Documente Academic

Documente Profesional

Documente Cultură

Presentation - Refurbishment of Tula and Tule 4 For Australia GT Conferance

Încărcat de

thanarajtnbTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Presentation - Refurbishment of Tula and Tule 4 For Australia GT Conferance

Încărcat de

thanarajtnbDrepturi de autor:

Formate disponibile

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

REFURBISHMENT OF SIEMENS

V94.2 STAGE 4 BLADE AND

VANE COMPONENTS AFTER

Hakcipta Azril Dahari

100,000 EOH

THANARAJ SANMUGHAM

TNB REMACO

23TH NOVEMBER 2016

17TH AUSTRALIAN GAS TURBINE CONFERANCE

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

AGENDA

TNB REMACO REPAIR CENTRE AND ITS CAPABILITY

Hakcipta Azril Dahari

OBJECTIVE OF PROJECT

METHODOLOGY AND ISSUES

REPAIR PROCESS

CONCLUSION

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

TNB REMACO REPAIR CENTRE AND ITS CAPABILITY

Hakcipta Azril Dahari

MAIN SUBSIDIARY

OF

TENAGA NASIONAL

BERHAD

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

TNB REMACO REPAIR CENTRE WORLD MAP

Hakcipta Azril Dahari

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

TNB REMACO REPAIR CENTRE : 4 MAIN ACTIVITIES

MAINTENANCE

SERVICE

Hakcipta Azril Dahari

REPAIR CENTRE

MAIN SUBSIDAIRIES

TEST AND

DIAGNOSTICS

OF

TENAGA NASIONAL

PROJECT AND

BERHAD

OPERATION

MANAGEMENT

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

HOT GAS PATH REFURBISHMENT MAIN DATA

Product Range:

GE/Siemens/ABB Turbine Blade,

Stationary and Combustor Parts,

Bearing and Rotor On-Site Machining

Hakcipta Azril Dahari

Equipment:

Coating Room, Acid Stripping, Rotor

Lathe Machine, White Light Scanner,

Laser Welding, EDM Die Sinker,

Brazing, Vacuum Furnace, Metallurgical

Lab, CMM, NC

Number of Employee: 115

Workshop Total Floor Space: 95293 SQF

Quality: Siemens and GE Certified Shop

ONE STOP CENTRE

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

OBJECTIVE OF PROJECT

COST SAVINGS

Hakcipta Azril Dahari

OPERATE FOR

ANOTHER

CYCLE

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

LOCATION OF ROW 4 TULA AND TULE

Hakcipta Azril Dahari

TULA 4

> 110,000EOH

TULE 4

> 152,000EOH

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

METHODOLOGY AND REVERSE ENGINEERING

Hakcipta Azril Dahari

Scan data

Dimension

inspection

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

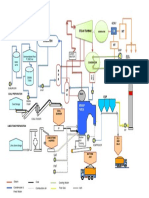

DESIGN REPAIR FLOW

Visual and

Metallurgical

Hakcipta

Azril Dahari

Inspection

Final Delivery

Blasting, Heat

Treatment

and FPI

Dimensional

Inspection /

Drop Check

Blend and

Welding

Shot Peen

and Bucket

Moment

Weight

Brazing,

Frequency

Test and

Drop Check

Post Weld,

Dimensional

Inspection

and FPI

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

METHODOLOGY / PREPARATION/ INSPECTION TEST

PLAN

Process /

HakciptaMilestone

Azril Dahari

Welding

Quality Inspection

WPS, WQT, VI,100%PT

Fitting /

Dimension inspection and Drop check

Assembly

Heat Treatment HT Chart, Recorder calibration

cert.,100%PT

Final Inspection Dimensional inspection, VI

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

METALLURGICAL INSPECTION FOR TULA 4

Hakcipta Azril Dahari

Material: IN 939

The grain size was generally fine.

The tensile test properties were

above the expected minimum

levels.

There was no evidence of sigma

phase formation.

Able to run for another cycle

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

METALLURGICAL INSPECTION FOR TULE 4

Hakcipta Azril Dahari

Material: Nimonic 90

The grain size was generally fine

The stress rupture properties

were above the expected

minimum levels.

The root and 50% span

microstructures appeared similar

NO CHANGES IN GAMMA

PRIME

Able to run for another cycle

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

ISSUES DURING INSPECTION

Hakcipta Azril Dahari

DEFECTS

FOUND

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

REPAIR PROCESS INCOMING INSPECTION

Hakcipta Azril Dahari

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

DROP CHECK FOR TULE

Hakcipta Azril Dahari

Drop check for Tule 4 was replicated using Siemens GT Casing to

verify the hi-low and mismatch between inner shroud

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

BRAZING FOR TULE PLATFORM

Hakcipta Azril Dahari

Braze Process was carried out at the defective outer platform at Tule

4 as part of repair process.

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

STATIONARY FREQUENCY TEST

Hakcipta Azril Dahari

Free-free boundary

Fixed boundary

This test was performed to ensure the repaired Tula 4 will be not in

resonance mode during operation. The test results was compared with

new blades

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

REPAIR PROCESS

Hakcipta Azril Dahari

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

DURATION OF REPAIR WORKS

Aug

Hakcipta Azril Dahari

Sep

Oct

Refurbishment Process

Warranty: 1 year / 8000 EOH / 18 months after delivery

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

CONCLUSION

The refurbished Stage 4 Tula Tule was

successfully installed in our Siemens fleet in

Hakcipta Azril Dahari

February 2016.

The Gas Turbine has run more than 7000 EOH

without any issues.

Similar methodology has been utilized by TNB

REMACO for other parts fabrication.

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

Hakcipta Azril Dahari

Any Questions?

TNB REPAIR AND MAINTENANCE SDN. BHD.

REPAIR CENTRE

Hakcipta Azril Dahari

Thank You

S-ar putea să vă placă și

- Albany Profile (GT) RevDocument48 paginiAlbany Profile (GT) RevHeri SetyantoÎncă nu există evaluări

- Coal-Fired Power Plant Heat Rate Improvement Options, Part 1Document13 paginiCoal-Fired Power Plant Heat Rate Improvement Options, Part 1Ravi SatyapalÎncă nu există evaluări

- Soot BlowerDocument8 paginiSoot BlowerArun YogaÎncă nu există evaluări

- Pltu: Boiler Stoker:: Sesuai Data Unit: Sesuai Data Unit: Mei 2020 (Rev 00)Document5 paginiPltu: Boiler Stoker:: Sesuai Data Unit: Sesuai Data Unit: Mei 2020 (Rev 00)sandrositohangÎncă nu există evaluări

- Standard Vibrasi ISO 10816Document2 paginiStandard Vibrasi ISO 10816Anonymous R9u2vabQ7sÎncă nu există evaluări

- Uninterrupted and Reliable Operation For CFB BOILERDocument59 paginiUninterrupted and Reliable Operation For CFB BOILERRizqi PriatnaÎncă nu există evaluări

- Boiler Management Success Keys As Per EPRIDocument3 paginiBoiler Management Success Keys As Per EPRImasgrahaÎncă nu există evaluări

- Gas Turbine Blade RejuvenationDocument2 paginiGas Turbine Blade Rejuvenationnadiaaira12Încă nu există evaluări

- ASEAN Coal Awards 2019 Application Form SummaryDocument15 paginiASEAN Coal Awards 2019 Application Form SummaryRiza RifaldyÎncă nu există evaluări

- WhertecDocument31 paginiWhertechamzahÎncă nu există evaluări

- Lesson 2 Rev Introduction To Power PlantDocument53 paginiLesson 2 Rev Introduction To Power Plantfelix asadeÎncă nu există evaluări

- Digital RSO Test of 25MW STG Rotor in ThailandDocument5 paginiDigital RSO Test of 25MW STG Rotor in ThailandSchubert D'SouzaÎncă nu există evaluări

- Desalination in Saudi Arabia An Overview1 DR NadaDocument44 paginiDesalination in Saudi Arabia An Overview1 DR NadashoaibshahjeÎncă nu există evaluări

- Turbine Sealant For Parting Planes - BirkositDocument2 paginiTurbine Sealant For Parting Planes - BirkositProject Sales CorpÎncă nu există evaluări

- PRESENTASI Thermography For Condition MonitoringDocument33 paginiPRESENTASI Thermography For Condition MonitoringRizky Farhan HafiliÎncă nu există evaluări

- Life Time Deterioration of Turbine ComponentsDocument10 paginiLife Time Deterioration of Turbine Componentsபிரசன்னகுமார் ஆனந்தன்Încă nu există evaluări

- Gas Turbine Performance, Operational, Reliability Improvement and Maint Cost Reduction in Process & Power Generation Plants PDFDocument1 paginăGas Turbine Performance, Operational, Reliability Improvement and Maint Cost Reduction in Process & Power Generation Plants PDFSyedNadeemAhmedÎncă nu există evaluări

- Data Pengukuran BFPT ADocument3 paginiData Pengukuran BFPT AazisyuswandiÎncă nu există evaluări

- CFB BangkaDocument39 paginiCFB BangkaYosep Wildan FebrianaÎncă nu există evaluări

- B&W IR-CFB: Operating Experience and New Development: Technical PaperDocument8 paginiB&W IR-CFB: Operating Experience and New Development: Technical PaperS. P.Încă nu există evaluări

- Presentation of Turbine Erection 1Document42 paginiPresentation of Turbine Erection 1Trung Quan Vo100% (1)

- Performance Improvement Through Energy Audit of A 250MW Coal Fired Thermal Power Plant-Ijaerdv04i0477633 PDFDocument9 paginiPerformance Improvement Through Energy Audit of A 250MW Coal Fired Thermal Power Plant-Ijaerdv04i0477633 PDFronaldopasaribuÎncă nu există evaluări

- Dong Fang HistoryDocument55 paginiDong Fang Historyramnadh803181Încă nu există evaluări

- Steam Turbin Thermal EvaluationDocument22 paginiSteam Turbin Thermal EvaluationRi Ko100% (1)

- EPRI TranslateDocument41 paginiEPRI TranslateMuhammad Reza FahlevyÎncă nu există evaluări

- BISNIS PROSES PLTU PELTAR 2 X 8 MW NETT PT.BUKIT ASAM -TARAHANDocument1 paginăBISNIS PROSES PLTU PELTAR 2 X 8 MW NETT PT.BUKIT ASAM -TARAHANapurnomoÎncă nu există evaluări

- Optimization of Startups - RTPDocument11 paginiOptimization of Startups - RTPmoh1234buk100% (1)

- Check Vacuum System Sizing for Condenser Backpressure IssuesDocument3 paginiCheck Vacuum System Sizing for Condenser Backpressure IssuesYulianto KartonoÎncă nu există evaluări

- 锅炉一次风机及其系统调试措施Boiler PAF Commissioning ProcedureDocument34 pagini锅炉一次风机及其系统调试措施Boiler PAF Commissioning ProcedurekvsagarÎncă nu există evaluări

- PT Nusantara Turbin & PropulsiDocument29 paginiPT Nusantara Turbin & PropulsiSandi NurmalikÎncă nu există evaluări

- TR 107422 V2Document168 paginiTR 107422 V2FRANCISCO JOSE GARCIA IBAÑEZÎncă nu există evaluări

- Generator End-Winding Vibration AnalysisDocument8 paginiGenerator End-Winding Vibration AnalysisMohsen Vafaei Zadeh100% (1)

- The Handbook of Biomass Combustion and Cofiring: January 2008Document8 paginiThe Handbook of Biomass Combustion and Cofiring: January 2008khan khanÎncă nu există evaluări

- Blu Ram HSDocument1 paginăBlu Ram HSM Roy HaqiqiÎncă nu există evaluări

- Coal-Fired Power Plant Heat Rate Improvement Options, Part 1 - PowermagDocument12 paginiCoal-Fired Power Plant Heat Rate Improvement Options, Part 1 - PowermagRavi Satyapal100% (1)

- Rotor End of Life InspectionDocument26 paginiRotor End of Life InspectionJJÎncă nu există evaluări

- Test for Half of Condenser Operation冷凝器半面运行试验Document2 paginiTest for Half of Condenser Operation冷凝器半面运行试验erwin5sambas5aryanaÎncă nu există evaluări

- Sharing Boiler CFB PT Indonesia Power PDFDocument30 paginiSharing Boiler CFB PT Indonesia Power PDFhamzahÎncă nu există evaluări

- Condition Based MaintenanceDocument16 paginiCondition Based MaintenanceWafiik Aumeer100% (1)

- Power Plant O&M Services GuideDocument4 paginiPower Plant O&M Services GuideAhmed El TayebÎncă nu există evaluări

- Executive Summary - Sintang 12 MW BTG Biomass Power PlantDocument11 paginiExecutive Summary - Sintang 12 MW BTG Biomass Power PlantKomang SuantikaÎncă nu există evaluări

- FMEA - MOV Main Condensate PipingDocument4 paginiFMEA - MOV Main Condensate PipingazisyuswandiÎncă nu există evaluări

- List of ASME PTC Codes and Their Respective TitlesDocument2 paginiList of ASME PTC Codes and Their Respective TitlesChauhdry Sahab100% (3)

- RLA Steam Turbine GeneratorDocument5 paginiRLA Steam Turbine GeneratorAditya PrajasÎncă nu există evaluări

- Steam Turbine Blade Erosion Protection Options: Donald R Leger and Paul Franklin EthosenergyDocument13 paginiSteam Turbine Blade Erosion Protection Options: Donald R Leger and Paul Franklin EthosenergySh.nasirpurÎncă nu există evaluări

- BalancingDocument83 paginiBalancingfirmanrusydiÎncă nu există evaluări

- Plant Component Chart For Condition Assessment Services: Unique or Patented B&W ServicesDocument2 paginiPlant Component Chart For Condition Assessment Services: Unique or Patented B&W ServicesGautam GhoshalÎncă nu există evaluări

- Analysis of Indian Coal Compared to Indonesian, Australian and South African CoalDocument7 paginiAnalysis of Indian Coal Compared to Indonesian, Australian and South African CoalVikram Raj SinghÎncă nu există evaluări

- Maintenance and Application Guide For Centrifugal PumpDocument256 paginiMaintenance and Application Guide For Centrifugal Pumpjprakashbandaru100% (2)

- Rcfa Kebocoran Furnace Rear Wall Tube (f18) (Rev1) 1Document30 paginiRcfa Kebocoran Furnace Rear Wall Tube (f18) (Rev1) 1andidesisunarnoÎncă nu există evaluări

- Diesel Leak TestDocument3 paginiDiesel Leak Testsbmmla67% (3)

- Erection & Commissioning of Trfr.-Sh.c.p.deshmukhDocument25 paginiErection & Commissioning of Trfr.-Sh.c.p.deshmukhKaran Tripathi100% (2)

- Project Mba ReportDocument17 paginiProject Mba ReportAkshay RautÎncă nu există evaluări

- Wireline Presentation 14th September 2016Document26 paginiWireline Presentation 14th September 2016Kamry AhmadÎncă nu există evaluări

- PS - 2K - PC210-10M0 - BY - FATI - Copy (1) (2) (Read-Only)Document19 paginiPS - 2K - PC210-10M0 - BY - FATI - Copy (1) (2) (Read-Only)Fatra JuliandÎncă nu există evaluări

- Post-hydrotesting procedure for Dadri-Bawana pipelineDocument7 paginiPost-hydrotesting procedure for Dadri-Bawana pipelineVineet SinghÎncă nu există evaluări

- 24.tank Oil Chalk TestDocument3 pagini24.tank Oil Chalk TestShubham ShuklaÎncă nu există evaluări

- Oil & Gas Maintenance Training GuideDocument64 paginiOil & Gas Maintenance Training Guideeng_moh04Încă nu există evaluări

- Mech ForemanDocument4 paginiMech ForemanSiva SabarishÎncă nu există evaluări

- Major Process Equipment Maintenance and RepairDe la EverandMajor Process Equipment Maintenance and RepairEvaluare: 4 din 5 stele4/5 (4)

- Case Study 14Document20 paginiCase Study 14thanarajtnbÎncă nu există evaluări

- Machining Tool and Methode For Abradable CoatingDocument11 paginiMachining Tool and Methode For Abradable CoatingthanarajtnbÎncă nu există evaluări

- Studies On The Determination of Natural Frequencies of Industrial Turbine BladesDocument23 paginiStudies On The Determination of Natural Frequencies of Industrial Turbine BladesthanarajtnbÎncă nu există evaluări

- 2 Technology EvolutionDocument7 pagini2 Technology EvolutionthanarajtnbÎncă nu există evaluări

- H25-H15 CatalogueDocument12 paginiH25-H15 CatalogueTong Chaipanyakul100% (1)

- Gas Turbine Mechanical Components, Material Requirements, Auxiliary Systems, Control Systems, and Protection SystemsDocument143 paginiGas Turbine Mechanical Components, Material Requirements, Auxiliary Systems, Control Systems, and Protection SystemsAndreas100% (1)

- TSL Fr5001 1st Stage BucketsDocument1 paginăTSL Fr5001 1st Stage BucketsthanarajtnbÎncă nu există evaluări

- A210-Handheld: Operating InstructionsDocument24 paginiA210-Handheld: Operating InstructionsAleksandarÎncă nu există evaluări

- Despiece Honda CBR 900 RRDocument121 paginiDespiece Honda CBR 900 RRJorge ButticeÎncă nu există evaluări

- Serway Physics II Example Questions Chapter 8Document1 paginăSerway Physics II Example Questions Chapter 8AizuddinÎncă nu există evaluări

- PRV Spirax Sarco 25P - 25PADocument17 paginiPRV Spirax Sarco 25P - 25PAwen.cokÎncă nu există evaluări

- Demand Side Management and Its ProgramsDocument15 paginiDemand Side Management and Its ProgramsAhmad H Qinawy100% (1)

- Study of Tig WeldingDocument11 paginiStudy of Tig WeldingChandan Srivastava100% (1)

- Concrete DurabilityDocument19 paginiConcrete Durabilityapi-3766593100% (2)

- MAXCLEAN WIPER-600 S4ff7987c7ba99Document2 paginiMAXCLEAN WIPER-600 S4ff7987c7ba99Amirul ShamÎncă nu există evaluări

- 4unsafe Unhealthy Act Conditions PDFDocument41 pagini4unsafe Unhealthy Act Conditions PDFej constantino100% (1)

- Sony Dcrpc105EDocument93 paginiSony Dcrpc105EKarim SansÎncă nu există evaluări

- Jeppview For Windows: General Information General InformationDocument13 paginiJeppview For Windows: General Information General InformationEmerald Gr100% (1)

- HeatPipe WrapAroundDocument2 paginiHeatPipe WrapAroundJohnson ChuaÎncă nu există evaluări

- Expanbar PVC: Centrally and Externally Placed PVC Waterstops. UsesDocument5 paginiExpanbar PVC: Centrally and Externally Placed PVC Waterstops. UsesZaid AhmedÎncă nu există evaluări

- Din Rail Mounted FBM Subsystem Users GuideDocument292 paginiDin Rail Mounted FBM Subsystem Users GuideLockon Kum100% (2)

- Poultry House Heat GainDocument1 paginăPoultry House Heat GainPrestoneKÎncă nu există evaluări

- Presented by Intramantra Global Solution PVT LTD, IndoreDocument14 paginiPresented by Intramantra Global Solution PVT LTD, IndoreDeepak RathoreÎncă nu există evaluări

- Drilling Cost and Hole ProblemsDocument39 paginiDrilling Cost and Hole ProblemsArun Sharma100% (1)

- Science 4, Q3, Module 6, ReyesDocument12 paginiScience 4, Q3, Module 6, ReyesIyutaann Kantutan100% (1)

- Project On SamsungDocument39 paginiProject On SamsungAbbas0% (1)

- XYZ Murders (Aka Crimewave)Document94 paginiXYZ Murders (Aka Crimewave)Danny Steel100% (1)

- Sheet 1 - RTL Part1Document2 paginiSheet 1 - RTL Part1sad birdÎncă nu există evaluări

- Math4220 PDFDocument10 paginiMath4220 PDFjhonmt7Încă nu există evaluări

- Sirena Policial AmericanaDocument9 paginiSirena Policial AmericanaromarioÎncă nu există evaluări

- DSP Course Overview by Prof. Deepa KundurDocument2 paginiDSP Course Overview by Prof. Deepa KundurBEN AMAR100% (1)

- Addis Ababa Science and Technolog1 (Autorecovered) (Autorecovered)Document70 paginiAddis Ababa Science and Technolog1 (Autorecovered) (Autorecovered)penihaniÎncă nu există evaluări

- 1999 Ford Ranger Owner's ManualDocument216 pagini1999 Ford Ranger Owner's Manualtacosoft100% (6)

- Soft Box System Product Presentation 1Document26 paginiSoft Box System Product Presentation 1jmiller9842Încă nu există evaluări

- List Inventaris PPPDocument7 paginiList Inventaris PPPasep nathanÎncă nu există evaluări

- Power System Harmonics Causes and Effects PDFDocument8 paginiPower System Harmonics Causes and Effects PDFRamon DrakeÎncă nu există evaluări

- Form Location Tolerances enDocument2 paginiForm Location Tolerances enSanjay Mehrishi100% (3)