Documente Academic

Documente Profesional

Documente Cultură

185 190 Ivk3 2012 VMM BG Na TM

Încărcat de

Lluís Vidales SerresTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

185 190 Ivk3 2012 VMM BG Na TM

Încărcat de

Lluís Vidales SerresDrepturi de autor:

Formate disponibile

Vesna O. Miloevi-Miti1, Branka Gaea2, Nina M. Aneli1, Tako .

Maneski1

NUMERICAL CALCULATION OF THE WATER-TUBE BOILER USING FINITE ELEMENT

OF THE ORTHOTROPIC PLATE

NUMERIKI PRORAUN VODENOG CEVNOG KOTLA PRIMENOM KONANIH

ELEMENATA ORTOTROPNE PLOE

Originalni nauni rad / Original scientific paper

UDK /UDC: 621.18:519.673

Rad primljen / Paper received: 21.09.2012.

Adresa autora / Author's address:

1)

University of Belgrade, Faculty of Mechanical Engineering, Belgrade, Serbia, vmilosevic@mas.bg.ac.rs

2)

J.CHRISTOF d.o.o, Bulevar Mihajla Pupina 10, Novi

Beograd, Serbia

Keywords

water-tube boiler

temperature

membrane wall

orthotropic plate

stress field

Kljune rei

vodocevni kotao

temperatura

membranski zid

ortotropna ploa

naponsko polje

Abstract

Izvod

Norms handle the issues concerned with calculation of

pressurized boiler components, however not considering

the influences of thermal strains. Application of FEM in

boiler design is suggested in calculating all components

that are not covered by the norm. Detailed numerical

calculation of the water-tube boiler type VU60-Minel

Kotlogradnja is presented in the paper. Stress and strain

fields are obtained based on numerical models for various

types of loading. The influences of the over-pressure and

thermal loading are discussed. Distribution of membrane

and bending stresses for substructures and distribution of

deformation energy are involved in the analysis. Membrane

walls (tube panels) of the water-tube boilers are exposed to

large loads. They are modelled using elements of a thin

orthotropic plate. The influence of the buck-stays on the

structural behaviour is discussed.

Norme uglavnom pokrivaju proraun delova pod pritiskom, ali uglavnom bez uticaja termikih optereenja. Primena metode konanih elemenata predlae se pri proraunu svih komponenti koje norme ne obuhvataju. U radu je

prikazan detaljan numeriki proraun vodocevnog kotla

tipa VU60 Minel Kotlogradnja. Na osnovu numerikih

modela odreena su polja napona i deformacija za razliita

optereenja. Razmatran je uticaj natpritiska i termikog

optereenja. Primenjeni su i parametri dijagnostike vrstoe kao to su raspodela membranskih i savojnih napona

po podstrukturama i raspodela energije deformacije. Membranski zidovi (cevni paneli) vodocevnih kotlova izloeni su

veoma velikim optereenjima. Modelirani su elementima

tanke ortotropne ploe. Razmotren je uticaj pojaseva ukruenja na ponaanje konstrukcije kotla.

considered in /6/. A recent approach in the estimation of

boiler integrity using FEM on vertical superheater is presented in /7/. The methodological approach for the state

analysis of the boiler pipe system in the case of hot-water

boiler VKL50 and methods for testing the parent metal and

welded joints are presented in /8/. Distance in thermal

dilatations on the coupled components of the steam boiler

can lead to large plastic deformation /9/ and to the increase

of dynamic strength. Membrane walls can be modelled

using finite elements of thin orthotropic plate /10/. This

gives a decrease in nodal points and elements of the global

model of the boiler structure and a decrease in calculation

time /11/.

The methodology of condition and behaviour diagnostics

for boiler structures which has been necessary to perform in

order to make a decision on further operation is presented

in /12/. An algorithm is defined that illustrates methods for

collecting data needed for diagnostics. During exploitation

the boiler state can be evaluated by comparing to the initial

stress state. The obtaining of the initial stress state of boiler

tubes for structural integrity assessment is shown in /13/.

INTRODUCTION

Norms such as EN 12952-3 and EN 12953-3 /1/ give

exact rules for calculation of pressurized elements in boiler

structures, they define allowed stresses for a given temperature and bring formulas for strength calculation. Norms do

not explicitly consider the influence of thermal stresses and

local stress-concentration. This problem can be solved with

the application of the finite element method-FEM.

Taljat et al. /2/ had done thermomechanic analysis for

membrane walls of composite tubes for the black liquor

recovery boiler. The problem of contraction of the

membrane wall during sedimentation of stainless-steel on

damaged panel is considered in /3/. A proposal for partial

replacement of boiler wall-tubes is defined in /4/ and a

sequence of service recommendations how to prevent the

appearance of wall tubing damage was also given. In /5/ it

was presented that temperature is the most important factor

in failure investigation on deformed horizontal super-heater

tube. The influence of welded shanks between super heatertubes on the high temperature stresses near the welds is

INTEGRITET I VEK KONSTRUKCIJA

Vol. 12, br. 3 (2012), str. 185190

185

STRUCTURAL INTEGRITY AND LIFE

Vol. 12, No 3 (2012), pp. 185190

Numerical calculation of the water-tube boiler using finite

Numeriki proraun vodenog cevnog kotla primenom konanih

Water-tube boilers have a large capacity and they are

designed for high steam pressures and temperatures. Membrane walls are stiffened with buck-stays placed to prevent

large wall deformations. FEM-modelling and analysis are

usually applied for individual components, without modelling of a global boiler structure. In the paper, a numerical

model of the global structure of the water-tube boiler type

VU60 is presented, as well as the results for deformation

and stress fields obtained by a numerical procedure.

CHARACTERISTICS OF THE WATER-TUBE BOILER

The next calculation is presented for the stress and strain

state of the steam water-tube boiler with two drums fabricated by Minel Kotlogradnja Belgrade /14/. The boiler

operates in the over-pressure condition.

Maximal permanent steam production is 110 t/h and the

short overloading (max. two hours) was 121 t/h. The highest

over-pressure in the upper drum was 55 bar. Over pressure

in the lower drum was 51 bar and the appropriate water

temperature 271C. On the outlet fitting, steam overpressure was 44.6 bar and temperature 412C. Basic dimensions of boiler are: length 9104 mm, width 4896 mm and

distance between upper and lower drum 10975 mm. Upper

(steam) drum was placed at 13475 mm height and had

external radius of 1700 mm. The lower (water) one was at

2500 mm with external diameter of 1000 mm. The boiler

had buck-stays on lateral walls at 5548 mm and at 9148 mm

height, as well as flanges on the floor and on the ceiling.

The boiler consisted of following structures: tube system

of membrane walls (exposed evaporator), collectors with

appropriate tubes, tube colander, tubes between drums (convectional evaporator), upper drum, lower drum, super-heater,

economizer, buck-stays, isolation, steel construction with

galleries, armature and equipment of the boiler.

Steam super-heater is of bilateral type. Because of the

construction it was separated from the boiler and analysed

as an individual structure.

MODELLING OF THE MEMBRANE WALLS

The membrane wall of the water-tube boiler type VU60

is consisted of tubes diameter 71.6 mm and thickness

4.5 mm with weldments thickness 6 mm. Tube distance is

102 mm. Elastic characteristics of the steel for temperature

T = 321C are: modulus of elasticity E = 18300 kN/cm2 and

Poissons ratio = 0.328.

In the numerical finite element model of the water-tube

boiler, the membrane wall can be modelled using the finite

element of the reduced orthotropic plate. For this type of

finite element, the reduced elasticity matrix is obtained and

involved in the calculation as presented in /10/ and /11/.

MODELS FOR CALCULATION

a) membrane wall

In the paper the influence of the buck-stays on the

strength of the boiler structure is analysed. The load is

divided in three parts: pressure load, thermal load and

weight of the construction. According to that, five models

are formed and discussed:

Model U1, has no buck-stays; pressure and thermal load,

Model U2, buck-stays; pressure and thermal load,

Model U3, buck-stays; pressure and thermal load, weight,

Model U4, buck-stays; only pressure load,

Model U5, buck-stays; only thermal load.

The basic geometry of the global model U2 is presented

in Fig. 2 using three projections. The whole structure of the

boiler is formed using 8385 nodal points, 3747 beam and

5638 plate finite elements.

Substructures of the global model are signed as:

upper and lower drum with the supports,

B membrane walls,

C sections and flanges of the busk-stays,

D collectors with supports, tubes,

E fictive beams.

Substructures A, B and C are formed using plate finite

elements, while substructures D and E are formed using

beam finite elements.

Membrane walls (substructure B) are important structural parts for strength analysis of water-tube boiler. They

can be modelled using finite element of an orthotropic plate

which leads to decreasing in node and element numbers of

the global boiler model and a reduction in calculation time.

For this kind of finite element, a reduced elasticity matrix is

obtained.

b) plate

Figure 1. Membrane-wall and reduced orthotropic plate.

Slika 1. Membranski zid i redukovana ortotropna ploa

For the presented example of the membrane wall

(Fig. 1a), the elasticity matrix for the reduced orthotropic

plate thickness of 3 cm (Fig. 1b) has the following form:

for membrane load

0

6832 27

kN

27 82

,

(1)

0

cm2

0 6890

0

for bending load

0

24406 98

kN

98

.

(2)

367

0

cm2

0

0

6890

In the same way, for plate thickness of 1 cm, the elasticity matrix for membrane load has the form

0

20530 82

kN

82

.

(3)

247

0

cm2

0

0

6890

For the other type of membrane-wall the whole procedure for obtaining elasticity matrix is performed.

INTEGRITET I VEK KONSTRUKCIJA

Vol. 12, br. 3 (2012), str. 185190

186

STRUCTURAL INTEGRITY AND LIFE

Vol. 12, No 3 (2012), pp. 185190

Numerical calculation of the water-tube boiler using finite

Numeriki proraun vodenog cevnog kotla primenom konanih

Figure 3. Deformation of the plate elements; Model U1.

Slika 3. Deformacije elemenata ploe; model U1

Figure 2. Model for calculation signed as U2.

Slika 2. Model za proraun oznaen kao U2

Geometry characteristics of beam cross-sections (substructures D and E) are analytically obtained and involved in the

finite element calculation.

Loading

The calculation was done for over-pressure of 55 bar in

the upper drum and 55.8 bar in the lower one. Over-pressure of 23.4 mbar is adopted in the chamber, while temperatures of the structural parts are adopted according to

EN norms and SRPS M.E2.030. So, assumed temperature

of the exposed walls is 321C and 296C of the convective

evaporator. The temperature of the walls under the pressure

is adopted as 271C. The referent temperature is assumed

as 20C.

Figure 4. Deformation of the plate elements; Model U2.

Slika 4. Deformacije elemenata ploe; model U2

STRESS AND STRAIN ANALYSIS

Deformations

Numerical calculation is done using the programme

package KOMIPS /15, 16/.

The Deformation field for plate elements of Model U1

without busk-stays is presented in Fig. 3. Maximal calculated value is fmax = 10.8 cm. This case of construction had

great deformations of lateral walls induced by over-pressure.

Appropriate deformation of the Model U2 is shown in

Fig. 4. As could be noticed, the maximal calculated value is

only 4.9 cm. Buck-stays had dimidiated deformations of the

membrane-walls.

Deformations of substructures formed using beam finite

elements are presented in Fig. 5. On the model with buckstays (U2) the dominant influence on the deformation field

was the thermal load.

INTEGRITET I VEK KONSTRUKCIJA

Vol. 12, br. 3 (2012), str. 185190

Figure 5. Deformation of beam elements; Model U2.

Slika 5. Deformacije elemenata nosaa; model U2

187

STRUCTURAL INTEGRITY AND LIFE

Vol. 12, No 3 (2012), pp. 185190

Numerical calculation of the water-tube boiler using finite

Numeriki proraun vodenog cevnog kotla primenom konanih

Stress field

The same analysis of Model U3 with added weight of the

boiler structure showed that the stress field was similar to

the case of the previous Model U2. Maximal stress was

20 kN/cm2.

The equivalent stress is obtained by using the HuberHacky-Misses hypothesis.

The stress field, from 0 to 55.8 kN/cm2, step 2 kN/cm2,

in the plates of model U1 without buck-stays is presented in

Fig. 6. The obtained maximal value due to thermal and

pressure load is higher then the tension solidity of the material. So, this type of a structure is unfavourable.

DISTRIBUTION OF MEMBRANE AND BENDING

STRESS DEFORMATION ENERGY

Distribution of membrane (shear) stress and bending stress

/16/ over the beam and plate finite elements of models U1

and U2 is presented in Table 1. As could be noticed, buskstays gave better behaviour in the boiler structure.

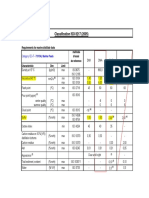

Table 1. Fractions of memb. and bend. stresses in plates and beams.

Tabela 1. Udeli membr. i savojnih napona u ploama i nosaima

kN/cm2

Model

U1

U2

Membrane and bending stress (%)

Plates

Beams

membrane

bending

membrane

bending

32.0

68.0

25.8

74.2

53.1

45.9

60.4

39.6

Detailed distribution over substructures is given in Table 2.

Membrane stress is present in plates of the upper (A1) and

lower (A2) drum, as well as in their heads and supports

(A3). In water-tube panels of membrane walls (B) the bending stress is dominant for Model U1. Model U2 has a better

stress distribution. In plates of buck-stays (C) the membrane

stress is dominant in case of Model U2. In tubes formed of

beam finite elements (D) the stress is in the same relation in

both models.

Figure 6. Equivalent stress 055.8/2 kN/cm2 of Model U1.

Slika 6. Ekvivalentni napon 055,8/2 kN/cm2 modela U1

Table 2. Distribution of a deformation energy. Stress distribution

over substructures.

Tabela 2. Raspodela deformacione energije. Raspodela napona u

podstrukturama.

The stress field, from 0 to 19.9 kN/cm2, step 1 kN/cm2,

in the plates of model U2 with buck-stays is presented in

Fig. 7. Maximal stress based on thermal and pressure loading of 19.9 kN/cm2 is located in horizontal plates of buckstays, at boiler corners. In lateral walls, stress concentration

gave the value of 17 kN/cm2. In the membrane walls near

the boiler corners, the stress was about 16 kN/cm2.

Substr

A1

A2

A3

B

C

D

E

kN/cm2

Mem. and bend. stress (%)

Model U1

Model U2

mem. bend mem. bend

8.4

0.9

8.9

1.0

5.4

1.2

5.8

1.2

11.5

8.1

12.2

8.6

5.0

54.2

7.6

24.1

13.2

5.3

1.4

3.9

1.4

3.4

5.8

1.5

31.7 68.3 54.9 45.1

100

100

Deformation energy (%)

Model U1

Model U2

28.5

8.2

4.8

35.8

22.7

100

27.7

7.7

4.6

35.1

5.4

18.7

0.8

100

Distribution of deformation energy through sub-structures for both models U1 and U2 is presented in Table 2.

The highest value is in the upper drum (A1) and part of the

boiler ceiling with walls of chamber (B). The energy distribution is presented in Fig. 8 for plates of Model U2.

STRESS UNDER PRESSURE AND THERMAL LOAD

The equivalent stress field in plates of model U4 (only

pressure load) is shown in Fig. 9. The stress concentration

is presented in the covers of both drums.

The same analysis is made for Model U5 loaded only by

temperature. The obtained results are presented in Fig. 10.

As a result of thermal load, a stress concentration in plates

of buck-stays placed on boiler corners and in plates of

membrane walls appeared.

Figure 7. Equivalent stress 019.9/1 kN/cm2 of Model U2.

Slika 7. Ekvivalentni napon 019,9/1 kN/cm2 modela U2

The value of the maximal obtained stress in the beams of

Model U2 is 13 kN/cm2. In the tubes of the lower collector

the stress was 5.5 kN/cm2, while in collectors it was

3.7 kN/cm2.

INTEGRITET I VEK KONSTRUKCIJA

Vol. 12, br. 3 (2012), str. 185190

188

STRUCTURAL INTEGRITY AND LIFE

Vol. 12, No 3 (2012), pp. 185190

Numerical calculation of the water-tube boiler using finite

Numeriki proraun vodenog cevnog kotla primenom konanih

CONCLUSION

Obtained results show the great influence of buck-stays

on the boiler behaviour. Buck-stays had reduced the deformation and equivalent stress in membrane walls due to

over-pressure loading. Distribution of membrane and bending stress is much favourable especially in the lateral sides

of the chamber.

Maximal obtained equivalent stress due to the pressure

and thermal loading (Model U2) is 19.9 kN/cm2 and it is

located in plates of the buck-stays on boiler corners. The

yield stress for the appropriate material P235GH at the

estimated temperature is 13 kN/cm2 (SRPS EN 10028-2).

So, plastic deformation could be expected.

In membrane walls of the boiler, the calculated maximal

stress is about 17 kN/cm2. As membrane walls are formed

using finite elements of an orthotropic plate, the obtained

stress values are average. For the material of the wall-tubes

(P235GH) at temperature 321C, the yield stress is

12.7 kN/cm2 (SRPS EN 10216-2) and for the material of

the flanges (16Mo3) it is 15.2 kN/cm2. So, small plastic

deformation can be expected in some places of membrane

walls. The maximal stress in beam elements is about

13 kN/cm2, close to the value of yield stress in these

elements.

The equivalent stress in the lower drum is 17.5 kN/cm2,

less than yield stress 22.7 kN/cm2 (P355GH) at temperature

of 271C.

The presented analysis showed that the high level of

stress in plates on boiler corners is the consequence of the

inhibition of thermal dilatations. So, the geometry of buckstays is unfavourable and needs reconstruction.

kNcm

Figure 8. Deformation energy distribution in plates of Model U2.

Slika 8. Raspodela deformacione energije u ploama modela U2

ACKNOWLEDGEMENTS

This work is a contribution to the Ministry of Science

and Technological Development of Serbia funded projects

TR 35040 and TR 35011.

Figure 9. Equivalent stress 017.6/1 kN/cm2 in plates of model U4.

Slika 9. Ekvivalentni napon 017,6/1 kN/cm2 u ploama modela U4

REFERENCES

1. European standards: EN 12952-3:2001, Water-tube boilers and

auxiliary installations-Part 3: Design and calculation for pressure parts; EN 12953-3:2002, Shell boilers-Part 3: Design and

calculation for pressure parts.

2. Taljat, B., Zacharia, T., Wang, L., Keiser, J.R., Swindeman, R.W.,

Hubbard, C.R., Mechanical Design of Steel Tubing for Use in

Black Liquor Recovery Boiler, Proc. of 9th Int. Symp. on Corrosion in the Pulp and Paper Industry, Vancouver, Canada

(1998), pp.193-197.

3. Mac Lean, K., Fournier, E., Gomez-Grande, J., Scandroli, T.,

The Worlds Largest Inconel Waterwall Weld Overlay,

Power Engineering (Barrington), 13, No.11 (2010).

4. ijaki eravi, V., Baki, G., uki, M., Andjeli, B., Analysis of test results of hot-water boiler as a basic for its integrity

assessment, Structural Integrity and Life, 7 (2) (2007): 133-140

5. Othman, H., Purbolaksono, J., Ahmad, B., Failure Investigation

on Deformed Superheater Tubes, Engineering Failure Analysis,

16, No1 (2009) pp.329-339.

6. Caligiuri, R., Foulds, J., Sire, R., Andrew, S., Thermal Constraint Consideration in Design of a Heat Recovery Boiler,

Engineering Failure Analysis, 13, No 8 (2006) pp.1388-1396.

Figure 10. Equivalent stress 022.6/1 kN/cm2 in plates of model U5

Slika 10. Ekvivalentni napon 022,6/1 kN/cm2 u ploama modela U5

INTEGRITET I VEK KONSTRUKCIJA

Vol. 12, br. 3 (2012), str. 185190

189

STRUCTURAL INTEGRITY AND LIFE

Vol. 12, No 3 (2012), pp. 185190

Numerical calculation of the water-tube boiler using finite

Numeriki proraun vodenog cevnog kotla primenom konanih

7. Maneski, T., Sedmak, A., Burzi, Z., Gaea, B., Integritet

konstrukcije parnih kotlova, Proc of 33rd SMEITS, Belgrade

(2002) pp.327-333.

8. Arsi, M., Aleksi, V., Hut, N., Analysis of state and integrity

assessment of boilers Structural performance diagnostics,

Structural Integrity and Life, 5 (1) (2005) : 3-17.

9. Serti, J., Kozak, D., Konjati, P., Kokanovi, M., Analytical

and numerical investigation of the connecting pipes between

header and steam superheater, Proc of 6th Int Congress of

Croatian Society of Mechanics, Zagreb (2009) p.119.

10. Maneski, T., Miloevi-Miti, V., Gaea, B., Problems in the

Modeling of Steam Boilers, Proc of 1st Int Cong. of Serbian

Soc. of Mech. (2007) pp.451-456.

11. Miloevi-Miti, V., Gaea, B., Kozak, D., Maneski, T.,

Serti, J., Modeling of boiler membrane wall using finite

element of reduced orthotropic plate, Strojarstvo 54 (1) (in

press) (2012).

12. Gaea, B., Maneski, T., Miloevi-Miti, V., Condition and

Behaviour Diagnostics of Boiler Constructions, FME Transactions 40 (2) (2012) : 87-92.

13. Kurai, J., Burzi, Z., Gari, N., Zrili, M., Aleksi, B., Initial

stress state of boiler tubes for structural integrity assessment,

Structural Integrity and Life 7 (3) (2007) : 187-194.

14. Gaea, B., Doctoral thesis, University of Belgrade, Faculty of

Mechanical Engineering (2011).

15. Maneski, T., Computer modelling and calculation of structures, University of Belgrade, Faculty of Mechanical Engineering, Belgrade (1998).

16. Maneski, T., Miloevi-Miti, V., Numerical and experimental

diagnostics of structural strength, Structural Integrity and Life

10 (1) (2010) : 3-10.

Podseamo Vas da su detaljnije informacije o radu

Drutva za integritet i vek konstrukcija dostupne na Internetu

http://divk.org.rs ili/or http://divk.inovacionicentar.rs

We remind You that more detailed information on the activities of the

Society for Structural Integrity and Life are located on the Internet

INTEGRITET I VEK KONSTRUKCIJA

STRUCTURAL INTEGRITY AND LIFE

Zajedniko izdanje

Drutva za integritet i vek konstrukcija (DIVK) i

Instituta za ispitivanje materijala

Joint edition of the

Society for Structural Integrity and Life and

the Institute for Testing of Materials

http://divk.org.rs/ivk ili/or http://divk.inovacionicentar.rs/ivk/home.html

Cenovnik oglasnog prostora u asopisu IVK za jednu godinu

Advertising fees for one subscription yearper volume

Pomaui lanovi DIVK imaju popust od 40% navedenih cena.

DIVK supporting members are entitled to a 40% discount.

Kvalitet*Quality

Dimenzije * Dimensions (mm)

Cene u din.

EUR

Kolor*Colour

40.000

700

obe strane * two pages 2A4

strana * page A4/1

25.000

450

Dostava materijala: CD (Adobe Photoshop/CorelDRAW)

Submit print material: CD (Adobe Photoshop/CorelDRAW)

Crno/belo*Black/White

strana * page A4/1

12.000

250

8.000

150

str A4 * 1/2 page A4(1812)

Dostava materijala: CD (Adobe Photoshop/Corel DRAW)

Submit print material: CD (Adobe Photoshop/Corel DRAW)

INTEGRITET I VEK KONSTRUKCIJA

Vol. 12, br. 3 (2012), str. 185190

190

STRUCTURAL INTEGRITY AND LIFE

Vol. 12, No 3 (2012), pp. 185190

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Case 1088 Repair Manual (Crawler Excavator) PDFDocument971 paginiCase 1088 Repair Manual (Crawler Excavator) PDFrida100% (7)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Yuken HydraulicDocument24 paginiYuken HydraulicDian Pramadi100% (1)

- Liebhaber NESC 2017 ChangesDocument80 paginiLiebhaber NESC 2017 ChangesEdgar ZapanaÎncă nu există evaluări

- Valve Material ApplicationDocument16 paginiValve Material Applicationehab8320014413100% (1)

- Heat Exchanger Design Lecture - 07Document24 paginiHeat Exchanger Design Lecture - 07Mohmmad ShaikhÎncă nu există evaluări

- Fundamentals of Mechanical DesignDocument150 paginiFundamentals of Mechanical DesignMiguelDiazVÎncă nu există evaluări

- World Pump 2017 03Document51 paginiWorld Pump 2017 03Abshar ParamaÎncă nu există evaluări

- RACORDocument25 paginiRACORDaniel LaymeÎncă nu există evaluări

- Refining Process HBDocument296 paginiRefining Process HBsomucdm6023Încă nu există evaluări

- New Holland Engine F4ge Backhoe en Service ManualDocument10 paginiNew Holland Engine F4ge Backhoe en Service Manualenrique100% (47)

- Furnace Incident During DecokingDocument9 paginiFurnace Incident During DecokingMohamed Sayed AbdoÎncă nu există evaluări

- Cause Effect Analysis of Oil Loss in Edible Oil IndustryDocument60 paginiCause Effect Analysis of Oil Loss in Edible Oil IndustrySaurabh RaiÎncă nu există evaluări

- 320, 320L Medicion de Presiones Bomba Hidraulica PDFDocument181 pagini320, 320L Medicion de Presiones Bomba Hidraulica PDFrprim100% (2)

- May12 GSODocument4 paginiMay12 GSOLluís Vidales SerresÎncă nu există evaluări

- Coupling 2Document19 paginiCoupling 2tushar9810080Încă nu există evaluări

- Thermaloxidiser PDFDocument27 paginiThermaloxidiser PDFLluís Vidales SerresÎncă nu există evaluări

- Engineering, Construction: IPS-G-CE-250Document20 paginiEngineering, Construction: IPS-G-CE-250Lluís Vidales SerresÎncă nu există evaluări

- Install and maintain SAM turbo pumpsDocument17 paginiInstall and maintain SAM turbo pumpsJigyesh SharmaÎncă nu există evaluări

- Bref Cloro Sosa 288eb04f5f668e4fDocument178 paginiBref Cloro Sosa 288eb04f5f668e4fLluís Vidales SerresÎncă nu există evaluări

- Case Study Vent SizingDocument5 paginiCase Study Vent SizingLluís Vidales SerresÎncă nu există evaluări

- The Role of Stainless Steel in Petroleum RefiningDocument57 paginiThe Role of Stainless Steel in Petroleum RefiningfrlocatiÎncă nu există evaluări

- Buying Your First TelescopeDocument4 paginiBuying Your First TelescopeLluís Vidales SerresÎncă nu există evaluări

- Thermaloxidiser PDFDocument27 paginiThermaloxidiser PDFLluís Vidales SerresÎncă nu există evaluări

- Steam Cracker PDFDocument13 paginiSteam Cracker PDFLluís Vidales SerresÎncă nu există evaluări

- SSF Cooling TowersDocument30 paginiSSF Cooling TowersDhirendra Singh RathoreÎncă nu există evaluări

- Steam CrackerDocument13 paginiSteam CrackerLluís Vidales SerresÎncă nu există evaluări

- NI 0466 G EnglishDocument22 paginiNI 0466 G English1975.venkat7685Încă nu există evaluări

- Deepwater Training Seminar Presented ToDocument36 paginiDeepwater Training Seminar Presented ToSergio Jesus MarquezÎncă nu există evaluări

- Design and Generating Energy As A Car Alternator TDocument7 paginiDesign and Generating Energy As A Car Alternator TJohnny TestÎncă nu există evaluări

- MT Lab Final RecordDocument85 paginiMT Lab Final RecordPRABATH MADHAVANÎncă nu există evaluări

- Waste Water-Sewage PumpDocument111 paginiWaste Water-Sewage Pumpcharadeg100Încă nu există evaluări

- Model AR Ellipse® Annular Flow Meter PDFDocument2 paginiModel AR Ellipse® Annular Flow Meter PDFjhorlanÎncă nu există evaluări

- 4 - ch01 - SQ - E: Solutions MarksDocument37 pagini4 - ch01 - SQ - E: Solutions Marks5A35 YIP HOI PAKÎncă nu există evaluări

- Multidisciplinary Nature of Environmental StudiesDocument6 paginiMultidisciplinary Nature of Environmental StudiesWiz Calvin ManutdÎncă nu există evaluări

- DG Set SelectionDocument12 paginiDG Set SelectionDr. R. SharmaÎncă nu există evaluări

- EssayDocument3 paginiEssayKarina RamirezÎncă nu există evaluări

- Automatic Street Light Control Using LDRDocument39 paginiAutomatic Street Light Control Using LDRAyush Kumar100% (1)

- SOF National Science Olympiad 2018-19 GuidelinesDocument7 paginiSOF National Science Olympiad 2018-19 GuidelinesRahul SinhaÎncă nu există evaluări

- Classification ISO 8217 (2005)Document5 paginiClassification ISO 8217 (2005)Salah JallaliÎncă nu există evaluări

- Flat Roof 1Document10 paginiFlat Roof 1agent206Încă nu există evaluări

- Adelino Horizontal Multistage PumpDocument13 paginiAdelino Horizontal Multistage PumpJaved HasanÎncă nu există evaluări

- Hydrographic SurveyDocument24 paginiHydrographic SurveyKamal Veer100% (1)

- Electrical Properties of Materials Mod-1Document18 paginiElectrical Properties of Materials Mod-1Darshan rajÎncă nu există evaluări

- Ptmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportDocument23 paginiPtmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportPIYUSH GOPALÎncă nu există evaluări

- Xref 2010Document1 paginăXref 2010Axel Mahya AvichenaÎncă nu există evaluări

- 2563-Wireless Catalogue enDocument151 pagini2563-Wireless Catalogue enElafanÎncă nu există evaluări

- JP For RadiographyDocument7 paginiJP For Radiographytaparia_piyushÎncă nu există evaluări

- IFFCO Urea ProcesspdfDocument3 paginiIFFCO Urea ProcesspdfBalas43Încă nu există evaluări