Documente Academic

Documente Profesional

Documente Cultură

EDG Test

Încărcat de

yogacruiseTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

EDG Test

Încărcat de

yogacruiseDrepturi de autor:

Formate disponibile

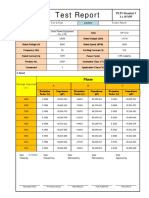

EDG Test Procedure

Page 1 of 7

HK-E-HV701

Document Class

PT. HUTAMA KARYA (Persero)

EPC DIVISION

JOB. No. HV701

For Commissioning

Revised as comment

Revised as comment

For approval

Sep. 08,

2015

Ayhu

Rev.

Description

Date

Prepared Checked Reviewed Approved

Tirda

Tirda

OWNER`S

DWG.NO

PT. PLN (PERSERO)

JASA SERTIFIKASI

Clients Project No.

DWG. NO.

E07007-PR-TM-3007

PLTU KENDARI UNIT 3 1x10 MW

DATE OF ISSUED

REVISION NO.

Sep.08, 2015

Yoga

PLTU Kendari Unit 3 (110 MW) Project

EDG Test Procedure

REV 0

HK-E-HV701

Page 2 of 7

Commissioning Procedure

Table of Contents

1

2

3

4

5

6

7

8

9

COVER

SCOPE

OBJECTIVE

REFERENCE

TEST INSTRUMENT

RISK AND SAFETY PRECAUTION

BUSBAS PROTECTION TEST ITEM

BUSBAS PROTECTION PROCEDURE

ATTACHEMENT

1

2

3

3

3

3

3

3

3

PLTU Kendari Unit 3 (110 MW) Project

EDG Test Procedure

REV 0

HK-E-HV701

Page 3 of 7

Commissioning Procedure

1.

Title

EDG Test Procedure

2.

Scope

EDG body, local panel of EDG, incoming switch 0.4Kv protection.

3.

Objective

This is to assure that the requirements of electrical individual test works c1re

meets the codes requirements and contract specifications. To make sure, the

works are carried out in acceptable workmanship and follow requirements

in the quality manual.

4. Reference

a) HK/SDMIEC Quality manual

b) Applicable manufacture manual/standard

c) Design drawing provided by Design Institute ZT-F201115S-D0201-03

(2/3)

5. Test Instrument

Fluke 17B

Secondary Phase Sequence Tester

DC Resistance Tester

Insulation Resistance Tester

Relay Tester.

6. Risk and Precaution

a.

b.

c.

d.

Everyone must be wear safety

High voltage test area should be circle by rail with warning board.

If happen anything abnormal, testing must be stop

Clean all instrument and tools

PLTU Kendari Unit 3 (110 MW) Project

EDG Test Procedure

REV 0

HK-E-HV701

Page 4 of 7

Commissioning Procedure

7.

EDG Test Item

Visual inspection

Individual Test of EDG.

Local Stop/Start EDG

Local Protection

8.

EDG Test Procedure

8.1.1

Visual Inspection.

Check name plate of each protection and write down.

8.1.2

Individual Test of EDG.

8.1.3

Test of EDG body

1.Measure of EDG DC resistance value between each phase 1%

2.Measured the insulation resistance of EDG winding to ground.

Insulation resistance shall > 5 M.

Test of EDG local control system

1.Checked that inside and outside of EDG control panel are clean.

2.Cable connection of row terminal in EDG control panel is good.

3.Supply power normal work for EDG controller.

4.Simulated normal current, voltage and frequency by protection tester.

5.Checked following fault whether controller action is correct.

Local start/stop of EDG

Put operation, alarm, signal power switch into operation.

Manually start EDG locally.

Regulated voltage of EDG make it run and no load voltage of 400V

Check whether EDG outlet phase sequence is correct.

Checked and record following value after EDG run normally.

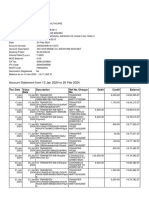

PLTU Kendari Unit 3 (110 MW) Project

BUSBAS PROTECTIONTest Procedure

REV 0

HK-E-HV701

Page 5 of 7

Commissioning Procedure

9.

.

Manually stop EDG locally.

Manually start and stop EDG local 3 times. Checked the battery capacity.

ATTACHEMENT

Test form

Calibration date of equipment test

Drawing Equipment

S-ar putea să vă placă și

- User Request/Certification of Access Rights Form For Emds (For Agency)Document2 paginiUser Request/Certification of Access Rights Form For Emds (For Agency)Philip Jansen Guarin50% (6)

- ECS 06-0022 Grid and Primary Earthing Construction PDFDocument38 paginiECS 06-0022 Grid and Primary Earthing Construction PDFRajendra Prasad ShuklaÎncă nu există evaluări

- Actom Hve Ctb36 Outdoor Circuit Breakers Aug 2018 LRDocument6 paginiActom Hve Ctb36 Outdoor Circuit Breakers Aug 2018 LRGary FortuinÎncă nu există evaluări

- Post Insulator Installation ChecklistDocument1 paginăPost Insulator Installation ChecklistUtku Can KılıçÎncă nu există evaluări

- Home Electrical Wiring BasicsDocument3 paginiHome Electrical Wiring BasicswilliamII100% (2)

- Three Level Password Authentication SystemsDocument5 paginiThree Level Password Authentication SystemsMahesh IbsÎncă nu există evaluări

- Buffalo Link Station Quad LS-QL-R5 User ManualDocument96 paginiBuffalo Link Station Quad LS-QL-R5 User Manualbernardng5591Încă nu există evaluări

- D.K. Moriarty Ltd. P2 P1: Current Transformer NoDocument1 paginăD.K. Moriarty Ltd. P2 P1: Current Transformer Noaravindhana1a1Încă nu există evaluări

- Recommended Busduct InstallationDocument3 paginiRecommended Busduct InstallationNon Etabas GadnatamÎncă nu există evaluări

- Service Setting Said SadiqDocument2 paginiService Setting Said SadiqHimdad TahirÎncă nu există evaluări

- Csu600 enDocument2 paginiCsu600 enEimear DevlinÎncă nu există evaluări

- Understanding Generator Set Ratings: Chad Dozier Market Development Manager Electric Power DivisionDocument7 paginiUnderstanding Generator Set Ratings: Chad Dozier Market Development Manager Electric Power DivisionSakthivel MurthyÎncă nu există evaluări

- SafeGrid Reference ManualDocument16 paginiSafeGrid Reference Manualrajarao1234Încă nu există evaluări

- LSIS Bus Duct System CatalogDocument52 paginiLSIS Bus Duct System CatalogedcooÎncă nu există evaluări

- Standard Inspection and Test Plan ITP No: 936 Unit Auxiliary TransformersDocument4 paginiStandard Inspection and Test Plan ITP No: 936 Unit Auxiliary TransformersZaid RÎncă nu există evaluări

- Hyundai Electric BrochureDocument36 paginiHyundai Electric BrochurebadbenzationÎncă nu există evaluări

- Alstom Grid - GIS Lifecycle ManagementDocument16 paginiAlstom Grid - GIS Lifecycle ManagementKristina FlemingÎncă nu există evaluări

- Lightning Protection System Installation Works Inspection ChecklistDocument1 paginăLightning Protection System Installation Works Inspection ChecklistReda HamedÎncă nu există evaluări

- ABB Medium-Voltage Surge Arresters - Application Guidelines 1HC0075561 E2 AC (Read View) - 6edDocument60 paginiABB Medium-Voltage Surge Arresters - Application Guidelines 1HC0075561 E2 AC (Read View) - 6edAndré LuizÎncă nu există evaluări

- Sepam 10 Seped307026en Int PDFDocument22 paginiSepam 10 Seped307026en Int PDFJeffrey Reynaldo RidwanÎncă nu există evaluări

- 5003 PDFDocument7 pagini5003 PDFamitbheltbgÎncă nu există evaluări

- Gen Air TestDocument14 paginiGen Air TestPRINCE SHARMAÎncă nu există evaluări

- 6 RTU Specifications III A 2216Document10 pagini6 RTU Specifications III A 2216rasim_m1146Încă nu există evaluări

- ACE - 66kV GIS 03.09.2022Document236 paginiACE - 66kV GIS 03.09.2022Chandan KumarÎncă nu există evaluări

- ReadmeDocument190 paginiReadmeJAIMES ALFONSO JINA MARIAÎncă nu există evaluări

- Iris Power Condition Based Monitoring Turbo GuardII PDFDocument4 paginiIris Power Condition Based Monitoring Turbo GuardII PDFarthamonifanÎncă nu există evaluări

- WB Brush Seals Labyrinth - A4Document2 paginiWB Brush Seals Labyrinth - A4triplbingaziÎncă nu există evaluări

- 11kV Surge Arrestor HE-12Document2 pagini11kV Surge Arrestor HE-12shabbir4Încă nu există evaluări

- Livening Up NotesDocument1 paginăLivening Up NotesAceel FitchÎncă nu există evaluări

- Grounding System For High Resistivity Limited Area Substations in Hilly Region of Himachal PradeshDocument7 paginiGrounding System For High Resistivity Limited Area Substations in Hilly Region of Himachal Pradeshostojic007Încă nu există evaluări

- 66 KV Single Core XLPE Power Cable PDFDocument11 pagini66 KV Single Core XLPE Power Cable PDFRani VjÎncă nu există evaluări

- Cathodic Protection BOMDocument4 paginiCathodic Protection BOManonymous542Încă nu există evaluări

- Sie10166 Cba1000Document28 paginiSie10166 Cba1000Aditya ManÎncă nu există evaluări

- Cable Installation Check ListDocument1 paginăCable Installation Check Listfadhlan hidayat100% (2)

- Optimal Load Scheduling (NEC)Document26 paginiOptimal Load Scheduling (NEC)Rudanek100% (1)

- Lightening Arrester 500kVTest Report EnglishDocument20 paginiLightening Arrester 500kVTest Report Englishashwani2101Încă nu există evaluări

- CEA Self Certification FormsDocument20 paginiCEA Self Certification FormsKoti ReddyÎncă nu există evaluări

- SUB-02-613 Appendix 2 Flow Chart PDFDocument1 paginăSUB-02-613 Appendix 2 Flow Chart PDFsurag1982Încă nu există evaluări

- 18.10.18 - Malindi - EPC - Schedule - MASTER VERSION - 4Document150 pagini18.10.18 - Malindi - EPC - Schedule - MASTER VERSION - 4Abhay DubeyÎncă nu există evaluări

- Schedule of Charges and Procedure PDFDocument58 paginiSchedule of Charges and Procedure PDFabhi...Încă nu există evaluări

- KEPCODocument27 paginiKEPCOToVanÎncă nu există evaluări

- F-QAQC-17, Rev.B - FAT LV Panel PDFDocument3 paginiF-QAQC-17, Rev.B - FAT LV Panel PDFpw ptusa100% (1)

- Neutral Grounding Resistors PDFDocument4 paginiNeutral Grounding Resistors PDFRajendra Prasad ShuklaÎncă nu există evaluări

- Punch ListDocument2 paginiPunch ListAwais Shafiq100% (1)

- CA - HD4 - IEC-GOST (EN) E - 1VCP000245 - 10.2017 - Ok PDFDocument70 paginiCA - HD4 - IEC-GOST (EN) E - 1VCP000245 - 10.2017 - Ok PDFpowerbullÎncă nu există evaluări

- Scsasacj0 - Distribution Technology Home - EskomDocument11 paginiScsasacj0 - Distribution Technology Home - EskomRichman MakwiramitiÎncă nu există evaluări

- E1 2 Example String NotesDocument1 paginăE1 2 Example String NotesSAEL SOLARÎncă nu există evaluări

- SF6 Insulated Instrument Transformers For Outdoor Installation From 72.5 KV To 300 KVDocument4 paginiSF6 Insulated Instrument Transformers For Outdoor Installation From 72.5 KV To 300 KVxor_45Încă nu există evaluări

- Tech Spec of PTR 33 11 KVDocument34 paginiTech Spec of PTR 33 11 KVAnonymous sAmJfcVÎncă nu există evaluări

- QAP of HT Breaker Panel SchneiderDocument1 paginăQAP of HT Breaker Panel Schneidermadhu_bedi12Încă nu există evaluări

- A20Document7 paginiA20aravindhana1a1Încă nu există evaluări

- Vacuum ContactorDocument4 paginiVacuum ContactorArun Kumar0% (1)

- SP145-GIS Installation ProcedureDocument14 paginiSP145-GIS Installation ProcedureWalangMajikaÎncă nu există evaluări

- Erection Procedure For 6.6 KV Bus DuctDocument7 paginiErection Procedure For 6.6 KV Bus DuctAnmohieyÎncă nu există evaluări

- Ts108 Technical Standard For Distribution Equipment and Transformer RoomsDocument30 paginiTs108 Technical Standard For Distribution Equipment and Transformer RoomsHimdad TahirÎncă nu există evaluări

- The Product Life Cycle Support Policy See Life Cycle Overview Is (1) ...Document4 paginiThe Product Life Cycle Support Policy See Life Cycle Overview Is (1) ...Pradeep KumarÎncă nu există evaluări

- BS Iec Iee-56486979874967Document25 paginiBS Iec Iee-56486979874967ramasamy2012Încă nu există evaluări

- Haryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)Document37 paginiHaryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)samkarmakar2002Încă nu există evaluări

- Indelec Survey Report - Lightning ProtectionDocument3 paginiIndelec Survey Report - Lightning Protectionblack_3289Încă nu există evaluări

- Datasheet For Induction MotorDocument5 paginiDatasheet For Induction MotorRohan GuravÎncă nu există evaluări

- 1 - Hi Pot Test Procedure For SwitchyardDocument6 pagini1 - Hi Pot Test Procedure For Switchyardbayu dewanto100% (1)

- Project Owner Contractor Inspection Surveillance Report (Isr)Document20 paginiProject Owner Contractor Inspection Surveillance Report (Isr)destri_742053763Încă nu există evaluări

- 3.3-12K-EMC IEC&EN Report-1 PDFDocument58 pagini3.3-12K-EMC IEC&EN Report-1 PDFUdara DissanayakeÎncă nu există evaluări

- Evvo 1 3.3kw g3 - Ip65 ReportDocument6 paginiEvvo 1 3.3kw g3 - Ip65 ReportUdara DissanayakeÎncă nu există evaluări

- Tan Delta-FDocument1 paginăTan Delta-FyogacruiseÎncă nu există evaluări

- Vibration Guidelines C132530Document1 paginăVibration Guidelines C132530yogacruiseÎncă nu există evaluări

- Protection Relay of Generator TestDocument6 paginiProtection Relay of Generator Testyogacruise100% (2)

- Honeywell Chart Recorder QuestionDocument1 paginăHoneywell Chart Recorder QuestionyogacruiseÎncă nu există evaluări

- Steam BlowingDocument6 paginiSteam BlowingS V NAGESHÎncă nu există evaluări

- Hipot Testing Dielectric Strength Test EepDocument14 paginiHipot Testing Dielectric Strength Test EepyogacruiseÎncă nu există evaluări

- Boiler Feed Pump KSBDocument9 paginiBoiler Feed Pump KSByogacruiseÎncă nu există evaluări

- Calculation Sheet of Bus Protection Unit 3 FinalDocument17 paginiCalculation Sheet of Bus Protection Unit 3 Finalyogacruise100% (1)

- Harga Batubara Acuan April 2012Document6 paginiHarga Batubara Acuan April 2012satuiku100% (1)

- Magnetrol Level Flow Tech HandbookDocument44 paginiMagnetrol Level Flow Tech HandbookDelfinshÎncă nu există evaluări

- XA Manual-V1.2Document72 paginiXA Manual-V1.2Mohamed Elsayed100% (1)

- Ge DGCM Field Rtu CatalogDocument12 paginiGe DGCM Field Rtu CatalogyogacruiseÎncă nu există evaluări

- Tan Delta-FDocument1 paginăTan Delta-FyogacruiseÎncă nu există evaluări

- Budget For FEED of An Onshore Oil FieldDocument1 paginăBudget For FEED of An Onshore Oil FieldyogacruiseÎncă nu există evaluări

- If The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1Document8 paginiIf The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1yogacruiseÎncă nu există evaluări

- Stiffness Coefficients For Nozzles in API 650 Tanks - 2Document8 paginiStiffness Coefficients For Nozzles in API 650 Tanks - 2yogacruise100% (2)

- Non Metallic Expansion JointDocument2 paginiNon Metallic Expansion JointyogacruiseÎncă nu există evaluări

- Refractory Repair and ProcedureDocument3 paginiRefractory Repair and Procedureyogacruise50% (2)

- WUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangDocument4 paginiWUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangyogacruiseÎncă nu există evaluări

- Zirconium IdentificationDocument2 paginiZirconium IdentificationyogacruiseÎncă nu există evaluări

- Pure Argon For Non Carbon SteelDocument3 paginiPure Argon For Non Carbon SteelyogacruiseÎncă nu există evaluări

- Chimney RateDocument6 paginiChimney RateyogacruiseÎncă nu există evaluări

- Manhole On Weld SeamDocument1 paginăManhole On Weld SeamyogacruiseÎncă nu există evaluări

- What Code To Design Chlorine TankDocument3 paginiWhat Code To Design Chlorine TankyogacruiseÎncă nu există evaluări

- 3 Heating Load Calculation: 3.1 Heat Transmission LossDocument14 pagini3 Heating Load Calculation: 3.1 Heat Transmission LossyogacruiseÎncă nu există evaluări

- Expansion Bellows Leak RepairDocument1 paginăExpansion Bellows Leak RepairyogacruiseÎncă nu există evaluări

- Instrument Cable LayoutDocument2 paginiInstrument Cable LayoutyogacruiseÎncă nu există evaluări

- Maximum Temperature For SS 310Document3 paginiMaximum Temperature For SS 310yogacruiseÎncă nu există evaluări

- Surge Gas Pilene Cross CountryDocument2 paginiSurge Gas Pilene Cross CountryyogacruiseÎncă nu există evaluări

- Reverse-Engineering and Implementation of The RDP 5 ProtocolDocument121 paginiReverse-Engineering and Implementation of The RDP 5 ProtocolПьяный МастерÎncă nu există evaluări

- Siyaram Health Care 2Document5 paginiSiyaram Health Care 2bm.india58Încă nu există evaluări

- "User Manual" Pmegp E-Portal EDP Training Pmegp SchemeDocument8 pagini"User Manual" Pmegp E-Portal EDP Training Pmegp Schemeraghu myÎncă nu există evaluări

- Asset Management Policy TemplateDocument4 paginiAsset Management Policy Templatesadaf_saadÎncă nu există evaluări

- Dynamic Security Testing of CAN-bus SystemsDocument4 paginiDynamic Security Testing of CAN-bus SystemsNon SenseÎncă nu există evaluări

- VmwareDocument2 paginiVmwareRama KrishnaÎncă nu există evaluări

- KetabDocument9 paginiKetablittlefarbod100% (1)

- 473-NAL Computer Ethics & SocietyDocument48 pagini473-NAL Computer Ethics & SocietyHumera GullÎncă nu există evaluări

- Mingw64: Clonar El Repositorio Creado en La Nube en La PC Loca / Conexión RemotaDocument6 paginiMingw64: Clonar El Repositorio Creado en La Nube en La PC Loca / Conexión RemotaFredSpinozaCamposÎncă nu există evaluări

- Lab Test 2 Report Muhammad Faiz Bin ZakariahDocument4 paginiLab Test 2 Report Muhammad Faiz Bin ZakariahMuizz ZainolÎncă nu există evaluări

- Professional Regulation Commission: Application For Professional Identification Card (Pic)Document1 paginăProfessional Regulation Commission: Application For Professional Identification Card (Pic)cashellemÎncă nu există evaluări

- BirdRes - TrainRetrievePNRDocument1 paginăBirdRes - TrainRetrievePNRSaurabh KumarÎncă nu există evaluări

- Template HETTICH EDI Connection Plan RauchsDESADVDocument44 paginiTemplate HETTICH EDI Connection Plan RauchsDESADVSREEDHARÎncă nu există evaluări

- Red Hat Enterprise Linux-7-System Administrators Guide-en-US PDFDocument493 paginiRed Hat Enterprise Linux-7-System Administrators Guide-en-US PDFQedew ErÎncă nu există evaluări

- Health & Safety PolicyDocument8 paginiHealth & Safety PolicyClay Lee100% (1)

- Paymentwall Subscriptions APIDocument11 paginiPaymentwall Subscriptions APIgagomatÎncă nu există evaluări

- Osstmm 3.0 LiteDocument52 paginiOsstmm 3.0 LiteGermán DelgadilloÎncă nu există evaluări

- National ID SystemDocument2 paginiNational ID SystemJohnPaulRomeroÎncă nu există evaluări

- WR1500N - 2.0 User GuideDocument73 paginiWR1500N - 2.0 User GuidesmrahimÎncă nu există evaluări

- Risk Assessment PA 20Document3 paginiRisk Assessment PA 20Trinity CharnockÎncă nu există evaluări

- Building Technologies Division: Automatic Forced Draft Burners For Gaseous FuelsDocument35 paginiBuilding Technologies Division: Automatic Forced Draft Burners For Gaseous FuelsZulfikar FahmiÎncă nu există evaluări

- IEEE Projects in VLSIDocument5 paginiIEEE Projects in VLSIKumarasamy RamasubramanianÎncă nu există evaluări

- Affidavit For Address ProofDocument4 paginiAffidavit For Address ProofKaur NavneetÎncă nu există evaluări

- Armor Magazine, September-October 1990Document56 paginiArmor Magazine, September-October 1990"Rufus"Încă nu există evaluări

- Test CasesDocument12 paginiTest Casesritesh aherÎncă nu există evaluări