Documente Academic

Documente Profesional

Documente Cultură

Murata Products Thin Film M04e PDF

Încărcat de

alltheloveintheworldTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Murata Products Thin Film M04e PDF

Încărcat de

alltheloveintheworldDrepturi de autor:

Formate disponibile

Note This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd.

. Therefore, its specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

sales representatives or product engineers before ordering.

This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

M04E.pdf

08.7.11

Thin Film Circuit Substrate(RUSUBTM)

RU Series

! Features

1. Low insertion loss for using high Q-value dielectric

substrate.

2. A wide selection of substrate material to meet your

needs.

3. Excellent reliability by means of developed suitable film

structure.

4. For compatibility with gold electrodes, die bonding with

AuSn and wire bonding with gold wire are possible.

5. Thin film microfabrication technology allows precise

micro pattern.

6. Through via hole, and AuSn pre-coating are available.

7. CR complex product is available when combining a

capacitor with a high dielectric substrate and a thin film

resistor.

Pic. 1

Resistor

! Main Applications

Gold electrode

Subject product: Devices for microwave, millimeter wave,

and optical communications.

Application: MIC circuit substrate, impedance matching

circuit, bypass circuit substrate, couplers, filter,

capacitor, capacitor networks, resistor

networks, etc.

Substrate

Through via hole

Fig. 1

! Substrate characteristics and practical correspondent scope

Table 1. Substrate characteristics and practical correspondent scope.

Through hole

TaN

Resistance

L/S min.

[m] (*4)

Coefficient of

Thermal

Expansion

[ppm/C] (*1)

Temperature

conductivity

[W/(mC)] (*1)

20/20

4.6

200.0

20/20

7.0

33.5

0.25Z0.25Z0.09

0T30

30/20

6.6

1.9

0.25Z0.25Z0.09

330T120

30/20

9.2

2.3

150

0.25Z0.25Z0.09

750T120

30/20

11.7

2.0

250

0.25Z0.25Z0.09

750T600

30/20

12.2

4.0

300

0.25Z0.25Z0.09

2200T500

30/20

10.4

2.6

3000

0.25Z0.25Z0.09

T10%

30/20

10.7

2.5

10000

0.25Z0.25Z0.09

+30, 80%

30/20

10.5

1.6

15000

0.25Z0.25Z0.09

+30, 90%

30/20

14.0

2.4

Dielectric

constant

[ r] (*1)

Size min. (LZWZT)

[mm] (*2)

Capacity

Temperature

characteristics

[ppm/C] (*3)

0.25Z0.25Z0.09

10

0.25Z0.25Z0.20

39

90

Series

(*1) Typical value.

(*2) L=length, W=width, T=thickness.

(*3) Temperature range 25 to 85C, reference temperature 25C

(*4) L=line, S=space

Cat. No. M04E-1

Note This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, its specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

sales representatives or product engineers before ordering.

This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

! Practical correspondent scope of resistor

Table 2. Practical correspondent scope of resistor

Material

TaN

Sheet resistance []

12.5, 25, 50

Operating temperature range [C]

55 to +125

Rated power [mW/mm ]

100

Resistance tolerance [%] *

T20

Resistance temperature coefficient [ppm/C]

70T50

* Please contact us for other tolerance than indicated above.

! Practical correspondent scope of through via

hole

Table 3. Practical correspondent scope of through via hole

a: Hole to hole [mm]

0.22 min.

b: Distance between hole and electrode [mm]

0.10 min.

c: Distance between electrode and chip edge [mm]

0.15 min.

Hole diameter:

0.1 to 0.3mm

when t=0.38mm or below.

0.2 to 0.3mm

when t=0.50mm, 0.64mm or below.

a

c

t=Thickness of substrate

Fig. 2 Through via hole diameter

Table 4. AuSn Pre-Coating Specification

1.AuSn Pre-Coating Thickness

52m,103m,154m

Min 150m10m (5m Thickness)

2.Coating Size

Min 150m20m

(10,15m Thickness)

3.AuSn-Electrode Offset

(Topside)

4.AuSn-Electrode Offset

(Backside)

U25m

U50m

Electrode with backside offset

! Note

Data sending method: When requiring our product, please

send pattern by CAD data and

information to the below e-mail

address.

Table 5. Information of sending data

CAD data format

DXF, DWG

Mail address

rusub@murata.co.jp

M04E.pdf

08.7.11

Note This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, its specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

sales representatives or product engineers before ordering.

This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

M04E.pdf

08.7.11

! Product Example

Six types of standard samples of RUSUB C+R

(Capacitor + Resistor) are available.

The custom substrate size, capacity, resistance value,

and electrode pattern shape is available upon request.

Size

Thickness

Capacitance

Resistance

RUCYT101K00009GNTC

Part Number

1.0mm0.5mm

0.11 0.025mm

100pF 10%

50 20%

RUCYT101K00011GNTC

1.0mm0.5mm

0.11 0.025mm

100pF 10%

100 20%

RUCYT101K00012GNTC

1.0mm0.5mm

0.11 0.025mm

100pF 10%

200 20%

RUCYT201K00010GNTC

1.0mm1.0mm

0.12 0.025mm

200pF 10%

50 20%

RUCYT201K00013GNTC

1.0mm1.0mm

0.12 0.025mm

200pF 10%

100 20%

RUCYT201K00014GNTC

1.0mm1.0mm

0.12 0.025mm

200pF 10%

200 20%

! Shape

1.0x1.0mm size

Top Side

1.0

0.5

1.0x0.5mm size

Top Side

1.0

Bottom Side

1.0

Bottom Side

(in mm)

(in mm)

! Frequency Characteristics

0

Transmission Characteristics (dB)

-10

RUSUBt

-20

IN

OUT

-30

-40

-50

-60

0.01

RUCYT101K00009GNTC (100pF+50)

RUCYT101K00011GNTC (100pF+100)

RUCYT101K00012GNTC (100pF+200)

RUCYT201K00010GNTC (200pF+50)

RUCYT201K00013GNTC (200pF+100)

RUCYT201K00014GNTC (200pF+200)

Fig. Equivalent Circuit (Measured at 50 ohm)

0.1

10

100

1000

10000

100000

Frequency (MHz)

Note This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, its specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

sales representatives or product engineers before ordering.

This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

M04E.pdf

08.7.11

Notice

! Notice (Storage and Operating Condition)

! Notice (Soldering and Mounting)

Note the following to prevent poor die bonding and poor wire

bonding.

1. Store the capacitors in manufacturer's package in the

following conditions without a rapid thermal change in an

indoor room.

Temperature: -10 to 40C

Humidity: 30 to 70%RH

2. Avoid storing the capacitors in the following conditions.

(a) Ambient air containing corrosive gas. (Chlorine gas,

Hydrogen sulfide gas, Ammonia gas, Sulfuric acid

gas, Nitric oxide gas, etc.)

(b) Ambient air containing volatile or combustible gas

(c) In environments with high concentration of airborne

particles

(d) In liquid (water, oil, chemical solution, organic

solvents, etc.)

(e) In environments where condensation may occur

(f) In direct sunlight

(g) In freezing environments

1. Die bonding of substrate

(1) Using materials and bonding conditions

Solders: Au -20%Sn

Bonding temperature: 300 to 320C

Bonding time: less than 1 minute

Bonding atmosphere: N2 atmosphere

(2) Notice

(a) Please scrub the capacitors while mounting.

(b) Die bonding condition is affected by what kind of

solder and base substrate is used. Please

evaluate die bonding condition in advance with the

same materials as mass production materials and

make sure that there is no effect, especially

cracking of the ceramics.

2. Wire Bonding

(1) Using materials and bonding conditions

Wire lead: 25 microns diameter gold wire

Bonding temperature: 150 to 250C

Bonding methods: Thermocompression or

thermosonic bonding

(2) Notice

Please do not bond closer than 25 microns from the

edge of the electrode.

PLEASE CONTACT US BEFORE USING OUR

PRODUCTS IN OTHER BONDING CONDITIONS NOT

LISTED ABOVE.

! Notice (Handling)

Do not directly touch capacitors with bare hands to prevent

poor die bonding and poor wire bonding.

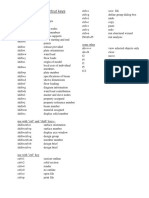

o Part Numbering

3Substrate Materials

Code

Thin Film Circuit Substrates (RUSUBTM)

(Part Number)

RU C

1

D 1R5K 01001 GT TC

2 3 4

1Product ID

Pruduct ID

RU

Code

r

250

10

300

39

3000

90

10000

150

15000

Substrate material code: A=Alumina, N=Aluminum Nitride

Thin film circuit substrate

4Structure of metalized film: Indicated by 1 alphabet.

2Representative Characteristics

5Characteristic values: Characteristic value by representative

characteristics will be indicated with 4

Code

Representative characteristics

Capacitance

Resistance

6Individual specification code: Indicated by 5 digit number.

Dimension

7Other specifications: Indicated by 2 alphabets.

digit number.

8Packaging

Code

Packaging

TC

Tray

Note This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, its specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

M04E.pdf

08.7.11

sales representatives or product engineers before ordering.

This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Note This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, its specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

sales representatives or product engineers before ordering.

This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Head Office

1-10-1, Higashi Kotari, Nagaokakyo-shi, Kyoto 617-8555, Japan

Phone: 81-75-951-9111

Cat. No. K99E-13

International Division

3-29-12, Shibuya, Shibuya-ku, Tokyo 150-0002, Japan

Phone: 81-3-5469-6123 Fax: 81-3-5469-6155 E-mail: intl@murata.co.jp

M04E.pdf

08.7.11

S-ar putea să vă placă și

- LIT1615 Weidmuller IP20-IP67 Gateway Module Flyer v3Document2 paginiLIT1615 Weidmuller IP20-IP67 Gateway Module Flyer v3alltheloveintheworldÎncă nu există evaluări

- Lit1607 Act20p Cmtlineflyer May2016Document2 paginiLit1607 Act20p Cmtlineflyer May2016alltheloveintheworldÎncă nu există evaluări

- LIT1408 - Remote IO U-Remote FAQDocument6 paginiLIT1408 - Remote IO U-Remote FAQalltheloveintheworldÎncă nu există evaluări

- LIT1405 Analog Action Sales Flyer v5Document2 paginiLIT1405 Analog Action Sales Flyer v5alltheloveintheworldÎncă nu există evaluări

- Lit1126e Act20mDocument8 paginiLit1126e Act20malltheloveintheworldÎncă nu există evaluări

- Lit1302e Termseries Datasheet v1Document16 paginiLit1302e Termseries Datasheet v1alltheloveintheworldÎncă nu există evaluări

- Lit1127 Act20m - 03 - 14Document2 paginiLit1127 Act20m - 03 - 14alltheloveintheworldÎncă nu există evaluări

- LIT1424 TERMSeries C1D2 Datasheet v5Document4 paginiLIT1424 TERMSeries C1D2 Datasheet v5alltheloveintheworldÎncă nu există evaluări

- Lit1127 Act20m - 03 - 14Document2 paginiLit1127 Act20m - 03 - 14alltheloveintheworldÎncă nu există evaluări

- Lit1126e Act20mDocument8 paginiLit1126e Act20malltheloveintheworldÎncă nu există evaluări

- Lit1302e Termseries Datasheet v4Document20 paginiLit1302e Termseries Datasheet v4alltheloveintheworldÎncă nu există evaluări

- Lit1126e Act20mDocument8 paginiLit1126e Act20malltheloveintheworldÎncă nu există evaluări

- Lit1302e Termseries Datasheet v1Document16 paginiLit1302e Termseries Datasheet v1alltheloveintheworldÎncă nu există evaluări

- LIT1117 RingLug Datasheet v9Document6 paginiLIT1117 RingLug Datasheet v9alltheloveintheworldÎncă nu există evaluări

- Weidmuller Dual Level Terminals DatasheetDocument2 paginiWeidmuller Dual Level Terminals DatasheetalltheloveintheworldÎncă nu există evaluări

- LIT1126 ACT20M Datasheet 03 14Document16 paginiLIT1126 ACT20M Datasheet 03 14alltheloveintheworldÎncă nu există evaluări

- LIT1117 RingLug Datasheet v9Document6 paginiLIT1117 RingLug Datasheet v9alltheloveintheworldÎncă nu există evaluări

- LIT1024 WDK 2.5 DU PE TR Terminals DatasheetDocument2 paginiLIT1024 WDK 2.5 DU PE TR Terminals DatasheetalltheloveintheworldÎncă nu există evaluări

- LIT1031 TB Application Guide InstrumentationDocument5 paginiLIT1031 TB Application Guide InstrumentationalltheloveintheworldÎncă nu există evaluări

- Lit1105 Act20p FlyerDocument2 paginiLit1105 Act20p FlyeralltheloveintheworldÎncă nu există evaluări

- LIT1023 WSI Fuse TerminalsDocument2 paginiLIT1023 WSI Fuse TerminalsalltheloveintheworldÎncă nu există evaluări

- LIT1103 TERMOPTO Relays DatasheetDocument8 paginiLIT1103 TERMOPTO Relays DatasheetalltheloveintheworldÎncă nu există evaluări

- Lit0908 Wave Tta FlyerDocument2 paginiLit0908 Wave Tta FlyeralltheloveintheworldÎncă nu există evaluări

- LIT0914 WSI6 WSI6-2 Fuse Terminals With Low LeakageDocument2 paginiLIT0914 WSI6 WSI6-2 Fuse Terminals With Low LeakagealltheloveintheworldÎncă nu există evaluări

- WMF 2.5 Terminal Series GuideDocument8 paginiWMF 2.5 Terminal Series GuidealltheloveintheworldÎncă nu există evaluări

- LIT1011 DelconRelaysDocument4 paginiLIT1011 DelconRelaysalltheloveintheworldÎncă nu există evaluări

- Lit0903 Wave TtaDocument2 paginiLit0903 Wave TtaalltheloveintheworldÎncă nu există evaluări

- LIT0904 WAVEPak DCDCDocument2 paginiLIT0904 WAVEPak DCDCalltheloveintheworldÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Propagation of LightDocument14 paginiPropagation of LightProy DCÎncă nu există evaluări

- Optical CouplerDocument28 paginiOptical CouplerHai Tạ LóÎncă nu există evaluări

- AIEEE Chemistry 2005 PDFDocument14 paginiAIEEE Chemistry 2005 PDFMisti DasÎncă nu există evaluări

- Lab2 ReportDocument18 paginiLab2 Reportsparee1256Încă nu există evaluări

- Map ReadingDocument21 paginiMap Readingyagya singhÎncă nu există evaluări

- IPmux 4 ManualDocument117 paginiIPmux 4 ManualRhakko RamirezÎncă nu există evaluări

- KWIKWIT - The Online Exam Portal Project ReportDocument58 paginiKWIKWIT - The Online Exam Portal Project ReportManiÎncă nu există evaluări

- 16.412J/6.834J Intelligent Embedded Systems: Problem Set #3 SolutionsDocument16 pagini16.412J/6.834J Intelligent Embedded Systems: Problem Set #3 SolutionsjoudetÎncă nu există evaluări

- Antipole Tree IndexingDocument16 paginiAntipole Tree IndexingJesus Alberto Arcia HernandezÎncă nu există evaluări

- Staad Pro Shortcut KeysDocument1 paginăStaad Pro Shortcut KeysjomarÎncă nu există evaluări

- Orientation to Discrete Mathematics (CSC303Document18 paginiOrientation to Discrete Mathematics (CSC303vinod N. AloneÎncă nu există evaluări

- Troubleshooting Radiated Emissions Using Low Cost Bench MethodsDocument12 paginiTroubleshooting Radiated Emissions Using Low Cost Bench MethodsgclarkiiÎncă nu există evaluări

- KHT Breech LockDocument8 paginiKHT Breech Locksumantra1976100% (1)

- 840DDocument818 pagini840DCicero MelloÎncă nu există evaluări

- Week 1-2 InterventionDocument7 paginiWeek 1-2 InterventionDiana Marie Mendoza100% (1)

- Solid State Relay PDFDocument12 paginiSolid State Relay PDFjroyal692974Încă nu există evaluări

- ITU Recommendation on International Morse CodeDocument7 paginiITU Recommendation on International Morse CodeNitinSrivastavaÎncă nu există evaluări

- Mutually Exclusive EventDocument10 paginiMutually Exclusive EventMark Kevin Geraldez100% (2)

- UA723Document13 paginiUA723rordenvÎncă nu există evaluări

- Moment PDFDocument5 paginiMoment PDFMohan RaoÎncă nu există evaluări

- OTDR Calibration FormDocument2 paginiOTDR Calibration FormdetmkcmÎncă nu există evaluări

- CAT Delta 30, 90 X-Ray - Service ManualDocument171 paginiCAT Delta 30, 90 X-Ray - Service ManualLuis Fernando Garcia SÎncă nu există evaluări

- 2018 Gauss 7 ContestDocument4 pagini2018 Gauss 7 ContestpriyagvÎncă nu există evaluări

- PCon - Planner System RequirementsDocument2 paginiPCon - Planner System RequirementsKristof MCÎncă nu există evaluări

- Saddam 024222000534-1194 Sec D-39thDocument14 paginiSaddam 024222000534-1194 Sec D-39thSaddam KhanÎncă nu există evaluări

- Infobright Community Edition-User GuideDocument90 paginiInfobright Community Edition-User GuidemishaIV100% (4)

- Domino 6 IMAP PerformanceDocument3 paginiDomino 6 IMAP Performancebkiran633Încă nu există evaluări

- Conservation of EnergyDocument4 paginiConservation of EnergyHannySyÎncă nu există evaluări

- Mechanical Engineering Mcqs Part 2: Nts ResultsDocument20 paginiMechanical Engineering Mcqs Part 2: Nts Resultsfake7083Încă nu există evaluări

- MISSING ISOMETRIC VIEWSDocument91 paginiMISSING ISOMETRIC VIEWSChaithanya ChatrathiÎncă nu există evaluări