Documente Academic

Documente Profesional

Documente Cultură

2835-Dies & Their Uses

Încărcat de

syllavethyjimDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2835-Dies & Their Uses

Încărcat de

syllavethyjimDrepturi de autor:

Formate disponibile

The ability to solder properly is an essential

requirement for every engineer.

In this article

GEOMETER explains the processes involved in .

SOFT

BEGINNERS

WORKSHOP

SOLDERING

HE SIMPLEST METHOD

Of jointing

metals is by soft soldering,

which can be performed by a

soldering iron or copper bit heated

in a flame or the domestic fire. A

variety of metals can be soldered

in this way, including brass, copper,

bronze, iron, steel, pewter and

lead, on which the beginner should

practise.

A typical soldering iron consists of

a copper bit on a steel shank in a

wooden handle. A common size

for the bit is about 3/4 in. square and

2-1/2 in. long.Larger sizes are used for

heavy work requiring much heat,

and smaller ones for fine work like

soldering wires.

Soldering irons may also be heated

electrically or from a gas supply.

These avoid the reheating process

which is essential when the ordinary

iron cools off.

Using blowpipes

Many classes of soldering and

tinning can be performed without

a soldering iron, using only a suitable

blowpipe. A simple blowpipe may

use gas and air from a foot bellows,

or small blower, or an oxy-acetylene

blowpipe, or torch, can be used with a

very small nozzle to keep down the

ordinarily fierce heat.

A mouth blowpipe can be used for

very small work. This consists of

a tapered tube ending in a very small

hole, and is held in the mouth to

blow a fine jet of flame from the flame

of a spirit lamp, the work to be

soldered being held in the hands.

Types of solder and fluxes

Solders consist of a mixture of pure

tin and lead, and sometimes antimony

to a proportion of not more than

six per cent. The tin/lead proportion

varies greatly from about 15 per

cent. tin and 85 per cent. lead, to

almost pure tin. For general purposes

29 SEPTEMBER 1955

a 50/50 solder of tin/lead is common.

Solders may be obtained as sticks,

wire, or in strips, cored with flux,

or plain.

Fluxes are the medium for causing

the molten solder to run and adhere

to the metals, and are usually necessary even after surfaces have been

well cleaned. Killed spirit or zinc

chloride can be used for most of the

metals mentioned in the first paragraph and a suitable preparation is

Bakers Soldering Fluid, obtainable

in tins. Tallow can be used for

pewter and lead. Paste fluxes are

also obtainable for general use, or

for electrical work.

Cleaning the metal

The surface to be soldered must be

perfectly clean, and this is effected

by scraping, filing or rubbing with

emery cloth. Only surfaces already

tinned will solder without preparation.

With the surface clean, a quantity of

flux is applied with a small brush or

strip of wood, and it is then ready

for tinning or soldering.

Tinning is performed by heating

the metal in a flame and applying

solder from a stick, the solder spreading, and being assisted in this by

further applications of flux as required.

will be burnt off; its faces should

then be filed clean, heated, dipped in

flux, and solder applied.

Typical operations

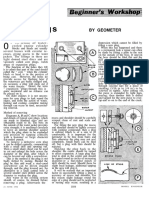

The drawing illustrates typical

operations. Before a cable is cut,

it should be soldered. (A). A frayed

cable may be bound and soldered (B).

Fillets should be formed at the edges

of joints and round nipples (C and D).

Solder may be placed as lumps in a

vessel, and this heated over a flame

to produce an internal fillet by revolving (E). A patch should be tacked

and held with a screwdriver while

soldering (F). A wire may be soldered

round the base of a metal jug to

absorb the wear (G).

q

-

Typical operations in soldering

.

Soldering details

Soldering can be carried out without

preliminary tinning, though the latter

process renders the work easier.

The iron is heated to a point where it

gives off a blue-green flame. It is

then dipped at the end in a small

quantity of flux in a jar, and is ready

to work. If only a small quantity of

solder is to be applied, the iron is

touched on the solder, then on the

work. Otherwise, both iron and solder

are applied to the work and moved

along the joint. It is important for

the solder really to flow along and

in the joint being made.

If an iron is overheated, the tinning

427

MODEL ENGINEER

S-ar putea să vă placă și

- 2836 Soft SolderingDocument1 pagină2836 Soft SolderingIvan Nugali ChocolatesÎncă nu există evaluări

- Welding A Cast IronDocument9 paginiWelding A Cast Ironjatin jainÎncă nu există evaluări

- Eme Mod2@Azdocuments - inDocument31 paginiEme Mod2@Azdocuments - inPratham BalikaiÎncă nu există evaluări

- Soft and Hard Soldering +brazingDocument28 paginiSoft and Hard Soldering +brazingJoseph Magbanua Dato-on67% (3)

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithDe la EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithÎncă nu există evaluări

- Welding of Nickel AlloysDocument4 paginiWelding of Nickel AlloysMuhammed SulfeekÎncă nu există evaluări

- Welding of Cast IronDocument35 paginiWelding of Cast IronincaurcoÎncă nu există evaluări

- SolderDocument11 paginiSolderahmedÎncă nu există evaluări

- Manuale Saldatura WellerDocument0 paginiManuale Saldatura WellerTorero CamomilloÎncă nu există evaluări

- Brazing ManualDocument2 paginiBrazing ManualKarin Aca OviÎncă nu există evaluări

- Tig RwtiDocument39 paginiTig RwtiSaptarshi PalÎncă nu există evaluări

- Welding of Cast IronDocument12 paginiWelding of Cast IronwalitedisonÎncă nu există evaluări

- 11 SolderingDocument11 pagini11 SolderingrameshÎncă nu există evaluări

- Unit 2: Manufacturing ProcessesDocument93 paginiUnit 2: Manufacturing Processesharshaggarwalofficial1Încă nu există evaluări

- Group 2 Cpe479Document35 paginiGroup 2 Cpe479Azike valentineÎncă nu există evaluări

- Brazing: Brazing Is A Joining Process Whereby A NonDocument23 paginiBrazing: Brazing Is A Joining Process Whereby A Nonshayan sohailÎncă nu există evaluări

- Govpub C13Document18 paginiGovpub C13amitsony9818Încă nu există evaluări

- Joining MethodsDocument15 paginiJoining MethodsAliyu Ibrahim SalihuÎncă nu există evaluări

- BME Joining ProcessesDocument11 paginiBME Joining ProcessesalysonmicheaalaÎncă nu există evaluări

- Soldering March IntakeDocument49 paginiSoldering March IntakeoriverbmwasotemwasoteÎncă nu există evaluări

- Cast Iron Welding ProcedureDocument2 paginiCast Iron Welding ProcedureAnand Kesarkar100% (1)

- ForgingDocument50 paginiForgingdeepakr93100% (1)

- Welded Joints Welded Joints: Vedat Temiz Assistant Professor of Machine DesignDocument34 paginiWelded Joints Welded Joints: Vedat Temiz Assistant Professor of Machine DesignRam RanjanÎncă nu există evaluări

- Experiment No. 5: 1. SolderingDocument4 paginiExperiment No. 5: 1. SolderingArun kumar rouniyarÎncă nu există evaluări

- UTP Brazing Filler MetalsDocument8 paginiUTP Brazing Filler MetalsIvan Dulic100% (1)

- Unusual, Given The Brittle Nature of Most Cast Iron.: Electrode SelectionDocument2 paginiUnusual, Given The Brittle Nature of Most Cast Iron.: Electrode SelectionparmindersinÎncă nu există evaluări

- Welding of Aluminum: Cast Iron Welding Practice: Jobs 9-J45 and J46Document6 paginiWelding of Aluminum: Cast Iron Welding Practice: Jobs 9-J45 and J46Willy UioÎncă nu există evaluări

- Soldering - TLEDocument2 paginiSoldering - TLELady StaAnaÎncă nu există evaluări

- Guide Cast Iron WeldingDocument8 paginiGuide Cast Iron WeldingAgustine SetiawanÎncă nu există evaluări

- Basic Mechanical - Engineering-Soldering Brazing and WeldingDocument10 paginiBasic Mechanical - Engineering-Soldering Brazing and WeldingRavichandran GÎncă nu există evaluări

- Welding: IntrdutionDocument10 paginiWelding: IntrdutionJoseph George KonnullyÎncă nu există evaluări

- Manufacturing TechniquesDocument7 paginiManufacturing TechniquesKanak KhandelwalÎncă nu există evaluări

- Copper AlloysDocument4 paginiCopper AlloysMuhammed SulfeekÎncă nu există evaluări

- ProjectDocument34 paginiProjectSTAR PRINTINGÎncă nu există evaluări

- Flux-Core Solder : Flux Reducing Agent ReduceDocument86 paginiFlux-Core Solder : Flux Reducing Agent ReduceIonut Ciprian CojocaruÎncă nu există evaluări

- Soldering TutorialDocument15 paginiSoldering Tutorialyrikki100% (1)

- Bohler - Manual de Reparatii Prin SuduraDocument53 paginiBohler - Manual de Reparatii Prin Suduracostelino72100% (1)

- WELDINGDocument36 paginiWELDINGSOURABH GANGWARÎncă nu există evaluări

- Braze Welding and Advanced Gas Welding Practice:: Jobs 9-J39-J49Document6 paginiBraze Welding and Advanced Gas Welding Practice:: Jobs 9-J39-J49Willy UioÎncă nu există evaluări

- SolderingDocument7 paginiSolderingjitendrakitawatÎncă nu există evaluări

- April 25, 1967 E. M. Kent 3,315,350: Method of Manufacturing Repla Ceable Soldering Iron TipsDocument3 paginiApril 25, 1967 E. M. Kent 3,315,350: Method of Manufacturing Repla Ceable Soldering Iron TipsChristofer HairichiÎncă nu există evaluări

- Brazing and SolderingDocument18 paginiBrazing and SolderingbendutsÎncă nu există evaluări

- 15 Soldering Brazing and RivetingDocument39 pagini15 Soldering Brazing and RivetingAyush50% (2)

- WeldingDocument2 paginiWeldingAnonymous Qha8B2Încă nu există evaluări

- YintroDocument6 paginiYintroJoshua StrykrÎncă nu există evaluări

- Welding, Brazing & Soldering PDFDocument9 paginiWelding, Brazing & Soldering PDFSuryakant PrabhuÎncă nu există evaluări

- Pitch Deck PresentationDocument16 paginiPitch Deck PresentationRay CahayagÎncă nu există evaluări

- Porosity - This Occurs When Gases Are Trapped in The Solidifying Weld Metal. These May AriseDocument34 paginiPorosity - This Occurs When Gases Are Trapped in The Solidifying Weld Metal. These May AriseSheshikanth DonÎncă nu există evaluări

- Mech Mod 4Document82 paginiMech Mod 4brave playerÎncă nu există evaluări

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsDe la EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsÎncă nu există evaluări

- TIG Welding: Process CharacteristicsDocument3 paginiTIG Welding: Process CharacteristicsRaj BindasÎncă nu există evaluări

- WeldingDocument27 paginiWeldingperlan1234Încă nu există evaluări

- Welding Metallurgy of Titanium AlloysDocument46 paginiWelding Metallurgy of Titanium AlloysBaraneedharanÎncă nu există evaluări

- Guidelines For Welding Cast IronDocument3 paginiGuidelines For Welding Cast IronNguyễn Thanh SơnÎncă nu există evaluări

- Welding of Nickel AlloysDocument12 paginiWelding of Nickel Alloysaj87_goswamiÎncă nu există evaluări

- Welding Definition: by S K MondalDocument26 paginiWelding Definition: by S K MondalSaajal SharmaÎncă nu există evaluări

- Welding Complete PPT With QuestionDocument50 paginiWelding Complete PPT With QuestionKBSMANITÎncă nu există evaluări

- 2890-Nuts & Spanners PDFDocument1 pagină2890-Nuts & Spanners PDFsyllavethyjimÎncă nu există evaluări

- 2885-Dent & Bulge Removal PDFDocument1 pagină2885-Dent & Bulge Removal PDFsyllavethyjimÎncă nu există evaluări

- 2884-Panel Beating PDFDocument1 pagină2884-Panel Beating PDFsyllavethyjim100% (1)

- 2880-Supporting & Steadying PDFDocument1 pagină2880-Supporting & Steadying PDFsyllavethyjimÎncă nu există evaluări

- 2886-Stud Fitting & Removal PDFDocument1 pagină2886-Stud Fitting & Removal PDFsyllavethyjimÎncă nu există evaluări

- 2889-Further Drilling Methods PDFDocument1 pagină2889-Further Drilling Methods PDFsyllavethyjimÎncă nu există evaluări

- IMP Workshop ManualDocument336 paginiIMP Workshop Manualsyllavethyjim67% (3)

- 2881-Radii Functions and Checking PDFDocument1 pagină2881-Radii Functions and Checking PDFsyllavethyjimÎncă nu există evaluări

- Contours 1: Hile It CannotDocument1 paginăContours 1: Hile It CannotsyllavethyjimÎncă nu există evaluări

- 2879-Clamping & Holding PDFDocument1 pagină2879-Clamping & Holding PDFsyllavethyjimÎncă nu există evaluări

- 2888-Oblique Drilling PDFDocument1 pagină2888-Oblique Drilling PDFsyllavethyjimÎncă nu există evaluări

- 2887-Broken Drills & Taps PDFDocument1 pagină2887-Broken Drills & Taps PDFsyllavethyjimÎncă nu există evaluări

- 2883-Metal Working PDFDocument1 pagină2883-Metal Working PDFsyllavethyjimÎncă nu există evaluări

- 2873-Cotters & Wedges PDFDocument1 pagină2873-Cotters & Wedges PDFsyllavethyjimÎncă nu există evaluări

- 2874-Fitting Core Plugs PDFDocument1 pagină2874-Fitting Core Plugs PDFsyllavethyjimÎncă nu există evaluări

- 2872-Circular Clips #2 PDFDocument1 pagină2872-Circular Clips #2 PDFsyllavethyjimÎncă nu există evaluări

- 2871-Circular Clips #1 PDFDocument1 pagină2871-Circular Clips #1 PDFsyllavethyjimÎncă nu există evaluări

- 2876-Belt Fasteners PDFDocument1 pagină2876-Belt Fasteners PDFsyllavethyjimÎncă nu există evaluări

- 2867 Case HardeningDocument1 pagină2867 Case HardeningEr Sukhwinder SinghÎncă nu există evaluări

- 2878-Chains & Sprockets PDFDocument1 pagină2878-Chains & Sprockets PDFsyllavethyjimÎncă nu există evaluări

- 2875-Belt Drives PDFDocument1 pagină2875-Belt Drives PDFsyllavethyjimÎncă nu există evaluări

- 2870-Simple Screw Assembly PDFDocument1 pagină2870-Simple Screw Assembly PDFsyllavethyjimÎncă nu există evaluări

- 2877-Roller Chain & Sprockets PDFDocument1 pagină2877-Roller Chain & Sprockets PDFsyllavethyjimÎncă nu există evaluări

- 2868-Glands & Pipe Fittings PDFDocument1 pagină2868-Glands & Pipe Fittings PDFsyllavethyjimÎncă nu există evaluări

- 2865-Testing & Facing Valves PDFDocument1 pagină2865-Testing & Facing Valves PDFsyllavethyjimÎncă nu există evaluări

- 2864-Poppet Valves & Seating PDFDocument1 pagină2864-Poppet Valves & Seating PDFsyllavethyjimÎncă nu există evaluări

- 2861-Wheel & Shaft PullersDocument1 pagină2861-Wheel & Shaft PullersSandra Barnett CrossanÎncă nu există evaluări

- 2869-Fitting & Joining Pipes PDFDocument1 pagină2869-Fitting & Joining Pipes PDFsyllavethyjimÎncă nu există evaluări

- 2866-Hardening & Tempering PDFDocument1 pagină2866-Hardening & Tempering PDFsyllavethyjimÎncă nu există evaluări

- 2863-Valve Seating Tools PDFDocument1 pagină2863-Valve Seating Tools PDFsyllavethyjimÎncă nu există evaluări

- General Chemistry Ii: A. Paint Thinner and OilDocument3 paginiGeneral Chemistry Ii: A. Paint Thinner and OilCherry A. BallesterosÎncă nu există evaluări

- Organic Syntheses Collective Volume 6Document1.299 paginiOrganic Syntheses Collective Volume 6caltexas100% (2)

- Science Magazine April 07 2006 PDFDocument144 paginiScience Magazine April 07 2006 PDFAndrés FrankowÎncă nu există evaluări

- 2 3 - 2 3 25 1Document4 pagini2 3 - 2 3 25 1GoGUtkokAÎncă nu există evaluări

- Broadband Drop CableDocument28 paginiBroadband Drop CableAngel LopezÎncă nu există evaluări

- Gravimetri in EnglishDocument4 paginiGravimetri in EnglishGeo RuciÎncă nu există evaluări

- Proposal FYP1 Example For Malaysian UniversityDocument6 paginiProposal FYP1 Example For Malaysian UniversityDuniaku ComelÎncă nu există evaluări

- Aderco Marine - Global Energy Sulphur Cap 2020 - v03Document24 paginiAderco Marine - Global Energy Sulphur Cap 2020 - v03Saw Win0% (1)

- GenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Document22 paginiGenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Junelle Ramos Aquino100% (1)

- (59-68) Monitoring and Modeling of Fayoum Distribution Networks According To Tri Halo Me Thanes FormationDocument11 pagini(59-68) Monitoring and Modeling of Fayoum Distribution Networks According To Tri Halo Me Thanes FormationAlexander DeckerÎncă nu există evaluări

- Punjab Boards 10th Class Physics Book English Medium 6368072829234769390 PDFDocument201 paginiPunjab Boards 10th Class Physics Book English Medium 6368072829234769390 PDFSaqib SaleemÎncă nu există evaluări

- Semiconductor - Experiment PDFDocument116 paginiSemiconductor - Experiment PDFMuthu KumarÎncă nu există evaluări

- Tribology of Polymers and Their Composites - Environmental EffectsDocument45 paginiTribology of Polymers and Their Composites - Environmental EffectsJigar M. UpadhyayÎncă nu există evaluări

- GED Chemistry Note1 (Atoms, Molecules and Their Properties)Document6 paginiGED Chemistry Note1 (Atoms, Molecules and Their Properties)Shahadat Hussain Parvez100% (2)

- Tle Report 3rd QuarterDocument5 paginiTle Report 3rd QuarterZaren MendozaÎncă nu există evaluări

- OpticsHW Ch11KeyDocument12 paginiOpticsHW Ch11KeyJane Winner100% (1)

- TSB339Document6 paginiTSB339Anderson Alejandro Benites ZelayaÎncă nu există evaluări

- tmp327F TMPDocument228 paginitmp327F TMPFrontiersÎncă nu există evaluări

- STP 550-1986Document58 paginiSTP 550-1986Anonymous pSozzNFcÎncă nu există evaluări

- Dovidovits - Geopolymer Chemistry and Applications PDFDocument33 paginiDovidovits - Geopolymer Chemistry and Applications PDFdimas dibiantara0% (1)

- Modal Damping Estimates From Static Load-Deflection CurvesDocument8 paginiModal Damping Estimates From Static Load-Deflection CurvesJose ManuelÎncă nu există evaluări

- FINAL LCCP Handbook v2.1 With Appendix - JAN 2015Document67 paginiFINAL LCCP Handbook v2.1 With Appendix - JAN 2015Sean CrossÎncă nu există evaluări

- PCAB List of Licensed Contractors For CFY 2017-2018 As of 18 Oct 2017 - WebDocument667 paginiPCAB List of Licensed Contractors For CFY 2017-2018 As of 18 Oct 2017 - WebAlfredo Miguel M. BuenaventuraÎncă nu există evaluări

- William Crookes On Radiant MatterDocument38 paginiWilliam Crookes On Radiant Matterde7yT3izÎncă nu există evaluări

- Was The Driver Drunk? An Instrumental Methods Experiment For The Determination of Blood Alcohol ContentDocument3 paginiWas The Driver Drunk? An Instrumental Methods Experiment For The Determination of Blood Alcohol ContentRashitaAsfdakldjÎncă nu există evaluări

- Zangar C Water Percolation 5 Water OcrDocument86 paginiZangar C Water Percolation 5 Water Ocrreem.ranoom.moonÎncă nu există evaluări

- WHO Monograph CurcumaDocument8 paginiWHO Monograph CurcumaMuhammad Miftahul HudaÎncă nu există evaluări

- Fiitjee: Talent Reward Exam - 2018Document19 paginiFiitjee: Talent Reward Exam - 2018DSÎncă nu există evaluări

- Module 4 HIgh Cycle and Low Cycle FatigueDocument21 paginiModule 4 HIgh Cycle and Low Cycle FatiguerohanÎncă nu există evaluări

- Sizing of LPG Air Mix System (24mmbtu 60B-40P, 50psig)Document1 paginăSizing of LPG Air Mix System (24mmbtu 60B-40P, 50psig)ekabudiartiÎncă nu există evaluări