Documente Academic

Documente Profesional

Documente Cultură

Sea 297

Încărcat de

PetricaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sea 297

Încărcat de

PetricaDrepturi de autor:

Formate disponibile

No. 297 Feb. - Mar.

2003

IHI MU completes 6,492TEU post Panamax container carrier

IHI Marine United Inc. completed construction of the

NYK Apollo (HN: 3155), a 6,492TEU Post Panamax Container Carrier for delivery to Great River Line S.A. of

Panama, at the Kure Shipyard on November 29, 2002.

The NYK Apollo is the first of a series of seven 6,492TEU

Post Panamax Carriers to be chartered by NYK Line for

transport services in routes centered on the Europe and

Far East.

The carrier with a beam of over 40.0m can load containers of nine tiers in 14 rows in cargo holds and six tiers in

16 rows on the upper deck, totaling 6,492TEUs.

She has the fixed cell guide system in holds and lashing

bridges to enable the containers be stacked up as high as

six tiers on deck. For reefer containers, 83 plugs in holds

and 450 plugs on deck are provided.

Principal Particulars of NYK Apollo

Length, o.a.:

299.90m

Length, b.p.:

283.80m

Breadth, mld.:

40.00m

Depth, mld.:

23.90m

Scantling draft:

14.00m

Gross tonnage:

75,484t

Deadweight:

81,171MT

Speed, service:

25.0kt

Main engine:

DU-Sulzer 12RTA96C diesel x 1 unit

Output

MCR:

61,350kW x 97.7rpm

NOR:

52,150kW x 92.5rpm

Classification:

NK

For further information please contact:

JAPAN SHIP EXPORTERS' ASSOCIATION

15-16, Toranomon 1-chome, Minato-ku, Tokyo 105-0001 Tel: (03) 3508-9661 Fax: (03) 3508-2058 E-Mail: postmaster@jsea.or.jp

Topics

No. 297 Feb. - Mar. Page 2

5,576TEU container carrier Genoa Bridge built by Imabari

The Imabari group led by Imabari

Shipbuilding Co., Ltd. had the largest market share in Japan, or fourth

in the world, in terms of gross tonnage

for newbuildings in fiscal 2001. The

group has introduced newly-developed facilities and constructed a large

dock to cope with the requirements of

VLCCs and VLOCs, etc., and started

development of LNG carrier construction technology to enter the market

for LNG carriers. The group now continues to cope with demand for a variety of ships from small to large. For

example, the group built the following container carrier last year.

*****

The Genoa Bridge, a container carrier, was completed at Koyo Dockyard

Co., Ltd. of the Imabari group on Sept.

9, 2002. The carrier is the last of a series of six container carriers that were

constructed continuously. Performance of the carriers has fully met

the requirements of the

owner and operator.

The carrier is

the over Panamax type measuring 270.94m

in overall length,

40.00m in beam

and can carry

Toyohashi completes

container carrier

Kota Gembira

and 4).

The main engine uses a low-speed,

long-stroke diesel engine to reduce the

fuel cost, and AIS (automatic identification system) is installed.

Principal particulars

L (o.a) x B x D x d: 226.54m x 32.20m

x 16.80m x11.50m

DWT/GT: 37,114t/28,676t

Main engine: Mitsui-MAN B&W

7S70MC-C diesel x 1 units

MCR: 21,735kW x 91rpm

Speed, service: 22.0kt

Classification: NK

Completion: Nov. 19, 2002

Toyohashi Shipbuilding Co., Ltd.

(formerly Kanasashi Co., Ltd., renamed Jan. 1, 2003) has completed

the 2,607TEU container carrier, Kota

Gembira (HN: 3556), for Kota

Gembira Limited. The carrier is the

largest container carrier ever built by

Toyohashi and is the third of a series

of four ships.

The carrier can load containers of

956TEUs in the

cargo hold and

1,651TEUs six tiers

on the upper deck.

It can also carry

reefer containers

(278FEUs plus

22TEUs) on the upper deck and dangerous cargo containers on the upper

deck and in the

holds (Nos. 1, 2, 3,

5,576TEUs of containers. Hull construction has obtained the SHR notation from the American Bureau of

Shipping. The hull strength is shared

by the hatch side coamings, not by boxtype longitudinal girders in the conventional concept. This design can

achieve good container loading efficiency into the holds, that is, 9 tiers in

14 rows across the beam can be loaded

at midships, and on the upper deck,

lashing bridges are also adopted to

enable loading containers in 5 or 6

tiers on the hatch covers, permitting

a variety of container loading such as

high cubic size and 45' size containers. About 9% of the total container

carrying capacity can be allotted for

reefer containers, 430 plugs are provided on the hatchways and 70 plugs

in the cargo holds.

The engine room consists of reliable

machinery and has obtained the

+ACCU notation from ABS. The main

engine is a super long-stroke, 2-cycle

diesel engine, Mitsui MAN B&W

10K98MC (VI). The bore is the worlds

largest of 980mm, and the output is

7,780ps per cylinder. Navigation

speed is 25.0 knots. A water-tube type

auxiliary boiler (380cSt/50oC) is used

for reliable operation in both navigation and cargo handling operation. An

exhaust economizer with a capacity

of 3,200kg/h x 0.6MPa is installed.

Four generators produce 2,750kVa

(2,200kW x 720rpm), and an emergency generator of 150KVA (120kW

x 800rpm) is provided.

Principal particulars

Hull No.: 2152

Ship Type: 5,576TEU Container Carrier

L (o.a.) x L (b.p.) x B x D x d: 278.94m

x 262.00m x 40.00m x 24.00m

x12.50m

DWT/GT: 67,197M.T./66,292

Main engine: Mitsui-Man B&W

10K98MC(VI) x 1 unit

MCR: 57,200kW x 94.0rpm

NOR: 48,620kW x 89.0rpm

Speed, service: 25.00kt

Classification: ABS

Endurance: abt. 20,000nm

Topics

No. 297 Feb. - Mar. Page 3

Shin Kurushima completes multipurpose cargoship

Shin Kurushima Dockyard Co.,

Ltd. has completed the 17,500GT

multipurpose cargoship, Coral Islander (HN: 5205), which can carry

containers, automobiles, rolling stock,

heavy cargo and sundry goods simultaneously. Nippon Yusen Kaisha

(NYK) is now chartering this nextgeneration multipurpose cargoship

through one of the NYK friendly owners during a period of 15-18 years.

The cargo ship uses unique ship

design to navigate among islands in

the Pacific Ocean. On the planned

navigation routes, seaborne cargoes

are comparatively small lots per item,

and cargo handling must be conducted

frequently as the ship will visit several ports in a short period.

To cope with these requirements,

the Coral Islander has combined container and vehicle carrying functions

together with other cargoes such as

heavy loads, steel materials, and general cargoes. Vehicle handling is

achieved by the roll-on and -off

method.

The ship can load containers of 912

TEUs, for which 100 reefer plugs are

included, 615 passenger cars and navigate at 18 knots.

Special features of the ship include

the following:

60% of the hull section toward the

bow is designed as the hull of the

containership, and the remaining 40%

toward the stern is the same construction as a car carrier. The container

holds have cell guides to permit efficient container handling. For the car

decks, a shore ramp is installed at the

starboard stern for roll-on and -off of

vehicles.

Two 40t container cranes installed

on the upper deck allow container

handling at a small port without shore

material handling equipment.

The combined operation of the two

cranes also allows handling of a heavy

cargo weighing up to 65 tons. The combined use is applicable to loading and

unloading vehicles and construction

Coral Islander

machinery that cannot run on the

shore ramp as well as heavy and massive cargoes.

Cargo holds are strengthened to

load heavy steel materials like steel

coils. Eye plates to fasten cargoes are

provided at bulkheads of the fore and

aft sides and both ship sides. This permits cargo loading in three to six tiers,

effectively coping with various types

and quantities of cargoes.

Cargo holds Nos. 2, 3, and 4 have

container stoppers and container

beams to provide a clearance below

the bottom containers for loading

other cargoes (vehicles or heavy and

large cargoes). In a conventional ship,

cargoes with a great weight cannot be

loaded on tank tops even if there is a

vacancy at the top in a cargo hold.

However, these devices enable effective use in cargo holds when loading

fewer containers.

Cargo holds Nos. 3 and 4 are provided with a movable second deck like

a pontoon. The combined use of the

second deck, stoppers and beams can

provide one more car deck. This permits coping with changes in the load

between cars and containers. When

not used, the second decks are accommodated on the exposed deck in the

front of the accommodation quarters.

The second deck has a maximum

loading capacity of 0.5t/m2. Consequently, lighter general cargoes can

be placed on the second deck within

the limit. Cars or heavy cargoes are

loaded on the cargo hold bottom.

Cargo holds Nos. 3 and 4 have a

total of eight second decks, stoppers,

and beams at the fore and aft sections

and both ship sides. Setting positions

of these devices can be decided optionally and independently according to

the requirements of loading sections,

allowing effective mixed loading.

Principal particulars

Ship Type: Multipurpose cargoship

L (o.a.) x L (b.p.) x B x D x d: 160.70m

x 151.20m x 25.00m x 1.80m x

9.20m

DWT/GT: 17,500t/17,000t

Main engine: 7UEC 50LS II diesel x

1 unit

Output: 13,087ps x 124rpm

Speed, service: 18.0kt

Classification: NK

Carrying capacity

Vehicles: 607 units (4.50m x 1.70m

passenger car basis)

Containers: 914TEUs

Proportional loading: 470 cars plus

914TEUs, or 607 cars plus

828TEUs

Topics

No. 297 Feb. - Mar. Page 4

Namura completes 105,500-dwt product and crude oil carrier

The 105,500-dwt double-hull,

double-bottom product and crude oil

carrier, Song Lin Wan (HN: 238), was

built by Namura Shipbuilding Co.,

Ltd. After delivery in Japan on 27th

November, 2002, the vessel sailed off

to China where coating of the cargo

oil tanks was carried out.

Mitsui Engineering & Shipbuilding

Co., Ltd. (MES) has developed a new

electronically-controlled lubricating

system, the Alpha Lubricating System, to reduce consumption of diesel

engine cylinder lubricating oil, and

recently achieved remarkable savings

in cylinder oil on a large container ship

of 4,900TEUs, which is equipped with

a Mitsui MAN-B&W 1OK9OMC engine of 59,600 BHP. The saving rate

on the ship as of today is 20% plus,

Pump station

This is the second vessel of

Namuras newly developed Aframax

tanker series that have achieved superior propulsive performance due to

a newly developed hull form based on

Namuras latest technology and long

experience. The large diameter propeller is driven by a long-stroke, lowrevolution and

fuel-efficient

main engine for

better propulsive efficiency.

Special consideration is given to

safety against

environmental

pollution, labor

saving and operational

MES develops new

lubricating system

for diesel engines

but is expected to reach more than

50% in the near future.

The Alpha Lubricating System, by

application of the electronic control

device, can rapidly inject the oil at

optimum timing

and can eventually save consumption of cylinder oil by

about 30% compared with a

conventional

mechanical lubricating system. This highperformance lubricating system

can easily be installed on existing engines.

When the system is installed

o n

t h e

10K9OMC engine, the initial

investment cost

will be repaid in

economy.

Principal particulars

Length (o.a.):

241.03m

Breadth (mld.):

42.00m

Depth (mld.):

21.20m

Draft (mld.):

14.90m

Gross tonnage:

57,000t

Deadweight:

105,500t

Main engine: Hitachi B&W 6S60MC

diesel x 1 unit

MCR:

16,003ps x 101rpm

NOR:

14,398ps x 97.5rpm

Speed (max. trial):

15.77 knots

(service):

abt. 14.50 knots.

Complement:

32

Classification:

BV

Cargo pump:2,500 m3/h x 135 m T.H.

x 3 units

Loading capacity (tank):122,116.5 m3

about 2 years, thus reducing the operational cost of the ship.

MES has obtained orders for about

40 units, of which seven are already

installed on ships. MES has a worldwide service network for Alpha Lubricating System in close cooperation

with MAN B&W to offer quick service all over the world.

Alpha lubricating system (main unit)

No. 297 Feb. - Mar. Page 5

Industry News in Brief

Sanoyas completes Panamax bulk carrier Orange Tiara

Sanoyas Hishino Meisho Corp. has

completed the Panamax bulk carrier,

Orange Tiara (HN: 1202), which was

ordered by Handbell Shipping S. A.

and delivered to Esmeralda Lines,

S.A., at the Mizushima Works and

shipyard.

The carrier is the 12th Sanoyas

75,000DWT type Panamax bulker

with the maximum beam permitted

to pass through the Panama Canal.

The cargo space is divided into seven

cargo holds with topside tanks and

hopper bottoms. Hydraulic, motordriven, side-rolling hatch covers are

used, and hatch openings are maximized to facilitate cargo handling.

The main engine is a low-speed,

super long-stroke, two cycle diesel

engine, which is combined with a large

diameter propeller to achieve efficient

operation with low fuel consumption.

The Orange Tiara is a highly economical Panamax bulker with the largest

deadweight available and excellent

propulsion performance.

Principal particulars

L (o.a.) x B x D x d: 225.00m x 32.26m

x 19.30m x 13.994m

DWT/GT: 75,846mt/38,871t

To our readers

Please notify us of any change in

address by letter or telefax together with the old mailing label

to ensure you continue to receive

SEA-Japan.

We welcome your comments

about SEA-Japan. Please address

all correspondence to the Japan

Ship Exporters' Association

(JSEA), or the Japan Ship Centre in London.

Address (Tokyo): 15-16,

Toranomon 1-chome, Minatoku, Tokyo 105-0001 / Tel: (03)

3508-9661 Fax: (03) 3508-2058

E-mail: postmaster@jsea.or.jp

Address (London): Ground

Floor, 9 Marshalsea Road, London SE1 1EP, UK / Tel: +44 (0)

20 7403 1666 / Fax: +44 (0) 20

7403 1777

E-mail: info@jsc.org.uk

URL: http://www.jsc.org.uk

Main engine: MAN-B&W 7S50MC-C

diesel x 1 unit

MCR: 12,200ps

Cargo capacity (grain): 89,250m3

New automatization

component for

container cranes

developed

Target Scanning System (TSS)

Mitsui Engineering & Shipbuilding

Co., Ltd. (MES) has developed a Target Scanning System that is a component technology to automate onshore

operation of container cranes. It has

been proved that the system is effective to detect targets and facilitate

crane operation, reducing the load on

the operator.

TSS can scan objects three-dimensionally by sensors with laser beams.

Position and attitude of objects (chassis, containers, AGVs, etc.) are detected to permit automatic operation of the

crane. This system can

be used for semiautomatic manned operation as a guidance system to position the crane

spreader right over a

chassis.

Main features:

The scanning sensor

consists of a laser range

finders, two-axis mov-

Speed, service: 14.5kt

Classification: NK

Complement: 25

able mirrors, and control units. Scanning is achieved by revolving laser

beams that target containers, chassis,

and AGVs. Three-dimensional appearance of the object is obtained, and

based on this information, distance

and posture of the target are computed

as output data.

The system is not affected by rain

due to the ingenious data processing

procedure. When using TSS, crane operation on the shore can be automatically achieved, leaving the operator

cabin suspended over the ship. This

reduces fatigue of the operator, facilitating container handling. When TSS

is used as the guidance system to set

the position of the crane spreader over

chassis in semi-automatic operation

on the shore, the time required for positioning is shortened.

No. 297 Feb. - Mar. Page 6

Shipyard Activities

GALLINA

Koho I

Owner: Nestor Lines S.A.

Builder: IHI Marine United Inc.

Hull No.: 3160

Ship Type: Oil Tanker

L(o.a.) x B x D x d: 333m x 60.00m x

29.50m x 21.428m (ext.)

DWT/GT: 301,045mt/154,260t

Main Engine: DU-Sulzer 7RTA84T

Speed, service: 16.15kt

Classification: NK

Completion: November 21, 2002

Althea Gas

Owner: I. S. Carriers S. A.

Builder: Kawasaki Shipbuilding Corporation

Hull No.: 1515

Ship Type: LPG carrier

L(o.a.) x L (b.p.) x B x D x d:

227.00m x 216.62m x 36.00m x

21.90m x 11.60m

DWT/GT: 53,677t/46,393t

Cargo hold capacity: 82,488m3

Main Engine: Kawasaki MAN B&W

5S70MC MkVI diesel x 1 unit

Speed, service: 17.0kt

Classification: ABS

Completion: Jan. 27, 2003

Owner: Shell Bermuda (Overseas)

Limited

Builder: Mitsubishi Heavy Industries, Ltd.

Hull No.: 2173

Ship Type: LNG Carrier

L(o.a.) x L (b.p.) x B x D x d:

290.00m x 46.00m x 25.50m x

11.00m

DWT/GT: 68,696t / 111,459t

Main Engine: Mitsubishi MS32-2

Speed, service: 19.0kt

Classification: LRS

Completion: Dec. 27, 2002

Front Page

Owner: Front Saga Inc.

Builder: Universal Shipbuidling

Corp.

Hull No.: 4980

Ship Type: Double-hull VLCC

L(o.a.) x B x D x d: 329.99m x 60.00m

x 29.70m x 21.50m

DWT/GT: 299,164t/156,916t

Main Engine: Hitachi Zosen MAN

B&W 7S80MC diesel x 1 unit

Speed, service: 16.2kt

Classification: ABS

Completion: Sept. 30, 2002

Balder

Peneda

Owner: Peneda Shipping Company

Sociedade Portuguesa de Navios

Tangues, S. A.

Builder: Sumitomo Heavy Industries, Ltd.

Hull No.: 1289

Ship Type: Aframax tanker

L(o.a.) x L (b.p.) x B x D x d:

239.00m x 229.00m x 42.00m x

21.30m x 12.19m

DWT/GT: 105,538t/56,255t

Main Engine: DU-Sulzer 6RTA58T

diesel x 1 unit

Speed, service: abt. 14.95kt

Classification: DNV

Completion: Oct. 31, 2002

Owner: Klaveness Shipping AS

Builder: Oshima Shipbuilding Co.,

Ltd.

Hull No.: 10302

Ship Type: Self-unloading, doublehull bulk carrier

L(o.a.) x B x D x d: 189.99m x

32.26m x 16.67m x 11.724m

DWT/GT: 30,739t/48,184t

Main Engine: Kawasaki MAN B&W

6S50MC-C diesel x 1 unit

Speed, service: 14.5kt

Classification: DNV

Completion: May 13, 2002

Prepared and edited by Eureka International Inc.

Printed in Japan

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Sea 302Document6 paginiSea 302PetricaÎncă nu există evaluări

- Marine Engines CatalogDocument39 paginiMarine Engines CatalogMuhamad Sidiq Fanani67% (3)

- Sea 301Document6 paginiSea 301PetricaÎncă nu există evaluări

- Sea 300Document6 paginiSea 300PetricaÎncă nu există evaluări

- Sea 299Document6 paginiSea 299PetricaÎncă nu există evaluări

- Sea 298Document6 paginiSea 298PetricaÎncă nu există evaluări

- Sea 296Document6 paginiSea 296PetricaÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- IO0085 The Mary Celeste1Document1 paginăIO0085 The Mary Celeste1Bel EscanesÎncă nu există evaluări

- Y&B Design - The Disgn of BoatsDocument66 paginiY&B Design - The Disgn of BoatsEuclides Cagnini100% (1)

- Atlantico: Deck Machinery IdentificationDocument1 paginăAtlantico: Deck Machinery Identificationluis eduardoÎncă nu există evaluări

- Inspection Test Record (Itr) - A Jacket Post Loadout ST09-ADocument1 paginăInspection Test Record (Itr) - A Jacket Post Loadout ST09-AMomo ItachiÎncă nu există evaluări

- Ships,: Being A List of Common Vessels of The Era, Their Capaci-Ties, Armament, and RigDocument21 paginiShips,: Being A List of Common Vessels of The Era, Their Capaci-Ties, Armament, and Rigduchessjack100% (1)

- Humphree Course StabilisingDocument8 paginiHumphree Course StabilisingMatÎncă nu există evaluări

- Trailing Suction Hopper Dredger OranjeDocument2 paginiTrailing Suction Hopper Dredger OranjeAthanasius Kurniawan Prasetyo AdiÎncă nu există evaluări

- Contingency PlanningDocument18 paginiContingency PlanningAkash KandwalÎncă nu există evaluări

- Ttnu-239615-7 HistoryDocument1 paginăTtnu-239615-7 HistoryHaseeb AhsenÎncă nu există evaluări

- Internship ReportDocument10 paginiInternship ReportAbel Ebin0% (1)

- The First Hybrid CRP-POD Driven Fast ROPAX Ferry (Paper)Document5 paginiThe First Hybrid CRP-POD Driven Fast ROPAX Ferry (Paper)pal_malayÎncă nu există evaluări

- Piri Reis University Maritime Higher Vocational School 2021-2022 AUTUMN TERM Computer Aided Ship Geometry (GIN2071)Document10 paginiPiri Reis University Maritime Higher Vocational School 2021-2022 AUTUMN TERM Computer Aided Ship Geometry (GIN2071)Mert EsitÎncă nu există evaluări

- Boat SpecificationDocument3 paginiBoat SpecificationDSDSDÎncă nu există evaluări

- BosunDocument182 paginiBosunnavigator1977100% (1)

- C - 3.1 Timber CargoDocument9 paginiC - 3.1 Timber CargoНикита НовикÎncă nu există evaluări

- SSL Gujarat Ship PerticularDocument3 paginiSSL Gujarat Ship Perticularprabu680Încă nu există evaluări

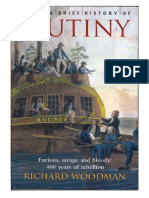

- A Brief History of Mutiny - Richard WoodmanDocument82 paginiA Brief History of Mutiny - Richard WoodmanOtto Heinrich WehmannÎncă nu există evaluări

- SVR Part 5C1 e PDFDocument872 paginiSVR Part 5C1 e PDFChristian Rodrigo Gonzalez CockbaineÎncă nu există evaluări

- Cv. Rai Rynaldo Februari 2023Document2 paginiCv. Rai Rynaldo Februari 2023ikhzan cadetÎncă nu există evaluări

- Pontoon BoatsDocument3 paginiPontoon BoatsRachmat Hidayat SapwariÎncă nu există evaluări

- Problems On Coefficients (Naval Architecture)Document3 paginiProblems On Coefficients (Naval Architecture)James67% (3)

- Appendix 1 868 Ballast Water Reporting FormDocument1 paginăAppendix 1 868 Ballast Water Reporting Formapi-26251207100% (1)

- Asymmetrical Asymmetrical: Ex T Ax Ret Ail Price List A12-1 - Grand'LargerangeDocument7 paginiAsymmetrical Asymmetrical: Ex T Ax Ret Ail Price List A12-1 - Grand'LargerangeGiacomo Marco ToigoÎncă nu există evaluări

- MaritimeSecurity CheckOnlineForLatest 20200926 10535885Document178 paginiMaritimeSecurity CheckOnlineForLatest 20200926 10535885Win Myint Thein100% (1)

- REP2 Rules For Ships - Part B Vol.1 1.1.2022Document106 paginiREP2 Rules For Ships - Part B Vol.1 1.1.2022Alessandro CitroÎncă nu există evaluări

- Beluga 1Document1 paginăBeluga 1Pedro GalinzogaÎncă nu există evaluări

- Port of Poro: Poro, Camotes Island, CebuDocument9 paginiPort of Poro: Poro, Camotes Island, CebuAldrin CabrigaÎncă nu există evaluări

- (B) Unit 2Document43 pagini(B) Unit 2crystalÎncă nu există evaluări

- Juan Carlos I (L61) Landing Helicopter Dock All-Round Warship, SpainDocument15 paginiJuan Carlos I (L61) Landing Helicopter Dock All-Round Warship, SpainhindujudaicÎncă nu există evaluări

- Deck Machinery PartsDocument3 paginiDeck Machinery Partsmihat jasneyÎncă nu există evaluări