Documente Academic

Documente Profesional

Documente Cultură

Mod-05 Rev

Încărcat de

vcpTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mod-05 Rev

Încărcat de

vcpDrepturi de autor:

Formate disponibile

MODULE 5

1.

Which of the following do not contain job quality requirements?

A.

B.

C.

D.

E.

2.

Of the following, which may be considered mandatory?

A.

B.

C.

D.

E.

3.

Code

Standard

Specification

A and B above

B and C above

Something set up and established by authority as a rule to measure quantity, quality, value, or

weight is a:

A.

B.

C.

D.

E.

7.

Code

Standard

Specification

Both A and B above

All of the above

The type of document that describes the requirements for a particular material or component is

referred to as :

A.

B.

C.

D.

E.

6.

Codes

Standards

Specifications

Drawing

None of the above

The type of document that has legal status by definition is :

A.

B.

C.

D.

E.

5.

Codes

Specifications

Standards

All of the above

None of the above

The job documents that best describe the size and configuration of a weldment are:

A.

B.

C.

D.

E.

4.

Codes

Drawings

Specifications

Text books

Standards

Specification

Standard

Code

Drawing

None of the above

Of the following types of documents, which have general acceptance in the welding industry ?

A.

B.

C.

D.

E.

Contracts

Standards

Specifications

Drawings

All of the above

Page 1 of 5

8.

The code that covers the welding of steel structure is:

A.

B.

C.

D.

E.

9.

The code that covers the design of metallic unfired pressure vessel is:

A.

B.

A.

B.

C.

10.

Guide the inspector on permissible size variations

Show the total amount of variation permitted from the design size

Both A and B above

None of the above

Tolerances can be expressed :

A.

B.

C.

D.

E.

15.

Section V

Section XI

Section III

Section VIII

Section IX

Tolerances are required on drawings to :

A.

B.

C.

D.

14.

Color coding

Alpha - numeric coding

Heat number transfer

Bar coding

Segregation by alloy

Which section of the ASME Code covers qualification of welders ?

A.

B.

C.

D.

E.

13.

AWS D1.X

AWS D14.X

AWS A5.1 - A5.31

ASTM A 53

ASTM A 36

Which of the following methods for controlling materials in a fabrication shop is most suitable for

automation ?

A.

B.

C.

D.

E.

12.

ASME Section IX

ASME Section VIII

ASME Section X

API 1104

AWS D1.1

The series of specifications covering the requirements for welding electrodes is designated:

A.

B.

C.

D.

E.

11.

ASME Section IX

ASME B 31.1

API 1104

AWS D1.1

ASME B 31.3

As a variation between limits

As plus or minus dimension

As a design size with either a plus or a minus

All of the above

None of the above

Drawing notes can be classified as :

A.

B.

C.

D.

E.

General

Local

Specifications

All of the above

None of the above

Page 2 of 5

16.

Hold points refer to :

A.

B.

C.

D.

17.

The welding inspector is not responsible for checking to make sure all welding and testing

personnel have adequate certifications.

A.

B.

18.

ASTM Standards

ASME Code, Section II, Part A and B

It is not required to specify base metals

A and B above

None of the above

The AWS Specifications designated as A5.XX refer to :

A.

B.

C.

D.

E.

24.

True

False

Base metals used in fabrication can be bought to confirm with which of the following ?

A.

B.

C.

D.

E.

23.

Section III

Section II, Part C

Section II, Part D

Section IX

None of the above

Standards are never considered mandatory.

A.

B.

22.

True

False

In what Section of the ASME Code are the filler materials found ?

A.

B.

C.

D.

E.

21.

One

Two

Three

Four

Six

When inspecting unfired pressure vessels to the ASME Code, the inspector will usually use

several different Sections.

A.

B.

20.

True

False

The American Welding Society has developed how many welding codes ?

A.

B.

C.

D.

E.

19.

The points for lifting an object

A delay in fabrication to permit inspection

A shutdown at the end of the day

None of the above

Filler metals

Rules for bridges

Cross country pipelines

Pressure vessel fabrication

None of the above

An effective materials control system will :

A.

B.

C.

D.

E.

Be as simple as possible

Contain check and balances

Not be necessary unless the fabrication is for nuclear work

Be based on first in - first out

A and B above

Page 3 of 5

25.

UNS refers to :

A.

B.

C.

D.

E.

26.

Who is normally responsible for the qualification of welding procedures and welders ?

A.

B.

C.

D.

E.

27.

1G

2G

5G

6G

6GR

What is the pipe welding position where the axis of the pipe lies fixed at a 45 - degree angle ?

A.

B.

C.

D.

E.

31.

Face bend

Root bend

Side bend

Nick break

Tensile

What is the pipe welding position where the pipe remains fixed with its axis horizontal, so the

welder must weld around the joint ?

A.

B.

C.

D.

E.

30.

Shielded metal arc

Submerged arc

Short - circuiting transfer gas metal arc

Spray transfer gas metal arc

Flux cored arc

Of the following types of test specimens, which used by API and not ASME for procedure and

welder qualification testing ?

A.

B.

C.

D.

E.

29.

Welder

Architect

Welders employer

Engineer

Code body

Which of the following processes is not considered prequalified in accordance with AWS D1.1 ?

A.

B.

C.

D.

E.

28.

United Nondestructive Society

United National Standards

Unified National System

Unified Numbering System

None of the above

1G

2G

5G

6G

None of the above

What is the pipe position test for welders who are trying to qualify to weld T, K and Y connections

?

A.

B.

C.

D.

E.

1G

2G

5G

6G

6GR

Page 4 of 5

32.

If a welder qualifies to weld with an E6010 electrode, which is an F3 group electrode, he is also

qualified to weld with all of the following except:

A.

B.

C.

D.

E.

33.

With relation to procedure and welder qualification, which of the following can be an important

task for the welding inspector ?

A.

B.

C.

D.

E.

34.

E6011

E6012

E7018

E7024

E6013

Watching the welding qualification test

Identifying samples

Cutting and testing specimens

Monitoring production welding

All of the above

For most codes, if a welder continues of use particular process and procedure, how long does the

welders qualification remain in effect?

A.

B.

C.

D.

E.

Indefinitely

6 months

1 year

3 years

Until the welder produces a rejectable weld

Page 5 of 5

S-ar putea să vă placă și

- Lesson 17Document1 paginăLesson 17vcpÎncă nu există evaluări

- Lesson 16Document1 paginăLesson 16vcpÎncă nu există evaluări

- Lesson 14Document1 paginăLesson 14vcpÎncă nu există evaluări

- RT Quiz on Radiation Protection ConceptsDocument1 paginăRT Quiz on Radiation Protection ConceptsvcpÎncă nu există evaluări

- RT Lesson 7 Quiz - True/False Radiography QuestionsDocument1 paginăRT Lesson 7 Quiz - True/False Radiography QuestionsvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 10: RT Lesson 11 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 10: RT Lesson 11 QuizvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 13: RT Lesson 9 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 13: RT Lesson 9 QuizvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 14: RT Lesson 15 QuizDocument2 paginiKindly Select A' For TRUE & B' For FALSE 1 To 14: RT Lesson 15 QuizvcpÎncă nu există evaluări

- RT Quiz on Radiation Protection ConceptsDocument1 paginăRT Quiz on Radiation Protection ConceptsvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 11: RT Lesson 12 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 11: RT Lesson 12 QuizvcpÎncă nu există evaluări

- Lesson 08Document2 paginiLesson 08vcp0% (1)

- Kindly Select A' For TRUE & B' For FALSE 1 To 22: RT Lesson 6 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 22: RT Lesson 6 QuizvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 11: RT Lesson 12 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 11: RT Lesson 12 QuizvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 13: RT Lesson 9 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 13: RT Lesson 9 QuizvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 6: RT Lesson 10 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 6: RT Lesson 10 QuizvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 17: RT Lesson 4 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 17: RT Lesson 4 QuizvcpÎncă nu există evaluări

- Lesson 03Document2 paginiLesson 03vcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 16: RT Lesson 5 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 16: RT Lesson 5 QuizvcpÎncă nu există evaluări

- Lesson 03Document2 paginiLesson 03vcpÎncă nu există evaluări

- We SDP 2DDocument15 paginiWe SDP 2DvcpÎncă nu există evaluări

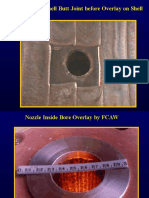

- Nozzle # Shell Butt Joint Before Overlay On ShellDocument14 paginiNozzle # Shell Butt Joint Before Overlay On ShellvcpÎncă nu există evaluări

- Lesson 02Document1 paginăLesson 02vcpÎncă nu există evaluări

- We SDP 2CDocument12 paginiWe SDP 2CvcpÎncă nu există evaluări

- Kindly Select A' For TRUE & B' For FALSE 1 To 14: RT Lesson 1 QuizDocument1 paginăKindly Select A' For TRUE & B' For FALSE 1 To 14: RT Lesson 1 QuizvcpÎncă nu există evaluări

- Radiography: Limitations of Rt-MethodDocument25 paginiRadiography: Limitations of Rt-MethodvcpÎncă nu există evaluări

- Radiography: Limitations of Rt-MethodDocument25 paginiRadiography: Limitations of Rt-MethodvcpÎncă nu există evaluări

- Cr-Mo / Cr-Mo-V Material - Issues: - Temper EmbrittlementDocument15 paginiCr-Mo / Cr-Mo-V Material - Issues: - Temper EmbrittlementvcpÎncă nu există evaluări

- We SDP 2ADocument14 paginiWe SDP 2AvcpÎncă nu există evaluări

- RT Safety1 IDocument5 paginiRT Safety1 IvcpÎncă nu există evaluări

- RT Safety1aDocument11 paginiRT Safety1avcpÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)