Documente Academic

Documente Profesional

Documente Cultură

Spe 176106 MS

Încărcat de

Prayudha RifqiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Spe 176106 MS

Încărcat de

Prayudha RifqiDrepturi de autor:

Formate disponibile

SPE-176106-MS

Reviving the Mature Field of Bekapai: Integrated Work From Subsurface to

Network Optimization

Yan Muhazir, Supriady Supriady, Andy Kristianto, and Henricus Herwin, Total E&P Indonesie

Copyright 2015, Society of Petroleum Engineers

This paper was prepared for presentation at the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition held in Nusa Dua, Bali, Indonesia, 20 22 October 2015.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents

of the paper have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect

any position of the Society of Petroleum Engineers, its officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written

consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may

not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Bekapai is a mature oil and gas field located in the offshore Mahakam Delta, Indonesia. The hydrocarbons

are accumulated in complex multilayered reservoirs. Ten platforms were constructed to accommodate the

oil production coming from 74 wells drilled between 1974 and 1996. The production started in 1974 with

peak production at ~60,000 BOPD in 1978, followed by a period of decline until it reached its lowest point

at 1,000 BOPD in 2007.

A field re-development project, so-called Phase 1 initiated in 2008, had increased the production to

10,000 BOPD and 46 MMSCFD by the end of 2013. It consisted of 9 development wells. Following this

successful project, a new 3D OBC seismic was acquired and further development plan, Phase 2, initiated,

consisting of 10 development wells and gas production facility debottlenecking. Two wells have been

drilled in 2014 and contribute in stabilizing the production of 2014 at 11,500 BOPD and 38 MMSCFD,

the highest oil production of the past 25 years. The gas production decreases as a consequence to field

production facility limitation. It was shelved due to priority of oil development. However, it is expected

to increase to 100 MMSCFD in 2015 after the debottlenecking. In parallel, idle wells reactivation to access

the shallow gas resources is also reviewed. Besides contributing to gas export, the gas is also used as

artificial lift to revitalize the oil wells.

This paper demonstrates the main elements of the redevelopment: evolution of the geological model

achieved through seismic and petrophysical data, production management in a complex production system

and various optimizations at the production network in order to unlock the production capacity limit

through debottlenecking projects and chemical injection at the export line. A continuous effort in even

further redeveloping the field is also shown through Phase 2, the objective of which will be chasing the

attic oil, blowing down the gas-cap, and double the gas production.

Introduction

Bekapai is a mature oil and gas field located in the offshore Mahakam Delta, Indonesia. The field was

discovered in 1972. Following the discovery, series of exploration and delineation wells were drilled to

appraise the hydrocarbon extension. The hydrocarbons are accumulated in a faulted anticline structure

with multilayered sandstone reservoirs, deposited in a fluvio-deltaic environment.

SPE-176106-MS

The initial development of the field took place between 1974 and 1996. The production started in July

1974 from a single well. One year later, a multi-well production platform, offshore processing platform,

and a living quarter were installed. Between 1974 and 1996, ten platforms were constructed and 74 wells

were drilled. The gas and liquid are treated in the offshore process facilities prior to sending it to onshore

facility. The peak production at ~60,000 BOPD was achieved in 1978. Most of the oil production is

coming from the zone located between 1,250 -1,500 m subsea. After a long period of decline, the field

reached its lowest point at 1,000 bopd in 2007.

A field re-development project, so-called Phase 1, was initiated in 2008. By the end of 2013, the field

was able to produce 10,000 BOPD and 46 MMSCFD. Following this successful project, a further

development plan, so-called Phase 2, was proposed and a new 3D OBC seismic was acquired to support

the re-development plan. Two wells of this phase have already been drilled in 2014 and contributed in

reaching a new peak of production in 2014 at 11,500 BOPD and 38 MMSCFD, the highest oil production

of the past 25 years.

In addition to the development projects mentioned above, routine production optimization activities

such a wireline intervention, idle wells revival, and Drag Reducing Agent (DRA) injection also hold

important roles in sustaining the field production and even unclock the field production limitation.

Geological Context

The field is a faulted anticline structure with multi-layered sandstone reservoirs of late Miocene-Pliocene

age, deposited in a fluvio-deltaic environment. The structural scheme is a Pliocene dome-shaped anticline

elongated in a NNE-SSW trend, parallel to the regional structural frame work. The center of the fold is

cut by post sedimentary normal faults in NNW-SSE direction. The faults consist of two major faults and

several minor faults in the graben. Those faults divide the field into three main compartments: West,

Central and East.

The Bekapai field consists of five stratigraphic intervals. The Deep zone (MF7.5-MF8.5) consists of

stacked mouth-bars facies, deposited in delta front environment during the regressive period. The Lower

zone (MF6-MF7.5) was deposited in the delta front to prodelta environment during the transgressive

period. The Upper zone (MF4-MF6) is the lower part of the Fresh Water Sand formation. It was deposited

in lower delta plain to delta front environment in the beginning of the regressive period. The reservoir

consists of distributary channel sand in the top and some mouth bars facies in the bottom. The Main zone

(BETA-MF4) is the upper part of the Fresh Water Sand formation. The interval was deposited in the

flood-plain (fluvial) to delta plain environment during the major regressive period. The reservoir is thick,

medium to coarse-grained, with inter-bedded shale and some coal intercalation. The Shallow zone

(U05-BETA) was deposited in the delta plain to delta front environment. The reservoirs are distributary

channel and mouth bar sand.

The reservoir pressure depletion is the main driving mechanism in the Lower and Deep zones while

strong aquifer and gas cap expansion are the main reservoir driving mechanism in the Shallow, Main and

Upper zones. Figure 1 illustrates the geological context of the Bekapai field.

SPE-176106-MS

Figure 1Geological Context of Bekapai Field

Field Development Concept

Oil and gas are found almost in all the layers, except Shallow reservoirs where only gas exists. However,

most of the hydrocarbon is located in the Main zone thus the initial development of Bekapai was focused

to this area. As consequence, the remaining zones were underdeveloped and they became the targets for

Phase 1 and Phase 2 Re-Development phases. In brief, Bekapai is developed through successive phases

of development as follows:

Initial Field Development (1974-1996)

The initial field development was performed progressively through six phases between 1974 and

1996. The development started with the exploitation of the oil accumulation located in the flank

of Main zone western panel. However, few wells were drilled penetrating the upper and lower zone

to appraise the hydrocarbon potential in those zones. The main zone has the most important oil

accumulation, which is 75% of field OOIP.

Phase 1 Re-Development (2007-2011)

The Phase 1 Re-Development was performed between 2007 and 2011. The targets of this

development were:

X

X

Gas and by-passed oil at the higher structure of the Main zone.

Gas and oil in the underdeveloped zones: Upper, Lower, and Deep zones.

SPE-176106-MS

Phase 2 Re-Development (2013-Today)

The Phase 2 Re-Development started in 2013 and is still on-going with the following targets:

X

X

X

Attic Oil and Gas Cap in the Main and Upper zones.

Gas and oil in the Shallow, Lower, and Deep zones.

Gas and oil in the Central and East panels.

The development phases are illustrated in Figure 2.

Figure 2Bekapai Development Concept Illustration

The reservoirs are divided in two categories, as different completions are needed:

Sand prone reservoirs

It consists of Shallow, Main, and Upper zones. Sand control devices, such as Gravel Pack (GP) and

Screen, are required to be installed in order to produce the hydrocarbons safely. Normally, these

zones are the first to be produced as the stakes and the productivity are higher compared to the

lower zones, and the intervention is easier as it requires only slickline intervention to open or close

the sleeves.

Non-sand prone reservoirs

SPE-176106-MS

It consists of Lower and Deep zones. As the sand production risk is low, the zones are only

equipped with liner completion to allow direct perforation and water shut-off operation in the

future. These zones are second to be produced as the stakes and the productivity are lower

compared to the upper zones, and the intervention is more complicated as it requires electric-line

intervention.

Evolution of Geological Understanding

The first 3D seismic acquisition survey for Bekapai Field was performed in 1994, before that date only

2D lines being available. The geological understanding especially the structural scheme changed dramatically after the first 3D acquisition. However, several subsurface uncertainties remained; the fault shadow,

push-down, and seismic signal absorption due to gas cloud in the shallow zone are the main challenges

in the seismic imaging. A new acquisition technique implementing Oceanic Bottom Cable (OBC) with

four components (4C) receiver was acquired in 2012 to answer the challenges of the seismic imaging. The

4C receivers allow recording and processing in conventional P-wave (PP) and converted S-wave (PS). The

nature of S-waves with a lower velocity than P-waves and being insensitive to fluid effect resulted in a

much improved image of the gas cloud area. Figure 3 shows the comparison of P-wave seismic and

S-wave seismic.

Figure 3Comparison of P-wave seismic and S-wave seismic

In the period of 70s to 90s, the 2D geomodeling was implemented in the Bekapai field as support for

the initial development plans. The first 3D geomodel was constructed in 2006 integrating the result of

seismic reprocessing in 2002 in order to be implemented for Phase 1 re-development. That was the period

of puzzle geomodel where an individual model was constructed for each zone and compartment due to

the complexity of the structural scheme (double truncation fault). In 2010, the first full field geomodel was

SPE-176106-MS

made by integrating the result of PSDM re-processing of the 3D seismic 1994. There are a lot of

improvements in the structural modeling, but the workflow was very heavy and time-consuming

(Kristianto, et al. 2014).

The seismic OBC interpretation resulted in a new structural scheme where the West fault is more open

to the north and less compartmentalization in the Central panel. This also creates a new potential in the

Central panel by a new closure in the northern part (Figure 4) (Siawira, et al. 2015). The new structural

modeling technique, so-called Volume Base Model (VBM) has been successfully tested and implemented

in order to construct the double truncation fault model. Integration of all the data lead to improve the well

placement in the Phase 2 re-development. Figure 5 shows the sub-surface evolution of the Bekapai field.

Figure 4 Comparison of old and new structural interpretation

SPE-176106-MS

Figure 5Subsurface Understanding Evolution of Bekapai Field

Field Development Results

Initial Field Development (1974-1996)

During this period, ten platforms were installed and 74 wells were drilled. In 1974, the field production

was coming from a single well. One year later, a multi-well platform, offshore processing facility, and

living quarter were installed. The gas-oil-water production was treated at the offshore processing facility

prior to sending it to the onshore terminal. Until 1976, the oil production was transferred to onshore

terminal using tanker. In 1977, a 12 x 24 km sealine linking offshore processing facility and onshore

terminal was commissioned to replace the oil production transfer mean. The peak production was

achieved in 1978 with ~60,000 BOPD. In order to stop the gas flaring and to produce it instead, a gas

compressor was installed at the offshore processing facility in 1985. The gas and oil are then sent to

onshore terminal in multi-phase flow through the 12 sealine. Bekapai network illustration is shown in

Figure 6.

SPE-176106-MS

Figure 6 Bekapai Network Illustration

Three tripod platforms were installed to develop the central panel in 1981 and it contributed 10,000

BOPD of additional oil production by 1982. In 1996, an additional well was drilled targeting the gas and

oil reservoirs in the west panel. The high pressure gas from this well is used as a source for gas lifting.

In general, the wells were completed with dual string completion (Long String and Short String) in

order to connect as many potential reservoirs as possible and produce them in commingle. However, well

accessibility is a drawback to this type of completion. Hence, a water breakthrough or sand issue from one

reservoir could jeopardize the production of the well as it cannot be isolated from the other reservoirs. In

addition, production allocation is also a challenge in this type of completion since PLT cannot detect the

flow contribution of each reservoir.

A total of 56 development wells were drilled within the envelope of initial development period and 5

wells are still contributing to current production, where 4 of them were revived through idle wells revival

project carried out in 2013. Until May 2015, this phase contributes 192 MBO and 266 BCF to the field

production with more than 90% of the production coming from the Main zone.

Phase 1 Re-Development (2007-2011)

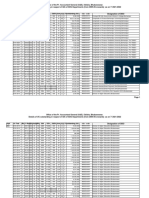

Seven development wells were initially proposed in the frame of Phase 1 Re-Development. However, 2

additional wells were added later on following the good results of the preceding wells. The well results

can be seen in Figure 7. The better than expected results are mainly due to higher netpay encountered in

the wells, with details as follows:

SPE-176106-MS

Figure 7Phase 1 Re-Development Well Results comparison Realization vs Prognosis

Unpredicted gas pays in the Shallow zone.

Lower Oil-Water contact in the Main zone.

Thicker oil and gas pay in the Upper zone.

Phase 1 Re-Development wells confirmed the strong aquifer support in the Main zone, where no

depletion was observed after 30 years of production. Meanwhile, in the other zones, minor depletion was

observed suggesting that the zones were underdeveloped. It also proves the wide extension of the Upper

and Lower zones, where very few penetrations were done during the initial development. The situation is

further highlighted in Figure 8.

10

SPE-176106-MS

Figure 8 Normalized pressure versus Subsea depth for depletion observation. Higher depletion is observed in the Lower zone of the

Bekapai Field

A combined completion type, multizone gravel pack with selective system and liner, was intalled in

the wells of this phase as depicted in Figure 9 (Banman, et al. 2008). The multizone GP could

accommodate up to 4 producing zones and the liner section is accessible for any wireline intervention.

Normally, one GP zone can accommodate 1 reservoir but depending on the reservoir thickness and the

distance between the reservoirs, additional reservoirs can also be accomodated. The multizone GP

technology evolved and in 2011 it was possible to accommodate up to 5 producing zones. However, the

number of potential reservoirs found in a well was often more than the maximum number of multizone

GP, leaving behind significant amount of uncompleted netpay. Based on the well results, not all of the

total netpay in the Main and Upper zones can be accommodated by the existing completion type as

depicted in Figure 10. Thus, the remaining uncompleted zones became the potential targets for Phase 2

Re-Development.

SPE-176106-MS

11

Figure 9 Multizone Gravel Pack with Selective System and Liner Completion

Figure 10 High un-completed pay zones due to GP zone limitation

12

SPE-176106-MS

As part of Phase 1 Re-Development project, production network debottlenecking was carried out to

anticipate higher gas production. The objective was to increase the gas production capacity from 30 to 50

MMSCFD. A new three-phase high pressure separator was installed in the offshore processing facility and

a compressor re-bundling was performed in the onshore terminal to this end.

A combination of good subsurface results and production network debottlenecking succeeded to

increase the field production from 1000 to 8000 BOPD and from 7 to 45 MMSCFD. Before Phase 2

Re-Development commenced in 2014, the Phase 1 Re-Development contributed 80% to the total field

production with Upper and Lower zones as the main contributor.

Phase 2 Re-Development (2013-Today)

Ten development wells are proposed in the frame of Phase 2 Re-Development. However, the existing

production capacity is still limited and it will not be able to accommodate the production of these wells.

For that reason, the development project is divided into 2 sub-phases:

Phase 2A Re-Development

The project consists of drilling 2 new wells to saturate the existing production capacity. The

optimum production configuration of the existing network is found at 11,400 BOPD and 37

MMSCFD. A higher oil production should be compensated by a lower gas production and vice

versa.

Two wells, drilled in 2014, showed encouraging results. The total netpay encountered is 25%

higher than prognosis. The thicker gas netpay was found mainly in Shallow zone, whilst the

thicker oil netpay was found mainly in the Lower zone. In the shallow zone, the sand extension

was found wider than expected. It is due to the clustering effect in the prediction where the well

data distributions are clustered around the platform. In the Lower zone, the oil water contact

(OWC) was found deeper than expected resulting in a thicker netpay than prognosis. The netpay

comparison is depicted in Figure 11.

Figure 11Phase 2A Re-Development Well Results Comparison Realization vs Prognosis

These two wells contributed in reaching a new peak of production in 2014 at 11,500 BOPD and

38 MMSCFD with Upper and Lower zones as the main contributor. They are currently producing

50% of the field oil production. The production profile is shown in Figure 12.

SPE-176106-MS

13

Figure 12Bekapai Production Profiles

Phase 2B Re-Development

The project consists of drilling 8 new wells and the installation of a new gas pipeline 12 x 16 km

from Bekapai offshore processing facility to onshore terminal through Peciko offshore network, to

further debottleneck the existing production capacity. The gas production capacity is expected to

increase up to 100 MMSCFD after the debottlenecking. The situation is illustrated in Figure 13.

The Phase 2B Re-Development had just started in April 2015. The drilling campaign and the new

14

SPE-176106-MS

Figure 13Bekapai Network Illustration after New Gas Pipeline Installation

pipeline installation are still ongoing. The location of the future wells are optimized based on the

information coming from recently drilled wells and OBC seismic result. The new pipe line will be

ready in July 2015 and the first well of this phase will be put on production in October 2015. While

waiting for the new wells to fill the new pipeline, the gas production will be supplied by the

existing wells through well interventions.

Phase 2 Re-Development wells is using an improved version of Phase 1 Re-Development well

completion. It is now able to accomodate up to 6 six GP producing zones.

Production Optimization

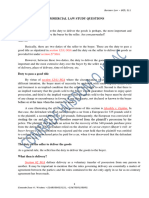

In addition to big scale projects outlined above, routine production optimization activities also hold

important roles in maintaining the field production at the high level. Some routine production optimization

activities performed in Bekapai are listed below:

Wireline Intervention

This activity is the key in sustaining the field production. Each well in Bekapai can encounter tens

of oil and gas reservoirs with different pressure regimes. Thus, a good reservoir management

practice is important in order to optimize the well production and, eventually, maximizing the field

resources (Oceaneawan, et al. 2015). The number of well intervention activities has been

increasing since 2007, when the re-development project started. However in 2013 and 2014, the

activities were particularly lower compared to previous years due to Phase 2A preparation

restraining the access to the platform and limiting full production capacity (Figure 14). In terms

of production gain, the well intervention activity has a significant contribution in 2011 and 2012,

when it contributes 40% to 45% to the field production. Figure 15 is showing the contribution of

the well intervention activity in yearly cumulative production.

SPE-176106-MS

15

Figure 14 Number of Well Intervention Evolution

Figure 15Well Intervention and New Well Contribution to Yearly Cumulative Production

Idle Wells Revival

Gas was not the main target of the initial development of Bekapai. Hence, albeit being penetrated

with almost all wells, the gas reservoirs have been rarely completed. Today, some of these wells

are in idle condition due to well performance or mechanical issues. Efforts to revive those wells

involve: annulus cementing, perforation, and sand control device installation. The revival efforts

were performed in 2013 in 2 wells by targeting the gas reservoirs. The gas is then used to revive

the neighboring oil wells through gas-lift injection. Up to today, a total of 4 wells have been

successfully revived through this project. The production figures can be seen in Figure 16. A study

for a larger implementation of this concept is still ongoing.

16

SPE-176106-MS

Figure 16 Idle Well Revival: Gas Source Well and Gas-Lifted Well

Minimizing Flow Friction In Pipeline

In 2013, Drag Reducing Agent (DRA) was injected into the 12 x 42 km pipeline from offshore

processing facility to onshore terminal. It was able to reduce the friction between the fluid and pipe

by forming a thin layer on the inner pipes surface and thus resulting in lower backpressure to the

well (Utama, Armi and Nuzulliany 2014). As a result, the export pressure reduced from 36 Barg

to 30 Barg creating capacity for an additional 3000 BOPD production (Figure 17).

Figure 17Impact of DRA injection to Production

SPE-176106-MS

17

Conclusion

Bekapai has been producing outstandingly for 40 years. The field development was started in 1974 with

the initial development phase and followed by successful efforts of field revival through Phase 1 and

Phase 2A Re-Development 30 years later. A new production peak of 11,500 BOPD and 38 MMSCFD

achieved in 2014 was the highest field production of the past 25 years. The on-going Phase 2B

Re-Development will further unlock the field potential in order to increase the gas production up to 100

MMSCFD.

Acknowledgments

The authors would like to thank MIGAS, INPEX, and Total E&P Indonesie for permission to publish this

paper. Our biggest gratitude is given to Bekapai G&G and Reservoir teams.

References

Banman, M., Delattre, E., Sofyan, M., & Suryadana, S. 2008. Single Trip Multi-Zone Gravel Packing

- Case Study at Handil, Bekapai & Sisi-Nubi Fields. Paper IPTC-12388 presented at the International Petroleum Technology Conference. Kuala Lumpur, 3-5 December.

Kristianto, A., Schulbaum, L., Choliq, M. T., Suardiputra, A., & Berger, N. B. 2014. Structural

Modeling of Double-Truncation Fault in Bekapai Field: Implementation of Volume Based Model

Technique. Paper IPA14-G-089 presented at the Indonesian Petroleum Association Thirty-Eighth

Annual Convention & Exibition. Jakarta, 21-23 May.

Utama, A., Armi, G., & Nuzulliany, R. 2014. Application of Drag Reducing Agent (DRA) In

Multiphase Pipeline For Bekapai Production Debottlenecking. Paper IPA14-E-069 presented at

the, Indonesian Petroleum Association Thirty-Eighth Annual Convention & Exibition. Jakarta,

21-23 May.

Oceaneawan, G., Santo, A., Hasanah, U., & Mahardhini, A. 2015. Innovative Early Development of

the Shallow Zone to Sustain the Production of the Mature Field Bekapai. Paper IPA15-E-095

presented at the Indonesian Petroleoum Association Thirty-Ninth Annual Convention & Exibition.

Jakarta 20-22 May.

Siawira, E., Kristianto, A., Bonnafe, J., Anggriani, N., Adam, C., Abidin, Z. Kurniawan F, B.,

Supriady., Strobbia, C., Liu, Y., Li, Y., Miao, X., Zi, L., Wang, G. 2015. A Breakthrough of

Converted S-wave Processing and Its Positive Impact to Structural Interpretation. Paper IPA15G-064 presented at the Indonesian Petroleum Association Thirty-Ninth Annual Convention &

Exhibition. Jakarta, 20-22 May.

S-ar putea să vă placă și

- SPE 158831 The Evolution of The NCMA Well Start-Up PhilosophyDocument10 paginiSPE 158831 The Evolution of The NCMA Well Start-Up Philosophymatheus_moreira0990Încă nu există evaluări

- Offshore Gas Hydrates: Origins, Development, and ProductionDe la EverandOffshore Gas Hydrates: Origins, Development, and ProductionÎncă nu există evaluări

- Development of Volcanic Gas Reservoirs: The Theory, Key Technologies and Practice of Hydrocarbon DevelopmentDe la EverandDevelopment of Volcanic Gas Reservoirs: The Theory, Key Technologies and Practice of Hydrocarbon DevelopmentÎncă nu există evaluări

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeDe la EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeEvaluare: 4 din 5 stele4/5 (2)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDe la EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingÎncă nu există evaluări

- Spe 171342 MSDocument8 paginiSpe 171342 MSDavid MontoyaÎncă nu există evaluări

- SPE-174699-MS Dalia/Camelia Polymer Injection in Deep Offshore Field Angola Learnings and in Situ Polymer Sampling ResultsDocument18 paginiSPE-174699-MS Dalia/Camelia Polymer Injection in Deep Offshore Field Angola Learnings and in Situ Polymer Sampling ResultslimbergÎncă nu există evaluări

- Coiled ProductionTubing TechnologyDocument67 paginiCoiled ProductionTubing TechnologyFaraj NabiyevÎncă nu există evaluări

- Best Practice and Lessons Learned For The Development and Calibration of Integrated Production Models For The Cooper Basin, AustraliaDocument40 paginiBest Practice and Lessons Learned For The Development and Calibration of Integrated Production Models For The Cooper Basin, AustralianoorÎncă nu există evaluări

- Nanotechnology Applied To The Enhancement of Oil and Gas Productivity and Recovery of Colombian FieldsDocument68 paginiNanotechnology Applied To The Enhancement of Oil and Gas Productivity and Recovery of Colombian FieldsMontes? 021Încă nu există evaluări

- Spe 133268 MS PDFDocument18 paginiSpe 133268 MS PDFPhuc TruongÎncă nu există evaluări

- Spe 167350 Ms - Fast Screening ProcessesDocument15 paginiSpe 167350 Ms - Fast Screening ProcessesAtrian RahadiÎncă nu există evaluări

- Matrix Stimulation Manual Rev4.0Document129 paginiMatrix Stimulation Manual Rev4.0DZPRO KORAÎncă nu există evaluări

- Manifa Oil Field Development Program - Onshore and Offshore ShallowDocument9 paginiManifa Oil Field Development Program - Onshore and Offshore ShallowJavier DiazÎncă nu există evaluări

- 1 Introduction of EOR LecturesDocument19 pagini1 Introduction of EOR LecturesAilene VasileÎncă nu există evaluări

- Tantalum FieldDocument12 paginiTantalum FieldKaushik ReddyÎncă nu există evaluări

- An Introduction To EORDocument4 paginiAn Introduction To EORMnesÎncă nu există evaluări

- SPE 126719 Matrix Acid Systems For Formations With High Clay ContentDocument15 paginiSPE 126719 Matrix Acid Systems For Formations With High Clay ContentJose Miguel GonzalezÎncă nu există evaluări

- OTC 15191 Case History of A 5 Zone Multi-Drop Hydraulic Control Intelligent Offshore Completion in BruneiDocument7 paginiOTC 15191 Case History of A 5 Zone Multi-Drop Hydraulic Control Intelligent Offshore Completion in BruneihuongvieteventÎncă nu există evaluări

- LSU - Down Hole Water Sink TechnologyDocument5 paginiLSU - Down Hole Water Sink TechnologyVivarodÎncă nu există evaluări

- Peterhead - 11.097 Well Completion Concept Select ReportDocument148 paginiPeterhead - 11.097 Well Completion Concept Select ReportF SedighiÎncă nu există evaluări

- Site SelectionDocument14 paginiSite SelectionmardiradÎncă nu există evaluări

- Spe 39437 MSDocument14 paginiSpe 39437 MSAndrés Bojacá MatizÎncă nu există evaluări

- Black Oil DefinitionsDocument21 paginiBlack Oil Definitionsmanish.7417Încă nu există evaluări

- JPTDocument144 paginiJPTbilalÎncă nu există evaluări

- How To Increase Recovery of Hydrocarbons Utilizing Subsea Processing TechnologyDocument14 paginiHow To Increase Recovery of Hydrocarbons Utilizing Subsea Processing TechnologySara AguilarÎncă nu există evaluări

- JPT 2019-09 PDFDocument108 paginiJPT 2019-09 PDFroastÎncă nu există evaluări

- OptimizingHorizontal PLT Open HoleDocument5 paginiOptimizingHorizontal PLT Open HoleOmar RosarioÎncă nu există evaluări

- 4.0 Hydrates, Wax, Asphaltenes and Chemical InjectionDocument30 pagini4.0 Hydrates, Wax, Asphaltenes and Chemical InjectionJair IParraÎncă nu există evaluări

- SPE 71546 A Systematic Approach in Deepwater Flow Assurance Fluid CharacterizationDocument12 paginiSPE 71546 A Systematic Approach in Deepwater Flow Assurance Fluid CharacterizationJessica CehÎncă nu există evaluări

- Geology & Geophysics: Coiled Tubing TechnologyDocument4 paginiGeology & Geophysics: Coiled Tubing TechnologyUji PanuntunÎncă nu există evaluări

- A Case Study of An Efficient and Cost-Saving ICD Completion Design To Manage Production Flow Heterogeneity in Filanovskogo Russia FieldDocument18 paginiA Case Study of An Efficient and Cost-Saving ICD Completion Design To Manage Production Flow Heterogeneity in Filanovskogo Russia FieldSara Kamil Abd Al-RedahÎncă nu există evaluări

- Flowing WellsDocument18 paginiFlowing WellsJorge RidezÎncă nu există evaluări

- Editing - Petrobowl Questions - FlashcardsDocument45 paginiEditing - Petrobowl Questions - FlashcardsManuel Marquez CequeaÎncă nu există evaluări

- SPE 130768 Multi-Field Asset Integrated Optimization BenchmarkDocument19 paginiSPE 130768 Multi-Field Asset Integrated Optimization BenchmarkIndo UtamaÎncă nu există evaluări

- Spe 184869 MSDocument16 paginiSpe 184869 MSSS100% (1)

- Iptc-19506-Ms - Total Well Management - Maximising Well Lifecycle ValueDocument8 paginiIptc-19506-Ms - Total Well Management - Maximising Well Lifecycle ValueAtrian RahadiÎncă nu există evaluări

- 1001 385v2-STIMPRO ISDocument2 pagini1001 385v2-STIMPRO ISRodolfo PerezÎncă nu există evaluări

- New and Novel Fracture Stimulation Technologies For The Revitalization of Existing Gas Storage Wells: Interim Project ResultsDocument87 paginiNew and Novel Fracture Stimulation Technologies For The Revitalization of Existing Gas Storage Wells: Interim Project ResultsPinkesh ShahÎncă nu există evaluări

- Reeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuideDocument5 paginiReeve Up or Change Out A Winch Line (Tugger Line) : Cormorant Alpha Drilling Operations GuidealiÎncă nu există evaluări

- Water Problem and Water Control PDFDocument22 paginiWater Problem and Water Control PDFwikenblessyÎncă nu există evaluări

- SPE-188958-MS Successful Field Trials of Water Control in High Water Cut Wells Using An Improved Downhole Water Sink/Drainage SystemDocument13 paginiSPE-188958-MS Successful Field Trials of Water Control in High Water Cut Wells Using An Improved Downhole Water Sink/Drainage SystemBa NeenÎncă nu există evaluări

- Multilateral AsiaDocument2 paginiMultilateral AsiaNazer CorleoneÎncă nu există evaluări

- Chemical Flooding in EOR: A Case Study of Enhanced Oil Recovery Using Surfactant and Polymer InjectionDocument18 paginiChemical Flooding in EOR: A Case Study of Enhanced Oil Recovery Using Surfactant and Polymer InjectionAli AbukhzamÎncă nu există evaluări

- Introduction To EOR ProcessesDocument23 paginiIntroduction To EOR Processesحسين رامي كريم A 12Încă nu există evaluări

- A Review of Downhole Separation TechnologyDocument8 paginiA Review of Downhole Separation TechnologyIbrahim NugrahaÎncă nu există evaluări

- EOR of VNDocument26 paginiEOR of VNVann Torng BmcÎncă nu există evaluări

- Spe 120632 MS PDocument0 paginiSpe 120632 MS PMagaña AuryÎncă nu există evaluări

- 231 PDFDocument20 pagini231 PDFhawar abdul-khaliqÎncă nu există evaluări

- How Does Gas Injection WorkDocument3 paginiHow Does Gas Injection WorkrajasekharboÎncă nu există evaluări

- 4 General Design CriteriaDocument13 pagini4 General Design CriteriaGaluh PramudiptoÎncă nu există evaluări

- Spe-193121-Ms - Integrated Production Optimization WorkflowDocument22 paginiSpe-193121-Ms - Integrated Production Optimization WorkflowAtrian RahadiÎncă nu există evaluări

- IPTC 10562 Low-Dosage Hydrate Inhibitors (LDHI) : Advances in Flow Assurance Technology For Offshore Gas Production SystemsDocument8 paginiIPTC 10562 Low-Dosage Hydrate Inhibitors (LDHI) : Advances in Flow Assurance Technology For Offshore Gas Production SystemsWaleed Barakat MariaÎncă nu există evaluări

- A Continuous and Dynamic Production Allocation Method For Commingled Gas Wells Using An Arithmetic Progression ApproachDocument13 paginiA Continuous and Dynamic Production Allocation Method For Commingled Gas Wells Using An Arithmetic Progression ApproachKasanto22Încă nu există evaluări

- FazeproDocument8 paginiFazeproMaria Fernanda Zenteno CastilloÎncă nu există evaluări

- Reservoir Production ConceptsDocument11 paginiReservoir Production ConceptsUsman HasanÎncă nu există evaluări

- Baker Hughes Caisson ESP (2010)Document2 paginiBaker Hughes Caisson ESP (2010)hermit44535Încă nu există evaluări

- PetroSkills - Surface Production OperationsDocument2 paginiPetroSkills - Surface Production OperationsMausam GauravÎncă nu există evaluări

- SPE-169245-MS Overcoming Ultradeepwater Cementing Challenges in The CaribbeanDocument16 paginiSPE-169245-MS Overcoming Ultradeepwater Cementing Challenges in The CaribbeanAhmed Ali AlsubaihÎncă nu există evaluări

- Positive Reactions in CarbonateDocument31 paginiPositive Reactions in CarbonateJulian Carrero Carreño100% (1)

- Narrative Report - Food Safety and SanitationDocument4 paginiNarrative Report - Food Safety and SanitationMarjorie Dela CruzÎncă nu există evaluări

- Brochure Delta iConPro Controller PDFDocument8 paginiBrochure Delta iConPro Controller PDFvicvaldon100% (1)

- Procedure For Loading ASI On Existing Robot and Keeping All Programs and SettingsDocument4 paginiProcedure For Loading ASI On Existing Robot and Keeping All Programs and SettingsRafael Ramírez MedinaÎncă nu există evaluări

- Philippine Department of Education lesson on productivity toolsDocument5 paginiPhilippine Department of Education lesson on productivity toolsKarl Nonog100% (1)

- SGR Recruiting Packet 12page Pages PDFDocument12 paginiSGR Recruiting Packet 12page Pages PDFAnonymous p92QjltÎncă nu există evaluări

- Philippine Environmental Laws SummaryDocument54 paginiPhilippine Environmental Laws SummaryHayel Rabaja50% (2)

- 48V100 DatasheetDocument2 pagini48V100 Datasheetmrashid286100% (1)

- C2022 04Document72 paginiC2022 04Leo2pbÎncă nu există evaluări

- Dashboard - Harare PolytechnicDocument4 paginiDashboard - Harare PolytechnicTeewyz MarÎncă nu există evaluări

- Waste MGMT Research PPRDocument6 paginiWaste MGMT Research PPRRohit Amorso RanjanÎncă nu există evaluări

- Assessing The Effectiveness of South Korea's Development Assistance in VietnamDocument16 paginiAssessing The Effectiveness of South Korea's Development Assistance in VietnamPhạm Phương AnhÎncă nu există evaluări

- Jurnal Harga Vskepuasan Pelanggan Vs Loyalitas PelangganDocument13 paginiJurnal Harga Vskepuasan Pelanggan Vs Loyalitas PelangganSyahrin AsmanÎncă nu există evaluări

- Probationary DigestsDocument22 paginiProbationary DigestsMatt ManlapidÎncă nu există evaluări

- Bangalisan V Ca G.R. No. 124678 July 31, 1997 Regalado, J.: FactsDocument1 paginăBangalisan V Ca G.R. No. 124678 July 31, 1997 Regalado, J.: FactsKate GaroÎncă nu există evaluări

- Grove GMK6350Document20 paginiGrove GMK6350cornel_lupuÎncă nu există evaluări

- Intercompany EntriesDocument19 paginiIntercompany EntriesJamilÎncă nu există evaluări

- Operand Storage in The CPUDocument3 paginiOperand Storage in The CPUisaac setabiÎncă nu există evaluări

- B.Tech CST R20Document212 paginiB.Tech CST R20ẞyed RehamanÎncă nu există evaluări

- SENSOR and Signal Processing UnitDocument57 paginiSENSOR and Signal Processing UnitRohit Ghulanavar100% (1)

- FINANCIAL RATIOS AND CALCULATIONSDocument13 paginiFINANCIAL RATIOS AND CALCULATIONS1 KohÎncă nu există evaluări

- Edu Uc Ddo 05 06 Onwards 7-21Document20 paginiEdu Uc Ddo 05 06 Onwards 7-21biplabsahoo10Încă nu există evaluări

- Direct Cuspal Coverage Posterior Resin Composite RestorationsDocument8 paginiDirect Cuspal Coverage Posterior Resin Composite Restorationsdentace1Încă nu există evaluări

- Gemstone MineralsDocument8 paginiGemstone MineralsRina Shane PascuaÎncă nu există evaluări

- CTF France PDFDocument2 paginiCTF France PDFmeka_nathÎncă nu există evaluări

- Construction ScheduleDocument3 paginiConstruction Schedulegroup2sd1314100% (1)

- 083E Relative Humidity Sensor Accurate and ReliableDocument2 pagini083E Relative Humidity Sensor Accurate and Reliablehuguer1Încă nu există evaluări

- OBLICON REVIEWER Article 1162Document1 paginăOBLICON REVIEWER Article 1162Oh SeluringÎncă nu există evaluări

- Commercial Law Study QuestionsDocument33 paginiCommercial Law Study QuestionsIfeanyi NdigweÎncă nu există evaluări

- 2020 Scrum Guide ArabicDocument15 pagini2020 Scrum Guide Arabicnbo100% (1)