Documente Academic

Documente Profesional

Documente Cultură

10 5923 C Jmea 201502 03

Încărcat de

angelaacruzTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

10 5923 C Jmea 201502 03

Încărcat de

angelaacruzDrepturi de autor:

Formate disponibile

Journal of Mechanical Engineering and Automation 2015, 5(3B): 15-18

DOI: 10.5923/c.jmea.201502.03

Designing of Feeding System for Investment

Casting Process A Case Study

A. A. Chalekar*, A. A. Somatkar, S. S. Chinchanikar

Mechanical Engineering Department, S. P. Pune University, V.I.I.T, Kondhwa, Pune, Maharashtra, India

Abstract In order to reduce the process development time and maintain profit along with increasing reliability of the

system, it has become necessary for foundry engineers to optimize gating system and thus prevent defects before the

production of casting starts. It has been observed that location and size of feeders that provide liquid metal to compensate for

shrinkage of solidifying metal are determined by the ingenuity of the foundry engineer. Even if different combinations of

feeder location and size can be tried using computer simulation, the optimum design is quite difficult to obtain. Hence,

geometry based approaches are still important in process design. It was observed that lot of research work has been published

giving out various theories and formulas for design of feeding system but, there is little data available which show actual

application of those formulas for calculating individual dimensions of feeding system in day to day use. The aim of this paper

is to present a step by step guide to design a gating system for spacer which can be further generalised for any other

component.

Keywords Design, Gating system, Modulus method

1. Introduction

In any casting process, when an alloy is poured into a

mold, it starts to shrink or contract in volume as it cools

down to liquidus temperature, and subsequently solidifies.

These two stages of volumetric contraction are

compensated by adding feeders to the mold cavity design.

But unlike sand casting, in investment casting the

gating/feeding elements provide dual or combined function

of both.

The gating/feeding system initially governs the mold

filling operation and guides the molten metal as it flows into

the mold filing cavity, later while solidification it guides the

feeding liquid into this cavity as compensation for the first

two stages of alloy contraction. There are many methods

available for dimensioning of feeding elements like Caines

method, Bishops method, Chvorinovs rule, Wlodawers

method etc. [2]

The method used for dimensioning of feeding elements

used in this case study is derived from the rules that have

been formulated based on the original concepts by

Chvorinov and subsequently elaborated by Wlodawer. This

method is known as Modulus method. [4]

2. Modulus Method

* Corresponding author:

chalekarakash@gmail.com (A. A. Chalekar)

Published online at http://journal.sapub.org/jmea

Copyright 2015 Scientific & Academic Publishing. All Rights Reserved

Modulus is defined as the ratio of the volume to the

cooling surface area of the casting (or a part of the casting)

or the feeder.

M=V/A

(1)

Where, V is the volume of casting, or feeder

A is the cooling surface area.

Chvorinov rule [3] state that, solidification time

increases as the square of volume to area ratio increase, and

hence M, increase.

Or,

T = C * (V/ CS) 2

(2)

Where, T is solidification time, and C is constant.

It is easy to calculate this ratio for simpler objects, but in

real practice the objects involved are much more complex.

For complicated shapes, the casting is subdivided into

smaller basic shapes and modulus is calculated for each

section. It should be noted that during calculations only

cooling surface areas are to be included. Also, complex

junctions like curves are to be approximated. Feeding

requirement for each section then calculated for each

section as required.

As a general rule, the feeder must solidify no sooner than

the casting has solidified (heat transfer criterion). Also, the

feeder must contain sufficient liquid to meet the volume

contraction requirement (feed volume criterion). Thus a

feeder of optimum size must satisfy both of these

requirements.

Heat transfer criteria

According to Wlodawers technique, the modulus of the

feeder should be greater than that of the casting. Thus, using

16

A. A. Chalekar et al.: Designing of Feeding System for Investment Casting Process A Case Study

4. Case Study

a 20% factor of safety,

MF 1.2 MC

(3)

Where, MF and MC are modulus of feeder and casting

respectively.

To avoid shrinkage cavities near the feeder neck the

following ratio should be maintained:

MC: MN: MF = 1 : 1.1 : 1.2

(4)

Where, MN is modulus of neck at the junction of Casting

In this case feeding system for producing spacers (lantern

bush) is to be designed. This casting has a slightly

complicated geometry. In case defects are observed after

prototype production the rework cost will be very high.

Hence, instead of mere manual calculations the feeding

system was designed with the assistance of computer

modelling.

Feed volume criterion

4.1. 3D Model of Spacer

The feeder should not only solidify later than the casting,

it should also have enough volume to compensate the

shrinkage. Feed volume requirement is give by the relation:

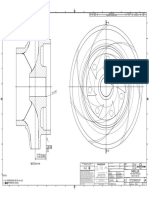

As per the 2D drawing specifications, 3D model of

spacer was prepared which will be used for simulation

purpose and will be helpful in verification of the theoretical

design data.

Fig. 2 shows the 3D model of spacer prepared using

CATIA V5. Casting metal used is CA15 corrosion resistant

alloy

The spacer has 4 columns; it is having outer diameter and

inner diameter as 114 mm and 88 mm respectively.

Vf/Vc = { / ( )}

(5)

Where, = efficiency of the feeder,

= solidification shrinkage,

Vf = volume of the feeder, and

Vc = volume of the casting.

The feeder volume given by the feed volume requirement

does not depend on the casting shape but that given by the

mass transfer or modulus criterion does.

The higher of the two values of feeder volume given by

equations (3) and (5) is taken as the actual volume of the

feeder.

3. Steps for Dimensioning Feeding

System

The procedure for designing of feeding system is

presented in Fig.1.

Prepare a 3D model of given component

Calculate number of feeders per casting

Determine location of feeder

Calculate minimum volume criterion

Design based on thermal criterion

Figure 2. 3D model of spacer

4.2. Number of Feeders Per Castings

As the component to be cast (spacer), has no protruding

parts and has simple geometry, hence the casting is fed by a

single feeder.

4.3. Positioning of Feeder

The spacer is divided into 3 sections based on the change

in geometry as shown in Fig 3.

3

Calculate feeder dimensions

Check for volumetric adequacy

Calculation of neck dimensions

Determine number of castings per cluster

Figure 1. Basic steps in feeding system design

Figure 3. Division of spacer in sections

Journal of Mechanical Engineering and Automation 2015, 5(3B): 15-18

The sequence in which the sections freeze is found by

calculating the modulus of each section as shown in

Table 1.

Table 1. Modulus of individual sections of spacer

17

iii. Cross-section = 30mm * 30mm, length=up to 250mm

The feeder with side 25 mm and length 200 mm is

selected.

4.7. To Ensure That the Feeder is volumetrically

adequate

Section

Volume (V)

(mm3)

Cooling surface Area

(CS) (mm2)

Modulus

(V / CS)

65988.58

12433.24

5.03

40331.72

7348.88

5.16

At 150 mm length the volume of feeder,

VF = D * D * L

= 125000 mm3

10080.93

2694.912

3.74

Total volume of casting,

7561.60

2307.36

3.277

Note: The surfaces not facing mold are excluded in calculating cooling

surface area.

For casting to be free from shrinkage defect, the feeder is

positioned at the slowest freezing section i.e. the section

having maximum modulus.

As it can be seen that the maximum modulus (Mc) is

found to be 5.16 and is for section 2, hence feeding element

is to be attached at section 2.

4.4. Volumetric Criterion or Minimum Volume Ratio

For the feeder to have adequate volume of feed liquid to

be supplied to casting being fed, following condition needs

to be satisfied,

Vf/Vc = { / ( )}

Where, Vf and Vc are the volumes of feeder and the

casting sections being fed, is alloy solidification shrinkage

= 3.5 [6], is the available feeding liquid factor = 18 [6]

VC = 123972.83 mm3

Therefore, this feeder has volume ratio of VF/VC = 1.008

when attached to a single casting. 1.008 > 0.24 (volumetric

criterion satisfied). Theoretically 4(1.008/0.24) castings can

be cast per feeder. But, due to length restriction of feeder

only 3 spacers are attached per feeder.

4.8. Calculation of Neck Dimensions

Feeder is connected to the casting by means of feeder

neck. The feeder neck has a reduced cross-section than that

of feeder, for ease of removal of feeders while cutoff and

also to control the temperature gradients. For the casting to

be free from shrinkage defects or bubble cavities, it is

essential that the neck solidifies after the casting and before

the feeder.

Modulus of neck is given by,

MN = 1.1 * 5.16

= 5.676

Vf/Vc = {3.5 / (18 3.5)}

Therefore, Vf/Vc = 0.24

L2

4.5. To Ensure That the Feeder is thermally adequate

L1

It is very essential that the feeder freezes adequately later

than the casting to be fed.

MF = 1.2 * 5.16 = 6.2

(a)

4.6. Selection of Feeder

DN

The standard feeder with square cross-section is to be

selected.

D

D

(b)

Figure 5.

Figure 4.

Cross-sectional view of feeder

Length of side of cross section (D) = MF * 4 = 24.88 mm

The standard square feeders available at the foundry are

i. Cross-section = 18mm * 18mm, length = up to 300mm

ii. Cross-section = 25mm * 25mm, length = up to 300mm

Dimensions of feeder neck (a) Side view (b) Top View

4.9. Calculation of Neck Dimensions

MN = 1.1 * 5.16

= 5.676

Minimum dimension of neck, DN = 4 * MN = 22.704 mm

i. We take DN = 23 mm (reduced over distance of

18

A. A. Chalekar et al.: Designing of Feeding System for Investment Casting Process A Case Study

H=15mm)

ii. We take L = 25 mm

iii. And, L2 = 23 mm

5. Conclusions

Trial and error approach for designing feeder leads to

either one of following conditions.

4.10. 3D Model of Wax-Pattern

1. Underestimation which causes improper filling of

mold and gives rise to defects like blowholes,

underfill, etc.

2. Overestimating which causes wastage of financial

resources related with melting of metal and

component finishing.

The 3D model of wax-pattern attached with feeder neck

is prepared by scaling the 3D model of spacer by a factor of

2.24 (patternmakers shrinkage allowance) and attaching a

neck as per calculated dimensions as shown in Fig. 6.

Figure 6.

3D model of Wax-pattern of spacer

The step by step guide provided in this paper, established

by Wlodawer eliminated all above drawbacks. The

advantage of following above procedure is that the correct

dimensions are obtained in first attempt itself. The calculated

dimensions can be verified before actual production by using

the 3D models for computer based simulation purpose.

Geometrical approach for designing can replace the

traditional way of trial and error commonly used in

industries today. This will lead to reduction in time between

the concept and manufacturing phase by a significant amount.

Also, the cost of rework and redesign is eliminated

increasing profit of industry.

4.11. 3D Model of Cluster

Cluster is assembly of number of wax patterns to a

feeding system so as to cast them simultaneously. As

calculated earlier 3 wax patterns are attached to a single

feeder. The 3D model of cluster is as shown in fig. 7

Figure 7. 3D model of cluster

REFERENCES

[1]

Vipul M Vasava, Prof D.R. Joshi, Identification of Casting

Defects by Computer Simulation A Review, IJERT Vol. 2

Issue 8, August 2013.

[2]

The Feeding Systems, Lecture 15, Prof. A. K. M. Bazlur

Rashid, Department of MME, BUET, Dhaka.

[3]

The Feeding Systems, Lecture 16, Prof. A. K. M. Bazlur

Rashid; Department of MME, BUET, Dhaka.

[4]

Wlodawer, R, Directional Solidification of Steel Castings,

Pergamon London 1966.

[5]

Steel castings handbook, Supplement 8.

S-ar putea să vă placă și

- Design of Gating and Feeding Systems: Experiment SixDocument1 paginăDesign of Gating and Feeding Systems: Experiment Sixkaushikb26Încă nu există evaluări

- Irjet V2i4147 PDFDocument5 paginiIrjet V2i4147 PDFPrasad RaikarÎncă nu există evaluări

- Starting Advantage With Simulation-Based Intelligent Feeder DesignDocument4 paginiStarting Advantage With Simulation-Based Intelligent Feeder DesignbvphimanshuÎncă nu există evaluări

- Orifice Plate Sizing Calculation Using A New Labview TechniqueDocument6 paginiOrifice Plate Sizing Calculation Using A New Labview TechniquesyamsulÎncă nu există evaluări

- Optimization of Catamaran Demihull FormDocument7 paginiOptimization of Catamaran Demihull FormwongyuliongÎncă nu există evaluări

- Chen 2000Document9 paginiChen 2000JUAN DIEGO FALCON CHURAÎncă nu există evaluări

- Design AID FOR Continuous Beams: BstractDocument13 paginiDesign AID FOR Continuous Beams: BstractAhmad HazimehÎncă nu există evaluări

- Simulation of The Heat Treatment of An Automotive Cast PartDocument6 paginiSimulation of The Heat Treatment of An Automotive Cast Partesteban vasquezÎncă nu există evaluări

- TUNING STATIONARY OBSERVERS APPLICATION TO A FLOTATI - 2007 - IFAC ProceedingsDocument6 paginiTUNING STATIONARY OBSERVERS APPLICATION TO A FLOTATI - 2007 - IFAC ProceedingssmeykelÎncă nu există evaluări

- Optimization of Catamaran Demihull FormDocument7 paginiOptimization of Catamaran Demihull FormshejtemaeiÎncă nu există evaluări

- The Use of Feeder Design Recommendations and Criteria Functions For The Efficient Feeding of Aluminum CastingsDocument10 paginiThe Use of Feeder Design Recommendations and Criteria Functions For The Efficient Feeding of Aluminum CastingsUbeyd ÇiçekÎncă nu există evaluări

- 07 Bubble BreakDocument25 pagini07 Bubble BreakWeb LogueandoÎncă nu există evaluări

- 7735 16925 1 PB - 2Document7 pagini7735 16925 1 PB - 2Athul DileepÎncă nu există evaluări

- Model-Based Procedure For Scale-Up of Wet Overflow Ball Mills Part I PDFDocument10 paginiModel-Based Procedure For Scale-Up of Wet Overflow Ball Mills Part I PDFMonica Ulloa LamasÎncă nu există evaluări

- Foundry Bhel1Document7 paginiFoundry Bhel1Charu MallÎncă nu există evaluări

- Ch-3 Mix Design ProcedureDocument13 paginiCh-3 Mix Design ProcedureMuhammad ImranÎncă nu există evaluări

- Cálculo de Volume em TanquesDocument7 paginiCálculo de Volume em TanquesMaurícioÎncă nu există evaluări

- Cap 5Document78 paginiCap 5Isaaias CTÎncă nu există evaluări

- Tutorial 2. Modeling Periodic Flow and Heat TransferDocument26 paginiTutorial 2. Modeling Periodic Flow and Heat Transferwaleed yehiaÎncă nu există evaluări

- User Journal 002Document7 paginiUser Journal 002Guruvenu KamanuruÎncă nu există evaluări

- A New Approach For Automated Measuring of The Melt Pool Geometry in Laser-Powder Bed FusionDocument11 paginiA New Approach For Automated Measuring of The Melt Pool Geometry in Laser-Powder Bed FusionСергей БадюкÎncă nu există evaluări

- The Design of Feeding SystemDocument10 paginiThe Design of Feeding SystemSantosh SÎncă nu există evaluări

- Minerals Engineering: Jens Lichter, King Lim, Alex Potapov, Dean KajaDocument5 paginiMinerals Engineering: Jens Lichter, King Lim, Alex Potapov, Dean KajaHosein HashemiÎncă nu există evaluări

- 1 s2.0 S0010448522001324 MainDocument12 pagini1 s2.0 S0010448522001324 Mainmahzad.sarghassabiÎncă nu există evaluări

- Using Modeling and Simulation For The Design of Full Scale Ball Mill CircuitsDocument23 paginiUsing Modeling and Simulation For The Design of Full Scale Ball Mill CircuitsJosé Helí Vallejos CoronadoÎncă nu există evaluări

- Reservoir Simulation Part ThreeDocument13 paginiReservoir Simulation Part ThreeAgbor taku juniorÎncă nu există evaluări

- Vibration Analysis of Rotary Cement Kiln Using Fin 2Document5 paginiVibration Analysis of Rotary Cement Kiln Using Fin 2nunchakuÎncă nu există evaluări

- Ubc 2003-791998Document135 paginiUbc 2003-791998nixontateli1Încă nu există evaluări

- OPTIMIZE CATAMARAN DESIGN WITH LOWEST RESISTANCEDocument6 paginiOPTIMIZE CATAMARAN DESIGN WITH LOWEST RESISTANCEgksahaÎncă nu există evaluări

- Validation of An Actuator Disc Model: Pire@risoe - Dtu.dk Nsqr@risoe - Dtu.dk Frza@risoe - Dtu.dkDocument10 paginiValidation of An Actuator Disc Model: Pire@risoe - Dtu.dk Nsqr@risoe - Dtu.dk Frza@risoe - Dtu.dkpierre_elouanÎncă nu există evaluări

- Ubc 1997-0068Document123 paginiUbc 1997-0068Vaibhav ShuklaÎncă nu există evaluări

- Peeters2015 1Document9 paginiPeeters2015 1AyoubÎncă nu există evaluări

- Reservoir-Simulation Lect 3Document41 paginiReservoir-Simulation Lect 3كهلان البريهيÎncă nu există evaluări

- Coaxial Filters OptimizationDocument6 paginiCoaxial Filters OptimizationThảo Phạm QuangÎncă nu există evaluări

- Powder Technology: Schalk Cloete, Stein Tore Johansen, Shahriar AminiDocument12 paginiPowder Technology: Schalk Cloete, Stein Tore Johansen, Shahriar AminiArpit DwivediÎncă nu există evaluări

- Cross Corner Delay Variation Model For Standard CeDocument17 paginiCross Corner Delay Variation Model For Standard Cekarunakara15gÎncă nu există evaluări

- Effect of The Use of Ceramic Filters in Steel CastingDocument6 paginiEffect of The Use of Ceramic Filters in Steel CastingBrijesh YadavÎncă nu există evaluări

- 2D Dynamic Mesh Model For Deposit Shape Prediction in Boiler Banks of Recovery Boilers With Different Tube Spacing ArrangementsDocument13 pagini2D Dynamic Mesh Model For Deposit Shape Prediction in Boiler Banks of Recovery Boilers With Different Tube Spacing ArrangementsZihan ZhangÎncă nu există evaluări

- Modelo Separacion Solido Liquido CentrifugaDocument14 paginiModelo Separacion Solido Liquido CentrifugausuarioyanniraÎncă nu există evaluări

- Development and Validation of A Gas-Liquid Two-PhaDocument242 paginiDevelopment and Validation of A Gas-Liquid Two-Phadibyendu ChakrabartyÎncă nu există evaluări

- Effect of The Use of Ceramic Filters in Steel CastingDocument6 paginiEffect of The Use of Ceramic Filters in Steel CastingJavier Escalante VillanuevaÎncă nu există evaluări

- Nodal Methods For Three-Dimensional Simulators: (Received JulyDocument23 paginiNodal Methods For Three-Dimensional Simulators: (Received JulyTopan SetiadipuraÎncă nu există evaluări

- Grain Size Distribution and Hydraulic PropertiesDocument17 paginiGrain Size Distribution and Hydraulic PropertiesAngel Alexis Mariño RomeroÎncă nu există evaluări

- Tutorial 2.0rc2 Ccm1Document25 paginiTutorial 2.0rc2 Ccm1Mehdin MujanovicÎncă nu există evaluări

- Dynamic Modeling of Multi Stage Flash (MSF)Document334 paginiDynamic Modeling of Multi Stage Flash (MSF)wojan100% (1)

- Chemical Engineering Science: Akram Avami, Wolfgang Marquardt, Yadollah Saboohi, Korbinian KraemerDocument12 paginiChemical Engineering Science: Akram Avami, Wolfgang Marquardt, Yadollah Saboohi, Korbinian KraemerDeepshikhaSinghÎncă nu există evaluări

- Case Study_1 report_21BME081Document7 paginiCase Study_1 report_21BME081krishnaÎncă nu există evaluări

- Heat Exchanger DesignDocument8 paginiHeat Exchanger DesignWilliam KearÎncă nu există evaluări

- A Performance Model For Impact CrusherDocument7 paginiA Performance Model For Impact CrusherAdil KhanÎncă nu există evaluări

- 07_chapter 3Document59 pagini07_chapter 3Sid ZainÎncă nu există evaluări

- An Overview of Impellers, Velocity Profile and Reactor DesignDocument7 paginiAn Overview of Impellers, Velocity Profile and Reactor DesignsrÎncă nu există evaluări

- Hook Load - FULLTEXT01 PDFDocument84 paginiHook Load - FULLTEXT01 PDFMarcoÎncă nu există evaluări

- Minerals: Open Pit Optimization Using The Floating Cone Method: A New AlgorithmDocument20 paginiMinerals: Open Pit Optimization Using The Floating Cone Method: A New AlgorithmCARLOS FABRIZIO MONTOYA VEGAÎncă nu există evaluări

- Boundary Value Design Method For Complex Demethanizer ColumnsDocument6 paginiBoundary Value Design Method For Complex Demethanizer ColumnsBabu ChaurasiaÎncă nu există evaluări

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsDe la EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsEvaluare: 5 din 5 stele5/5 (1)

- Process Plant Design: Heinemann Chemical Engineering SeriesDe la EverandProcess Plant Design: Heinemann Chemical Engineering SeriesEvaluare: 3.5 din 5 stele3.5/5 (11)

- Database Classification TypesDocument10 paginiDatabase Classification TypesBhiea Mische MatilacÎncă nu există evaluări

- Submittal Chiller COP 6.02Document3 paginiSubmittal Chiller COP 6.02juan yenqueÎncă nu există evaluări

- Facilities Assignment 1-2-2015Document2 paginiFacilities Assignment 1-2-2015Xnort G. Xwest0% (1)

- Visualizing Interstellar WormholesDocument14 paginiVisualizing Interstellar WormholesFranciscoÎncă nu există evaluări

- 04.protection of 33KV Feeder.Document16 pagini04.protection of 33KV Feeder.gnpr_10106080Încă nu există evaluări

- Practical-10: AIM: Installing Active Directory and Creating AD ObjectsDocument4 paginiPractical-10: AIM: Installing Active Directory and Creating AD ObjectsnisuÎncă nu există evaluări

- UnderstandingCryptology CoreConcepts 6-2-2013Document128 paginiUnderstandingCryptology CoreConcepts 6-2-2013zenzei_Încă nu există evaluări

- Design Plan: A Performance Task in GeometryDocument12 paginiDesign Plan: A Performance Task in GeometryRobert Ryan SantiagoÎncă nu există evaluări

- 02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0Document5 pagini02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0QQÎncă nu există evaluări

- Control PhilosophyDocument2 paginiControl PhilosophytsplinstÎncă nu există evaluări

- GL Setup ListDocument88 paginiGL Setup ListSundaroraclefinÎncă nu există evaluări

- Impeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLDocument1 paginăImpeller: REV Rev by Description PCN / Ecn Date CHK'D A JMM Released For Production N/A 18/11/2019 PDLSenthilkumar RamalingamÎncă nu există evaluări

- Excel 2007 Lesson 7 QuizDocument5 paginiExcel 2007 Lesson 7 Quizdeep72Încă nu există evaluări

- Admix Load CellDocument6 paginiAdmix Load Cellmanil_5Încă nu există evaluări

- The Order of Historical Time: The Longue Durée and Micro-HistoryDocument17 paginiThe Order of Historical Time: The Longue Durée and Micro-HistoryGeorgia KoutaÎncă nu există evaluări

- How Dna Controls The Workings of The CellDocument2 paginiHow Dna Controls The Workings of The Cellapi-238397369Încă nu există evaluări

- Xenomai 3 DocumentationDocument673 paginiXenomai 3 DocumentationGuile BonafiniÎncă nu există evaluări

- Scoop Atlas Wagner ST1810Document4 paginiScoop Atlas Wagner ST1810Juan Manuel PerezÎncă nu există evaluări

- Stereochemistry Practce PDFDocument6 paginiStereochemistry Practce PDFFerminÎncă nu există evaluări

- Sip TrainingDocument96 paginiSip Trainingronics123Încă nu există evaluări

- Mitsubishi diesel forklifts 1.5-3.5 tonnesDocument2 paginiMitsubishi diesel forklifts 1.5-3.5 tonnesJoniÎncă nu există evaluări

- Comparative Study Between Vyatra 3 and Vyatra 4 WBMDocument9 paginiComparative Study Between Vyatra 3 and Vyatra 4 WBMFatih RakaÎncă nu există evaluări

- UG WeibullDocument776 paginiUG WeibullCharles GuzmanÎncă nu există evaluări

- Smart Dustbin using ArduinoDocument22 paginiSmart Dustbin using ArduinoEr Dinesh TambeÎncă nu există evaluări

- HowTo Work With CR 90Document87 paginiHowTo Work With CR 90WagBezerraÎncă nu există evaluări

- 2017 Yr 9 Linear Relations Test A SolutionsDocument13 pagini2017 Yr 9 Linear Relations Test A SolutionsSam JeffreyÎncă nu există evaluări

- R8557B KCGGDocument178 paginiR8557B KCGGRinda_RaynaÎncă nu există evaluări

- Data Warehousing: Modern Database ManagementDocument49 paginiData Warehousing: Modern Database ManagementNgọc TrâmÎncă nu există evaluări

- Superalloy Brochure PDFDocument16 paginiSuperalloy Brochure PDFDaren NeradÎncă nu există evaluări

- Bobcat Technical Information Bulletin - CompressDocument2 paginiBobcat Technical Information Bulletin - Compressgerman orejarenaÎncă nu există evaluări