Documente Academic

Documente Profesional

Documente Cultură

L028 Me Dat 01 00122 001 00

Încărcat de

sivasan10006098Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

L028 Me Dat 01 00122 001 00

Încărcat de

sivasan10006098Drepturi de autor:

Formate disponibile

DRAGON OIL (TURKMENISTAN) LTD.

FUEL GAS CONDITIONING SKID FOR 1250 KVA

GAS GENERATOR PROJECT

Document Number:

SPG Prj. No.

C16-2955

Mechanical Data Sheet

for Fuel Gas Scrubber 28-V-001

Doc. Title

Area

L028

Disc.

ME

Doc. Class.

DAT

Country

01

Cluster

00122

Serial

001

Sh.

00

Page 1 of 8

Rev.A1

MECHANICAL DATA SHEET FOR

FUEL GAS SCRUBBER

28-V-001

L028-ME-DAT-01-D0001-001-00

A1

Rev.

06.10.16

Date

MS

Prepared

RT

OE

Checked

Approved

Revision Box

Issued for Approval

Purpose

DRAGON OIL (TURKMENISTAN) LTD.

FUEL GAS CONDITIONING SKID FOR 1250 KVA

GAS GENERATOR PROJECT

SPG Prj. No.

C16-2955

Mechanical Data Sheet

for Fuel Gas Scrubber 28-V-001

Doc. Title

Area

L028

Document Number:

Disc.

ME

Doc. Class.

DAT

Country

01

Cluster

00122

Serial

001

Sh.

00

Page 2 of 8

REVISION RECORD

Page

A1

Revision

A2 A3 A4

A5

Page

A1

A2

Revision

A3 A4

A5

Rev.A1

DRAGON OIL (TURKMENISTAN) LTD.

FUEL GAS CONDITIONING SKID FOR 1250 KVA

GAS GENERATOR PROJECT

Document Number:

SPG Prj. No.

C16-2955

Mechanical Data Sheet

for Fuel Gas Scrubber 28-V-001

Doc. Title

Area

L028

Disc.

ME

Doc. Class.

DAT

REV

Vessel Type: Vertical, Cylindrical

Shell Diameter:

ID

Shell Length:

Shell / Head Thickness:

Head Type:

Type of Support:

Design Code :

Fluid /Density

Volume:

Design Pressure

Design Temp.

Operating Pressure ( min/max)

Operating Temp.

( min/max)

Min. Design Metal Temperature:

Test Pressure:

Corr. Allow. Shell & Heads / Internals

Insulation Type/Thickness

Sour Service

Wind Code / Wind Velocity

Earthquake Code / Zone

Weight:

Shipping/Empty:

Test:

FABRICATION & INSPECTION REQUIREMENTS

Radiography / Joint Efficiency

Post Weld Heat Treatment

Stress Relieving

Impact Testing

Other Non-Destructive Testing

Surface Preparation and Painting

MATERIAL SPECIFICATION

Shell & Heads

Nozzles pipes (plate fabricated 24 )

Nozzle pipes (Seamless)

Forged( Nozzles & Flanges)

Reinforcing Pads

Legs

External Studs Bolts/Nuts

Internal Bolts/Nuts

Gaskets

Parts Welded On Pressure Parts (Int / Ext)

Removable Internals including Demister

Packing & Trays

Material Certification

*) Vendor to check and confirm

Country

01

Cluster

00122

Serial

001

Sh.

00

Page 3 of 8

Rev.A1

DESIGN DATA

Quantity: 1 pcs

800 mm

2500 mm T/T

12/12 mm (min)

NOTE 2

Elliptical 2:1

Legs

ASME VIII Div.1 / U Stamp Requiered

3

0

FUEL GAS / 3.19 kg/m (3 barg @ 2 C)

3

1.39 m

17 barg

NOTE 16

0

-29/85 C

3 / 15 barg

0

2 / 32 C

0

-29 C@ 17 barg

As per ASME Code

3 mm/NA

Yes

NOTE 22

NA

144Km/h (40 m/s)

Loading G , g=0.4

1700 Kg *)

3100 Kg *)

100%/ 1.0

AS PER CODE

AS PER CODE

AS PER CODE

AS PER CODE

NOTE 17

SA 516Gr.70

SA 516Gr.70

SA 106Gr.B

SA 105

SA 516Gr.70

A36

SA193 Gr. B7/ SA 194 Gr 2H

316L Stainless Steel

Spiral Wound, 304 SS, Graphite filler, non asbestos

SA 516Gr.70

316L Stainless Steel

NA

As per EN 10204

Type 3.1 for all pressure retaining parts and

all elements welded on pressure parts.

Type 2.2 for remaining parts

DRAGON OIL (TURKMENISTAN) LTD.

FUEL GAS CONDITIONING SKID FOR 1250 KVA

GAS GENERATOR PROJECT

SPG Prj. No.

C16-2955

Mechanical Data Sheet

for Fuel Gas Scrubber 28-V-001

Doc. Title

Document Number:

Area

L028

Disc.

ME

Doc. Class.

DAT

Country

01

Cluster

00122

Serial

001

Sh.

00

Page 4 of 8

Rev.A1

INTERNALS & ACCESSORIES

FURNISHED AND INSTALLED BY FABRICATOR

REV.

DESCRIPTION

X

X

X

X

X

X

X

Demister

Demister Support

Stingers

Inlet/Outlet Distributor

Inlet Deflector

Insulation Rings

L & P. Clips - Pads

Pipe Guide Pads

Lifting Lugs

Tie Down Straps

Nameplate

NOZZLE NO/

ADDITIONAL INFO

REV.

DESCRIPTION

X

X

X

N1

X

X

X

X

Primer

Top Coat

Davits (Manway)

Ladder Rungs Internal

Weir

Vortex Breaker

Tray Support (Rings

Bar)

Grounding Lugs (2)

Insulation

Legs

As Per ASME

Code

Internal Surface

Coating

X

Ext. Surface

Preparation

FURNISH

INSTALL.

Fab.

Other Fab.

Other

X

X

X

X

X

Insulation

Name Plate

Demister & Grid

Ladder & Platforms c/w cage

Packing Support

Packing Holddown

Packing Distributor

Packing

NOZZLE NO/

ADDITIONAL INFO

M1

N5

DRAGON OIL (TURKMENISTAN) LTD.

FUEL GAS CONDITIONING SKID FOR 1250 KVA

GAS GENERATOR PROJECT

SPG Prj. No.

C16-2955

Mechanical Data Sheet

for Fuel Gas Scrubber 28-V-001

Doc. Title

Document Number:

Area

L028

Disc.

ME

Doc. Class.

DAT

Country

01

Cluster

00122

Serial

001

Sh.

00

Page 5 of 8

Rev.A1

PROCESS NOTES

Rev

1.

Steam out: NO

2.

3.

Turndown flow rate is considered as 30% of Normal operating Flow rate.

The fuel gas scrubber 28-V-001 shall be provided with demister, for efficient liquid-gas separation and also

anti-vortex device in order to avoid gas flowing in bottom liquid stream.

Wire mesh efficiency: 99.9% removal of all liquid droplets greater than 5 microns entrained along with

vapour. Mesh material is stainless steel.

Maximum allowable pressure drop (inlet nozzle + drum inlet device) is about 10 kPa.

Pressure drop to be minimised by Manufacturer design.

4.

5.

28-V-001 FEEDSTOCK CHARACTERISTICS:

GAS

LIQUID

REV.

Maximum Case

3/15

2/32

1000

2.79

17.93

0.0105

0.9876

100

1024

18.02

76.05

1.645

Operating Pressure (barg)

0

Operating Temperature ( C)

Design Flow rate (kg/hr)

3

Density (kg/m )

Molecular weight

Viscosity(cP)

Compressibility

Design Flow rate (kg/hr)

3

Density (kg/m )

Molecular weight

Surface tension (dyne/cm)

Viscosity(cP)

NOZZLES SCHEDULE

MARK

SERVICE

N1

N2

N3

K1

K2A/B

K3

N4

N5

K4

K5

K6A/B

N6

M1

Vapour Inlet

Vapour Outlet

Vent

Level transmitter

Bridle

TI-101

Liquid outlet

Drain

PI-401

Pressure transmitter

PDIT

PSV-101

Manway

No

SIZE

PROJECTION

1

1

1

1

2

2

1

1

1

1

2

1

1

4

4

2

2

2

2

2

2

2

2

2

2

-

600

600

600

600

600/500

600

600

400

600

600

600

-

RAT.

150#

150#

150#

300#

300#

300#

150#

150#

300#

300#

300#

300#

150#

FACING

Remarks

WNRF

WNRF

WNRF

WNRF

WNRF

WNRF

WNRF

WNRF

WNRF

WNRF

WNRF

WNRF

WNRF

With Deflector

LSH-101

LG-101, LZT-102

With Cover & Davit

DRAGON OIL (TURKMENISTAN) LTD.

FUEL GAS CONDITIONING SKID FOR 1250 KVA

GAS GENERATOR PROJECT

Document Number:

Rev

REV

SPG Prj. No.

C16-2955

Mechanical Data Sheet

for Fuel Gas Scrubber 28-V-001

Doc. Title

Area

L028

Disc.

ME

Doc. Class.

DAT

Country

01

Cluster

00122

Serial

001

Sh.

00

Page 6 of 8

Rev.A1

REFERENCE SPECIFICATION AND STANDARDS ( The latest revision)

GENERAL SPECIFICATION FOR PAINTING & COATING

STDS-MC-STD-1-0002-03-00

GENERAL SPECIFICATION FOR PAINTING

CPSF-EQ-SPE-1-0594-11-00_A2

SPECIFICATION FOR HOT & COLD INSULATION

GTP1-EQ-SPE-1-0176-21_1

STANDARD SPECIFICATION FOR

STDS-EL-SPE-1-0001-07-00

ELECTRICAL REQUIREMENTS FOR PACKAGE EQUIPMENT

GENERAL NOTES

1)

All dimensions are in millimetres, unless otherwise specified.

2)

All thickness specified in this datasheet are minimum after forming & machining. The manufacturer shall

verify and is responsible for detail design.

3)

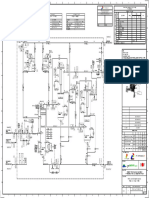

Nozzles elevations shown in sketch are informative only.

4)

Final nozzles elevations and orientation will be confirmed later by SPG.

5)

Manufacturer shall confirm the legs location and sizes.

6)

All flanges boltholes shall straddle the normal vessel centrelines.

7)

Nozzles projection are referred from vessel centre line or head TL to flange gasket face.

8)

Flange dimensions and facing shall be as per ASME B16.5 up to NPS 24 and ASME B16.47 series B

for flange sizes NPS 26 and above.

9)

Surface finish of flange gasket shall be serrated spiral finish with roughness 3.2 to 6.3 m (125 to 250 in.)

10) Manway shall be provided with blind flange, handle, bolts, nuts gasket and davit.

11) All nozzles shall be set-in type. The inner edges shall have inside corner rounded with a min.3mm radius.

12) All nozzles of size 2 (made from pipe) shall have 2 stiffeners placed at 90.

13) Vessel internal surface shall be dried after hydrotesting.

14) During hydrostatic test primary membrane stress shall not exceed 90% of the material yield stress.

15) Vendor shall furnish maximum allowable nozzles loads.

16) MAWP shall be limited by shell or heads.

17) All insulated and non-insulated external surfaces and internal surfaces shall be prepared and protected by

primer coat and top coat acc. to Painting Specification CPSF-EQ-SPE-1-0594-11-00_A2 and STDS-MC-STD-10002-03-00.

All machined surfaces such as flange facing, bolts and nuts shall be protected against corrosion by coating with

heavy rust preventive grease.

18) Thickness, weights and loads are for estimation purpose only. Data will be checked and confirmed by the

vessel Manufacturer.

Manufacturer

hasattachments

to confirm mechanical

design,

weight and

19)

All welded

to the vessel

to be supplied

by loads.

the vessel manufacturer.

20) 2 (two) grounding lugs type shall be located on two opposite legs

21) Design life of 25 years.

22) Vendor shall provide electrical heat tracing for Liquid portion of the vessel.

Insulation /Winterization for entire vessel is also in the Vendor scope.

DRAGON OIL (TURKMENISTAN) LTD.

FUEL GAS CONDITIONING SKID FOR 1250 KVA

GAS GENERATOR PROJECT

Document Number:

SPG Prj. No.

C16-2955

Mechanical Data Sheet

for Fuel Gas Scrubber 28-V-001

Doc. Title

Area

L028

Disc.

ME

Doc. Class.

DAT

Country

01

Cluster

00122

Serial

001

Sh.

00

Page 7 of 8

Rev.A1

DRAGON OIL (TURKMENISTAN) LTD.

FUEL GAS CONDITIONING SKID FOR 1250 KVA

GAS GENERATOR PROJECT

Document Number:

SPG Prj. No.

C16-2955

Mechanical Data Sheet

for Fuel Gas Scrubber 28-V-001

Doc. Title

Area

L028

Disc.

ME

Doc. Class.

DAT

Country

01

Cluster

00122

Serial

001

Sh.

00

Page 8 of 8

Rev.A1

S-ar putea să vă placă și

- Anex 1Document59 paginiAnex 1rotatic_engineerÎncă nu există evaluări

- DC S3-1301 REV.0 OriginalDocument93 paginiDC S3-1301 REV.0 OriginalPeja JusohÎncă nu există evaluări

- Mist EliminatorDocument90 paginiMist EliminatordhurjatibhuteshÎncă nu există evaluări

- 10P87-D0003-046-R0-WHRU by TEPLDocument23 pagini10P87-D0003-046-R0-WHRU by TEPLjigarÎncă nu există evaluări

- PDFDocument1 paginăPDFdhaktodesatyajitÎncă nu există evaluări

- Fsi Catalog Filter VesselsDocument35 paginiFsi Catalog Filter VesselsarietilangÎncă nu există evaluări

- FO14-104 Vacuum Deaerator Datasheet - Rev ADocument3 paginiFO14-104 Vacuum Deaerator Datasheet - Rev AHuzefa Calcuttawala100% (2)

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 paginiE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinÎncă nu există evaluări

- HeatExchanger ReportDocument5 paginiHeatExchanger ReportNur Izzati KamrulnizamÎncă nu există evaluări

- PMS Rev 0Document36 paginiPMS Rev 0rami ghorbelÎncă nu există evaluări

- Pump and Line CalcDocument1 paginăPump and Line CalcPRATIK P. BHOIRÎncă nu există evaluări

- Perhitungan Pressure Vessel LengkapDocument70 paginiPerhitungan Pressure Vessel LengkapReo Aditya MahesaÎncă nu există evaluări

- Catalyst Final CalculationsDocument47 paginiCatalyst Final CalculationsPrable SekhriÎncă nu există evaluări

- 48" X 15' Three Phase Test SeparatorDocument2 pagini48" X 15' Three Phase Test Separatorpraash bhattÎncă nu există evaluări

- Total Length Calcs For Pipes Valves and FittingsDocument6 paginiTotal Length Calcs For Pipes Valves and FittingsImtinan MohsinÎncă nu există evaluări

- KIRK Sep-Calc SoftwareDocument4 paginiKIRK Sep-Calc Softwaredhl_tuÎncă nu există evaluări

- Loadsheet Demin Water Pump PU-1202 ABDocument13 paginiLoadsheet Demin Water Pump PU-1202 ABGunturMudaAliAkbarÎncă nu există evaluări

- Mechanical Data Sheet Pressure Vessel: GeneralDocument2 paginiMechanical Data Sheet Pressure Vessel: GeneralEDUARDOÎncă nu există evaluări

- BBS 10 P1 PID 0045 ModelDocument1 paginăBBS 10 P1 PID 0045 ModelAdianto RahmanÎncă nu există evaluări

- Project Site Job No. ClientDocument5 paginiProject Site Job No. ClientSapna NigadeÎncă nu există evaluări

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 paginiPig Receiver Data Sheet 91303 - 8 InchSinaÎncă nu există evaluări

- PV Newsletter - Skirt Connections PDFDocument5 paginiPV Newsletter - Skirt Connections PDFDivyesh PatelÎncă nu există evaluări

- HRD Hot Water Pump P001Document6 paginiHRD Hot Water Pump P001nguyenquoc1988Încă nu există evaluări

- Datasheet For FiltersDocument13 paginiDatasheet For FiltersAntonio MendesÎncă nu există evaluări

- Zirco Ltd. Pressure/Vacuum Relief Valve: ClientDocument1 paginăZirco Ltd. Pressure/Vacuum Relief Valve: Clientsusanto100% (1)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 paginiMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqÎncă nu există evaluări

- Fire Jockey Pump. Rev B1Document3 paginiFire Jockey Pump. Rev B1Pump SpesialistÎncă nu există evaluări

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 paginăK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjÎncă nu există evaluări

- 7-12-0020 Rev6 (Inlet Deflector Baffles) PDFDocument1 pagină7-12-0020 Rev6 (Inlet Deflector Baffles) PDFsumit kumarÎncă nu există evaluări

- Volume Calculation For Pressure Vessel TankDocument2 paginiVolume Calculation For Pressure Vessel Tanksai srikarÎncă nu există evaluări

- Heater DataDocument2 paginiHeater DataEDUARDOÎncă nu există evaluări

- Gas/Liquids Separators - Part 3: Quantifying Separation PerformanceDocument14 paginiGas/Liquids Separators - Part 3: Quantifying Separation PerformanceWendellReeceFrankÎncă nu există evaluări

- Data SheetDocument6 paginiData Sheetnalawade_pradeepÎncă nu există evaluări

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pagini15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanÎncă nu există evaluări

- Toyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpDocument4 paginiToyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpNicolas Celis Perez100% (1)

- API 650 Baseplate DesignDocument3 paginiAPI 650 Baseplate DesignmjlazoÎncă nu există evaluări

- Heat Exchanger CalcDocument34 paginiHeat Exchanger Calcميثة الغيثيةÎncă nu există evaluări

- Values Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesDocument7 paginiValues Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesaltruismÎncă nu există evaluări

- PDS Air CompressorDocument1 paginăPDS Air Compressordhavalesh1Încă nu există evaluări

- Electric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Document3 paginiElectric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Tuấn VũÎncă nu există evaluări

- Shell Entrance Area Calculation-R0Document2 paginiShell Entrance Area Calculation-R0nagtummalaÎncă nu există evaluări

- Pressure Vessel: General DescriptionDocument4 paginiPressure Vessel: General DescriptionTiny Tấn MinhÎncă nu există evaluări

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 paginiData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- New Heat Exchaner Design - 5mwDocument20 paginiNew Heat Exchaner Design - 5mwDaniel Perez0% (1)

- Restriction Orifice Final CalculationDocument1 paginăRestriction Orifice Final CalculationJasperTanÎncă nu există evaluări

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 paginiLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiÎncă nu există evaluări

- Data Sheet N2 BottleDocument5 paginiData Sheet N2 BottleandrianoÎncă nu există evaluări

- TW6151A - Wake Freq CalcaDocument2 paginiTW6151A - Wake Freq Calcakkd3Încă nu există evaluări

- JT Assembly English A4Document2 paginiJT Assembly English A4HectorÎncă nu există evaluări

- Mechanical Data Sheet - Air Filter (031-GN-002AB)Document5 paginiMechanical Data Sheet - Air Filter (031-GN-002AB)Gaurav PandeyÎncă nu există evaluări

- 8015-0151-SECL-00-000-ME-BD-00004 - 02 - Design Basis For Rotating and Package Equipment PDFDocument26 pagini8015-0151-SECL-00-000-ME-BD-00004 - 02 - Design Basis For Rotating and Package Equipment PDFDamiano Tondelli100% (1)

- Mds ScrubberDocument2 paginiMds ScrubberwahyuÎncă nu există evaluări

- Data Sheet Tag 180-Pu-011eDocument8 paginiData Sheet Tag 180-Pu-011eSarah PerezÎncă nu există evaluări

- B 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerDocument11 paginiB 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerpragatheeskÎncă nu există evaluări

- Fire Water Make Up PumpDocument7 paginiFire Water Make Up PumpAlvin SmithÎncă nu există evaluări

- Volume3A MechDocument321 paginiVolume3A MechAdeel JamilÎncă nu există evaluări

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 paginiSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988Încă nu există evaluări

- IsometricsDocument4 paginiIsometricsMuhammedHafisÎncă nu există evaluări

- BladderDocument7 paginiBladderJohnSengsuÎncă nu există evaluări

- LoadsDocument135 paginiLoadssivasan10006098Încă nu există evaluări

- BIDBOLLAND PILE Schedule Equipment Load ArhDocument3 paginiBIDBOLLAND PILE Schedule Equipment Load Arhsivasan10006098Încă nu există evaluări

- International BrochureDocument6 paginiInternational Brochuresivasan10006098Încă nu există evaluări

- Lifting Calculation - RunwayDocument8 paginiLifting Calculation - Runwaysivasan10006098Încă nu există evaluări

- SPG 2016 OreDocument44 paginiSPG 2016 Oresivasan10006098Încă nu există evaluări

- Foundation Calculation For Refrigerant Surge Tanks, V-503-001A/B/CDocument6 paginiFoundation Calculation For Refrigerant Surge Tanks, V-503-001A/B/Csivasan10006098Încă nu există evaluări

- Engineering: TEL: (O8) 9302 4166Document1 paginăEngineering: TEL: (O8) 9302 4166sivasan10006098Încă nu există evaluări

- Released: Lighting Calculations FOR Refrigeration AreaDocument90 paginiReleased: Lighting Calculations FOR Refrigeration Areasivasan10006098Încă nu există evaluări

- Padeye CheckDocument12 paginiPadeye CheckBen100% (1)

- Piperack Bridge NDC Reaction ComparitionDocument12 paginiPiperack Bridge NDC Reaction Comparitionsivasan10006098Încă nu există evaluări

- 1258902862-Speech - Al KhalifaDocument24 pagini1258902862-Speech - Al Khalifasivasan10006098Încă nu există evaluări

- MHS E000 El CC 107 05Document24 paginiMHS E000 El CC 107 05sivasan10006098Încă nu există evaluări

- STAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters SuchDocument6 paginiSTAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters Suchsivasan10006098Încă nu există evaluări

- Pile Estimation of Pile Types 450 & 600 MM Dia (For Quotation Pourposes Only)Document12 paginiPile Estimation of Pile Types 450 & 600 MM Dia (For Quotation Pourposes Only)sivasan10006098Încă nu există evaluări

- Voltage Drop Calculation For Highest Rating Motor Starting: ReleasedDocument134 paginiVoltage Drop Calculation For Highest Rating Motor Starting: Releasedsivasan10006098Încă nu există evaluări

- Geotechnical Study 2016Document7 paginiGeotechnical Study 2016sivasan10006098Încă nu există evaluări

- Geotechnical Study 2010Document19 paginiGeotechnical Study 2010sivasan10006098Încă nu există evaluări

- Sleeper Way To JettyDocument23 paginiSleeper Way To Jettysivasan10006098Încă nu există evaluări

- "Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionDocument7 pagini"Baseplt9" - Steel Column Base Plate Analysis: Program Descriptionsivasan10006098Încă nu există evaluări

- Staircase Technical Information - BS 5395 PT - LLDocument3 paginiStaircase Technical Information - BS 5395 PT - LLsivasan10006098Încă nu există evaluări

- Grade 3 - Unit 1 Increase and Decrease PatternDocument7 paginiGrade 3 - Unit 1 Increase and Decrease PatternKyo ToeyÎncă nu există evaluări

- Grammar and Vocabulary TestDocument5 paginiGrammar and Vocabulary TestLeonora ConejosÎncă nu există evaluări

- Financial Market - Bsa 2A Dr. Ben E. Bunyi: Imus Institute of Science and TechnologyDocument3 paginiFinancial Market - Bsa 2A Dr. Ben E. Bunyi: Imus Institute of Science and TechnologyAsh imoÎncă nu există evaluări

- The Rise of Australian NovelDocument412 paginiThe Rise of Australian NovelSampath Kumar GummadiÎncă nu există evaluări

- Boom-Block Gambit: Redemption'S RiseDocument44 paginiBoom-Block Gambit: Redemption'S RiseNone OfyourbuisnessÎncă nu există evaluări

- Perdarahan Uterus AbnormalDocument15 paginiPerdarahan Uterus Abnormalarfiah100% (1)

- Simon Ardhi Yudanto UpdateDocument3 paginiSimon Ardhi Yudanto UpdateojksunarmanÎncă nu există evaluări

- Based On PSA 700 Revised - The Independent Auditor's Report On A Complete Set of General Purpose Financial StatementsDocument12 paginiBased On PSA 700 Revised - The Independent Auditor's Report On A Complete Set of General Purpose Financial Statementsbobo kaÎncă nu există evaluări

- Full Project LibraryDocument77 paginiFull Project LibraryChala Geta0% (1)

- (Sat) - 072023Document7 pagini(Sat) - 072023DhananjayPatelÎncă nu există evaluări

- Boundary Value Analysis 2Document13 paginiBoundary Value Analysis 2Raheela NasimÎncă nu există evaluări

- Maya Deren PaperDocument9 paginiMaya Deren PaperquietinstrumentalsÎncă nu există evaluări

- CFD Turbina Michell BankiDocument11 paginiCFD Turbina Michell BankiOscar Choque JaqquehuaÎncă nu există evaluări

- JCP4 XDOBursting EngineDocument13 paginiJCP4 XDOBursting Enginesubhash221103Încă nu există evaluări

- BBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)Document2 paginiBBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)NinaÎncă nu există evaluări

- Yetta Company ProfileDocument6 paginiYetta Company ProfileAfizi GhazaliÎncă nu există evaluări

- SW OSDocument11 paginiSW OSErnest OfosuÎncă nu există evaluări

- SubaruDocument7 paginiSubaruclaude terizlaÎncă nu există evaluări

- Session 1Document18 paginiSession 1Akash GuptaÎncă nu există evaluări

- The Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalDocument6 paginiThe Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalMahad Abdi100% (1)

- Debate ReportDocument15 paginiDebate Reportapi-435309716Încă nu există evaluări

- Li JinglinDocument3 paginiLi JinglincorneliuskooÎncă nu există evaluări

- Colfax MR Series CompresorDocument2 paginiColfax MR Series CompresorinvidiuoÎncă nu există evaluări

- Angle Modulation: Hệ thống viễn thông (Communication Systems)Document41 paginiAngle Modulation: Hệ thống viễn thông (Communication Systems)Thành VỹÎncă nu există evaluări

- The Turning Circle of VehiclesDocument2 paginiThe Turning Circle of Vehiclesanon_170098985Încă nu există evaluări

- NHD Process PaperDocument2 paginiNHD Process Paperapi-203024952100% (1)

- D&D 5.0 Combat Reference Sheet Move Action: Interact With One Object Do Other Simple ActivtiesDocument2 paginiD&D 5.0 Combat Reference Sheet Move Action: Interact With One Object Do Other Simple ActivtiesJason ParsonsÎncă nu există evaluări

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDocument30 paginiThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanÎncă nu există evaluări

- Answers For Some QuestionsDocument29 paginiAnswers For Some Questionsyogeshdhuri22Încă nu există evaluări

- IR2153 Parte6Document1 paginăIR2153 Parte6FRANK NIELE DE OLIVEIRAÎncă nu există evaluări