Documente Academic

Documente Profesional

Documente Cultură

Materials in Space Working in A Vacuum by J Dauphin

Încărcat de

Allaine UyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Materials in Space Working in A Vacuum by J Dauphin

Încărcat de

Allaine UyDrepturi de autor:

Formate disponibile

Vacuum~volume 32/number 10/11/pages 669 to 673/1982

Printed in Great Britain

0042-207X/82/110669-05803.00/0

Pergamon Press Ltd

M a t e r i a l s in space: w o r k i n g

in a v a c u u m

J Dauphin, Materials Section, ESA/ESTEC, PO Box 299, 2200 AG, Noordwijk, The Nether~ands

1. General

Space environment is characterized primarily by vacuum. This is

not an extraordinary environment, it is the most common within

the universe where matter is the exception rather than the rule.

A few decades ago, when starting to explore space, we had to

make a choice, either be able to make equipment work

satisfactorily in a vacuum or to enclose it in a sort of bubble of

earth environment, i.e. to pressurize it. The first option, which is

also the most versatile, was chosen, at least in the USA and

Europe, and forced us into new technological concepts.

Let us first recall the basic characteristics of the Space

Environment, i.e. what occurs 200 km upwards from home.

1.1. Space environment (Table 1). The first parameter to be

considered is pressure, or more precisely gaseous density, since

defining a pressure necessitates a thermodynamic equilibrium

which is not always realized in space.

It is not necessary to go to a very high altitude to see the first

effects of a reduced pressure on the life support ability of the

atmosphere. Dynamic effects vary quickly with altitude, but there

is still a measurable drag on satellites in low orbits. Gas dynamics

also changes, and effects are observed on backscattering 4 and

plume shapes s of propulsion motors.

Before becoming a perfect electrical insulant, vacuum, in the

intermediate pressure zone, is a favoured medium for electrical

discharges (Paschen Law). When the gas density becomes low

enough--say less than 10 t2 per cm3--thermal exchange can no

longer take place via conduction and convection and occur by

radiation, which is a rather inefficient process.

In the frame of space technology, all these effects have to be

considered. The major problem, however, is really what occurs

when materials are brought into the space vacuum and this will be

the main point of the present paper. What are the possible

damages to the intrinsic and functional properties of hardware

and what is the interaction between its different constituents?

These are the basic questions to be answered when designing a

space vehicle.

The other parameters of space environment certainly play a

role in the problem defined above and it is necessary to consider

the effect of UV radiation from the sun (Figure 1), protons and

electron fluxes in the Van Allen belts, at geostationary altitude or

elsewhere in space. Radiation is known to induce damage in

materials, vacuum will modulate these effects such that the results

might be different to those observed under atmospheric conditions. Electron fluxes are also capable of triggering high

electrical potentials on some surfaces and consecutive discharges

with possible damage to materials 6.

To be complete, we must also cite the existing micro-meteoroid

fluxes as a parameter of the space environment.

1.2. Spacecraft environment. Interaction between the space

environment and hardware induces a specific environment

around each spacecraft and it is this which must be taken into

account in assessing the potential damaging effects.

Gas densities in and around the vehicle are the result of the

interaction of the local conditions and the outgassing fluxes of all

the constituting materials. Pressure history of the different

compartments of a spacecraft depend on the venting and

outgassing potential of their content. The vehicle will be

Table 1. Summary of the space environment (orders of magnitude)*

Altitude

!,km)

Pressure

(torr)

Kinetic

Gaseous

temperature density

(K)

(p/cm -s)

Composition

Sea level

760

~300

2.5 x 1019

78% N2, 21% O2,1% A

30

200

800

6500

10

10 -6

10- 9

10- ~3

-~ 1200

~ 1300

_

4 x 10~

10~

106

103

N2, 02, A

N 2, O, 02, O +

O, He, O +, H

H +, H, He*

Section of solar spectrum

,l>0.3

Absorption zone

Full solar spectrum

Full solar spectrum

Full solar spectrum

22,000

< 10-13

__

lOl_lO 2

85% H +, 15% HE 2+

Full solar spectrum

Ultra-violet

radiation

Particle radiation

(particles cm -2 s -1 )

104 protons > 35 MeV

104 electrons >40 keY

l0 s protons >5 MeV

10s electrons >40 keV

104 electrons > 1.6 MeV

* Based on references 1, 2 and 3.

869

J Dauphin: Materials in space: working in a vacuum

Vll~.-E

X-RAYS

ULTRAVIOLET

ios

"T::1

O'J

0

.9

n.,

ILl

INFRARED

I/ .... \\

6,ooo-.

,o.

!

I

,o.

~1

I

,ooo.\

\\ e,OOO'K

X

,/

II

\~

U.l

U

Z

<

II

n.,

n.-I

n.

,o2

/:F',.......y.,

\\

"

I--

UJ

O.

/)

,o

0,000t

0,00t

......

0,ol

0,t

40

400

WAVELENGTH (JJ)

SUN (MEASUREMENTS)

................ BUN (ESTIMATIONS)

.......

BLACK BODY AT VARIOUS TEMPERATURES

(BASED ON REF. 2)

Figure 1. The solar electromagnetic radiation spectrum.

surrounded by an expanding gas cloud, the shape of which

depends on the venting paths of the hardware, the outgassing

fluxes from the external surfaces and baekseattering by the local

atmosphere. The latter becomes negligible at an altitude of

1000km but still gives a well defined wake to low orbit

satellites 4.7.

The temperature of an object in space is typically an 'induced'

environment, it is determined by the absorbed radiation, which

depends on the absorptance and emittance of surfaces. This is

modulated somewhat by the heat transfer paths and the heat

evolution of embarked equipment. Temperature and also variations in temperature have, in turn, a dramatic influence on the

outgassing and recondensation phenomena in spacecraft and on

the ageing or fatigue failure of materials.

Radiation is absorbed by materials with subsequent physicochemical effects: excitation and ionization of molecules leading to

physical property changes, increased outgassing, stabilization of

condensed deposits, etc. Damage depends on a first approximation on the absorbed energy dose. This concept is rather

straightforward for particle radiation (Figure 2), but could be

extended to UV photons s. The radiation dose can be considered

as an induced environment of spacecraft.

670

2. Materials behaviour

r

Coming back on the central point of this paper, i.e. vacuum effects,

we will now expand somewhat on the phenomena of outgassing

and recondensation and these associated problems in space.

2.1. Outgassing. All materials outgass in space vacuum but the

phenomenon is only noticeable for the lightest species; even the

so-called vaporizable metals (for example Cd) which were highly

suspected in the first years of the space era 2, have been proven

later as rather inert at reasonable temperatures. Outgassing is

therefore mainly to be considered with organic materials, but

these are indispensable in space vehicles if their cost is to be kept

within acceptable limits.

Except for relatively pure light products, used for example as

liquid lubricants, the famous Langmuir formula a is strictly not

applicable since outgassing is not a simple evaporation. The

evolved gases originate in fact in the adsorbed or absorbed

impurities and in the degradation products of the large organic

molecules which constitute the technological polymers. The

outgassing phenomenon is regulated by the kinetics of the.

possible degradation routes (thermal, catalytic, radiation-

J Dauphin: Materials in space: working in a vacuum

,&

we can still use an apparent activation energy within the relatively

narrow temperature domain which is of interest for most space

applications.

109

~OSTATIONNARY

ZSEE s ~ ' ~ ' - , , x N ~ =

1o'

10s

C3

n-

10

I.I

II

~o

1o

I2

~

I3

~

I

~

~'

PENETRATION (MICRONS)

Figure 2. Radiation doses on different spacecraft orbits (doses in AI

p=2.7).

induced) and by the diffusion rates through the bulk material and

the possible surface coatings. The observed curve of outgassing as

a function of time is rather simple (Figure 3). Temperature has an

accelerating effect on the phenomenon which, in simple cases, can

be treated by an Arrhenius approach. In more complicated cases

2.2. Recondensation. In space, the mean fre path of an outgassed

molecule becomes very large compared to the size of spacecraft

and we have seen that return by backscattering is only significant

to the lowest orbits (self-scattering is also a very limited method of

molecular return) 9. A surface will therefore be subjected to a flux of

outgassed molecules, but mainly if it is situated in the direct line of

sight of an outgassing source Or if some simple combination of

reflections can bring the molecule from the source to the target.

There might exist another mechanism of the return of molecules

which involves ionization and re-attraction by a charged surface,

but no clear demonstration of this mechanism has yet been

given l.

When a molecule hits a surface, it has a certain chance of staying

there. This chance depends on the nature of the incoming

molecule, on the nature of the encountered surface and on the

absolute temperature of the latter. There are many ways of

describing this condensation---sticking coefficient, accommodation coefficient, residence time---all reflecting a statistical phenomenon. The impinging molecule must lose its kinetic energy into

vibration energy of the couple surface-molecule in order to stay

on the surface. A bond is created which may be a Van der Waal's

bond (adsorption) or a stronger one (chemisorption). The

molecule can be liberated when statistically this bond breaks

(desorption or evaporation depending on whether the bond is

with a foreign surface or with sister molecules). The probability of

a break is exponential with temperature.

The observed shape of recondensation curves is also rather

simple and similar to the shape of outgassing curves except when

re-evaporation dominates.

INITIAL

IMPURITIES<

~OIFFUSION

INITIAL RATE

Figure 3. General shape of a typical mass-loss curve.

671

J Dauphin: Materials in space: working in a vacuum

The result of recondensation is a contaminant layer. The

recondensation :is accompanied by a phenomenon of nucleation

and growth which can give rise to different 'aspectst of the layer

depending on the couple 'surface-contaminant'. Sometimes

continuous films form rather quickly. In other cases isolated

droplets are normal up to large thicknesses.

2.3. Practical consequences. The first and most evident consequence of outgassirtg is the complete disappearance of a material

after exposure to space vacuum. This never happens to hulk

structural materials, since even the worst screening test should

help the designer avoid such material. But it may happen for

example to lubricants, which are liable in some cases to evaporate

completely and leave bare faying surfaces. Unlubricated metal

surfaces have a tendency to cold weld under very light pressure in

the clean and deep vacuum of space, the end effect is therefore

jamming of a mechanism. Such failure was observed on the early

Nimbus satellites solar panel drive and later in some despun

antennas. A practical use of completely volatile materials is the

,manufacture of 'vacuum activated' clamps for erectable

structures.

When only part of a material disappears under vacuum, the

properties of it will change. The effect may be beneficial, say for the

electrical insulation provided by Nylon. It may also be dangerous,

for example the loss of plasticizer in a damping material. It may

also be indeterminate, but to be taken into account in the design,

like dimensional changes occurring in carbon fibre reinforced

epoxy by drying-off under vacuum.

All the gases extracted from materials by vacuum cause an

increased pressure in satellite compartments and lead to the

'Cloud' surrounding the vehicle.

Bad venting can lead to areas where the pressure is relatively

high for a long period. Such pressures favour Corona discharge.

This phenomenon is frequently self-accelerating and terminates in

a breakdown arc which kills the electronics. 'Cloud' induced

perturbation is less catastrophic. It consists of an increased

background noise in optical experiments covering certain wavelengths ~t and can also give false determination ofthe residual gas

composition of the high altitude atmosphere when attempted.

Sensitive plasma experiments can also be endangered by high

density clouds which might get sufficiently ionized to become

troublesome.

Contamination has even more dramatic consequences than

uncondensed outgassing. The prime effect is on all optical

surfaces, transparent, reflecting, thermal control, etc. The damage

depends on the functional wavelength range and on the 'aspect" of

the contaminant. Diffusion of light is generally more dangerous

than plain absorption.

Under the influence of space radiation, contaminant films

polymerize and darken. Thus, not only their absorption becomes

larger, but they can no longer be cleaned-off by evaporation. This

mechanism is presently considered as the most dangerous for

space radiators made of second surface mirrors and used on

application spacecraft to dump large amounts of thermal energy

to space ~2.

Contaminant layers are also capable of masking the electrical

properties of surfaces. This might be rather dangerous in sliding

contacts. Conducting external surfaces used on satellites to avoid

charging up and discharges may also be damaged ~3, discharges

may then occur in the contaminant layer and spread it offin other

areas.

672

3. Design approaches and remedies

All the above has shown basic reasons for which designers should

be very careful in considering outgassing and contamination. It is

not surprising that this subject is a fashionable one in the USA 14

as well as in Europe is.

3.1. Materials selection and cleanliness policy. Like other design

problems, outgassing and contamination can be rather easily

solved if they are tackled in time, i.e. at the very beginning of the

design phase.

Almost 15 yr ago, a materials screening test was set up under

NASA sponsorship. The purpose was to sort out from the

materials proposed for use, the worst offenders under a set of

standard conditions.

This test, the Micro-VCM test, has been used as a basis for

materials selection in Europe t6 and in the USA ~7 for more than

10 yr. It is strictly speaking an arbitrary test, but has the

advantage of large accumulated experience and low cost, which

make it a basic tool even for the present space projects. The only

danger with this test is that some designers start playing with the

data as if it were a design tool. Most of these speculations are

dangerous and misleading.

Getting clean hardware into space calls, not only for a good

screening test, but also for a complete cleanliness policy during

manufacture, test and launch of the hardware. A good example of

such policy was given by Meteosat Is. ESA has published

specifications related to cleanliness ~9 and its verification2.

The main danger of hardware being contaminated on the

ground occur during vacuum chamber tests (heat balance or

thermal vacuum tests). Very careful procedure must be followed

and cleanliness control is a driving parameter.

3.2. Computations and predictions. Present spacecraft projects,

scientific as well as application ones, have less and less design

margin, yet have design lifetimes of between 3 and 10 yr. With such

requirements, materials selection has sometimes to be based on a

rather more sound basis than the Micro-VCM test alone. More

and more, outgassing and contamination are taken as a design

parameter which must be computed over the life of the vehicle.

Mathematically speaking, there is no basic difficulty in

establishing a computer programme to account for the outgassing

cloud around spacecraft and recondensation on its surfaces. Such

programmes exist in the USA 11 and Europe 9, the latter being not

yet fully developed.

The use of such programmes requires, however, a large pool

of background data on the complete outgassing kinetics of

materials, i.e. outgassing curves vs time and temperature plus

recondensation curves at various temperatures. We shall see, later,

how to obtain these results. On such a basis, it is possible to

determine a good contamination forecast for short missions like

Skylab or Shuttle flights. For extended missions, particularly of

application satellites, another requirement is to make long term

forecasts. Many papers have been published on the possible

analytical expression of outgassing data 14"t5. Until now there is

no really confirmed method. We in ESA are working hard on this

subject 2 l.

3.3. Laboratory and flight tests. In order to obtain data from which

sufficiently accurate calculations can be made of the 'cloud'

surrounding a space vehicle and of the possibility of contami-

J Dauphin: Materials in space: working in a vacuum

nation of its various surfaces, we need a laboratory method to

measure outgassing and contamination vs time and temperature.

For total outgassing measurement, the equipment is not new

and has been developed a long time ago 22. F o r contamination

measurements, several approaches were used 23, but the most

versatile is the use of a Quartz Crystal Monitor ( Q C M ) 2+. The

latter method is used at E S T E C in equipment known as ' V B Q C '

(Figure 4). It must be noted that this type of test is long and

expensive. Unfortunately it should be applied to all materials used

in a spacecraft if a complete picture of the outgassing is to be

obtained.

Notwithstanding the expected accuracy of measurements and

predictions, it is also recommended to obtain measurements in

real cases, i.e. on flying spacecraft. These measurements help in

normalizing and verifying the results obtained by computer

programmes 25 and Q C M s are the preferred tool for them. N o

such measurement has been run by ESA up till now, but some are

in preparation and the earliest one could fly in 1982 on ECS. ESA

is also interested in the development of a European advanced

Q C M model which could be used in flight as well as in test

chambers on the ground.

A third domain where the situation is rather satisfactory is in

the computer modelling of spacecraft environment.

However, there is still one area where we lack data and

understanding, it is on the real mechanism of outgassing/contamination phenomena and on exact forecasting of their effects.

References

i F S Johnson, Satellite Environment Handbook, 2nd edition, Stanford

University Press (1965).

z NASA SP 3051, Space Materials Handbook, 3rd edition (1969).

3 L D Jaffe and J B Rittenhouse, in Materials for Missiles and Spacecraft,

McGraw-Hill (1963).

+ J J Scialdone and A E Hedin, J Geophys Res 83, 195 (1978).

s M K Barsh et al., in NASA CP 2039, p 348 (1978).

e j Bosma and F Levadou, in ESA SP 145, p 189 (1979).

7 G Kulterer et al., MBB Bericht UR 52-70 (1970).

s j Bourriean, ONERA-CERT, rapport final, contrat ESTEC No

2515/75 (1976).

9 B Tatry in ESA SP 145, p 131 (1979).

lo j A Jeffery and C R Maag, in ESA SP 145, p 145 (1979).

11 L E Bareiss, 8th Space Simulation Conference, Silver Springs, Paper no

25 (1975).

lz j p Bouchez and D Howle, ESA Bulletin 26, 54 (1981).

la L Levy, ONERA-CERT, final scientific report, AFOSR Grant no

80.0183 (1980).

i+ j M Jemiola, AFML-TR-78-190/NASA-CP-2039 (1978).

ts j Dauphin, ESA SP 145 (1979).

le ESA Specification PSS-09/QRM-02T.

1~ ASTM Specification E595-77.

18 p G Edwards and J Marcoux, in ESA SP 145, p 91 (1979).

19 ESA Specification QRA-18, ESA Specification PSS51/QRA-23.

20 ESA Specification PSSIS/QRM-05T.

2t j Dauphin, Symposium on Materials to be used on-board satellites and

space probes. Toulouse, June 1982, ESA SP 178 (1982).

22 M Rivera and A Biette, Le Vide 124, 340 (1966).

z3 W Wilkens, International Seminar on simulation and space, Toulouse

1973.

24 A Zwaal, in NASA-CP-2039 (1978).

zs R O Rantanen, Symposium on effet de l'environnement spatial sur les

mat6riaux, Toulouse, 1974.

2e j Dauphin, De lnoenieur 80 (49), 196 (1968).

27 j Dauphin and P Joliet, ESA STM 206 (1978).

4. Conclusion

Thirteen years ago, I was asked to give a paper on almost the same

subject 26. At that time, the work was just starting on this subject in

Europe, but we had already a rather clear idea of the problems we

would meet in space by considering the bulk of data obtained on

the ground by vacuum specialists.

Over the last period of 13 yr, our progress has been considerable

and the first achievement is that outgassing/contamination

problems are now recognized by most satellite project managers

and acted upon at the right time, i.e. when design starts.

Another success is the accumulation of a very large library of

reference data on materials which are used in spacecraft

manufacture 27.

J

(

3x QUARTZCRYSTALBALANCE

r.,CELE$CO700A

CONDENSER

PLATE SHROUD

L= VACUUMBALANCE

SARTORIUS

4433

~

~

THERt4OCOAX

SHROUD

CONDENSERPLATEC O O L I N G , ~

QCM

COOLING -------.~.:

"COPPERBLACK"

ULTRAVIOLETLAMP

OSR~M

$APHIREWINDOW~

LENS.

REFLECTOR

MA5$ ~EC'T~NETER

TURBO-PUMP

Figure 4. VBQC-II outgassing system.

673

S-ar putea să vă placă și

- Guidelines For The Construction of Landfills PDFDocument299 paginiGuidelines For The Construction of Landfills PDFAllaine UyÎncă nu există evaluări

- Pyrolysis of AcetaldehydeDocument5 paginiPyrolysis of AcetaldehydeAllaine UyÎncă nu există evaluări

- Republic Act No. 8749 Philippine Clean Air Act of 1999 PDFDocument35 paginiRepublic Act No. 8749 Philippine Clean Air Act of 1999 PDFAllaine UyÎncă nu există evaluări

- The Coal Resource, A Comprehensive Overview of Coal (World Coal Institute)Document48 paginiThe Coal Resource, A Comprehensive Overview of Coal (World Coal Institute)alabamacoal100% (1)

- Bhopalgastragedy 140418123506 Phpapp02Document25 paginiBhopalgastragedy 140418123506 Phpapp02Allaine UyÎncă nu există evaluări

- Heat and Mass Transfer PDFDocument27 paginiHeat and Mass Transfer PDFAllaine UyÎncă nu există evaluări

- 07 Chapter 1Document41 pagini07 Chapter 1Allaine UyÎncă nu există evaluări

- Navier PDFDocument2 paginiNavier PDFRickyHerreraÎncă nu există evaluări

- Electric Circuit Analysis Chapter 2Document31 paginiElectric Circuit Analysis Chapter 2Allaine UyÎncă nu există evaluări

- Computer Methods in Chemical EngineeringDocument247 paginiComputer Methods in Chemical Engineeringkris010100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Como Desarmar Sony Vaio VGN-FE PDFDocument14 paginiComo Desarmar Sony Vaio VGN-FE PDFPeruInalambrico Redes InalambricasÎncă nu există evaluări

- Meteorology Konu Konu Ayrılmış SorularDocument278 paginiMeteorology Konu Konu Ayrılmış Sorularjames100% (1)

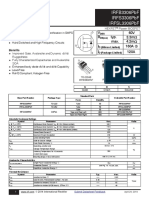

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocument12 paginiIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligÎncă nu există evaluări

- A Comparative Study On The Academic Performance ofDocument18 paginiA Comparative Study On The Academic Performance ofDiether Allen L. YnionÎncă nu există evaluări

- KVS - Regional Office, JAIPUR - Session 2021-22Document24 paginiKVS - Regional Office, JAIPUR - Session 2021-22ABDUL RAHMAN 11BÎncă nu există evaluări

- FI Printing Guide Vinyl-303Document1 paginăFI Printing Guide Vinyl-303tomasykÎncă nu există evaluări

- Java Lab Assignment.Document2 paginiJava Lab Assignment.KAYÎncă nu există evaluări

- Trigonometric Ratios LPDocument3 paginiTrigonometric Ratios LPjoshgarciadlt100% (2)

- Relay Maintenance and Testing: BenefitsDocument2 paginiRelay Maintenance and Testing: BenefitsojoladapoÎncă nu există evaluări

- Fiber SyllabusDocument1 paginăFiber SyllabusPaurav NayakÎncă nu există evaluări

- Famous MathematicianDocument116 paginiFamous MathematicianAngelyn MontibolaÎncă nu există evaluări

- 1.project FullDocument75 pagini1.project FullKolliparaDeepakÎncă nu există evaluări

- Sympoly Toolbox IssuesDocument7 paginiSympoly Toolbox IssuesAli FahemÎncă nu există evaluări

- Motionless Electromagnetic GeneratorDocument8 paginiMotionless Electromagnetic Generatorraja100% (1)

- Review Skills 1-8Document1 paginăReview Skills 1-8TegarÎncă nu există evaluări

- MOVIDRIVE-B Lab7Document6 paginiMOVIDRIVE-B Lab7GrungeokêÎncă nu există evaluări

- GS (2006) Vol 2 Rev20 S15 Steel ReinforcementDocument14 paginiGS (2006) Vol 2 Rev20 S15 Steel ReinforcementLap Chun TUNGÎncă nu există evaluări

- TMT Boron CoatingDocument6 paginiTMT Boron Coatingcvolkan1100% (2)

- Thermocouple: Seeback EffectDocument8 paginiThermocouple: Seeback EffectMuhammadHadiÎncă nu există evaluări

- Therapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Document11 paginiTherapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Jeroan MonteiroÎncă nu există evaluări

- Formula Sheet: Basic Trigonometric IdentitiesDocument4 paginiFormula Sheet: Basic Trigonometric Identitieschetan temkarÎncă nu există evaluări

- SR-X Script Reference - EDocument24 paginiSR-X Script Reference - EDomagoj ZagoracÎncă nu există evaluări

- LBX 6513DS VTMDocument4 paginiLBX 6513DS VTMsergiocuencascribÎncă nu există evaluări

- HANA OverviewDocument69 paginiHANA OverviewSelva KumarÎncă nu există evaluări

- Class - B Complementary Symmetry Power AmplifierDocument3 paginiClass - B Complementary Symmetry Power AmplifierAnonymous SH0A20Încă nu există evaluări

- Design and Analysis of Monopole Circularly Polarised Microstrip Patch Antenna Using HFSSDocument17 paginiDesign and Analysis of Monopole Circularly Polarised Microstrip Patch Antenna Using HFSSKashif FurkanÎncă nu există evaluări

- 3PAR DISK MatrixDocument6 pagini3PAR DISK MatrixShaun PhelpsÎncă nu există evaluări

- Finches Statistics Student-1Document7 paginiFinches Statistics Student-1api-319172404Încă nu există evaluări

- Chem 17 Exp 3 RDR Chemical KineticsDocument4 paginiChem 17 Exp 3 RDR Chemical KineticscrazypatrishÎncă nu există evaluări

- Completing The Square PDFDocument10 paginiCompleting The Square PDFgreg heffleyÎncă nu există evaluări