă nu există evaluări

- Control Air For ME Exh ValvesDocument8 paginiControl Air For ME Exh Valveshpss77Încă nu există evaluări

- SL03 418 PDFDocument2 paginiSL03 418 PDFKaushalKishoreÎncă nu există evaluări

- Man Service Letter About Main Engine 5s60-MC-C Startin Air System Maintenance For Marine EngineerDocument3 paginiMan Service Letter About Main Engine 5s60-MC-C Startin Air System Maintenance For Marine EngineersalllsaÎncă nu există evaluări

- SL97 351 PDFDocument5 paginiSL97 351 PDFKaushalKishoreÎncă nu există evaluări

- Slide Fuel ValvesDocument2 paginiSlide Fuel ValvesSpasoje100% (1)

- SL97-347 MC Engines Cracks in Welds of Supports For 2nd Order Moment CompDocument6 paginiSL97-347 MC Engines Cracks in Welds of Supports For 2nd Order Moment CompAnurag DimriÎncă nu există evaluări

- SL00 377Document7 paginiSL00 377Nazmul HassanÎncă nu există evaluări

- SL97-352 B&W Service LetterDocument2 paginiSL97-352 B&W Service LetterkamalÎncă nu există evaluări

- SL96-342 B&W Service LetterDocument5 paginiSL96-342 B&W Service LetterkamalÎncă nu există evaluări

- SL97-345 B&W Service LetterDocument5 paginiSL97-345 B&W Service Letterkamal100% (1)

- SL96-341 B&W Service LetterDocument4 paginiSL96-341 B&W Service LetterkamalÎncă nu există evaluări

- GHHDocument3 paginiGHHeldiego1790Încă nu există evaluări

- MAN B&W Diesel A/S: Service LetterDocument4 paginiMAN B&W Diesel A/S: Service LetterAleksandar Sasa SeferovicÎncă nu există evaluări

- SL97-344 B&W Service LetterDocument2 paginiSL97-344 B&W Service LetterkamalÎncă nu există evaluări

- SL99-373 B&W Service LetterDocument2 paginiSL99-373 B&W Service LetterkamalÎncă nu există evaluări

- Bearing Failure Service LetterDocument7 paginiBearing Failure Service LetterAurvin SinghÎncă nu există evaluări

- Checking Bolts in Camshaft Coupling MAN SL02-405Document6 paginiChecking Bolts in Camshaft Coupling MAN SL02-405harikrishnanpd3327Încă nu există evaluări

- SL98-359 B&W Service LetterDocument1 paginăSL98-359 B&W Service LetterkamalÎncă nu există evaluări

- MAN B&W Diesel A/S: Service LetterDocument1 paginăMAN B&W Diesel A/S: Service LetterkamalÎncă nu există evaluări

- SL01 397Document2 paginiSL01 397thiseus25Încă nu există evaluări

- VOLUME.2 MaintenanceDocument600 paginiVOLUME.2 MaintenanceMyo Khant100% (1)

- Cooling Water Inlet Temperature at Scavenge Air Cooler - DUN.31.2014Document3 paginiCooling Water Inlet Temperature at Scavenge Air Cooler - DUN.31.2014goginemÎncă nu există evaluări

- SL95-329 B&W Service LetterDocument2 paginiSL95-329 B&W Service LetterkamalÎncă nu există evaluări

- M.A.N - B&W Diesel: Service LetterDocument5 paginiM.A.N - B&W Diesel: Service LetterAleksandar Sasa SeferovicÎncă nu există evaluări

- SL07 480Document5 paginiSL07 480GianÎncă nu există evaluări

- s50mc Vol IIDocument778 paginis50mc Vol IIcengiz kutukcu100% (2)

- SL02 399Document3 paginiSL02 399Subramoniam MarineÎncă nu există evaluări

- MAN B&W Diesel A/S: Service LetterDocument2 paginiMAN B&W Diesel A/S: Service LetterKaushalKishoreÎncă nu există evaluări

- MAN B&W Diesel A/S: Service LetterDocument2 paginiMAN B&W Diesel A/S: Service Letterflorin100% (1)

- SL99-368 B&W Service LetterDocument5 paginiSL99-368 B&W Service Letterkamal100% (1)

- How to Extend Exhaust Valve Lifetime During Low-Load OperationDocument4 paginiHow to Extend Exhaust Valve Lifetime During Low-Load Operationlavkesh100% (1)

- SL98-356 B&W Service LetterDocument14 paginiSL98-356 B&W Service LetterkamalÎncă nu există evaluări

- L35MC 01Document804 paginiL35MC 01cengiz kutukcu100% (2)

- SL98-358 B&W Service LetterDocument3 paginiSL98-358 B&W Service LetterkamalÎncă nu există evaluări

- Man B&W WarningDocument284 paginiMan B&W WarningMarcin SrokaÎncă nu există evaluări

- SL95-327 B&W Service LetterDocument4 paginiSL95-327 B&W Service LetterkamalÎncă nu există evaluări

- SL 1999Document23 paginiSL 1999hpss77Încă nu există evaluări

- 2 Maintenance (D2379a)Document630 pagini2 Maintenance (D2379a)SimonaMaunaÎncă nu există evaluări

- MAN B&W Diesel A/S: Service LetterDocument2 paginiMAN B&W Diesel A/S: Service LetterAKINMOLADUN OMOLADEÎncă nu există evaluări

- Bearing Condition Monitoring MANDocument6 paginiBearing Condition Monitoring MANposteljicaplava100% (1)

- MAN B&W Service LettersDocument8 paginiMAN B&W Service LettersМаксим АгеевÎncă nu există evaluări

- MAN Diesel Service Letter on Condition Based OverhaulDocument6 paginiMAN Diesel Service Letter on Condition Based OverhaulDenim102Încă nu există evaluări

- HGS-MAN-SL-20-010 - Top Controlled Exh. Valve (TCEV)Document5 paginiHGS-MAN-SL-20-010 - Top Controlled Exh. Valve (TCEV)ajshsu5682Încă nu există evaluări

- Index - Vol.3-Đã G PDocument143 paginiIndex - Vol.3-Đã G Phuy huỳnhÎncă nu există evaluări

- ALERT Service Bulletin - Product Recall Action - ASB2009/12/23Document3 paginiALERT Service Bulletin - Product Recall Action - ASB2009/12/23Muhd Khir RazaniÎncă nu există evaluări

- ME Operational Manual MANB&W 7S70MC-CDocument576 paginiME Operational Manual MANB&W 7S70MC-CSamrat ThukralÎncă nu există evaluări

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe la EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- 2012 Calculating and Comparing CO2 Emissions From ShipsDocument26 pagini2012 Calculating and Comparing CO2 Emissions From ShipseconmechÎncă nu există evaluări

- Manual PpbRAE3000 RevEDocument120 paginiManual PpbRAE3000 RevEeconmech100% (1)

- ALBWARDY - DAMEN (Dubai - Fujairah - Sharjah) : Dmi (Hellas) LTDDocument2 paginiALBWARDY - DAMEN (Dubai - Fujairah - Sharjah) : Dmi (Hellas) LTDeconmechÎncă nu există evaluări

- Global Service NetworkDocument1 paginăGlobal Service NetworkeconmechÎncă nu există evaluări

- Bolt Cleat 2 PageDocument1 paginăBolt Cleat 2 PageeconmechÎncă nu există evaluări

- M-54 K4670433 Sewage Treatment SystemDocument8 paginiM-54 K4670433 Sewage Treatment SystemeconmechÎncă nu există evaluări

- 4-2015-757 Rev - ANNEXDocument2 pagini4-2015-757 Rev - ANNEXeconmechÎncă nu există evaluări

- YanmarRecommendList 6EY18ALW CylHead 20220601Document1 paginăYanmarRecommendList 6EY18ALW CylHead 20220601econmechÎncă nu există evaluări

- ANNA S NO.3 Aux EngineDocument8 paginiANNA S NO.3 Aux EngineeconmechÎncă nu există evaluări

- Pages From M-303 e Instruction Book Generator Diesel Engine-2Document1 paginăPages From M-303 e Instruction Book Generator Diesel Engine-2econmechÎncă nu există evaluări

- Mepc 76 Brief: Imo Strategy On GHG EmissionsDocument5 paginiMepc 76 Brief: Imo Strategy On GHG EmissionseconmechÎncă nu există evaluări

- Bolt Cleat 1 PageDocument1 paginăBolt Cleat 1 PageeconmechÎncă nu există evaluări

- Fo Transfer PipingDocument1 paginăFo Transfer PipingeconmechÎncă nu există evaluări

- Sterilizer To Be Checked, Lamps To Be Renewed and Dolomite Filters of Rehardening Filter To Be Renewed As WellDocument1 paginăSterilizer To Be Checked, Lamps To Be Renewed and Dolomite Filters of Rehardening Filter To Be Renewed As WelleconmechÎncă nu există evaluări

- BMP5 PDFDocument77 paginiBMP5 PDFSanjay GuptaÎncă nu există evaluări

- Bearing Terminology KingDocument1 paginăBearing Terminology KingeconmechÎncă nu există evaluări

- Earth Pressure TheoryDocument20 paginiEarth Pressure TheoryMohan ManickamÎncă nu există evaluări

- The Management of Ship-Generated Waste On-Board Ships - EMSA-OP-02-2016Document90 paginiThe Management of Ship-Generated Waste On-Board Ships - EMSA-OP-02-2016MasterPie1950Încă nu există evaluări

- Electrode Materials and Electrode SelectionDocument30 paginiElectrode Materials and Electrode SelectionNaveen TripuraneniÎncă nu există evaluări

- Evaluating Efficiency of Filtration - Ballast TechnologiesDocument33 paginiEvaluating Efficiency of Filtration - Ballast TechnologieseconmechÎncă nu există evaluări

- VF Fuel System 1503075185201Document2 paginiVF Fuel System 1503075185201econmechÎncă nu există evaluări

- TWForce LLicenciaturaDocument34 paginiTWForce LLicenciaturaeconmechÎncă nu există evaluări

- Checking Bolts in Camshaft Coupling MAN SL02-405Document6 paginiChecking Bolts in Camshaft Coupling MAN SL02-405harikrishnanpd3327Încă nu există evaluări

- SL03 415 PDFDocument2 paginiSL03 415 PDFeconmechÎncă nu există evaluări

- Checking Bolts in Camshaft Coupling MAN SL02-405Document6 paginiChecking Bolts in Camshaft Coupling MAN SL02-405harikrishnanpd3327Încă nu există evaluări