Documente Academic

Documente Profesional

Documente Cultură

RC Testing and Laboratory

Încărcat de

Daryl BadajosTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RC Testing and Laboratory

Încărcat de

Daryl BadajosDrepturi de autor:

Formate disponibile

n ABSTRACT

q SPECIMEN CONSTRUCTION

This experiment examines the behavior of a slender column

subjected to an eccentric axial load. Slender columns fail by

buckling or excessive lateral bending influenced by secondary

moments. In the experiment, a first-order displacement results

from the initial eccentricity. Second-order displacements are a

function of both Eulers formula for critical loading of a column

and the first-order deflection. The experiment provides evidence

that slenderness causes a column to undergo increased

moments and deflections, which in turn cause the column to fail

at a lower axial load than if slenderness effects were neglected.

Specifically, our results show that the column failed in flexure

due to yielding of steel before crushing of concrete. While this

matches conceptually with our predictions, the column failed at a

lower axial load possibly due to uncertainty in rebar placement

and additional moment caused by the self-weight of the column.

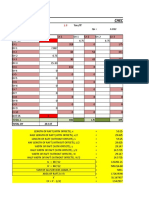

t TEST RESULTS

r INSTRUMENTATION

The specimen used nominal Grade 60, #4 longitudinal

reinforcement rebar. The material strength of the rebar was

tested prior to the experiment and an analysis of the stress-strain

plot was determined providing the actual values for modulus of

elasticity, yield stress, strain-hardening stress, and ultimate

stress for the #4 steel in the column. Concrete was tested in

compression on a 6 x 12 cylindrical concrete placed in between

rubber padding to compensate for the irregularity of the surface

of the concrete. Concrete was compressed until failure, and an

analysis of the stress-strain plot, Figure 4(c), determined the

maximum stress of the concrete to be 5.2 ksi. Photos of both

specimen testing are shown on Figure 4(b) and Figure 4(d).

The column failed at 28 kips axial load, much lower than

expected. The shape of the graph in Figure 7(a) indicates that

column behavior was greatly influenced by secondary moments

and slenderness effects. The column failed in flexure due to

yielding of steel before the concrete crushed as can be seen by

the P-M relation crossing the failure envelope below the balance

point. This corresponds to the theoretical prediction. In Figure

7(b), the curve may have been due to the self-weight of the

column inducing additional moment at mid-span. This would

result in a greater moment for smaller applied loads than

theoretically predicted. The difference in the curves in Figure 7(c)

may be explained by the fact that elastic axial displacement does

not account for slenderness effects. The axial vs. transverse

deflections are depicted in Figure 7(d). The predicted and

experimental curves generally follow the same shape, although

concrete shrinkage may have created a void that would explain

the apparent jump in initial measured axial deformation values.

Test specimen instrumentation consisted of a load cell to

measure the applied load and two LVDTs to measure the

transverse displacement at mid-span and the axial

displacement. The measurements were needed to determine

load and moment at failure, load-deflection curves, and axial

versus lateral displacement relations. Photos of the

instrumentation are shown in Figures 5(a), (b), (c), (d).

6.0

Model

5.0

test1

test2

Stress [ks

4.0

o OBJECTIVES

Theoretical and experimental results were compared to assess

common structural engineering approaches use to:

3.0

Figure 5(b) Axial LVDT

2.0

P-M Diagram

0.000

0.002

0.004

0.006

0.008

Figure 5(a) Mid-span LVDT

0.010

Strain

90

80

150

70

Load [kip

Figure 4(a) Rebar Stress-Strain

100

200

0.0

Compute axial deflection due to axial load using material,

force and cross sectional property relations.

Determine axial deflections versus lateral deflection

relations.

Predict the failure moment and load by comparing to a

P-M interaction diagram.

Assess the influence of slenderness by considering

buckling effects.

Determine mid-span column moment versus lateral

displacement relations.

Mid-Height Column Moment vs Lateral Displacement

250

1.0

Figure 4(c) Concrete Stress-Strain

Moment [kip-

Civil Engineering

CEE 142L REINFORCED CONCRETE TESTING LABORATORY

SLENDER COLUMN EXPERIMENT

G. Beretta, E. Chen, S.A. Cooke, D. Hurley, D. Naish

100

50

0

20

40

60

80

100

-50

-100

Moment [kip-in]

120

140

Figure 4(b) Reinforcing steel

Figure 4(d) Concrete cylinder (6 x 12)

Figure 5(c) Signal Conditioner

Figure 5(d) Axial Load Cell

P-M Diagram

column can be seen in the P-M interaction diagrams in Figure

6(a) for actual material strengths. It was expected to fail at a

125 kips and 125 kip-in due to the relationship M=P*e.

However, when considering slenderness, the expected failure

is 48 kip and 134 kip-in. The experiment was conducted to

compare to these expectations.

Photos below display the experiment process.

Load [kip

150

100

Figure 6(b) Before Loading

50

Figure 6(c) Initial Loading

0.2

0.4

20

40

60

80

100

120

140

160

ACI P-M including Slenderness

M=P*e

Class Derived, incl. 0.23 alpha

Euler Critical Buckling

-50

-100

Moment [kip-in]

P-M

Figure 6(a) P-M Interaction Diagram

0.6

0.8

1.2

Axial vs Transverse Deflection

0.5

40

0.45

lambda vs a Measured

lambda* vs a Theoretical

lambda* vs a Measured

lambda vs a Theoretical

0.4

25

20

Experimental

Theoretical

0.35

0.3

0.25

0.2

0.15

10

lambda* accounts for

elastic axial deformations

0.1

0.05

0.05

0.1

0.15

Axial Displacement [in]

0.2

0.25

Figure 7(c) Load-Displacement

0.5

1.5

2.5

3.5

4.5

Transverse (a) [in]

Figure 7(d) Axial-Transverse

u CONCLUSIONS

The results of this experiment indicate:

Theoretical axial capacity of the column was modified by the

slenderness ratio, which exceeded the ACI 318 limit.

Close placement of the longitudinal rebar to the center of

the section provided a narrow cage of flexural

reinforcement, which may have contributed to diminishing

the capacity, in accordance with predicted results.

Thus a column of this nature should be designed with

caution as slight eccentricities can cause major differences

in the behavior of the column.

v ACKNOWLEDGEMENTS

0

107"

4 #4 Total

1/4" Diam

45

15

The column was subjected to axial loading with an eccentricity of

one inch on one end of the column. Load magnitude was slowly

increased until the column buckled and experienced failure.

The behavior of the slender column was evaluated using ACI 31802 procedures. The P-M diagram was determined by finding the

moment capacity at various loads. The nominal strength of the

200

6"

Figure 7(b) Moment-Displacement

Axial (lambda) [

Axial Load[ki

s ANALYTICAL RESULTS & FAILURE EVALUATION

250

Figure 3 Column Dimensions

10

Axial Load vs. Axial Displacement

The test specimen was designed to be representative of a slender

column in a non-sway frame. The column dimensions were such

that the kl/r ratio was approximately 70 (greater than the ACI 318

section 10.12.2 limit of 22), indicating that buckling effects needed

to be considered. In addition, reinforcement was close to the

centroid of the section. The column was tested horizontally with

an axial load applied at one pinned end for simplicity, see Figure

2. Dimensional details, including reinforcement specifications are

shown in Figures 1 and 3.

1 " cover

216

Measured

Calculated

20

Lateral Displacement [in]

Figure 7(a) P-M Including Actual

p TEST OVERVIEW

Figure 2 Pinned Connection

40

160

ACI P-M including Slenderness

M=P*e

Class Derived, incl. 0.23 alpha

Euler Critical Buckling

P-M

Experimental

30

214"

50

30

0

35

Figure 1 Rebar Cage

60

Figure 6(d) Failure

Figure 6(d) Rebar Exposure

The authors would like to acknowledge the guidance and

leadership of the following people: Prof. John Wallace and

Leonardo Massone, for offering insight into the experiments and

challenging us to improve our lab-writing skills. We would also

like to thank Mr. Harold Kasper for his assistance in the

experiments and Kutay Orakcal for preparing us in CEE 142.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- 2 Story House Plans Photos PhilippinesDocument17 pagini2 Story House Plans Photos PhilippinesDaryl Badajos100% (5)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- 2 1 ExcavationBasementConstructionDocument18 pagini2 1 ExcavationBasementConstructionQuang Dang NgocÎncă nu există evaluări

- Raft DesignDocument27 paginiRaft DesignZain SaeedÎncă nu există evaluări

- Plan Bungalow House Plans With PhotosDocument28 paginiPlan Bungalow House Plans With PhotosDaryl Badajos100% (1)

- Foldable Helmet Project ReportDocument43 paginiFoldable Helmet Project ReportArnaz Asa Sholeh100% (2)

- Caterpillar E120 Hydraulic Excavator - RitchieWikiDocument1 paginăCaterpillar E120 Hydraulic Excavator - RitchieWikiDaryl Badajos100% (1)

- Bungalow House Plans Photos PhilippinesDocument16 paginiBungalow House Plans Photos PhilippinesDaryl Badajos100% (1)

- 117 Labreport #2Document21 pagini117 Labreport #2Glaize Anne Gamelong100% (1)

- 00a15f4e62f696fa910bb62b0e2b800cDocument1 pagină00a15f4e62f696fa910bb62b0e2b800cDaryl BadajosÎncă nu există evaluări

- Exodus LessonDocument307 paginiExodus LessonDaryl BadajosÎncă nu există evaluări

- Exc ExmplDocument6 paginiExc ExmplMagenta CamaclangÎncă nu există evaluări

- Top 10 Greatest Fortresses and Castles Ever BuiltDocument9 paginiTop 10 Greatest Fortresses and Castles Ever BuiltDaryl BadajosÎncă nu există evaluări

- Classification of Soils and Soil-Aggregate MixturesDocument1 paginăClassification of Soils and Soil-Aggregate MixturesDaryl BadajosÎncă nu există evaluări

- Modern Contractor Solutions October 2016 PDFDocument70 paginiModern Contractor Solutions October 2016 PDFDaryl BadajosÎncă nu există evaluări

- Animal List: Aquatic and Reptile CenterDocument4 paginiAnimal List: Aquatic and Reptile CenterDaryl BadajosÎncă nu există evaluări

- RC Testing and LaboratoryDocument1 paginăRC Testing and LaboratoryDaryl BadajosÎncă nu există evaluări

- ConcreteDESIGNmix ExamDocument2 paginiConcreteDESIGNmix ExamDaryl BadajosÎncă nu există evaluări

- 2174 PDFDocument40 pagini2174 PDFDaryl BadajosÎncă nu există evaluări

- Singing Success PDFDocument18 paginiSinging Success PDFdovys261075% (4)

- A Mighty Fortress Is Our GodDocument3 paginiA Mighty Fortress Is Our GodDaryl BadajosÎncă nu există evaluări

- Ceiling EstimateDocument1 paginăCeiling Estimatebertovalen100% (2)

- Ten Steps Building ProfitsDocument9 paginiTen Steps Building ProfitsVilaysak SayakoummaneÎncă nu există evaluări

- Chap 03Document16 paginiChap 03Ahmad Ashraf ZolkefliÎncă nu există evaluări

- Basic Steps in Construction Scheduling and ManagementDocument6 paginiBasic Steps in Construction Scheduling and ManagementDaryl BadajosÎncă nu există evaluări

- What Is The AprocyphalDocument11 paginiWhat Is The AprocyphalDaryl BadajosÎncă nu există evaluări

- Confess Our Sins QaDocument7 paginiConfess Our Sins QaDaryl BadajosÎncă nu există evaluări

- Drawing Cutting Edge AnatomyDocument1 paginăDrawing Cutting Edge AnatomyDaryl BadajosÎncă nu există evaluări

- Cut and Fill - 1 PDFDocument5 paginiCut and Fill - 1 PDFHabeeb MaruuÎncă nu există evaluări

- The ApocryphaDocument7 paginiThe ApocryphaDaryl BadajosÎncă nu există evaluări

- DepEd new Grading System only requires 60 to passDocument9 paginiDepEd new Grading System only requires 60 to passDaryl BadajosÎncă nu există evaluări

- How To Calculate Cut and FillDocument5 paginiHow To Calculate Cut and FillDaryl BadajosÎncă nu există evaluări

- 2174 PDFDocument40 pagini2174 PDFDaryl BadajosÎncă nu există evaluări

- Unit 11 - Monitoring Excavation in The HighwayDocument10 paginiUnit 11 - Monitoring Excavation in The HighwayDaryl BadajosÎncă nu există evaluări

- Induction Type RelayDocument17 paginiInduction Type RelayAnshuman BeheraÎncă nu există evaluări

- EN 13445-2 +A2 (2012) Unfired Pressure Vessels, Part 2 MaterialsDocument86 paginiEN 13445-2 +A2 (2012) Unfired Pressure Vessels, Part 2 Materials김창배Încă nu există evaluări

- Mechanical Resonance - Theory and ApplicationsDocument10 paginiMechanical Resonance - Theory and ApplicationsEbrahim Abd El HadyÎncă nu există evaluări

- M5 Nanotechnology and PolynomersDocument6 paginiM5 Nanotechnology and PolynomersMalvika RkÎncă nu există evaluări

- BJT Amplifier SimulationDocument11 paginiBJT Amplifier SimulationNiko de LemosÎncă nu există evaluări

- Polymer CompositeDocument3 paginiPolymer CompositeMayankBhattÎncă nu există evaluări

- Ultrathin-Metal-Film-Based Transparent Electrodes With Relative Transmittance Surpassing 100%Document8 paginiUltrathin-Metal-Film-Based Transparent Electrodes With Relative Transmittance Surpassing 100%ResalatFaruqueNuhÎncă nu există evaluări

- WEEK-4-Q2-GEN CHEM-Nov 20-24-DLLDocument7 paginiWEEK-4-Q2-GEN CHEM-Nov 20-24-DLLJennette Belliot100% (1)

- DBDsoft User ManualDocument93 paginiDBDsoft User ManualpouyamhÎncă nu există evaluări

- LP-Sept. 5 - Electric SymbolsDocument4 paginiLP-Sept. 5 - Electric SymbolsDiona Bangga - ModestoÎncă nu există evaluări

- Mcqs in Thermodynamics Part V: What Is Your Iq Score?Document10 paginiMcqs in Thermodynamics Part V: What Is Your Iq Score?Joshua OrlandaÎncă nu există evaluări

- ANS 002 Determination of Cristallinity of PET by DSCDocument2 paginiANS 002 Determination of Cristallinity of PET by DSCTiwiÎncă nu există evaluări

- Measuring Control of Construction MaterialsDocument7 paginiMeasuring Control of Construction MaterialsYOLO crapperÎncă nu există evaluări

- Failure of SpringDocument9 paginiFailure of SpringLeandro MarchiÎncă nu există evaluări

- Designing Electromagnetic Fields with Nanoplasmonic StructuresDocument21 paginiDesigning Electromagnetic Fields with Nanoplasmonic Structuressuraj mani dasÎncă nu există evaluări

- Pec Chapter 3 1Document37 paginiPec Chapter 3 1relkunkoÎncă nu există evaluări

- CaP Phosphoric AcidDocument4 paginiCaP Phosphoric AcidcrisÎncă nu există evaluări

- Heat Exchanger - z1 - Double PipeDocument26 paginiHeat Exchanger - z1 - Double PipeUğur ÖzçınarÎncă nu există evaluări

- MT7605B DSDocument7 paginiMT7605B DSVishal dtuÎncă nu există evaluări

- Strength Analyses of Sandwich Pipes For Ultra Deep PDFDocument172 paginiStrength Analyses of Sandwich Pipes For Ultra Deep PDFClaudio PazÎncă nu există evaluări

- Principles of Food Engineering Lecture 1: Introduction to Transport Processes and Unit OperationsDocument6 paginiPrinciples of Food Engineering Lecture 1: Introduction to Transport Processes and Unit OperationsSuyash GuptaÎncă nu există evaluări

- European Steel and Alloy Grades: Gx7Crnimo12-1 (1.4008)Document2 paginiEuropean Steel and Alloy Grades: Gx7Crnimo12-1 (1.4008)farshid KarpasandÎncă nu există evaluări

- Defect and LimitationDocument4 paginiDefect and LimitationFirdaus IliasÎncă nu există evaluări

- Calculating Stresses and Strains in Structural ElementsDocument6 paginiCalculating Stresses and Strains in Structural ElementskÎncă nu există evaluări

- Loss of Field or Excitation Protection of Alternator or GeneratorDocument4 paginiLoss of Field or Excitation Protection of Alternator or Generatorsiddhant103Încă nu există evaluări