Documente Academic

Documente Profesional

Documente Cultură

Vol 4 3 322 327 Sharma Jain

Încărcat de

Raj EaswarmoorthiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Vol 4 3 322 327 Sharma Jain

Încărcat de

Raj EaswarmoorthiDrepturi de autor:

Formate disponibile

Journal of Engineering Science and Technology

Vol. 4, No. 3 (2009) 322 - 327

School of Engineering, Taylors University College

PHASE CHANGE MATERIALS FOR DAY LIGHTING

AND GLAZED INSULATION IN BUILDINGS

LOKESH JAIN1, S.D. SHARMA2,*

1

CSEM-UAE Innovation Center LLC, P.O. Box 31208,

Ras Al Khaimah, United Arab Emirates (UAE)

2

Emergent Ventures India Pvt Ltd, Plot # 19, Sector 33, Gurgaon 122 001, India

*Corresponding Author: lokejain@gmail.com

Abstract

This paper presents the experimental solar transmittance measurements of

commercial grade Phase Change Material (PCM). The effects of ambient

temperature, solar radiation and thickness on transmittance have been studied. The

study indicates that the PCM has higher transmittance than water. High

transmittance, low thermal conductivity and high latent heat of fusion make it

suitable transparent insulating building material (i.e. Window, sky roof etc.).

Keywords: Phase change material, Latent heat, Solar transmittance,

Thermal conductivity.

1. Introduction

Low energy consumption in buildings can be achieved by control of passive solar

heat gains. In the hot climate, solar heat gain is main load for cooling systems

where as in cold climate, enhancement of the passive solar heat gain can reduce

the heater load. Exterior glass windows in buildings can provide the necessary

day lighting but have adverse effect on energy consumption. Transparent

insulating phase change materials can be one of the ways to achieve this

objective. They can store solar thermal energy and has the advantages of high

storage density and the isothermal nature of the storage process. The information

on the latent heat thermal energy storage (LHTES) materials and systems is

enormous and published widely in the literature but very limited efforts have been

made to utilize these as transparent day lighting medium in windows [1].

LHTES materials usually have low thermal conductivity, and these materials

can act as self insulators. Because of the poor thermal conductivity and good optical

322

Phase Change Materials for Day lighting and Glazed Insulation in Buildings

323

Abbreviations

ADAM

LHTES

PCM

RTD

Advantech Data Acquisition Modules

Latent Heat Thermal Energy Storage

Phase Change Material

Resistance Temperature Detector

transmittance, these materials can be used as transparent insulation and can also

trap the heat. Many PCMs are highly transparent for the visible part of solar

spectrum where as the infrared part is absorbed within the PCM [2]. But no

efforts have been made to study the optical transmittance of these materials [3].

Such materials can be useful for trombe walls, solar windows and shutters [4].

When the sun is shining, the heat can be stored by the PCM, and this stored heat

can be transmitted to the living space when the sun is not shining.

The main objective of the present study is to measure the solar transmittance

of a PCM in the liquid phases experimentally for different thickness under natural

solar radiation and ambient conditions.

2. Experimental Set-up and Measurements

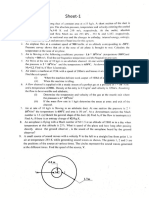

The experimental set up consists of a cuboidal shape glass box of dimensions of

560 mm in length, 460 mm in width and 48 mm in height for the PCM. The

glass used to make the box is 4 mm toughened glass. The top portion of the box

slides and the inside is divided into two equal compartments of 280 mm of

length by a vertical glass divider and it is made leak proof so that experiments

with two materials can be run simultaneously. The experimental set up is shown

in Fig. 1.

Fig. 1. Experimental Set-up.

Three pyranometers have been used for measurements of global solar

radiation and transmitted solar radiation through the two materials placed in

different compartments of the set up. The ambient temperature is also measured

using a Pt 100 RTD (Platinum resistance temperature detector). Measurements

Journal of Engineering Science and Technology

September 2009, Vol. 4(3)

324

L. Jain and S.D. Sharma

from pyranometers and ambient temperature were recorded at an interval of 1 s

using Advantech Data Acquisition modules (ADAM) with an accuracy of

0.1% or better. High precision pyranometers were used for measurements.

Two Eppley laboratory Pyranometers with calibration factors of 7.9910-6 and

7.8910-6 V/W/m2 were used. A third Pyranometer from Kipp and Zonen with a

calibration factor of 8.8510-6 V/W/m2 was also used.

Experiments were conducted at the test site of CSEM UAE Innovation Center

LLC, Ras Al Khaimah (latitude 25.62N, longitude 55.93E), United Arab

Emirates. Experiments were conducted between 11:15 am to 1:15 pm. This

duration has been selected because it is almost symmetrical about the solar noon

for the location, to avoid the effect of shading of the container on the PCM and to

have the smaller angle of incidence of the solar radiation.

Commercial grade PCM (purity 99.3%) has been chosen for solar

transmittance testing. Thermo physical properties are given in Table 1. The

PCM was selected on the basis of adequate melting point, high latent heat of

fusion and low thermal conductivity. The melting point was chosen to be near

to the average ambient temperature as this is suitable for PCM in a glazing

application. As sun rises, PCM will become liquid, so the user will gain the

advantage of natural daylight through the PCM glass window. Its low

conductivity will act as thermal barrier between the outside and inside of the

building and will not allow the heat to flow in either direction. Simultaneously

it will store the heat due to its heat capacity. Thus the PCM can act as a

transparent insulating material.

Table 1. Thermo-Physical Properties of PCM.

Melting point b

Heat of fusion b

Solid specific heat a

Liquid specific heat a

Solid thermal conductivity a

Liquid thermal conductivity a

Density a

31.98C

236.17 kJ/kgC

2.15 kJ/kg.K

2.18 kJ/kg.K

0.34 W/m.K

0.15 W/m.K

777 kg/m3 @ 25C

a: From literature [1] b: From differential scanning calorimeter measurement

3. Results and Discussions

A number of experiments were conducted to measure the solar transmittance of

the PCM. Measurements of the average PCM solar transmittance for thicknesses

in the range of 4 to 30 mm, the average solar radiation and average ambient

temperature are tabulated in Table 2. Variation of the PCM average solar

transmittance as a function of the thickness of the PCM is shown in Fig. 2. A

linear regression shows a best curve fit with the experimental results. The

coefficient of determination, R2, was found to be 0.992, which indicates the

goodness of fit.

Journal of Engineering Science and Technology

September 2009, Vol. 4(3)

Phase Change Materials for Day lighting and Glazed Insulation in Buildings

325

Table 2. Solar Transmittance Measurements

for Various Thicknesses under Outdoor Conditions.

PCM

Global solar

Ambient

PCM

thickness

radiation

temperature

transmittance

(mm)

(W/m2)+

(C)+

(%) +,*

4

10

15

20

30

744.2

775.3

786.6

771.8

698.8

38.7

40.1

40.6

38.9

38.6

67.6

65.3

63.9

62.9

59.9

+ These values are averaged values during the different days of measurements

* This value is system transmittance values with PCM layer between two glass covers.

68

Solar transmittance, %

R2 = 0.992

66

64

62

60

58

0

10

15

20

25

30

35

PCM thickness (mm)

Fig. 2. Variation of Average PCM Solar

Transmittance with PCM Thickness.

A trend of solar transmittance of PCM for the thickness of 4 mm and 30 mm

for experimental duration on typical day is shown in Fig. 3. It shows that there is

significant drop (around 7.7%) in PCM transmittance. Therefore, melting point

and thickness of PCM seems to play an important role in the selection of PCM as

a transparent insulating material for variety of applications.

90

30 mm

04 mm

Solar transmittance, %

80

70

60

50

40

Time

11:32:25 12:01:37 12:14:07 12:26:37 12:39:07 12:51:37 13:04:07

Time of Day

Fig. 3. Variation of Average PCM Solar Transmittance over a Day.

Journal of Engineering Science and Technology

September 2009, Vol. 4(3)

326

L. Jain and S.D. Sharma

Experiments with air and water were also conducted and a comparison for solar

transmittance of PCM, water and air is shown in Table 3. Results show that PCM

has higher transmittance (63.9%) than water (60.4%) for the thickness of 15 mm.

Table 3. Comparison of Solar

Transmittance of PCM with Water and Air.

Material

Transmittance @15 mm

PCM

Water

Air

63.9

60.4

74.6

Transmittance of PCM alone is given in Table 4 for different thickness, which

varies 90.6% (for 4 mm) to 80.2% (30 mm) respectively. Therefore, transmittance

of PCM (85.6%) alone is higher than water (80.9%) for 15 mm thickness. PCM

transmittance is almost in the same range of toughened glass with low iron

content for 4 mm thickness.

Tab. 4. Transmittance of PCM Alone.

PCM thickness (mm)

PCM alone

transmittance (%)

10

15

20

30

90.7

87.5

85.7

84.4

80.3

4. Conclusion

In the present study, the solar transmittance of PCM for different thicknesses

were measured and presented. The transmittance of the liquid phase PCM is

higher than the water for the same thickness. High transmittance and low

thermal conductivity makes it suitable transparent insulating medium for

building material (i.e. Window, sky roof etc.). Melting point and thickness of

PCM plays an important role in the selection of PCM as a transparent insulating

material for variety of applications. Transparent insulating PCM could be

suitable to save energy on one side and reduction of CO2 gas emissions on

another side.

Acknowledgment

Mr Subashchandra Padiyar and Mr. Gireesh from CSEM UAE Innovation Center,

Ras Al Khaimah, United Arab Emirates are duly acknowledged for their

continuous support and technical discussions from time to time during the

experiments. Authors are also grateful to the management of CSEM-UAE

Innovation Center LLC to provide all facilities during experiments and without

whose help; this research work could not be completed.

Journal of Engineering Science and Technology

September 2009, Vol. 4(3)

Phase Change Materials for Day lighting and Glazed Insulation in Buildings

327

References

1.

2.

3.

4.

Sharma, S.D.; and Sagara, K. (2005). Latent heat storage materials and

systems: A review. International Journal of Green Energy, 2(1), 156.

Weinlader, H.; Beck, A.; and Fricke, J. (2005). PCM faade panel for day

lighting and room heating. Solar Energy, 78(2), 177-186.

Buddhi, D.; and Sharma, S.D. (1999). Measurements of transmittance of

solar radiation through stearic acid: a latent heat storage material. Energy

Conversion and Management, 40, 1979-1984.

Sharma, S.D.; and Jain, L. (2007). Thermal energy storage materials and

systems, Annual review series, titled "Progress in Green Energy", to be

published by Springer (in progress).

Journal of Engineering Science and Technology

September 2009, Vol. 4(3)

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Atsc Final Cheat Sheet PDFDocument2 paginiAtsc Final Cheat Sheet PDFManan Shah100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Astm D5084 PDFDocument24 paginiAstm D5084 PDFTatiana ChitivaÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Project Title: Performance Improvement of Shell and ResponsibilitiesDocument1 paginăProject Title: Performance Improvement of Shell and ResponsibilitiesRaj EaswarmoorthiÎncă nu există evaluări

- L071ME4182DFADocument81 paginiL071ME4182DFAmegamech23Încă nu există evaluări

- ARK Journal Paper-Exp SetupDocument12 paginiARK Journal Paper-Exp SetupRaj EaswarmoorthiÎncă nu există evaluări

- CAVTDocument4 paginiCAVTRaj EaswarmoorthiÎncă nu există evaluări

- Importance Natural VentilationDocument3 paginiImportance Natural VentilationRaj EaswarmoorthiÎncă nu există evaluări

- FDM, Fem, FVMDocument32 paginiFDM, Fem, FVMRaj EaswarmoorthiÎncă nu există evaluări

- Application of The Water Table Fluctuation Method To Characterize Groundwater Recharge in The Pampa Plain Argentina PDFDocument12 paginiApplication of The Water Table Fluctuation Method To Characterize Groundwater Recharge in The Pampa Plain Argentina PDFLudwin MoranÎncă nu există evaluări

- Pollutants of Air AND Their Sources: PRESENTED BY: Nandita & GitikaDocument8 paginiPollutants of Air AND Their Sources: PRESENTED BY: Nandita & GitikaNandita MenhdirattaÎncă nu există evaluări

- Aibel Pioneering Design With Sesam - tcm8 60573Document2 paginiAibel Pioneering Design With Sesam - tcm8 60573Marcel JuleanÎncă nu există evaluări

- Ch311 Seminar PresentationDocument9 paginiCh311 Seminar PresentationShanya ShayalÎncă nu există evaluări

- Current Trends of Blade Cooling in Gas TurbinesDocument14 paginiCurrent Trends of Blade Cooling in Gas TurbinesPRAVEENÎncă nu există evaluări

- Ingeteam Wind Converter Catalogue 2019Document4 paginiIngeteam Wind Converter Catalogue 2019FBÎncă nu există evaluări

- Devoll Hydro Power (DHP), AlbaniaDocument122 paginiDevoll Hydro Power (DHP), AlbaniaSai SandeepÎncă nu există evaluări

- Rocks & Energy Chapter 1 & 2 Environmental Management 0680 Geography GCSE IGCSE O-LevelsDocument108 paginiRocks & Energy Chapter 1 & 2 Environmental Management 0680 Geography GCSE IGCSE O-LevelsIGCSE Physics & Chemistry100% (1)

- 5.periodicity - AnswersDocument7 pagini5.periodicity - AnswersAnshu MovvaÎncă nu există evaluări

- Eleven Magic Steps PDFDocument44 paginiEleven Magic Steps PDFGunalan PasubathyÎncă nu există evaluări

- E8. SBT HK2 (HS) PDFDocument82 paginiE8. SBT HK2 (HS) PDFBùi Thị Doan HằngÎncă nu există evaluări

- EWG LUT 100RE All Sectors Global Report 2019 PDFDocument321 paginiEWG LUT 100RE All Sectors Global Report 2019 PDFPai BuabthongÎncă nu există evaluări

- IAS Mains Geology Papers 1997: ExamraceDocument3 paginiIAS Mains Geology Papers 1997: ExamraceD DÎncă nu există evaluări

- D3R - Module-2 - 2ND Sem - Grade-11 - Stem-Del-Pilar - Stem-Malvar - Mr.-Arnold-PaombongDocument14 paginiD3R - Module-2 - 2ND Sem - Grade-11 - Stem-Del-Pilar - Stem-Malvar - Mr.-Arnold-PaombongArnold Arada PaombongÎncă nu există evaluări

- Physical ScienceDocument5 paginiPhysical ScienceJazz AddÎncă nu există evaluări

- Tutorial 4 Josephine Bakewa A00224059Document7 paginiTutorial 4 Josephine Bakewa A00224059Josephine BakewaÎncă nu există evaluări

- Tu Dong Nghia Global WarmingDocument1 paginăTu Dong Nghia Global WarmingNguyễn HòaÎncă nu există evaluări

- Problem Sheets 1 2 3 4Document12 paginiProblem Sheets 1 2 3 4AshutoshÎncă nu există evaluări

- Climatic Geomorphology PDFDocument769 paginiClimatic Geomorphology PDFGiovanna Hdz100% (3)

- Minimum Ignition Energy of A Dust Cloud in Air: Standard Test Method ForDocument8 paginiMinimum Ignition Energy of A Dust Cloud in Air: Standard Test Method ForMahletmelaku100% (1)

- Solar System 9th Edition Seeds Test BankDocument21 paginiSolar System 9th Edition Seeds Test Bankjoshuarussellbmrgzkdeia100% (10)

- Evolution of The Arabian Plate PDFDocument60 paginiEvolution of The Arabian Plate PDFscaldasoleÎncă nu există evaluări

- Protok Realnog Fluida-3Document34 paginiProtok Realnog Fluida-3konticvÎncă nu există evaluări

- AssignmenticsDocument4 paginiAssignmenticssattar280% (1)

- Combustion: Luminous Gas Flame Flame Front Luminous Non-LuminousDocument18 paginiCombustion: Luminous Gas Flame Flame Front Luminous Non-LuminousMd. Ahsanur RahmanÎncă nu există evaluări

- Hiring of Consultant For DFR of 9MW Ground Mounted Solar ProjectDocument2 paginiHiring of Consultant For DFR of 9MW Ground Mounted Solar ProjectsubudhiprasannaÎncă nu există evaluări

- Properties and Characterization of Kaolin Clay-1Document7 paginiProperties and Characterization of Kaolin Clay-1bkpadhi815Încă nu există evaluări