Documente Academic

Documente Profesional

Documente Cultură

Hes Reciprocating Compressor PDF

Încărcat de

BHAVINTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hes Reciprocating Compressor PDF

Încărcat de

BHAVINDrepturi de autor:

Formate disponibile

Why choose the HE-S

Global Services for Installation,

Support and Maintenance

GE Oil & Gas

GE Oil & Gas

HE-S worlds most powerful high speed

Full installation services

Via Felice Matteucci, 2

50127 Florence - Italy

T +39 055 423211

F +39 055 4232800

Nuovo Pignone S.p.A.

reciprocating compressor line designed

Expert maintenance

www.ge.com/oilandgas

according to API618 standards.

Remote Monitoring & Diagnostics (RM&D)

The patented GE Oil & Gas GEnyus diagnostic

system is able to detect deviations in

compressor behavior to increase safety during

operation and to optimize maintenance

programs.

Requires fewer compressors for the same

duty, delivering the highest reliability at

lower operating costs.

Contractual Service Agreements (CSAs)

HE-S ... the first reciprocating compressor frame

in the 9-10 MW natural gas segment capable of

A highly skilled staff of local engineers and

direct coupling with large gas engines.

technicians provides on-site technical support for

installation, commissioning, overhaul, repair, and

maintenance. This team is supported by our

headquarter experts, service shops, technical

assistants and project managers.

HE-S Range for Gas Storage

and Pipeline

Gas

Storage

10 MW

4HE-S 50-150 bar

4HE-S 30-200 bar

6HE-S 50-150 bar

6HE-S 30200 bar

6HE-S 50-75 bar

Power

2 MW

Pipeline

6HE-S 75-100 bar

4HE-S 50-75 bar

4HE-S 75-100 bar

Capacity

HE-S Reciprocating Compressor

1.0 million Nm3/h

The broadest capabilities in the medium frame range

covering both low and high speed applications

GE imagination at work

COMK/MARK 895/II - Designed by: Studio Tre Fasi

Printed by: Sagraf - 8-2008

2008 Nuovo Pignone S.p.A. all rights reserved

Introducing the HE-S an evolution of the existing HE Reciprocating Compressor

With more than a century of experience in

reciprocating compressor technology,

GE Oil & Gas has one of the most complete

lines of advanced and proven API618

machines.

The success of our current generation of

process compressors is the result of constant

technical innovation that draws on the global

resources and unmatched experience of GE.

Backed by the GE Oil & Gas engineering team

and a dedicated staff of Global Services

experts, our reciprocating compressor product

line guarantees customers an unmatched and

integrated approach along the entire plant life

cycle from design through to operation and

maintenance of the machinery. The result is

the highest level of performance, reliability

and availability in the industry.

Testifying to our ongoing commitment to

help customers achieve greater levels of

performance and productivity, we have

uprated the proven GE Oil & Gas HE line,

applying referenced design features to

achieve the highest capabilities in the

medium frame range for both gas engine

and electric motor driven applications.

The HE-S, an evolution of a heavy duty

machine with high speed characteristics.

Product Features

GE Oil & Gas API618 Product Range

Frame Size

# Throws

500 kN (112,000 lbf) max crosshead pin load

6 m/s (1,180 fpm) max average piston speed

Superior Design for Advanced Performance

Max Power

per throw *

[kW]

Piston Rod

Diameter

[mm]

Stroke

[mm]

Crankcase and Sliding Body

Max Speed

[rpm]

Heavily ribbed high-strength ductile iron

High stiffness to maintain correct alignment

of all moving and stationary parts

750 rpm max

OA

435

48

220

800

16,200 kW (21,700 HP) nominal max power at

full speed (6 throws)

OC

700

57

300

650

HA

2-4

500

48

180

1000

2-4-6 throws available

HB

2-6

625

57

210-230

800

Steel space bars for stiffening

Applications

HD

2-8

1,300

75

240-280

700

Designed for maintainability

Pipeline

HE

2-10

2,150

90

290-330

600

Storage

HF

2-10

2,850

110

320-360

470

Re-injection

HG

2-10

3,600

130

320-360-400

450

Refinery

HM

2-6

600

57

135-150

1200

The HE-S represents an addition to our portfolio of

reciprocating compressor products, which is designed

to address specific compression needs in all segments

of the oil and gas industry.

SHM

2-6

1,100

65

135-150

1200

SHMB

2-4

1,100

65

135-150

1200

HE-S

2-6

2,700

90

200-240

290-330

800

600

A Unique Entry into the Reciprocating

Compressor Market

Crankshaft

High strength forged steel, one piece, precision ground

* At max speed

Bolted-on counterweights to reduce unbalanced

rotating inertial forces

Lube oil holes and all discontinuities carefully smoothed

and polished to reduce stresses

Suitable for both slow and high speed API618

and API11P applications

Incorporating more than 100 years of GE Oil & Gas experience

Complete Product Support

Fully validated design

All units tested before shipment

24x7 support available anywhere

Localized training

2 throws 4 throws 6 throws

[mm]

[mm]

[mm]

Length

1,495

3,045

4,595

Height

1,510

1,510

1,510

Width, cylinders

excluded

3,760

3,760

3,760

Shaft center line

1,200

1,200

1,200

Ductile iron crosshead guides with external ribbing

The only reciprocating compressor capable of

750 rpm gas engine direct drive at 9MW and above

An ideal solution for API618 service allowing

moderate speed

Overall

Dimensions

Bearings

Crankcase

High-strength ductile iron

Tri-metal main and connecting rod bearings

No geometrical discontinuity in the highest loaded area

Crankshaft

High-strength forged steel

Mounted with split line in vertical position

Big-end bearings identical to journal bearings for spare

optimization

Crosshead

Tri-metal bearings

Fully machined forged steel body

Piston rod hydraulically connected

to flange

Sliding body

High-strength ductile iron

Four hydraulically tensioned bolts

connect the flange to crosshead pin

Crosshead body always under full

compression

S-ar putea să vă placă și

- High-Performance GM LS-Series Cylinder Head GuideDe la EverandHigh-Performance GM LS-Series Cylinder Head GuideEvaluare: 4.5 din 5 stele4.5/5 (2)

- API 610 PumpsDocument8 paginiAPI 610 PumpsSaurabh Singh67% (3)

- RH 120e HandbookDocument8 paginiRH 120e HandbookEgyiri Frederick100% (1)

- GE Reciprocating Compressor BrochureDocument13 paginiGE Reciprocating Compressor Brochurepratik banerjeeÎncă nu există evaluări

- Major Process Equipment Maintenance and RepairDe la EverandMajor Process Equipment Maintenance and RepairEvaluare: 4 din 5 stele4/5 (4)

- GE Oil Nuovo PignoneDocument27 paginiGE Oil Nuovo PignoneRogelio Soria100% (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualEvaluare: 3.5 din 5 stele3.5/5 (2)

- GE-turbo Generators PDFDocument7 paginiGE-turbo Generators PDFMilad MosalmanÎncă nu există evaluări

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDe la EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÎncă nu există evaluări

- GE Aeroderivative Product and Services SolutionsDocument16 paginiGE Aeroderivative Product and Services SolutionsCory TurnerÎncă nu există evaluări

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe la EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesÎncă nu există evaluări

- Control Valves For Critical ApplicationsDocument2 paginiControl Valves For Critical Applicationshichtn2009Încă nu există evaluări

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972De la EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Evaluare: 4.5 din 5 stele4.5/5 (3)

- Bettis Valve Actuator GuideDocument12 paginiBettis Valve Actuator Guideprufino2Încă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- GE - SeaSmart - Brochure 050313 2 FINAL PDFDocument7 paginiGE - SeaSmart - Brochure 050313 2 FINAL PDFCem MeteÎncă nu există evaluări

- NuovoPignone-Overhung Centrifugal CompressorsDocument7 paginiNuovoPignone-Overhung Centrifugal CompressorsMarcWorldÎncă nu există evaluări

- Ajax-Integral Engine CompressorDocument8 paginiAjax-Integral Engine CompressorShahzad AhmadÎncă nu există evaluări

- Brochure BEGEMANN PA Pumps-Low ResolutionDocument6 paginiBrochure BEGEMANN PA Pumps-Low ResolutionIsaac RubioÎncă nu există evaluări

- Siemens CompressorDocument12 paginiSiemens Compressorverat81100% (1)

- Brochure BEGEMANN BS Pumps-Low ResolutionDocument6 paginiBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorÎncă nu există evaluări

- Pump SCE B 2Document8 paginiPump SCE B 2Zankar R ParikhÎncă nu există evaluări

- Valve Automation Brochure USDocument8 paginiValve Automation Brochure USprufino2Încă nu există evaluări

- SGT5-8000H Proven in Commercial Operation PDFDocument16 paginiSGT5-8000H Proven in Commercial Operation PDFRonald CortezÎncă nu există evaluări

- Sgt-600 GT Mechdrive enDocument4 paginiSgt-600 GT Mechdrive enRoozbeh PÎncă nu există evaluări

- VS 6 - FlowserveDocument8 paginiVS 6 - FlowserveJung Jae YualÎncă nu există evaluări

- Brochure Siemens Gas-Turbine SGT-700 MDDocument4 paginiBrochure Siemens Gas-Turbine SGT-700 MDJohn_J2012Încă nu există evaluări

- Heat Recovery Steam Generators Optimized For Any ApplicationDocument7 paginiHeat Recovery Steam Generators Optimized For Any ApplicationKVVÎncă nu există evaluări

- CatalogoTurbineaGas PDFDocument34 paginiCatalogoTurbineaGas PDFshihabjamaan0% (1)

- Hed and Hed-Ds: Between Bearings, Two-Stage, Radially Split PumpsDocument8 paginiHed and Hed-Ds: Between Bearings, Two-Stage, Radially Split PumpsdwiaguspriyonoÎncă nu există evaluări

- Steam Turbine PDFDocument2 paginiSteam Turbine PDFeselcosacÎncă nu există evaluări

- Hot Gas ExpanderDocument2 paginiHot Gas ExpanderMary GomezÎncă nu există evaluări

- Medium & High Voltage and High Speed Motors PDFDocument16 paginiMedium & High Voltage and High Speed Motors PDFSandeep SinghÎncă nu există evaluări

- SGT5-8000H Brochure PDFDocument16 paginiSGT5-8000H Brochure PDFmyegnrÎncă nu există evaluări

- Goulds Model XHD - Heavy Duty Slurry PumpDocument11 paginiGoulds Model XHD - Heavy Duty Slurry Pumpalvarito12Încă nu există evaluări

- AJAX Brochure PDFDocument8 paginiAJAX Brochure PDFupper20cÎncă nu există evaluări

- Elliot CompressorsDocument12 paginiElliot Compressorsmatteo2009Încă nu există evaluări

- Drilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2Document40 paginiDrilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2MEREUEULEUÎncă nu există evaluări

- MEHH3000-00 - H75Es H95Es Hammers Specalog Indonesia and SEADocument8 paginiMEHH3000-00 - H75Es H95Es Hammers Specalog Indonesia and SEAlisahunÎncă nu există evaluări

- Turboexpander CompressorsDocument5 paginiTurboexpander CompressorsNuri LealÎncă nu există evaluări

- Drilling Profits DOMESTICDocument8 paginiDrilling Profits DOMESTICRamesh Rajamani100% (1)

- Siemens Fpso Offshore ProductionDocument4 paginiSiemens Fpso Offshore ProductionRoozbeh PÎncă nu există evaluări

- Cryostar Process Machinery PDFDocument0 paginiCryostar Process Machinery PDFJavad AmnianÎncă nu există evaluări

- ASME Presentation Nov 2014 PDFDocument56 paginiASME Presentation Nov 2014 PDFdf_campos33530% (2)

- MSB Hydraulic Breakers CatalogueDocument10 paginiMSB Hydraulic Breakers Cataloguemihneazlavoaga0% (1)

- Antisurge Valves For LNG MarketDocument2 paginiAntisurge Valves For LNG MarketAbbas MohajerÎncă nu există evaluări

- 1600 SERIES: Gear Pumps and MotorsDocument16 pagini1600 SERIES: Gear Pumps and Motorscoulibalyoumar100% (1)

- RENK MAAG Turbo Gearboxes 0413-1Document24 paginiRENK MAAG Turbo Gearboxes 0413-1RCMÎncă nu există evaluări

- 500 A 2500 KVA 1Document27 pagini500 A 2500 KVA 107939312Încă nu există evaluări

- The New M-Line: Marine Diesel EnginesDocument16 paginiThe New M-Line: Marine Diesel EnginesCornel N. ŞeitanÎncă nu există evaluări

- Valve Automation BrochureDocument8 paginiValve Automation Brochuredarkchess76Încă nu există evaluări

- Brochure MicroLNGDocument2 paginiBrochure MicroLNGbaanglore345Încă nu există evaluări

- 7 Com PDFDocument16 pagini7 Com PDFMarco AntonioÎncă nu există evaluări

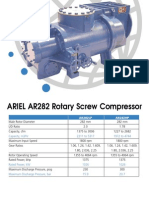

- ARIEL AR282 Rotary Screw Compressor: Capacity, m3/hr 2211 To 5317 1972 To 4744Document2 paginiARIEL AR282 Rotary Screw Compressor: Capacity, m3/hr 2211 To 5317 1972 To 4744michaelxiaoÎncă nu există evaluări

- Series G BETTISDocument6 paginiSeries G BETTISLuis Moran100% (1)

- HRSG 2011 BrochureDocument12 paginiHRSG 2011 BrochureAndry SetiawanÎncă nu există evaluări

- C1 - 2014 GS OilDocument2 paginiC1 - 2014 GS OilNathan KornÎncă nu există evaluări

- API 618 Reciprocating CompressorDocument12 paginiAPI 618 Reciprocating Compressorfoobar2016Încă nu există evaluări

- MO Assignment 2 NumericalDocument1 paginăMO Assignment 2 NumericalBHAVINÎncă nu există evaluări

- Production of Formalin From Methanol: BackgroundDocument8 paginiProduction of Formalin From Methanol: BackgroundDeri PermanaÎncă nu există evaluări

- Design Procedure For Outsidedrum Rotary Vacuum Filter 1965Document7 paginiDesign Procedure For Outsidedrum Rotary Vacuum Filter 1965BHAVINÎncă nu există evaluări

- MO Syllabus PDFDocument7 paginiMO Syllabus PDFBHAVINÎncă nu există evaluări

- Msds PDFDocument6 paginiMsds PDFNiranjanÎncă nu există evaluări

- MO Syllabus PDFDocument7 paginiMO Syllabus PDFBHAVINÎncă nu există evaluări

- Sec-Butyl Alcohol MSDS: Section 1: Chemical Product and Company IdentificationDocument5 paginiSec-Butyl Alcohol MSDS: Section 1: Chemical Product and Company Identificationgdfeiu dionwdnÎncă nu există evaluări

- Reactor Design Guide1Document27 paginiReactor Design Guide1Chau MaiÎncă nu există evaluări

- Pollution Acid Plants: NitricDocument7 paginiPollution Acid Plants: NitricduongchitrungÎncă nu există evaluări

- 1,1,1-Trichloroethane MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagini1,1,1-Trichloroethane MSDS: Section 1: Chemical Product and Company IdentificationBHAVINÎncă nu există evaluări

- Oxygen SeparationDocument117 paginiOxygen SeparationThabang MaphakisaÎncă nu există evaluări

- Water Pressure Boiling TemperatureDocument1 paginăWater Pressure Boiling TemperatureSourabh DhavalaÎncă nu există evaluări

- Msds Etanol 2005Document7 paginiMsds Etanol 2005Puput Trisnayanti Inanto PutriÎncă nu există evaluări

- Msds EthanolDocument7 paginiMsds EthanolHeru HarnadiÎncă nu există evaluări

- Motor ClasstyDocument128 paginiMotor Classtywatep_08Încă nu există evaluări

- Gas AbsDocument8 paginiGas AbsCharlyn Joy RamirezÎncă nu există evaluări

- Column Tray DesignDocument9 paginiColumn Tray DesignjuliancardonaÎncă nu există evaluări

- Lec 23Document19 paginiLec 23BHAVINÎncă nu există evaluări

- RefractoriesDocument6 paginiRefractoriesBHAVINÎncă nu există evaluări

- Electrical Safety HandbookDocument61 paginiElectrical Safety HandbookBHAVINÎncă nu există evaluări

- Lec 6Document15 paginiLec 6BHAVINÎncă nu există evaluări

- Lec 30Document18 paginiLec 30BHAVINÎncă nu există evaluări

- Remedies For OsteoarthritisDocument2 paginiRemedies For OsteoarthritisBHAVINÎncă nu există evaluări

- Piping Plan Pocket PalDocument66 paginiPiping Plan Pocket PalmflorespazosÎncă nu există evaluări

- Turbulent FlowDocument1 paginăTurbulent FlowRiki BiswasÎncă nu există evaluări

- PF RulesDocument39 paginiPF RulesBHAVINÎncă nu există evaluări

- Petcoke GasificationDocument7 paginiPetcoke GasificationBHAVINÎncă nu există evaluări

- Stdxi Voc Ema em 1 PDFDocument263 paginiStdxi Voc Ema em 1 PDFDino AlajbegovicÎncă nu există evaluări

- ReciprocatingcompressorsDocument13 paginiReciprocatingcompressorsasbuasbuÎncă nu există evaluări

- 6W105 Part BookDocument102 pagini6W105 Part Bookbapsi01100% (1)

- Machine Design (Kme 602) Unit 5: MCQ Based QuestionsDocument42 paginiMachine Design (Kme 602) Unit 5: MCQ Based QuestionsrahulprajapÎncă nu există evaluări

- Range of Services En1 PDFDocument11 paginiRange of Services En1 PDFBruno CecattoÎncă nu există evaluări

- Land Rover Factory D3 Air Suspension DescriptionDocument22 paginiLand Rover Factory D3 Air Suspension Descriptionhelen100% (1)

- GL1200. .Service - ManualDocument415 paginiGL1200. .Service - ManualIpavec RokÎncă nu există evaluări

- Hemi Tech ArticleDocument4 paginiHemi Tech ArticleBen WineÎncă nu există evaluări

- Online Auction O&K Excavator Parts of Handelsonderneming Het Zuiden B.VDocument35 paginiOnline Auction O&K Excavator Parts of Handelsonderneming Het Zuiden B.VWaldek LipskiÎncă nu există evaluări

- Service Experience: MAN B&W Low Speed Diesel EnginesDocument34 paginiService Experience: MAN B&W Low Speed Diesel Enginesalevent100% (3)

- Lns125-I Mio M3 Crankshaft & Piston PDFDocument1 paginăLns125-I Mio M3 Crankshaft & Piston PDFTeguhNugrohoÎncă nu există evaluări

- Rider RingsDocument4 paginiRider Ringspaulsonp_2Încă nu există evaluări

- Motor Psi 3.0 GM PDFDocument104 paginiMotor Psi 3.0 GM PDFRenato SanchezÎncă nu există evaluări

- Spare Parts List: Chain Saws 572 XP/XPGDocument42 paginiSpare Parts List: Chain Saws 572 XP/XPGVladut MariusÎncă nu există evaluări

- Product Technical Application Guide: Volvo RemanDocument49 paginiProduct Technical Application Guide: Volvo RemanJonah RagleÎncă nu există evaluări

- TM 9-1777a Heavy Tractor M1, Ihc TD-18Document322 paginiTM 9-1777a Heavy Tractor M1, Ihc TD-18Advocate100% (3)

- 017964Document536 pagini017964Francesco Ledda100% (1)

- Ingersoll Rand 2475 Parts ManualDocument28 paginiIngersoll Rand 2475 Parts Manualmason75750% (2)

- The Theory Behind The Engine BrakeDocument3 paginiThe Theory Behind The Engine BrakeJoseGarzaÎncă nu există evaluări

- 4-Cylinder Diesel Engine With Unit Injector PDFDocument282 pagini4-Cylinder Diesel Engine With Unit Injector PDFgeorge100% (1)

- 1985 FSM General Engine ServiceDocument25 pagini1985 FSM General Engine ServiceDiego Armando Martinez UrquijoÎncă nu există evaluări

- KZ650 Engine RebuildDocument6 paginiKZ650 Engine RebuildSenTTrox Rox100% (1)

- Dh24pc3 Hitachi RepairDocument47 paginiDh24pc3 Hitachi RepairDaghe De SblockÎncă nu există evaluări

- Audi 3.0 V6 TFSI Engine With Roots BlowerDocument58 paginiAudi 3.0 V6 TFSI Engine With Roots Bloweroscar miguel100% (1)

- Internal Combustion EnginesDocument5 paginiInternal Combustion EnginesSajith NawarathneÎncă nu există evaluări

- Vol 2 Introduction To Hydraulic Cylinder PDFDocument53 paginiVol 2 Introduction To Hydraulic Cylinder PDFmiraÎncă nu există evaluări

- Katalog Hidravlicnih Cilindrov Md18 Web 5Document20 paginiKatalog Hidravlicnih Cilindrov Md18 Web 5Kišić SpasojeÎncă nu există evaluări

- Cummins n14 Parts CatalogDocument10 paginiCummins n14 Parts Catalogjohn100% (51)

- Characteristics (Typical Figures) Eni CLADIUM 50 SAE Grade 30Document1 paginăCharacteristics (Typical Figures) Eni CLADIUM 50 SAE Grade 30ranjanguptÎncă nu există evaluări

- Mercury 6 - 8 - 9,9 - 10 - 15HP (1986) Service Manual (PDF, ENG, 2.49 MB) PDFDocument149 paginiMercury 6 - 8 - 9,9 - 10 - 15HP (1986) Service Manual (PDF, ENG, 2.49 MB) PDFbobÎncă nu există evaluări

- HATZ 2g30Document284 paginiHATZ 2g30CARLOS SALVADORÎncă nu există evaluări

- Introduction To CompressorDocument4 paginiIntroduction To CompressorRam VollalaÎncă nu există evaluări