Documente Academic

Documente Profesional

Documente Cultură

SPE-174932-MS Risk and Uncertainty Plans

Încărcat de

skywalk189Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SPE-174932-MS Risk and Uncertainty Plans

Încărcat de

skywalk189Drepturi de autor:

Formate disponibile

SPE-174932-MS

Uncertainty and Risk Management Plans are Critical for Team Alignment

and Better Decision Quality

R. Sawiris, C. S. Howes, J. A. Rodriguez, and W. L. Foley Chevron

Copyright 2015, Society of Petroleum Engineers

This paper was prepared for presentation at the SPE Annual Technical Conference and Exhibition held in Houston, Texas, USA, 28 30 September 2015.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents

of the paper have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect

any position of the Society of Petroleum Engineers, its officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written

consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may

not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

The Uncertainty Management Plan (UMP) and Risk Management Plan (RMP) processes are an integral

component of Reservoir Management and Project Management at Chevron. The UMP and RMP are key

to safely deliver and improve the movement of Resources to Reserves to Production (R2R2P) and the

maturation of Organic Resource Opportunities (ORO) in a timely and economical manner.

The UMP helps project teams identify key uncertainties and develop robust work plans to resolve these

uncertainties in order to improve decision quality and maximize value to the company. The RMP helps

project teams identify key technical, mechanical and commercial risks, and develop appropriate mitigation

and contingency plans for these risks. The RMP will also help the team identify and address process safety

risks related to subsurface integrity issues. The UMP and RMP drive development plans, technology

plans, surveillance plans, operating plans and resource loaded work plans. This is even more critical at the

current low oil prices where many projects become economically challenged; we need to focus our efforts

and resources to be decision driven and value driven.

We will compare and contrast the concepts of uncertainty and risk and present case studies of how the

UMP and RMP were successfully used on a variety of assets. We will also discuss some of the pitfalls,

lessons learned and best practices.

Introduction

The Chevron Reservoir Management community has established the UMP and RMP processes as part of

the Company subsurface project management toolkit. Project teams use UMP and RMP to identify key

subsurface, well construction, operational, subsurface integrity issues and commercial uncertainties and

risks. These may cause the project to fall short of expectations, throughout a project or asset lifecycle as

mentioned in several papers (Sarma et al 2015, Wu et al 2014, Oreilly et al 2014, Amudo et al 2014,

Ekweribe et al 2014, McKay et al 2013, Odusote 2013, Adeyemi 2013, Meddaugh et al 2013, Shook et

al 2009, and Rivera et al 2007).

The UMP supports different processes including the Asset Development Plan (ADP), Appraisal Plan,

Surveillance, Analysis and Optimization Plans (SA&O), Technology Plans, Project Execution Plans

(PEPs), and Operating Plans. The RMP process is actively applied to identify and address risks using

SPE-174932-MS

appropriate mitigation and contingency plans. The applications of the UMP and RMP processes have been

expanded and a scalable version of the process is currently used in brownfield and small capital projects.

UMPs and RMPs support improved decision quality and effective reservoir management practices.

Project teams keep UMPs and RMPs evergreen and review them periodically. Project teams use the UMP

process to prioritize uncertainties, articulate them to stakeholders, and develop plans to resolve key

uncertainties. (McKay et al 2013)

Materials and Methods

History and Background

Chevron created the Capital Stewardship Subsurface Evaluation Process (CSSEP) team to improve

project performance in 2000 (see Appendix A: History). The CSSEP team cited that the root cause for the

majority of projects that were underperforming was related to subsurface uncertainties, which provided

the business case for the UMP tool development.1 In 2001, the CSSEP team developed the UMP as one

of several tools to improve performance.

Halfway through the second decade of use, the UMP process has become well established as an integral

component of Chevron Reservoir and Project Management. The approach has expanded past subsurface

uncertainties to include operational, facilities, and other uncertainties relevant to project execution.

Improved predictability in forecasting and improved ability to develop contingency planning demonstrates

the value that the UMP process has provided. The structured process also improved dialogue and

alignment with partners in Non-operated Joint Venture (NOJV) assets.

How does uncertainty differ from risk?

Uncertainty and risk both result from a lack of certainty; they include downside risks and upside

opportunity outcomes and are subjective. (See Table 1)

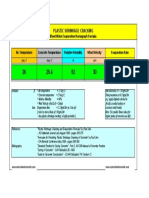

Table 1Uncertainty versus Risk

Definition

Uncertainty

Risk

Lack of information about

range of potential

outcomes and factors

that influence them

Probability of success or

failure relative to

defined objectives or

targets

Ranking

Handling

Impact on Key

Decisions

Resolution Planning

Impact on

Project and

Business

Objectives

Contingency and

Mitigation Plans

Measure

Expressed as a range of

values for a variable

resulting in a range

of outcomes

Probability of occurrence

and magnitude of

loss

In any sort of task we undertake, whether personal or professional, we deal with uncertainties and risks.

For example, there is uncertainty and risk in the simple task of traveling to the airport to catch a flight.

We must estimate how long it takes to get there and prepare ourselves for the commute. So we begin with

a clear objective: Arrive at the airport safely and in time to catch our flight. And the key decisions we need

to make are:

What time to leave?

What mode of travel to use?

What clothes to take?

Uncertainty refers to what we dont knowa lack of information about the range of potential outcomes

and the factors that influence them. These uncertainties will impact our decisions. In our example, we

1

Personal communications with W.F. Smith and S.C. Smith.

SPE-174932-MS

know the scheduled time of departure for our flight, but we dont know what the weather and traffic

conditions will be like. Will it be cool and clear, icy and slick, or rainy and congested? Risk, on the other

hand, can be described as the probability that a hazard or discrete event will result in a specified level of

loss, or failure. In our example, there is a risk that our car may break down or there is an accident on the

road blocking traffic and preventing us from achieving our goals and objectives.

So as a part of our planning and preparation, we need to consider and make plans to address both

uncertainties and risks. For example, to deal with the weather uncertainties, we might plan to have a

variety of gear available so we are prepared for a reasonable range of conditions. And for timing issues,

we may check traffic and road conditions and allow ourselves enough time. On the other hand, we

evaluate the risks and prepare mitigation and contingency plans to minimize impact or manage better in

case risk occurs. And to mitigate our car breakdown risks, we may schedule an appointment with a

mechanic to check the car and for other road risks; we may prepare a list of contacts and fallback options.

We apply this same approach to planning for uncertainties and risks in our business.

In the early years of the process, teams focused on uncertainty analysis, but the differences between

uncertainty and risk need to be fully understood to prepare Uncertainty and Risk Management Plans. The

PRMS (2011) defines Uncertainty as The range of possible outcomes in a series of estimates. For

recoverable resource assessments, the range of uncertainty reflects a reasonable range of estimated

potentially recoverable quantities for an individual accumulation or a project. In general, the wider the

range of values for a variable, the greater is the uncertainty that exists.

The PRMS (2011) defines Risk as The probability of loss or failure. As risk is generally associated

with the negative outcome, the term chance is preferred for general usage to describe the probability of

a discrete event occurring. Additionally, risk can be defined as a measure of potential loss in terms of

both the incident likelihood and the magnitude of the loss. Risk can be described as the probability that

a hazard or discrete event will result in a specified level of loss, injury, or failure. Risk focuses on events

or conditions that will have a negative outcome on our business or project objectives. Risk can be

technical, mechanical or commercial. (See Table 2)

Table 2Risk Type and Examples

Risk Type

Subsurface Integrity

Technical

Commercial

Mechanical

Other

Examples

Shallow hazards, Shallow faults, Reactivation of faults,

Breaching seal, Wellbore integrity, H2S and CO2

contaminants

Production, Estimated Ultimate Recovery, Quality and

connectivity, Oil/water contact, Gas water contact,

Aquifer

Contracts, Concession extensions, Joint Venture Partner

alignment, Government approvals, Public relations

and support, Rig Availability, Costs

Drilling problems, Completion Problems

Weather, Trade Unions, Security and Unrest

In the oil and gas industry, to understand and acknowledge the current range of uncertainties, one must

assess their impact on key decisions, and implement options to resolve uncertainties (e.g., drilling an

appraisal well or starting a pilot project). Conversely, to understand and acknowledge the risks, one must

determine their associated probability of occurrence and their impact on project and business objectives.

It is necessary to develop options to mitigate risks (e.g., sidetracking a well if the oil/water contact is

higher). Additionally, project teams develop contingency plans for both downside outcome and upside

outcome capture.

SPE-174932-MS

Updated Process

On the basis of feedback from reservoir management practitioners, the corporate Upstream Capability

Reservoir Management (UC-RM) group updated the UMP process in 2013 to include new workflows,

guidelines, and tools. The updated process aims to change the culture and the behavior of reservoir

management practitioners (see Figure 1). The process enables project and asset teams to be more decision

driven and to focus on key uncertainties that will make or change our decisions.

Figure 1Updated UMP and RMP Processes

The UMP and RMP processes are all about value creation. This can only be achieved with the

appropriate level of planning. As illustrated in Figure 2, too little effort could likely result in a wide range

of uncertainty and increase the risk of falling short of achieving project goals or also failing to capture

available upside and, therefore, erode value. Equally, if teams spend too much effort, time, and budget to

eliminate all uncertainties and risks, they would erode value by missing a market opportunity and over

insuring the project beyond what is required to make a quality decision. Also by over insuring, project

teams consume resources that might have added more value if applied to a different project.

Figure 2UMP / RMP All About Value Creation

The UMP is a fundamental component of the decision making process and relates to all aspects of

reservoir management. The intention of the updated UMP process is to help the project and asset team to

SPE-174932-MS

determine key uncertainties (i.e., what is not known). It also helps teams to identify the range of potential

outcomes and factors that influence them, and to identify the uncertainties with the highest impact on key

decisions, and therefore improve decision quality. The resolution options such as specific technical studies

or appraisal drilling identified in the UMP drives the subsurface workplans, surveillance activities, and

data acquisition programs. Figure 3 shows graphically how the UMP relates to project management.

Without a proper appreciationof the UMP process, we see teams being activity driven and focusing on

resolving uncertainties that have little or no impact on project decisions, leading to paralysis by analysis.

Figure 3Uncertainty Management and Project Management Integration

Similarly, by use of the updated RMP process, project teams will ensure that key risks (see Table 2)

are identified and appropriate mitigation and contingency plans are put in place to maximize value for the

stakeholders. Cost estimates for contingency plans can also be developed as a reality check to ensure they

are economically feasible, however protecting people and the environment remains our first priority. The

objectives of RMP include both the prevention of risk events from occurring and the minimization of the

impact if any of the risk events occurred. The RMP not only focuses on project execution risks, but also

on risks related to the full-field development plan, such as those related to adding infill drilling campaigns

or water/gas injection later in field life. The opposite of risk is opportunity, and it captures the potential

upside of the impact of an uncertain event on project and business objectives.

In addition, the UMP and RMP processes focus on process safety, flow assurance and Subsurface

Integrity (SSI) issues. Some examples of SSI issues are reservoir seal integrity, shallow faulting, injection

above fracture gradients, subsidence caused by depletion, fault reactivation resulting from over injection,

or possible contamination of shallow aquifers. We encourage teams to address these issues by modifying

the operating guidelines, conducting surveillance and performing technical studies.

Figure 4 summarizes the workflows for uncertainty and risk management planning. For each workflow,

the UC-RM group built a tool to help project and asset teams through the entire UMP and RMP processes.

Each of these workflows and tools apply to Major Capital Projects (MCP), Small Capital Projects (SCP)

and mature assets.

SPE-174932-MS

Figure 4 Uncertainty and Risk Management Plan Workflow

Data and Results

Since the UC-RM group launched the updated UMP and RMP processes in mid-2013, UC-RM has

facilitated numerous UMP/RMP workshops on assets across several business units, covering a variety of

projects and asset types:

Exploration prospects

Both green field and brownfield development

Onshore and offshore, including deepwater development

Operated and non-operated assets, with and without NOJV partner participation

Conventional and unconventional developments

Oil and gas/condensate fields, both clastic and carbonate

Light and heavy oil, including primary, secondary and enhanced recovery projects.

Key learnings are:

Focusing on prerequisites (see Figure 4) before a workshop, particularly updating the project frame

and achieving alignment on key decisions

Encouraging cross-functional participation and involvement of appropriate personnel

Scaling each UMP/RMP session to fulfill the asset or project teams requirements

Focusing on resolving key uncertainties that if resolved would help the project team either make

or change decisions rather than just narrowing the uncertainty range

Selecting resolution options that will resolve key uncertainties to help teams make quality

decisions to be value driven and decision driven rather than being activity driven

Updating and aligning workplans based on the UMP and RMP results to avoid conducting UMP

and RMP only to check the box before technical or peer reviews

SPE-174932-MS

Keeping UMP and RMP evergreen and updating them as new information becomes available or

when progressing through project management

Reinforcing the concept that the UMP and RMP are not the end products; they are interim products

that should drive or influence derivative products (see Figure 4).

Additionally, the UMP/RMP workflows have been used to enhance decision making in other areas

outside of subsurface uncertainties and risk, such as in employee development projects.

Case Study #1 Prioritization of Key Uncertainties based on Impact on

Key Decisions

The following example illustrates how using the UMP process helped a project team became more quality

decision driven rather than activity driven, and alleviated their need to perform activities that did not

impact the key project decisions. This case study is a deep water gas development project, where the

Company was a non-operating partner. The subsurface assessment carried out by the Company project

team identified several uncertainties, quantified the ranges and assessed the expected range of outcomes.

This illustrated a misalignment with the Operators recovery values and ranges. Company estimates were

more conservative and carried a wider range between the low and high estimates. However, the project

was still economic with the lower Company estimates (See Figure 5).

Figure 5Operator and Company EUR Ranges

To understand the differences and achieve alignment, the Company team initially planned to carry out

separate studies and build detailed reservoir models. The UMP workshop helped the Company project

team identify several uncertainties and assess their impact on the key project decisions. Through the UMP

process and discussions, the team realized that the identified uncertainties would not have had a significant

impact on the projects key decisions related to the project development plan (e.g., subsea development,

the subsea manifold location, size of flowline or the number, location and type of wells). As a result, the

Company project team became comfortable to support the operators plan to move the project forward.

They did, however, re-run economic sensitivities with Company estimates, thereby, not delaying the

project further with more time consuming shadow work such as duplicating the operators reservoir

modelling effort. The UMP process enabled Company personnel to be decision driven instead of activity

driven.

SPE-174932-MS

Case Study #2 Partner Alignment and Effective Communication of

Uncertainties

In this NOJV property, the Operator planned a flood expansion, which required the Company endorsement and financial commitment. The Companys internal governance process required a more robust

analysis of the opportunity. However the operator provided a limited amount of data to Company, and

made it difficult to carry out the analysis.

The Company NOJV team held an initial UMP session, and during the session the team identified the

key decisions and key uncertainties for the project (see Table 3). This initial workshop helped to obtain

internal team alignment. Company and Operator personnel held a second joint UMP workshop. Company

personnel provided a high level overview of the UMP process to the Operator personnel, so they could

become familiar with the process. Results from the initial UMP session were shared.

Table 3Case Study # 3 Uncertainty Impact and Level of Resolution Required

The operator confirmed the key decisions identified by the Company asset team, and provided some

insights about the range and impact of key uncertainties on the key decisions. By communicating

uncertainties to the Operator, the asset team effectively conveyed the reasoning for the request of

additional field information, which the Operator had available, and as a result of the workshop, the

Company received all information and data needed to finalize internal analysis and complete project

approval. In this case the Company used the UMP process as a structured approach to request data from

the Operator. If the data had not already been acquired by the Operator, the UMP and RMP should drive

data acquisition programs to resolve key uncertainties prior to proceeding with the project.

SPE-174932-MS

Case Study #3 Integration of UMP and RMP Processes into Asset

Development Plans

This case study illustrates how the UMP and RMP processes can be integrated into Integrated Production

Models (IPM) and Asset Development Plans (ADP) for producing assets. IPM can enable teams to

optimally and economically maximize hydrocarbon recovery by integrating all subsurface and surface.

Asset teams generated reliable forecasts where key uncertainties and risks were fully understood and

addressed. Asset teams use IPM to integrate and evaluate system wide impacts of uncertainties and risks.

The UMP provides a good pathway to help create cross functional alignment over key uncertainties. Quite

often, the team focuses on quantifying reservoir static and dynamic uncertainties without integrating all

other issues that may have larger impact on our decisions, such as facilities uncertainties. Liquefied

Natural Gas (LNG) projects are complex, expensive and take a long time to plan and implement. We have

to balance timely decision making with a good UMP and RMP to plan ahead for future projects to

maintain reliable supply and meet contractual obligations. The team can integrate the learnings from UMP

and RMP into the IPM models to generate reliable ranges of forecasts.

There are many uncertainties and risks that could impact the team decisions to execute the next project

to maintain reliable supply. Some issues are related to subsurface; others relate to facilities, others are

operational, while still other issues correspond to the commercial issues such as market supply and

demand. If the question is Will we have sufficient capacity to meet current and future demand?, the

answer may be needed at a portfolio level, at a field level, at a production level, or at a real-time reservoir

management level.

The asset team developed risked production profiles evaluating the production impact for a range of

probability of well failure (e.g., 1, 2, or 3 wells lost), facilities reliabilities and downtime and reservoir

performance. The asset team developed the workflow to support the drilling campaign timing decisions,

facilities debottlenecking and depletion compression projects. To effectively manage a portfolio of

multiple fields, an asset team can assess demand, well deliverability, system potential, and schedule

remaining opportunities to close any supply shortfall gaps. Automated calculation of production system

capability is analyzed and compared to short- and long-term production forecasts to identify production

opportunities and threats. Understanding bottlenecks throughout the production system is critical to assist

in supply planning and to provide validation of long-term forecasting models.

Case Study #4 - Identify Key Risks and Capture Upside Potential

Project teams discussed and identified all types of risks that apply to their project (Table 2), through a

facilitated RMP workshop. In addition, the team identified other risks that could apply to their asset, using

the pre-populated questions in the tool to stimulate the discussions. The team then assessed the likelihood

(or probability) of the risks and their impact (or consequences) on the project objectives. During the

discussions, the team acknowledged they succeeded in developing a comprehensive risk register and were

able to evaluate the dependencies of these risks that when combined could result in catastrophic events.

This helped the team develop thorough risk mitigation and contingency plans for the key risks, in case risk

occurs, modify the operating plan and identify additional technical studies that will be required to address

subsurface integrity issues. In addition, the team updated their surveillance and monitoring program, to

collect critical data which will help them in risk mitigation.

In addition, the team identified several issues related to upside potential. This helped the team to

modify the project development plan to capture the upside. For example, the team recognized there could

be an upside potential with deliverability and recovery which may require additional wells and facilities.

This helped the team to justify adding additional well slots on the platform and to allow for a facilities

upgrade in the future.

The team incorporated the following key procedures:

10

SPE-174932-MS

Maintaining injection below fracturing pressure

Monitoring reservoir and wellhead pressures on regular basis

Involving company Subject Matter Expert to complete rock mechanics studies and better understand the seal integrity

Building a dashboard to have real time monitoring of production and injection data, wellhead and

downhole pressures and temperatures, voidage replacement rations and Hall Plots

Using state-of-the-art techniques for remote monitoring and surveillance

The above procedures helped the project team to address the SSI issues.

Analysis and Implications

While the UMP and RMP cannot change the state of nature, such as a highly compartmentalized reservoir

or reservoir quality, they provide a mechanism to help project teams convey the potential uncertainties and

risks to decision makers before moving ahead with detailed work plans or a selected development plan.

It helps subsurface teams challenge themselves by asking questions like Why is my field different from

the other ones that had reservoir connectivity issues? or What could I do differently to mitigate the

downside if turns out to be similar? The RMP can help teams to develop mitigation and contingency

plans for key risks that could impact the project and business objectives.

Our goal is to share lessons learned from the past experiences that will be assimilated into future UMP

and RMPs to continuously improve decision quality. In the future, it is likely that the industry will be

developing more complex and challenging reservoirs, and proper assessment of key uncertainties and risks

will be critical to ensure success. UMP can help us understand the logic behind past decisions and when

combined with lookback data can help us improve future decisions for similar projects. The UMP helps

teams identify and evaluate alternatives such as less aggressive staged development plans, initiating a

pilot, or modifying the appraisal strategy to gather connectivity data. High performing asset teams

generate a full field asset development plan for the entire field life with regular updates of the UMP and

the RMP as uncertainties and risks change over time.

Conclusions

There are similarities between uncertainty and risk as both result from a lack of certainty, both include

downside and upside outcomes, and both are subjective based on our background and experience.

However, the workflows used to define, rank, and manage the uncertainties and the risks differ

significantly. The UMP and RMP workflows have evolved within the Chevron Reservoir Management

community and have led to the following key principles for effective Uncertainty and Risk Management

Planning:

While we strive to resolve uncertainties, we mitigate risk

Asset/Project Teams use the UMP to enable quality decisions in the presence of uncertainty, not

to eliminate uncertainty

The UMP enables the project team to identify key uncertainties by prioritizing their impact on key

decisions and to develop appropriate resolution plans for these uncertainties

The UMP process provides a vehicle for the team to quantify the uncertainty range, reach

consensus on the expected range of outcomes and achieve stakeholder alignment on resolution

plans

Asset/Project Teams use the RMP to identify and focus on the key risks which are identified by

prioritizing their impact on project objectives. The team also evaluates the dependencies between

risks that when combined could result in catastrophic events. Teams develop appropriate mitiga-

SPE-174932-MS

11

tion and contingency plans for these key risks. The RMP improved process safety and subsurface

integrity awareness and management

With risk comes opportunity the RMP should capture both the upside and downside potential.

The UMP and RMP are not the end products; they are interim products that should drive or

influence derivative products (i.e., SA&O plans, appraisal plans and data acquisition programs,

technology plans, pilots, workplans, and operating plans).

Data should be gathered, analyzed, and integrated in a timely manner to enable quality decisions

and maximize value

The components of the UMP and RMP evolve as a project matures through the project management phases, and should be kept evergreen throughout the life of the asset or project

Cross-functional participation and involvement of the appropriate personnel are crucial for

developing a successful UMP and RMP.

Acknowledgements

The authors of this article would like to thank Chevron for giving permission to publish this manuscript.

We would like to thank current and former members of the Chevron Upstream Capability Reservoir

Management group who have contributed at various phases of the updating of the UMP and RMP

processes including Jeb Blackwell, Jerry Hardouin, Tom Specht, Jay Byers, John Cochrane, Sharon

Rector, Chidi Amudo, Will Da Sie, and Mike Pillow. In addition, we would like to thank Bob McElrath,

Wayne F. Smith, Stephen C. Smith, Andrew Latham, and Paul Maslanka for their efforts in developing

and championing the UMP process within Chevron in the early years.

References

McKay, D. M., Wilcox, W., Yang, A., et al. (2013, May 6). Subsurface Appraisal and Field

Development Planning of the Gas Condensate Field GVLA. Offshore Technology Conference. doi:

10.4043/24108-MS

Odusote, F. (2013, August 5). Deepwater Nigeria Field Development: Challenges, Best Practices and

Lessons Learned from the Agbami Field. Society of Petroleum Engineers. doi: 10.2118/167534-MS

Sarma, P., Yang, C., Xie, J., et al. (2015, February 23). Identification of Big Hitters with Global

Sensitivity Analysis for Improved Decision Making Under Uncertainty. Society of Petroleum Engineers.

doi: 10.2118/173254-MS

Wu, R., Rijken, M. C. M., Macary, S., et al. (2014, November 12). Tengiz Sour Gas Injection

Modeling: A Geo-mechanics Approach to Understand Gas Breakthrough. Society of Petroleum Engineers. doi: 10.2118/172298-MS

Ekweribe, C., Choi, S. K., Dunger, D., et al. (2014, November 12). Tengiz Well Performance

Forecasting Using Wellbore Transient Flow Modeling. Society of Petroleum Engineers. doi: 10.2118/

172266-MS

Oreilly, D. I., Lightfoot, T. J., Das, S., et al. (2014, October 14). Applications and Lessons Learned

During Integrated Subsurface Experimental Design (ED) Studies of a Giant NW Australia Gas Field.

Society of Petroleum Engineers. doi: 10.2118/171526-MS

Amudo, C., Xie, J., Pivarnik, A., et al. (2014, May 19). Application of Design of Experiment

Workflow to the Economic Evaluation of an Unconventional Resource Play. Society of Petroleum

Engineers. doi: 10.2118/169834-MS

Adeyemi, O. S. (2013, October 28). Upstream Workflow Transformation in a Mature Joint Venture

Asset:- Design, Implementation and Adoption for Value Creation. Society of Petroleum Engineers. doi:

10.2118/167484-MS

12

SPE-174932-MS

Meddaugh, W. S., Frydl, P., Dvoretsky, R., et al. (2013, March 10). The Wafra Second Eocene Heavy

Oil Carbonate Reservoir, Partitioned Zone (PZ), Saudi Arabia and Kuwait: Reservoir Characterization,

Modeling, and IOR/EOR Evaluation. Society of Petroleum Engineers. doi: 10.2118/164247-MS

Rivera, N., Meza, N. S., Kim, J. S., et al. (2007, August 1). Static and Dynamic Uncertainty

Management for Probabilistic Production Forecast in Chuchupa Field, Colombia. Society of Petroleum

Engineers. doi: 10.2118/100526-PA

Shook, G. M., and Mitchell, K. M. (2009, January 1). A Robust Measure of Heterogeneity for Ranking

Earth Models: The F PHI Curve and Dynamic Lorenz Coefficient. Society of Petroleum Engineers. doi:

10.2118/124625-MS

Guidelines for Application of the Petroleum Resources Management System. (2011): n. pag. Society

of Petroleum Engineers; American Association of Petroleum Geologists; World Petroleum Council;

Society of Petroleum Evaluation Engineers; Society of Exploration Geophysicists, Nov. 2011. Web. 22

May 2015. http://www.spe.org/industry/docs/PRMS_Guidelines_Nov2011.pdf.

AUTHOR BIOGRAPHIES

Ramzy Sawiris is Reservoir Management Consultant at Chevron. Sawiris is the leader of the Uncertainty and Risk Management Community of Practice at Chevron. Sawiris has authored/co-authored

several technical papers in reservoir management, reservoir simulation, and reserves. Sawiris holds a BS

degree in Petroleum Engineering from Cairo University. Sawiris was Treasurer and Chair of the SPE

Western Australia Section.

C. Susan Howes is Reservoir Management Consultant at Chevron. Howes was formerly Learning and

Organizational Development Manager at Anadarko. Howes is a core team member of the Uncertainty and

Risk Management Community of Practice at Chevron. She has co-authored several articles on Talent and

Technology in the Journal of Petroleum Technology and The Way Ahead. Howes holds a BS degree in

Petroleum Engineering from the University of Texas. She is Chair of the SPE Soft Skills committee, served

as SPE Regional Director for Gulf Coast North America, and is an SPE Distinguished Member.

Javier A. Rodriguez is Reservoir Management Consultant at Chevron. Rodriguez is a core team

member of the Uncertainty and Risk Management Community of Practice at Chevron. Rodriguez has

published a technical paper in the area of artificial lift. Rodriguez holds a BS degree in Petroleum

Engineering from Zulia University in Venezuela.

W. L. Bill Foley is Reservoir Asset Management Consultant at Chevron. Foley is a core team member

of the Uncertainty and Risk Management Community of Practice at Chevron. Foley has published

technical papers in the area of artificial lift. Foley holds BS and MS degrees in Petroleum Engineering from

University of Pittsburgh.,

SPE-174932-MS

13

Appendices

History

Chevron created the Capital Stewardship Subsurface Evaluation Process (CSSEP) team to improve project performance in

2000. The CSSEP team identified an opportunity to develop and deploy an efficient, multi-functional subsurface process for

timely data collection, interpretation, analysis and integration to improve evaluation of reservoir risk, production forecasting

and decision quality in an optimal cycle time. CSSEP enhanced capital stewardship through use of a common process for better

understanding of subsurface evaluation risks/uncertainties and communicating these to management, thereby resulting in

pursuit of higher quality subsurface opportunities and delivery of projected investment outcomes. Critical success factors in

CSSEP included:

Uncertainty assessment and decision analysis integrated into the overall process

Technical employees trained in uncertainty assessment

Distribution of uncertainty as part of the corporate culture.

The CSSEP team cited that the root cause for the majority of projects that were underperforming was related to subsurface

uncertainties, which provided the business case for the UMP tool development. In 2001, the CSSEP team developed the UMP

as one of several tools to improve performance.

The CSSEP team established the UMP as a document to be prepared by the subsurface team that:

Identifies key uncertainties and their relevant ranges

Summarizes impact of each uncertainty on production and ultimate recovery

Details specific resolution plans (e.g., cost, timing)

Discusses opportunities to:

X

X

mitigate downside outcomes (risk mitigation)

capitalize on upside outcomes (options planning)

Identifies signposts and details specific action plans; and

The uncertainty resolutions included in the UMP will typically result from a structured Decision Analysis (DA) approach,

including Value of Information (VoI) analysis, when appropriate.

The UMP addressed the reasons for unreliable forecasts such as insufficient data, reservoir complexity, as well as gaps in

DA modeling. Understanding uncertainty is the first step towards building reliable forecasts. The CSSEP team originally

designed the UMP to provide the project team with a structured approach to identifying and assessing the criticality of a

projects uncertainties. It also forms the basis for the delineation/appraisal program, and as part of the technical review process,

it serves as a key document identifying reservoir management uncertainties following production start-up. The CSSEP team

designed the UMP to be scalable for all sizes and types of projects.

The CSSEP team documented the first successful use of UMP in a business unit in 2002. The UMP process enabled project

teams to articulate key uncertainties and to communicate them to review teams, partners, and Decision Review Boards (DRBs).

The consistent application of UMP process created a shared understanding of the key subsurface uncertainties between asset

teams and their respective DRBs, and provided effective documentation for project continuity.

Halfway through the second decade of use, the UMP process has become well established as an integral component of

Chevron Reservoir and Project Management. The approach has expanded past subsurface uncertainties to include operational,

facilities, and other uncertainties relevant to project execution. Improved predictability in forecasting and improved ability to

develop contingency planning demonstrates the value that the UMP process has provided. The structured process also improved

dialogue and alignment with partners in Non-operated Joint Venture (NOJV) assets

Nomenclature and Acronyms

(CAPEX) Capital Expenditure

(CSSEP) Capital Stewardship Subsurface Evaluation Process

(DA)

Decision Analysis

(DST)

Drill Stem Test

(EUR)

Estimated Ultimate Recovery

(FPSO) Floating, Production, Storage and Offloading

(IPM)

Integrated Production Modeling

14

(MCP)

(NOJV)

(OOIP)

(OPEX)

(ORO)

(OOIP)

(PRMS)

(PEP)

(R2R2P)

(RMP)

(SCP)

(SSI)

(SA&O)

(UMP)

(UC RM)

(VoI)

SPE-174932-MS

Major Capital Projects

Non-operated Joint Venture

Original Oil in Place

Operating Expenditure

Organic Resource Opportunities

Original Oil in Place

Petroleum Resources Management System

Project Execution Plan

Resources to Reserves to Production

Risk Management Plan

Small Capital Projects

Subsurface Integrity

Surveillance, Analysis and Optimization Plans

Uncertainty Management Plan

Upstream Capability Reservoir Management

Value of Information

S-ar putea să vă placă și

- Spotlight On Literature A - Answer KeysDocument33 paginiSpotlight On Literature A - Answer KeysÁngel Alexander Zelaya López54% (13)

- Indy Oil Field Development PlanDocument139 paginiIndy Oil Field Development PlanDaniel Dambo100% (7)

- Thermalnet Methodology Guideline On Techno Economic AssessmentDocument25 paginiThermalnet Methodology Guideline On Techno Economic Assessmentskywalk189Încă nu există evaluări

- The Modern Field Development ApproachDocument9 paginiThe Modern Field Development ApproachEyoma Etim100% (2)

- 04.PSC Budgeting and Reporting 1Document20 pagini04.PSC Budgeting and Reporting 1Jeni MeesterÎncă nu există evaluări

- Optimizing Corporate Portfolio Management: Aligning Investment Proposals with Organizational StrategyDe la EverandOptimizing Corporate Portfolio Management: Aligning Investment Proposals with Organizational StrategyÎncă nu există evaluări

- NOVA-Weathering The Future Video Questions KeyDocument2 paginiNOVA-Weathering The Future Video Questions KeyThomas NowellÎncă nu există evaluări

- Risk01 - Managing Risk For Global Energy ProjectsDocument3 paginiRisk01 - Managing Risk For Global Energy Projectsmechanical_engineer11Încă nu există evaluări

- Risk and Uncertainty ManagementDocument12 paginiRisk and Uncertainty ManagementSamuel DambaniÎncă nu există evaluări

- Subsurface Risk ManagementDocument33 paginiSubsurface Risk Managementdrg100% (1)

- Economic Evaluation of Oil and Gas ProjectsDocument3 paginiEconomic Evaluation of Oil and Gas ProjectsRoman HdezÎncă nu există evaluări

- Investment Decisions in Petroleum Exploration and ProductionDocument5 paginiInvestment Decisions in Petroleum Exploration and ProductionIkhwanushafa DjailaniÎncă nu există evaluări

- Field Development PlanningDocument49 paginiField Development PlanningShek Gh100% (2)

- Economics of Risk Based Inspection Systems in Offshore Oil and Gas ProductionDocument12 paginiEconomics of Risk Based Inspection Systems in Offshore Oil and Gas ProductionOmar Sandoval ArízagaÎncă nu există evaluări

- Operational Readiness Planning Intro Transnet18Document12 paginiOperational Readiness Planning Intro Transnet18DamirÎncă nu există evaluări

- Risk Management Oil and GasDocument21 paginiRisk Management Oil and GasPratick TibrewalaÎncă nu există evaluări

- GIS and Petroleum IndustryDocument16 paginiGIS and Petroleum IndustryTitoSootoÎncă nu există evaluări

- Economic Modeling For Petroleum ProjectsDocument31 paginiEconomic Modeling For Petroleum ProjectsKivuti100% (1)

- Uncertainty and Risk Analysis in Petroleum Exploration and ProductionDocument12 paginiUncertainty and Risk Analysis in Petroleum Exploration and ProductionOladimeji TaiwoÎncă nu există evaluări

- Marathon Digital OilfieldDocument24 paginiMarathon Digital Oilfieldakashmehta10Încă nu există evaluări

- Decision Making PDFDocument41 paginiDecision Making PDFgreg100% (1)

- Spe 110882 MS PDocument7 paginiSpe 110882 MS Peechzaan1233475Încă nu există evaluări

- Oil and Gas Accounting and Performance Measurement: Dr. Batool AlrfoohDocument170 paginiOil and Gas Accounting and Performance Measurement: Dr. Batool AlrfoohTote FrotyÎncă nu există evaluări

- Economic Evaluation For Oil and Gas ExplorationDocument62 paginiEconomic Evaluation For Oil and Gas ExplorationÉbano Nakama100% (2)

- Spe 114781 MSDocument16 paginiSpe 114781 MSJessica KingÎncă nu există evaluări

- SPE-142449-MS - The Seven Pillars of Well Integrity ManagementDocument16 paginiSPE-142449-MS - The Seven Pillars of Well Integrity ManagementIsaias Castro ArmendarizÎncă nu există evaluări

- Oil Gas Field DevelopmentDocument2 paginiOil Gas Field DevelopmentMartin Guerrero100% (1)

- Economic CalculationsDocument26 paginiEconomic CalculationsYudis TiraÎncă nu există evaluări

- Gordy Shan Ore orDocument25 paginiGordy Shan Ore orAndy ColeÎncă nu există evaluări

- Offshore Field Development PlanDocument44 paginiOffshore Field Development PlannagalakshmiÎncă nu există evaluări

- SPE-195068-MS When Petrophysics Meets Big Data: What Can Machine Do?Document25 paginiSPE-195068-MS When Petrophysics Meets Big Data: What Can Machine Do?Edwin TapiasÎncă nu există evaluări

- Petroleum Economic Decision ToolsDocument40 paginiPetroleum Economic Decision ToolscjÎncă nu există evaluări

- Risk Analysis - From ProspectTo Exploration Portfolio - Gordon M. KaufmanDocument70 paginiRisk Analysis - From ProspectTo Exploration Portfolio - Gordon M. KaufmanSuta VijayaÎncă nu există evaluări

- Uncertainty and Risk Analysis in Petroleum PDFDocument12 paginiUncertainty and Risk Analysis in Petroleum PDFabuobida100% (1)

- Whitepaper Marginal FieldsDocument8 paginiWhitepaper Marginal FieldsarispriyatmonoÎncă nu există evaluări

- 03-1 Risk Feb08Document17 pagini03-1 Risk Feb08sotorkÎncă nu există evaluări

- Sandstone Reservoir Quality Prediction The State of The Art AAPGBulletin Ajdukiewicz Lander 2010Document9 paginiSandstone Reservoir Quality Prediction The State of The Art AAPGBulletin Ajdukiewicz Lander 2010Jody Van RensburgÎncă nu există evaluări

- L-9. Risk Analysis in Capital Investment DecisionsDocument10 paginiL-9. Risk Analysis in Capital Investment DecisionsHimanshu Tulshyan100% (1)

- Petroleum Project Economics 05Document16 paginiPetroleum Project Economics 05ediwskiÎncă nu există evaluări

- Risk Analysis Applied in E & PDocument7 paginiRisk Analysis Applied in E & PKivuti NyagahÎncă nu există evaluări

- IBM Oil - Integrated Framework Makes Intelligent Oil Field A RealityDocument20 paginiIBM Oil - Integrated Framework Makes Intelligent Oil Field A RealityIBM Chemical and PetroleumÎncă nu există evaluări

- Benchmarking of Steamflood Field Projects in LightMedium Crude OilsDocument7 paginiBenchmarking of Steamflood Field Projects in LightMedium Crude OilsCarlos Mario Paba Martinez100% (1)

- SPE 135669 Best Practices For Candidate Selection, Design and Evaluation of Hydraulic Fracture TreatmentsDocument13 paginiSPE 135669 Best Practices For Candidate Selection, Design and Evaluation of Hydraulic Fracture TreatmentsJuan SueÎncă nu există evaluări

- Training and Developing EmployeesDocument49 paginiTraining and Developing EmployeesMostafaAhmedÎncă nu există evaluări

- PWC Western Canada Oil and Gas Benchmarking Report 2012 12 en PDFDocument24 paginiPWC Western Canada Oil and Gas Benchmarking Report 2012 12 en PDFogu100% (1)

- Economics Analysis On The Development of Nigerian Offshore Marginal FieldsDocument11 paginiEconomics Analysis On The Development of Nigerian Offshore Marginal FieldsJasgeoÎncă nu există evaluări

- Oil and Gas Economic EvaluationDocument4 paginiOil and Gas Economic EvaluationTemitope BelloÎncă nu există evaluări

- Petroleum Economics and Risk Analysis - 2022 Course FlyerDocument2 paginiPetroleum Economics and Risk Analysis - 2022 Course FlyernuzululÎncă nu există evaluări

- 02.project IntegrationDocument67 pagini02.project IntegrationEka KusumawÎncă nu există evaluări

- M SC Petroleum EconomicsDocument142 paginiM SC Petroleum EconomicsHector Garcia100% (3)

- SPE-119732 Forecasting PDFDocument17 paginiSPE-119732 Forecasting PDFLuis Alberto Colan Garcia100% (1)

- Economics Training ManualDocument157 paginiEconomics Training ManualJesus Ponce GÎncă nu există evaluări

- Integrated Reservoir Studymethodology - Weatherford 15 PagesDocument15 paginiIntegrated Reservoir Studymethodology - Weatherford 15 Pagesjorge_h_rivero100% (2)

- Offshore Field Development CourseDocument4 paginiOffshore Field Development Coursedbircs198150% (2)

- Well Integrity PDFDocument1 paginăWell Integrity PDFAdolfo AnguloÎncă nu există evaluări

- Capital BudgetingDocument36 paginiCapital BudgetingDevansh DoshiÎncă nu există evaluări

- Or&a Briefing 2019Document60 paginiOr&a Briefing 2019Sham Kumbhar100% (1)

- SPE 71414 - Improving Investment Decisions Using A Stochastic Integrated Asset ModelDocument16 paginiSPE 71414 - Improving Investment Decisions Using A Stochastic Integrated Asset ModelRayner SusantoÎncă nu există evaluări

- Quantifying Uncertainty in Subsurface SystemsDe la EverandQuantifying Uncertainty in Subsurface SystemsCéline ScheidtÎncă nu există evaluări

- Exploiting the Digital Oilfield: 15 Requirements for Business ValueDe la EverandExploiting the Digital Oilfield: 15 Requirements for Business ValueEvaluare: 5 din 5 stele5/5 (1)

- Internet of Things in Oil and Gas Second EditionDe la EverandInternet of Things in Oil and Gas Second EditionÎncă nu există evaluări

- Nuts and Bolts of Project Management: Right Timing + Right Decision = SuccessDe la EverandNuts and Bolts of Project Management: Right Timing + Right Decision = SuccessEvaluare: 5 din 5 stele5/5 (1)

- Multipoint Facies Modeling - Examples of A Turbidite and A Fluvial SystemDocument2 paginiMultipoint Facies Modeling - Examples of A Turbidite and A Fluvial Systemskywalk189Încă nu există evaluări

- 1.-January Newsletter EngDocument3 pagini1.-January Newsletter Engskywalk189Încă nu există evaluări

- Petrel 2015 3 InstallationGuide PDFDocument98 paginiPetrel 2015 3 InstallationGuide PDFskywalk189100% (2)

- Mitra Company Summary SenergyDocument23 paginiMitra Company Summary Senergyskywalk189Încă nu există evaluări

- 16 01 15 SDI Scottish Offshore Companies Supply Chain BrochureDocument52 pagini16 01 15 SDI Scottish Offshore Companies Supply Chain Brochureskywalk189100% (1)

- Drillsafe - Industry Trends & Opportunities: Working Together For A Safer WorldDocument37 paginiDrillsafe - Industry Trends & Opportunities: Working Together For A Safer Worldskywalk189Încă nu există evaluări

- Colin McPhee SPE London May 26 2015 & Backup - PetrophysicDocument32 paginiColin McPhee SPE London May 26 2015 & Backup - Petrophysicskywalk189100% (2)

- Colin McPhee SPE London May 26 2015 & Backup - PetrophysicDocument32 paginiColin McPhee SPE London May 26 2015 & Backup - Petrophysicskywalk189100% (2)

- 978-999-06-95-05-2 Techno EconomicDocument744 pagini978-999-06-95-05-2 Techno Economicskywalk189Încă nu există evaluări

- SCCS CO2 EOR JIP Techno Economic EvaluationDocument41 paginiSCCS CO2 EOR JIP Techno Economic Evaluationskywalk189Încă nu există evaluări

- Multiscale Parameterization and History Matching in Structured and Unstructured Grids: Theory and Field ApplicationDocument25 paginiMultiscale Parameterization and History Matching in Structured and Unstructured Grids: Theory and Field Applicationskywalk189Încă nu există evaluări

- Multiscale Parameterization and Streamline-Based Dynamic Data Integration For Production Optimization Norne Field E-SegmentDocument49 paginiMultiscale Parameterization and Streamline-Based Dynamic Data Integration For Production Optimization Norne Field E-Segmentskywalk189Încă nu există evaluări

- Esci344 Lesson01 IntroductionDocument12 paginiEsci344 Lesson01 IntroductionSajjad Husham SalihÎncă nu există evaluări

- B855E Instruction ManualDocument222 paginiB855E Instruction ManualManuel TorresÎncă nu există evaluări

- Soal Bahasa InggrisDocument3 paginiSoal Bahasa InggrisMita Elida PutriÎncă nu există evaluări

- ClimateDocument15 paginiClimateaulakhk372Încă nu există evaluări

- Tickle Day Poems From Father GooseDocument42 paginiTickle Day Poems From Father GooseClara OrtizÎncă nu există evaluări

- Critical Review of LiteratureDocument3 paginiCritical Review of LiteratureTomvie CephasÎncă nu există evaluări

- Arun Jose Tom, Module 3, Bme PDFDocument120 paginiArun Jose Tom, Module 3, Bme PDFAswith ShenoyÎncă nu există evaluări

- Science Lesson - 14Document3 paginiScience Lesson - 14Ribhi ShindeÎncă nu există evaluări

- El NinoDocument3 paginiEl NinoROBINSON HERPACIOÎncă nu există evaluări

- Edgar CayceDocument60 paginiEdgar CayceG-skunk Ayang Lemtor100% (7)

- Climate ControlDocument12 paginiClimate ControlVũ Đình QuangÎncă nu există evaluări

- Propper 2014 CatalogDocument31 paginiPropper 2014 CatalogPredatorBDU.com100% (1)

- Biometry PDFDocument28 paginiBiometry PDFDrAmit VermaÎncă nu există evaluări

- Tower Crane Operator's Handbook LRDocument32 paginiTower Crane Operator's Handbook LRPeter Verhoef100% (1)

- ConservationDocument34 paginiConservationAnonymous u7cQyr3QYÎncă nu există evaluări

- BIA03 SsbookDocument20 paginiBIA03 SsbookCARMEN OTONDO HERRERAÎncă nu există evaluări

- Plastic Shrinkage Cracking: Bleed Water Evaporation Nomograph FormulaDocument1 paginăPlastic Shrinkage Cracking: Bleed Water Evaporation Nomograph FormulaBesmir BeqiriÎncă nu există evaluări

- 202790-2017-2018-Syllabus Environmental ManagementDocument24 pagini202790-2017-2018-Syllabus Environmental Managementfaryal NaseemÎncă nu există evaluări

- Osnovna Škola PDFDocument71 paginiOsnovna Škola PDFŠemso SućeskaÎncă nu există evaluări

- SF Upper Intermediate Portfolio PDFDocument65 paginiSF Upper Intermediate Portfolio PDFtareas1978Încă nu există evaluări

- 37 Things To Do in Salalah, OmanDocument15 pagini37 Things To Do in Salalah, OmanMahesh MadasÎncă nu există evaluări

- Jessa L'Rynn - A Long HistoryDocument268 paginiJessa L'Rynn - A Long HistoryNatalie Hong100% (1)

- Carol of The Bells ResponseDocument2 paginiCarol of The Bells ResponseKendelÎncă nu există evaluări

- Work Sheet Class 5Document24 paginiWork Sheet Class 5mailtajinder100% (1)

- MS 402 PyranometerDocument2 paginiMS 402 PyranometerHeri AndoniÎncă nu există evaluări

- Ac CalculationDocument3 paginiAc CalculationVedant MahajanÎncă nu există evaluări

- Themaclassic F30E and F30E SB Instructions For Use Installation and ServicingDocument52 paginiThemaclassic F30E and F30E SB Instructions For Use Installation and ServicingAlonso CoradoÎncă nu există evaluări

- 2005 Duramax Manual PDFDocument78 pagini2005 Duramax Manual PDFmarcelo oliveira0% (2)