Documente Academic

Documente Profesional

Documente Cultură

"Big Red": Taylor Industrial Truck Preliminary Specifications

Încărcat de

Neil DesaiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

"Big Red": Taylor Industrial Truck Preliminary Specifications

Încărcat de

Neil DesaiDrepturi de autor:

Formate disponibile

Big Red

X-360L

Taylor Industrial Truck

Preliminary Specifications

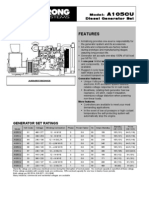

X-360L Rated Capacity 36,000-lbs. (16,330 kg)

24-in. (610 mm) Load Center

138-in. (3,505 mm) Wheelbase

Big Red X-360L

G

E

N

E

R

A

L

1.

Manufacturer

Manufacturers Name

2.

Model

Manufacturers Designation

Metric

3.

Capacity

Rated Capacity

4.

Load Center

Distance

5.

Power Type

Gas, LPG, Or Diesel

6.

Tire Type

Cushion, Pneumatic Front / Rear

7.

Wheels

Number (X = Driven) Front / Rear

8.

Upright Lift

Standard Lift (Top Of Fork)

in (mm)

135.5

Thickness

in (mm)

3.5

89

Width

in (mm)

203

Length

in (mm)

48

1,219

9.A

Forks

9.B

10.

Tilt Angle

lb (kg)

36,000

16,330

in (mm)

24

610

Diesel

Pneumatic / Pneumatic

4X / 2

Standard Upright - Forward / Backward

deg._

3,442

15 / 12

11.

Length To Face Of Forks

in (mm)

202.5

5,144

12.

Width (Standard Tires)

in (mm)

103

2,615

Height, Standard Upright Lowered

in (mm)

143

3,632

Height, Standard Upright Extended

in (mm)

209

5,308

15.

Height To Top Of Counterweight

in (mm)

55

1,397

16.

Height To Top Of A-Frame

in (mm)

126

3,200

17.

Minimum Outside

in (mm)

194

4,928

Minimum Inside

in (mm)

25

635

13.

14.

17.A

Overall

Dimensions

Turning Radius

18.

Load Distance

Center Of Wheel To Face Of Forks

in (mm)

32.5

825

19.

Aisle Width

(Add Load Length For 90 Stacking)

in (mm)

226.5

5,753

20.

Stability

Comply With ANSI?

mph (km/h)

17.4

28

fpm (m/s)

71

.36

Lift Speed - With Load

fpm (m/s)

68

.35

Lowering Speed - No Load / With Load

fpm (m/s)

75

.38

lb (kN)

26,080

116

21.

Travel Speed - Maximum Forward

22.

Lift Speed - No Load

22.A

23.

24.

X-360L

English

9.

D

I

M

E

N

S

I

O

N

S

TAYLOR

25.

25.A

26.

Speeds

Drawbar Pull

Gradeability

Ttl. Apprx. Wt.

27.

W 27.A

T

27.B

Axle Loading

27.C

28.

W 29.

H 30.

L 31.

S

/ 32.

T 32.A

I

33.

R

E 34.

S 35.

36.

P

W

R

37.

U

N

I

T

/

X

M

S

N

40.

38.

39.

41.

Yes

Powershift (Maximum At Stall)

Powershift (Maximum At Stall) No Load

Powershift (Maximum At Stall) With Load

34.7

31.4

Standard Truck

lb (kg)

41,000

18,598

Static With Rated Load - Front

lb (kg)

70,650

32,047

Static With Rated Load - Rear

lb (kg)

6,350

2,880

Static With No Load - Front

lb (kg)

19,900

9,027

Static With No Load - Rear

lb (kg)

21,100

9,571

Number - Front / Rear

Tires

4/2

Size - Front

12.00 x 20 - 24 PR

Size - Rear

Wheelbase

Tread

Ground

Clearance

Brakes

Battery

IInternal

t

l

Combustion

Engine

12.00 x 20 - 24 PR

Distance

in (mm)

138

3,505

Center Of Outside (Dual) Tires - Front

in (mm)

90

2,280

Center Of Tires - Rear

in (mm)

80

2,030

No Load At Lowest Point

in (mm)

230

No Load At Center Of Wheelbase

in (mm)

14

356

Service / Parking - Method Of Control

Foot / Hand

Service / Parking - Method Of Operation

Hyd / Spring

Volts / Ampere Hours (2 Batteries)

V/Ah

Make / Model

24 / 1150

Cummins QSB6.7-C173 Tier 4F Final

Output - Intermittent Per SAE Standards

hp (kW)

Governed Speed - With Load

173

rpm

Cycle / Number Of Cylinders / Displacement

cu-in (L)

4 / 6 / 408

4 / 6 / 6.7

42.

Clutch

Type

Inching

43.

Gear Change

Type

Hand

44.

45.

46.

Transmission

Relief Pressure

Number Of Speeds - Forward / Reverse

129

2200

3/3

Type

Powershift

For Attachments

psi (bar)

2,500

172

in (mm)

95.5

2,426

in (mm)

84

2,134

in (mm)

64.5

1,638

2,034,000

23,448

47.

Width Across Counterweight And Front Fenders

48.

Standard Fork Spread

49.

Ground To Top Of Carriage

50.

Load Moment

in-lbs (m-kg)

NOTE: Performance specifications are for trucks equipped as described on the back page of this specification sheet. Performance

specifications are affected by the condition of the vehicle, its components, and the nature and condition of the operating area. If these

specifications are critical, the proposed application should be discussed with your Taylor sales representative.

Big Red X-360L

Mast Dimensions (inches / millimeters)

Optional Lift Height (8)*

English

2 Stage

2-Stage

ULTRA-VU

Telescopic Mast

*Includes Fork Thickness

12

32

OAHL (13)

Metric

English

OAHR (14)

Metric

English

Metric

135.5

3,442

143

3,632

209

5,308

159.5

4,051

155

3,937

233

5,918

183.5

4,661

167

4,242

257

6,528

219.5

5,575

185

4,699

293

7,442

48

32A

47

Standard Engine For USA and Canada only

Cummins QSB6.7----C173 Tier 4F Final electronic turbocharged, charge air aftercooled (air to air)diesel, 6----cylinder

diesel engine has 409 cu----in. (6.7 L) displacement. 4.21----in.

(107 mm) bore x 4.88----in. (124 mm) stroke. Rated power of

173 (129 kW) horsepower at 2200 RPM. Peak power of 183

horsepower (136 kW) at 2000 rpm. Peak torque 620 ft----lbs.

(841 N----m) at 1500rpm. (SAE J1995 Conditions). Standard

features are (DOC) diesel oxidation catalysis, (CEGR) cooled

exhaust gas recirculation, electronic diagnostic and maintenance monitor, fuel/water separator and engine/transmission

protection systems.

Emission certification: Tier 4F Final.

Attention: a Taylor Max Air Intake Precleaner must be

added by the Sales person.

75_

17A

17

Warning:

The TIER 4F Final engines require the following new fluids.

Ultra Low Sulfer diesel fuel API CJ--4 Low Ash engine oil.

10

10

Warning:

The use of any fluids, in TIER 4F Final engines, other than

those specified above may result in engine damage and could

effect emissions and result in fines by the E.P.A..

OR

14

13

16

8

15

49

33, 34

18

31

11

Optional Engine For International shipment only. Not for

USA and Canada. Check with Sales Coordinator on this engine for availability.

Cummins QSB6.7----C160 Tier III TPEM electronic turbocharged, charge air aftercooled (air to air)diesel, 6----cylinder

diesel engine has 409 cu----in. (6.7 L) displacement. 4.09----in.

(104 mm) bore x 5.2----in. (132 mm) stroke. Rated power of

160 (119 kW) horsepower at 2200 RPM. Maximum power of

165 horsepower (123 kW) at 2000 rpm. Peak torque 540 ft---lbs. (732 N----m) at 1400 rpm. (SAE J1995 Conditions). Standard features are electronic diagnostic and maintenance monitor, fuel/water separator and engine/transmission protection

systems. Emission certification: US EPA Tier III, Carb Tier III,

EU Stage III.

Attention: Taylor models equipped with U.S. EPA Tier 3 certified engines are available for sale outside of the highly regulated countries of North America, Europe and Japan. Refer to

the off--road diesel engine emission regulations of the specific

country in question for verification.

The fuel tank capacity is 43 gallons (163 L).

Big Red X-360L

Air Cleaner

The dry type air cleaner is equipped with a safety element,

restriction indicator, and vertical air intake extension.

Attention: a Taylor Max Air Intake Precleaner must be added by the

Sales person.

Cooling System

The conventional top / bottom tank radiator has wide fin spacing

to reduce dirt build-up and provide optimum engine cooling.

Cooling includes engine charge air cooler, engine coolant air

cooler, transmission oil air cooler, and a separate wet disc and

hydraulic oil air cooler. Each can be serviced seperately.

Electrical, Instrumentation, and Accessories

The one-piece instrument panel is pre-wired to accommodate

heavy-duty accessories. All wiring is color and number coded.

The unit has a 24-volt electrical system with circuit breakers.

Standard equipment includes a key-type anti-restart ignition

switch system, 95-amp alternator, heavy-duty battery, electric

fuel gauge, lighted display, electric horn, keyswitch-actuated

amber strobe light, forward alarm, a reverse-actuated warning

horn and LED work lights total 8, 2 at front of each side of cab,

total 4, 2 at rear of cab mounted on A frame or back of cab

depending on model, 2 front on mast, one low and one high,

(two front, and two rear).

Display indicates functions for seat belt, engine oil pressure,

parking brake, battery indicator, and Tier 4F Final engine

electronic diagnostic light package.

The unit has tilt steering and rear view mirrors.

All machine controls are Taylor Integrated Control Systems

(TICS) using J1939 CANbus technology. This allows controllers

and sensors to communicate with minimal wiring between the

components. I/O modules are used to eliminate

electromechanical relay devices and add reliability to the

machine control system. J1939 CAN bus technology allows all

machine data to be accessed through the 7-in. diagonal touch

screen color display located in the cab. This display shows

engine data along with warnings, and man/ machine interface

data. The display allows service personnel to access data

needed during troubleshooting (such as sensor status and

controller outputs). Machine functions can be tuned through the

main display in the cab. Tuning functions are password

protected to prevent operator access.

Dual USB ports in cab.

Transmission

The three-speed, fully reversing, modulated powershift

transmission has inching, electric direction controls on push

buttons on joystick, and a separate air-to-oil cooler. The filler

pipe dipstick and large, heavy-duty oil filter are easily accessible.

Automatic powershift (standard).

Drive Axle

The bolted heavy-duty planetary drive axle utilizes a hypoid ring

gear and pinion. Positive rim mountings.

Steer Axle

The steer axle is a single hydraulic cylinder design with

heavy-duty links from the cylinder ram directly to tapered roller

bearing mounted spindles. Positive rim mountings.

Brake System

The internal force--cooled, hydraulic--actuated, wet disc, service

brakes (and the hydraulic oil) are cooled by an air--to--oil cooler

separate from the transmission cooler. The left pedal combines

actuation of service brakes and transmission inching; the right

pedal actuates the service brakes only. The parking brake

control is mounted on the instrument panel.

Power Steering

The hydrostatic, steer-on-demand steering system provides

constant response at all engine speeds.

Chassis

The all-welded frame has an integral counterweight. The hood

slides on rollers. The cab is 2-door and includes one 32,000

BTU heater, one circulation fan, front and rear windshield wipers,

front windshield washer, dome light, all glass tinted, door hold

back latches with trip handles, grey insulation, and black floor

mat inside cab. Cab color black only. The adjustable, black vinyl

covered air suspension seat with arm rest and orange seat belt

is standard. The seat has 15 / 20 rotation.

Hydraulic System

The high-capacity hydraulic tank has a spin-on tank breather,

wire-mesh strainers, and full-flow 10-micron return-line filters,

with a replaceable element in the tank. Tank refill capacity is 78

gallons (295 L).

The hydraulic system utilizes a gear-type pump and sectional

control valves. A tilt-lock valve reduces mast drift and torsional

stress. The lift cylinders have self-adjusting packing. The

standard joystick control lever is armrest mounted with multiple

adjustments for operator comfort.

Mast, Carriage, and Rollers

The 11-ft. (3.4 m) ULTRA-VU telescopic, nested-channel mast,

with two multiple-leaf lift chains, is constructed of high-strength

steel. The double-acting lift cylinders are nested to the rear of

the mast rails. Two lifting eyes and bolt-on caps permit safe,

easy removal. The lift chains are nested in the mast rails and

are hidden.

Pin-type 84-in. (2,134 mm) wide C carriage.

The mast and carriage main rollers are common and use

shielded roller bearings. Chain rollers use sealed ball bearings.

Side bearings are adjustable to compensate for wear.

Forks

The forks are pin-mounted and fully adjust from the outer

carriage plates to the center brace. They are forged from heat

treated steel and have square tips and bottom tapers. Sizes:

Size: 3.5-in. (89 mm) x 8-in. (203 mm) x 48-in. (1,219 mm)

This vehicle is certified to meet the applicable design and performance criteria

required for Powered Industrial Trucks in OSHA Safety and Health Standards, Title

29 CFR. Part 1910.178, and the applicable design and performance requirements

in ANSI B56.1 that were in effect at the time of manufacture. These standards also

apply to the user and should be adhered to while operating this vehicle.

All specifications are subject to change without notice. Some operating data may be

affected by the condition of the operating area. If these specifications are critical,

contact the factory.

Note: Illustrations of equipment may sometimes show optional

equipment not included on a standard model.

Taylor Machine Works, Inc.

650 North Church Avenue

Louisville, Mississippi 39339-2017

Phone (662) 773-3421 Fax (662) 773-9146

GG (3/15)

Printed in U.S.A.

S-ar putea să vă placă și

- "Big Red": Empty Container Handler Preliminary SpecificationsDocument4 pagini"Big Red": Empty Container Handler Preliminary SpecificationsNeil DesaiÎncă nu există evaluări

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDocument20 paginiSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezÎncă nu există evaluări

- Caterpillar C15 ACERT Tier 4Document4 paginiCaterpillar C15 ACERT Tier 4Alfred Hernandez MendozaÎncă nu există evaluări

- AX50PDocument4 paginiAX50PEdwin NgÎncă nu există evaluări

- HL7407ADocument6 paginiHL7407AluismdmjÎncă nu există evaluări

- pm565b PDFDocument8 paginipm565b PDFManuel Calderon Cortes100% (1)

- Cat C 15 AccertDocument4 paginiCat C 15 AccertRobles JmrÎncă nu există evaluări

- C15 Acert Spec SheetDocument4 paginiC15 Acert Spec SheetMalasquez Leon XavierÎncă nu există evaluări

- Cat C9 SpecsDocument3 paginiCat C9 SpecsHarry SinghÎncă nu există evaluări

- 1103D-33 Engine PN1896Document2 pagini1103D-33 Engine PN1896Paulo AzañeroÎncă nu există evaluări

- Cat. 262CDocument2 paginiCat. 262CPedro Aponte CamposÎncă nu există evaluări

- X9 Training SupportDocument33 paginiX9 Training Supportpassero202Încă nu există evaluări

- Caterpillar C9 Engine SpecsDocument3 paginiCaterpillar C9 Engine Specsjinxy577991% (11)

- 246DDocument4 pagini246DJose MaraviÎncă nu există evaluări

- 1104c 44t PerkinsDocument2 pagini1104c 44t PerkinsValeddia Beatriz Gutierrez NinaÎncă nu există evaluări

- Genset - 2MVA-2Document6 paginiGenset - 2MVA-2Shawn ZadehÎncă nu există evaluări

- Genset - 2MVA-5Document6 paginiGenset - 2MVA-5Shawn ZadehÎncă nu există evaluări

- BH35 2Document4 paginiBH35 2muthu85100% (1)

- L7044gsi 7045 0710Document2 paginiL7044gsi 7045 0710Martin Alejandro NievaÎncă nu există evaluări

- FPT Industrial Tier 3 EngDocument20 paginiFPT Industrial Tier 3 EngJesus Carreon100% (1)

- Spesifikasi Reach Stacker PDFDocument4 paginiSpesifikasi Reach Stacker PDFUswatun HasanahÎncă nu există evaluări

- K Series 750-1010 (K38)Document4 paginiK Series 750-1010 (K38)sameer_ponnadaÎncă nu există evaluări

- The Sullair: Portable Air CompressorDocument2 paginiThe Sullair: Portable Air CompressorJesus SalamancaÎncă nu există evaluări

- D12 MH Volvo Penta Inboard Diesel Engine Technical SpecsDocument4 paginiD12 MH Volvo Penta Inboard Diesel Engine Technical Specszulu800% (1)

- 1104C-44T Engine PN1644Document2 pagini1104C-44T Engine PN1644Ferran Alfonso100% (1)

- 277C SpecsDocument2 pagini277C SpecsLance RosenbergerÎncă nu există evaluări

- Boost Your Bucket Selection with Hyundai's New HL730-7A Wheel Loader GuideDocument6 paginiBoost Your Bucket Selection with Hyundai's New HL730-7A Wheel Loader Guideluismdmj100% (1)

- C13 Acert Industrial Engine: Tier 4 Final, Stage Iv Technology 287-388 Bkw/385-520 BHP at 1800-2100 RPMDocument4 paginiC13 Acert Industrial Engine: Tier 4 Final, Stage Iv Technology 287-388 Bkw/385-520 BHP at 1800-2100 RPMAjans Victor100% (2)

- (Lehw0191-00) 3512c (HD) Ataac With DGBDocument4 pagini(Lehw0191-00) 3512c (HD) Ataac With DGBvictor.ciprianiÎncă nu există evaluări

- Motor PerkinsDocument2 paginiMotor PerkinsFredy Castro100% (1)

- CaterpilarDocument4 paginiCaterpilarpangestu66100Încă nu există evaluări

- PC 400 LC 8Document8 paginiPC 400 LC 8James RoniÎncă nu există evaluări

- Cat 793FDocument4 paginiCat 793Fyoungk225812Încă nu există evaluări

- Identificación John DeereDocument19 paginiIdentificación John DeereCeciliagorra100% (2)

- Vehicle T-Atv1200 Mil Specs 2015 Tech DescrDocument22 paginiVehicle T-Atv1200 Mil Specs 2015 Tech DescrpeiyingongÎncă nu există evaluări

- 4BY150Document2 pagini4BY150Angga ClevneztÎncă nu există evaluări

- Apd125c 6Document4 paginiApd125c 6selvamejiaÎncă nu există evaluări

- Apd220c 6Document4 paginiApd220c 6Sulistyo AdiÎncă nu există evaluări

- B3.3 Series: Diesel Generator SetDocument4 paginiB3.3 Series: Diesel Generator Setsuresh babuÎncă nu există evaluări

- 236D EngDocument4 pagini236D EngElvis Eberth Huanca MachacaÎncă nu există evaluări

- Caterpillar-3516C HD Marine EngineDocument4 paginiCaterpillar-3516C HD Marine EngineViswanathan Damodaran100% (4)

- Compressor L7044GSI-7045 - 1210Document2 paginiCompressor L7044GSI-7045 - 1210Dedy Chasan Aflah MutoharÎncă nu există evaluări

- Serie 60 Plus 12l IndustrialDocument2 paginiSerie 60 Plus 12l IndustrialAlberto Celleri BravoÎncă nu există evaluări

- The Sullair: Portable Air CompressorDocument2 paginiThe Sullair: Portable Air CompressorJesus SalamancaÎncă nu există evaluări

- 1250 1500kvaDocument4 pagini1250 1500kvaAngon BhattacharjeeÎncă nu există evaluări

- Canter 3 5 FE84DDocument4 paginiCanter 3 5 FE84DShahul Hameed Jawahar100% (2)

- 540-170 JCB ThelehhandlerDocument4 pagini540-170 JCB ThelehhandlermanualdeutsÎncă nu există evaluări

- Yale 3000Document2 paginiYale 3000VitorMelloÎncă nu există evaluări

- APD100A-6: 100 kVA / 80 KWDocument4 paginiAPD100A-6: 100 kVA / 80 KWRonald H SantosÎncă nu există evaluări

- Motor c13 CatDocument4 paginiMotor c13 CatDiego Vicente50% (2)

- LeTourneau L2350Document6 paginiLeTourneau L2350Dennis Aspauza100% (1)

- C9 3Document4 paginiC9 3Jan HendriksÎncă nu există evaluări

- A105CU A105CU A105CU A105CU: FeaturesDocument4 paginiA105CU A105CU A105CU A105CU: FeaturesshahrilidzwanÎncă nu există evaluări

- Motorcycle, Solo (Harley-Davidson Model WLA)De la EverandMotorcycle, Solo (Harley-Davidson Model WLA)Încă nu există evaluări

- Designing and Tuning High-Performance Fuel Injection SystemsDe la EverandDesigning and Tuning High-Performance Fuel Injection SystemsEvaluare: 3.5 din 5 stele3.5/5 (7)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDe la EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsEvaluare: 5 din 5 stele5/5 (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÎncă nu există evaluări

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualEvaluare: 2.5 din 5 stele2.5/5 (2)

- 16 Ton Forklift Offer-KalmarDocument5 pagini16 Ton Forklift Offer-KalmarNeil DesaiÎncă nu există evaluări

- Tech Specs For Forklift 9-19 TonsDocument7 paginiTech Specs For Forklift 9-19 TonsNeil DesaiÎncă nu există evaluări

- Tech Specs For Forklift 9-19 TonsDocument7 paginiTech Specs For Forklift 9-19 TonsNeil DesaiÎncă nu există evaluări

- Self-Propelled Articulating Boom Lift: Gtbz16ADocument2 paginiSelf-Propelled Articulating Boom Lift: Gtbz16ANeil DesaiÎncă nu există evaluări

- Genie Z-60 - 34Document1 paginăGenie Z-60 - 34Neil DesaiÎncă nu există evaluări

- Manitou 200 AtjDocument2 paginiManitou 200 AtjNeil Desai100% (1)

- Genie Z-60/34 Boom LiftDocument2 paginiGenie Z-60/34 Boom LiftAnonymous arnc2g2NÎncă nu există evaluări

- 600 SeriesJLG PDFDocument2 pagini600 SeriesJLG PDFNeil DesaiÎncă nu există evaluări

- X-Series: Pneumatic Tire Lift TrucksDocument2 paginiX-Series: Pneumatic Tire Lift TrucksNeil DesaiÎncă nu există evaluări

- GP040-070VX Brochure 2.15Document16 paginiGP040-070VX Brochure 2.15Neil DesaiÎncă nu există evaluări

- MPB-VG: Motorized Hand Low Lift PalletDocument6 paginiMPB-VG: Motorized Hand Low Lift PalletNeil DesaiÎncă nu există evaluări

- GP060-070VX Spec SheetDocument6 paginiGP060-070VX Spec SheetNeil DesaiÎncă nu există evaluări

- MPB-VG: Walkie Low Lift PalletDocument16 paginiMPB-VG: Walkie Low Lift PalletNeil DesaiÎncă nu există evaluări

- Platform Lowlifter Truck: P-SeriesDocument4 paginiPlatform Lowlifter Truck: P-SeriesNeil DesaiÎncă nu există evaluări

- Problem Solving-Practice Test A PDFDocument23 paginiProblem Solving-Practice Test A PDFPphamÎncă nu există evaluări

- New Patient Application Form Cypress W Cover Letter1Document2 paginiNew Patient Application Form Cypress W Cover Letter1Neil DesaiÎncă nu există evaluări

- Platform Lowlifter Truck: P-SeriesDocument5 paginiPlatform Lowlifter Truck: P-SeriesNeil DesaiÎncă nu există evaluări

- Dyna PDFDocument12 paginiDyna PDFVernadette VenturaÎncă nu există evaluări

- Marc Sans, Barcelona ActivaDocument17 paginiMarc Sans, Barcelona ActivaPromoting EnterpriseÎncă nu există evaluări

- Jabra Evolve 40: More Than Headsets, A Workplace EvolutionDocument1 paginăJabra Evolve 40: More Than Headsets, A Workplace EvolutionSloba87Încă nu există evaluări

- TOT Calendar Oct Dec. 2018 1Document7 paginiTOT Calendar Oct Dec. 2018 1Annamneedi PrasadÎncă nu există evaluări

- Remedy Shortcut Keys: Home Solutions & Services Products Partners Support Education ConnectDocument2 paginiRemedy Shortcut Keys: Home Solutions & Services Products Partners Support Education Connectaert5683Încă nu există evaluări

- Emulsifier Solutions: Targeted Applications. Established SuccessDocument32 paginiEmulsifier Solutions: Targeted Applications. Established SuccessSen D' Favian100% (1)

- Ciphertext-Policy Attribute-Based EncryptionDocument15 paginiCiphertext-Policy Attribute-Based EncryptionJ_RameshÎncă nu există evaluări

- Detection of Phising Websites Using Machine Learning ApproachesDocument9 paginiDetection of Phising Websites Using Machine Learning Approachesshresthabishal721Încă nu există evaluări

- AeroCRS 5.95-Premier AirlinesDocument1 paginăAeroCRS 5.95-Premier AirlinesmohamedÎncă nu există evaluări

- Breadtalk AR 2011Document158 paginiBreadtalk AR 2011Wong ZieÎncă nu există evaluări

- Official Sponsorship LetterDocument3 paginiOfficial Sponsorship LetterWinona Marie Borla100% (1)

- Pearce v. FBI Agent Doe 5th Circuit Unpublished DecisionDocument6 paginiPearce v. FBI Agent Doe 5th Circuit Unpublished DecisionWashington Free BeaconÎncă nu există evaluări

- PfizerDocument4 paginiPfizerliqu1dcourageÎncă nu există evaluări

- 16.00 Luc Rudowski, PolysiusDocument14 pagini16.00 Luc Rudowski, PolysiusMohd AliÎncă nu există evaluări

- House Bill 470Document9 paginiHouse Bill 470Steven DoyleÎncă nu există evaluări

- Winter 2011Document128 paginiWinter 2011baoHVLABÎncă nu există evaluări

- Ascon PhivDocument48 paginiAscon PhivSDK341431100% (1)

- Introducing Global PoliticsDocument8 paginiIntroducing Global PoliticsMeann Joy BaclayonÎncă nu există evaluări

- Andhra Pradesh Land Reforms (Ceiling On Agricultural Holdings) (Amendment) Act, 2009Document3 paginiAndhra Pradesh Land Reforms (Ceiling On Agricultural Holdings) (Amendment) Act, 2009Latest Laws TeamÎncă nu există evaluări

- Schedule of BPSC Teacher - S 6 Day - SDocument1 paginăSchedule of BPSC Teacher - S 6 Day - SNarendraÎncă nu există evaluări

- 2018 Scaffold and Access Inspection Checklist FDocument6 pagini2018 Scaffold and Access Inspection Checklist FTaufiq YahayaÎncă nu există evaluări

- 18U61E0027 - INVESTMENT DECISION ANALYSIS - Indiabulls - NewDocument36 pagini18U61E0027 - INVESTMENT DECISION ANALYSIS - Indiabulls - NewMohmmedKhayyumÎncă nu există evaluări

- Three Column Cash BookDocument3 paginiThree Column Cash Bookahmad381Încă nu există evaluări

- Innovative Uses of Housing Lifting Techniques-JIARMDocument16 paginiInnovative Uses of Housing Lifting Techniques-JIARMPOOJA VÎncă nu există evaluări

- Saurabh Pandey - Management Trainee - Recruitment - 5 Yrs 10 MonthsDocument2 paginiSaurabh Pandey - Management Trainee - Recruitment - 5 Yrs 10 MonthsDevraj GurjjarÎncă nu există evaluări

- PROFILITE 60 EC Suspended 09 130 3001-01-830 Product Datasheet enDocument4 paginiPROFILITE 60 EC Suspended 09 130 3001-01-830 Product Datasheet enGabor ZeleyÎncă nu există evaluări

- Solaris 10 Service - (Management Facility (SMF: Oz Melamed E&M Computing Nov 2007Document18 paginiSolaris 10 Service - (Management Facility (SMF: Oz Melamed E&M Computing Nov 2007Anonymous 4eoWsk3100% (3)

- Design of Masonary Retaining Wall - SteppedDocument3 paginiDesign of Masonary Retaining Wall - Steppedmeenu100% (1)

- Jmeter Performance Testing Your Webapp 1203622239433273 3Document12 paginiJmeter Performance Testing Your Webapp 1203622239433273 3pallavi91Încă nu există evaluări

- Software Process & Quality Management: Six SigmaDocument26 paginiSoftware Process & Quality Management: Six SigmaPhu Phan ThanhÎncă nu există evaluări