Documente Academic

Documente Profesional

Documente Cultură

Plant Inspection Checklist: Faculty / Other Area (Foa) Information Date

Încărcat de

Anonymous 4e7GNjzGWTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plant Inspection Checklist: Faculty / Other Area (Foa) Information Date

Încărcat de

Anonymous 4e7GNjzGWDrepturi de autor:

Formate disponibile

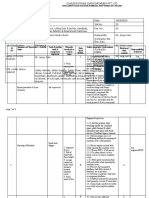

Plant Inspection Checklist

Page 1

FACULTY / OTHER AREA (FOA) INFORMATION

__________

Building:

Date:

FOA:

Plant Item

Location:

Deakin serial

number

Plant Identification: Model No,

Serial No etc

INSPECTED BY:

Supervisor: (name and

signature)

OHS Management Rep: (name

and signature)

ELEMENT

Employee HSR: (name and

signature)

Y/N/N

COMMENTS / HAZARDS

A

Y = Up to standard (adequate), N = Below standard (action required), NA = Not Applicable

1. Personal Hazards

1.1 Plant is protected from any hair,

clothing, gloves, jewelry, brushes, rags

or other materials becoming entangled

with moving parts.

1.2 Risk of crushing from parts of plant

falling off, or uncontrolled or

unexpected movement of plant has

been addressed.

1.3 Risk of being cut, stabbed or punctured

due to contact with moving parts, or

materials loaded into or taken out or

ejected, has been addressed

1.4 Risk of being injured from shearing

(caught between moving parts), friction

or being struck has been addressed

1.5 There is protection from contact with

electricity, heat, explosion, steam,

hydraulic fluid and toxic substances.

1.6 Plant is protected from contact with

overhead or underground power lines

and public authority services.

Actions: (include person responsible and target completion date)

2. General Hazards

2.1 Access and egress provisions are safe.

2.2 Risks associated with the plant when it

is not in use or when undergoing

maintenance have been addressed.

2.3 Controls are suitably identified and

conveniently located.

2.4 Controls can be locked off and power

disconnected when not in use.

2.5 Guarding is adequate for the type of

plant and the work being undertaken.

2.6 Regular inspections and maintenance

programs are carried out as scheduled

(including electrical testing).

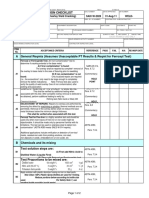

Plant Inspection Checklist

ELEMENT

Page 2

Y/N/N

COMMENTS / HAZARDS

A

Y = Up to standard (adequate), N = Below standard (action required), NA = Not Applicable

Actions: (include person responsible and target completion date)

3. Competency and Training

3.1 Is a certificate of competency required

If so, has it been obtained?

3.2 Is training required for operation If so

have operators been trained?

3.3 Operating instructions are available

and easily understood.

Actions: (include person responsible and target completion date)

4. Environmental Hazards

4.1 The environment is protected from

contamination by vapour, fumes, noise

etc.

4.2 The discharge of hazardous substances

has been contained.

4.3 Plant has been monitored for air

emission controls where required.

Actions: (include person responsible and target completion date)

5. Hazards with Plant used for Lifting

People or Materials

5.1 Lifting capacity is below the designated

safe working load.

5.2 Loads are protected if they are required

to be suspended over people

5.3 Safe egress is possible in the event of a

plant failure

Actions: (include person responsible and target completion date)

6 Ergonomics

6.1 Frequently used controls are within

easy access

6.2 Excessive force is not required to

operate the plant or controls

6.3 Work postures for operators are not

constrained or awkward.

6.4 Does the operator need to over-reach,

stretch, lift, carry or bend in such a way

that it may cause body strain?

Actions: (include person responsible and target completion date)

Plant Inspection Checklist

ELEMENT

Page 3

Y/N/N

COMMENTS / HAZARDS

A

Y = Up to standard (adequate), N = Below standard (action required), NA = Not Applicable

10 Chemical Aspects

10.1 MSDS available for any hazardous

chemicals

10.2 Containers are labelled with

chemical name and Class diamonds

10.3 Chemicals are stored appropriately

Actions: (include person responsible and target completion date)

11 Regulatory Aspects

11.1 Is there a register of all plant &

equipment with up to date

maintenance and testing records?

11.2 Does the plant meet current

standards and relevant regulations

Actions: (include person responsible and target completion date)

Other Comments:

General Recommendations:

S-ar putea să vă placă și

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 paginiExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Hand Over Notes SampleDocument3 paginiHand Over Notes SampleRosa Amri60% (5)

- Daily Tool Box MeetingDocument1 paginăDaily Tool Box MeetingVipul ShankarÎncă nu există evaluări

- Fire Extinguisher Inspection ReportDocument2 paginiFire Extinguisher Inspection ReportEmanuel LeoÎncă nu există evaluări

- Construction Safety CheckDocument6 paginiConstruction Safety CheckDarryl VeranoÎncă nu există evaluări

- Gas Cutting & Welding ChecklistDocument2 paginiGas Cutting & Welding ChecklistDth InfraÎncă nu există evaluări

- Site Safety OrientationDocument19 paginiSite Safety OrientationKrischaEverÎncă nu există evaluări

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 paginăFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 paginăFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- Welding Defect - MACRO PDFDocument5 paginiWelding Defect - MACRO PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Hydrostatic Test (Log) : Quality Control FormDocument22 paginiHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- Flash Point StandardsDocument177 paginiFlash Point Standardsgreat_triskelionÎncă nu există evaluări

- Index of OP Project HIRA Activities ID No. Activities Remarks Format NoDocument7 paginiIndex of OP Project HIRA Activities ID No. Activities Remarks Format NoSameer JogasÎncă nu există evaluări

- Improve Emergency Response with Mock Drill TestingDocument10 paginiImprove Emergency Response with Mock Drill TestingGobindaSahu100% (1)

- Shiva Enterprises accident logDocument1 paginăShiva Enterprises accident logRahul KumarÎncă nu există evaluări

- Asian Paints - Prem Gloss EnamelDocument1 paginăAsian Paints - Prem Gloss EnamelwilliumstÎncă nu există evaluări

- Work Order Standard Operating ProcedureDocument10 paginiWork Order Standard Operating ProcedureJemar B. BagnateÎncă nu există evaluări

- Saf 113 A Daily She Inspection Report 1Document4 paginiSaf 113 A Daily She Inspection Report 1saravana3kumar3ravic100% (1)

- 18A - FO - Permit To Work LogDocument2 pagini18A - FO - Permit To Work Lograjesh_rathÎncă nu există evaluări

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 paginiJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezÎncă nu există evaluări

- Accident Investigation GuideDocument8 paginiAccident Investigation GuideagusnurcahyoÎncă nu există evaluări

- Hip & Jsa For Abqq-472Document13 paginiHip & Jsa For Abqq-472javithÎncă nu există evaluări

- JSA Form - Installation of ATS atDocument4 paginiJSA Form - Installation of ATS atDarren OscarÎncă nu există evaluări

- JSA ScaffoldingDocument2 paginiJSA Scaffoldingmyco samÎncă nu există evaluări

- Powder Actuated ToolsDocument1 paginăPowder Actuated ToolsJayvee Baradas ValdezÎncă nu există evaluări

- SWP 003 Pouring ConcreteDocument1 paginăSWP 003 Pouring ConcreteJICKÎncă nu există evaluări

- 3.ceiling Installation JSA ADocument2 pagini3.ceiling Installation JSA APijah AhmadÎncă nu există evaluări

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 paginiNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroÎncă nu există evaluări

- Risk Assessment Record for BPGIC TerminalDocument4 paginiRisk Assessment Record for BPGIC TerminalAbdul HadiÎncă nu există evaluări

- ESH Compliance Check List: Noise ControlDocument1 paginăESH Compliance Check List: Noise ControlRichard BaileyÎncă nu există evaluări

- Confined Space Entry Risk AssessmentDocument9 paginiConfined Space Entry Risk Assessmentkoketso0% (1)

- Daily Safety Report TemplateDocument1 paginăDaily Safety Report TemplateMarkÎncă nu există evaluări

- Manual Handling ChartDocument20 paginiManual Handling ChartTatak Bay Ahmed100% (1)

- Near Miss Report FormDocument1 paginăNear Miss Report Formsieged_rj3165Încă nu există evaluări

- First Aid Box EmptyDocument1 paginăFirst Aid Box Emptylez2Încă nu există evaluări

- JSA Format Erection of Column 901-C-01Document9 paginiJSA Format Erection of Column 901-C-01sakthi venkatÎncă nu există evaluări

- HSE Hot Work PermitDocument3 paginiHSE Hot Work PermitCSD shakthiÎncă nu există evaluări

- Scaffold Tag: Inspection RecordDocument1 paginăScaffold Tag: Inspection RecordZainal AzizÎncă nu există evaluări

- General Site Safety - SignDocument1 paginăGeneral Site Safety - SignVũ GiangÎncă nu există evaluări

- Employee Health and Safety Induction Training Record 1Document6 paginiEmployee Health and Safety Induction Training Record 1kumar kannanÎncă nu există evaluări

- Health and Safety Method Statement: SA Scaffolding LimitedDocument8 paginiHealth and Safety Method Statement: SA Scaffolding LimitedAnonymous Wq35JtketnÎncă nu există evaluări

- Chemical Spill Kit ChecklistDocument1 paginăChemical Spill Kit ChecklistPrudhvi RajÎncă nu există evaluări

- Bending MachineDocument52 paginiBending MachineFarrukh AhmedÎncă nu există evaluări

- Weekly excavator checklist template for construction projectsDocument4 paginiWeekly excavator checklist template for construction projectssamiran RouthÎncă nu există evaluări

- Application To Perform Work - Grass CuttingDocument2 paginiApplication To Perform Work - Grass CuttingRauf HuseynovÎncă nu există evaluări

- SHE Committee Meeting Minutes ReviewDocument4 paginiSHE Committee Meeting Minutes ReviewCHETAN WANKHADE100% (2)

- Emergency Action ZamilDocument11 paginiEmergency Action ZamilTAUQEER AlamÎncă nu există evaluări

- Construction Assessment Checklist: Green TagDocument2 paginiConstruction Assessment Checklist: Green TagRyan GillespieÎncă nu există evaluări

- Daily Hse Report Job Safety Analysis MakcoDocument14 paginiDaily Hse Report Job Safety Analysis MakcoSafety Mohini100% (2)

- Safety BoardDocument1 paginăSafety BoardsunilÎncă nu există evaluări

- Permit Work at Qatar FoundationDocument1 paginăPermit Work at Qatar FoundationJeffersonDeGuiaÎncă nu există evaluări

- MW-OPS-SP-3.6.13F1 Work Authorization Permit FormDocument3 paginiMW-OPS-SP-3.6.13F1 Work Authorization Permit FormGabriel Tan100% (1)

- Trade Area: Construction Industry-PaintingDocument3 paginiTrade Area: Construction Industry-PaintingRam-tech Jackolito FernandezÎncă nu există evaluări

- 28.1.1 Mobile Equipment Inspection ChecklistDocument1 pagină28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemÎncă nu există evaluări

- R-16 Safety Management Review MeetingDocument2 paginiR-16 Safety Management Review MeetingSandeep Kumar100% (1)

- Mock DrillDocument2 paginiMock DrillTarun MajumdarÎncă nu există evaluări

- Tool Box Talk MeetingsDocument5 paginiTool Box Talk MeetingsSusyenSihiteÎncă nu există evaluări

- Brush Cutter Pre Use ChecklistDocument1 paginăBrush Cutter Pre Use ChecklistBruce Hove100% (2)

- Tower Crane Work Permit ChecklistDocument1 paginăTower Crane Work Permit Checklistfaisal nadeemÎncă nu există evaluări

- Checklist For Noise: ILO Programme For Occupational Safety and Health and Environment For The CaribbeanDocument1 paginăChecklist For Noise: ILO Programme For Occupational Safety and Health and Environment For The CaribbeanShivam SagarÎncă nu există evaluări

- R-20 Two Way Communication FormDocument1 paginăR-20 Two Way Communication FormSandeep KumarÎncă nu există evaluări

- Checklist ERDMP 100919Document3 paginiChecklist ERDMP 100919varunkumar415Încă nu există evaluări

- Aug Toolbox Talks Confined Spaces 0517Document2 paginiAug Toolbox Talks Confined Spaces 0517WaSim AKramÎncă nu există evaluări

- Siemens LTD.: General Work Permit Serial No.Document3 paginiSiemens LTD.: General Work Permit Serial No.Dakshinamurthy PÎncă nu există evaluări

- Critical housekeeping risksDocument5 paginiCritical housekeeping risksZegera MgendiÎncă nu există evaluări

- Plant checklistDocument2 paginiPlant checklistmj santosÎncă nu există evaluări

- Plant Inspection Checklist: Faculty / Other Area (Foa) Information DateDocument2 paginiPlant Inspection Checklist: Faculty / Other Area (Foa) Information Datemj santosÎncă nu există evaluări

- Store JDDocument2 paginiStore JDdhasdjÎncă nu există evaluări

- Welder and Welder Operator Qualification Record Form PDFDocument1 paginăWelder and Welder Operator Qualification Record Form PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- 1234 TranslateDocument1 pagină1234 TranslateAnonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 paginiSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWÎncă nu există evaluări

- Name Name Name Name: To: CCDocument1 paginăName Name Name Name: To: CCAnonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 paginăSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 paginiSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 paginiSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Warrior Tech Spare Parts List 2 PDFDocument1 paginăWarrior Tech Spare Parts List 2 PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Welding Procedure Specification Form PDFDocument2 paginiWelding Procedure Specification Form PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Weld Joint Preparation Weld Joint PreparationDocument1 paginăWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWÎncă nu există evaluări

- BrochureDocument2 paginiBrochureAnonymous 4e7GNjzGWÎncă nu există evaluări

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 paginiShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWÎncă nu există evaluări

- Maintenance ManagementDocument22 paginiMaintenance ManagementMANISH_64Încă nu există evaluări

- Planer Vs Non Planer DefectsDocument2 paginiPlaner Vs Non Planer DefectsSavad Alwye75% (8)

- Warrior Tech Spare Parts List 2Document1 paginăWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWÎncă nu există evaluări

- First We InvestigatedDocument1 paginăFirst We InvestigatedAnonymous 4e7GNjzGWÎncă nu există evaluări

- Kafou Health Safety Loss Prevention ProgramDocument117 paginiKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWÎncă nu există evaluări

- Change in B31.3 2016 PDFDocument2 paginiChange in B31.3 2016 PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Numbering Format: Project DocumentationDocument1 paginăNumbering Format: Project DocumentationAnonymous 4e7GNjzGWÎncă nu există evaluări

- Organisation ChartDocument1 paginăOrganisation ChartAnonymous 4e7GNjzGWÎncă nu există evaluări

- SA STD - SpecificationDocument10 paginiSA STD - SpecificationAnonymous 4e7GNjzGWÎncă nu există evaluări

- Bio Data-01.07.13Document2 paginiBio Data-01.07.13Anonymous 4e7GNjzGWÎncă nu există evaluări

- Fac Contracts Pre-Q - Quest Attachments - 2!8!2017 V002Document28 paginiFac Contracts Pre-Q - Quest Attachments - 2!8!2017 V002Anonymous 4e7GNjzGWÎncă nu există evaluări

- Designs CatalogDocument77 paginiDesigns CatalogGen MendozaÎncă nu există evaluări

- 008x TF-compressed PDFDocument66 pagini008x TF-compressed PDFJosé Francisco Blanco VillalbaÎncă nu există evaluări

- INTRODUCTION To FINOLEX Finolex Group Was EstablishedDocument24 paginiINTRODUCTION To FINOLEX Finolex Group Was EstablishedpraveennakkinaÎncă nu există evaluări

- 4) Ultrahib Msds EngDocument8 pagini4) Ultrahib Msds EngJose AlejandroBlancoÎncă nu există evaluări

- Bermad Strainer Model BC-70F-P: Buildings & ConstructionDocument2 paginiBermad Strainer Model BC-70F-P: Buildings & ConstructionGuillermo GuzmánÎncă nu există evaluări

- Ecotoxicology and Environmental Safety: ArticleinfoDocument7 paginiEcotoxicology and Environmental Safety: ArticleinfoEswin Hernandez ObregonÎncă nu există evaluări

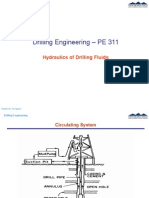

- Drilling Engineering Fluid PropertiesDocument29 paginiDrilling Engineering Fluid PropertiesDeepak RanaÎncă nu există evaluări

- Pokemon Emerald CheatDocument7 paginiPokemon Emerald CheatDimitri Iman P.Încă nu există evaluări

- GUNK Liquid Wrench Rust Inhibitor LC9 - 6 SDSDocument14 paginiGUNK Liquid Wrench Rust Inhibitor LC9 - 6 SDSYoutube For EducationÎncă nu există evaluări

- Packaging Evolution VaselineDocument11 paginiPackaging Evolution Vaseline2023185491Încă nu există evaluări

- Principles of Mineral ProcessingDocument1 paginăPrinciples of Mineral ProcessingMohamed HassanÎncă nu există evaluări

- Animal Physio Lab Report3-OsmoregulationDocument7 paginiAnimal Physio Lab Report3-OsmoregulationZari Novela100% (1)

- C2!6!455 Grout and Adhesive Rev.BDocument50 paginiC2!6!455 Grout and Adhesive Rev.BAreaya mahetemÎncă nu există evaluări

- NACE-MR0274 Mat Req For Polyolefin Cold-AppliedDocument7 paginiNACE-MR0274 Mat Req For Polyolefin Cold-Appliedluis fernando beltran balderasÎncă nu există evaluări

- Introduction To GFRCDocument3 paginiIntroduction To GFRCFred VictorÎncă nu există evaluări

- BiochemistryDocument410 paginiBiochemistryCaptainReeham79% (14)

- A4-80 Stainless Steel Grade Specification - Midland Bright SteelsDocument4 paginiA4-80 Stainless Steel Grade Specification - Midland Bright SteelsramonaghergheÎncă nu există evaluări

- Understanding and Managing Cell Culture Contamination PDFDocument24 paginiUnderstanding and Managing Cell Culture Contamination PDFPabloski AndreÎncă nu există evaluări

- API Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationDocument4 paginiAPI Standard 614 - Lubrication, Shaft-Sealing, and Control-Oil Systems For Special-Purpose ApplicationFabioSalaÎncă nu există evaluări

- Primus Operation FS6 To FS23Document50 paginiPrimus Operation FS6 To FS23Arun George50% (2)

- Solid, Liquid, Gas Explanation TextDocument2 paginiSolid, Liquid, Gas Explanation Textnettexts100% (1)

- Customer ListDocument10 paginiCustomer ListMohammed Tausif100% (1)

- Ecological Effects Test Guidelines: OPPTS 850.3020 Honey Bee Acute Contact ToxicityDocument8 paginiEcological Effects Test Guidelines: OPPTS 850.3020 Honey Bee Acute Contact ToxicityNatalie Torres AnguloÎncă nu există evaluări

- Peng Antar Minyak Bum IDocument13 paginiPeng Antar Minyak Bum ITara VergitaÎncă nu există evaluări

- USP <1115> Impact on Bioburden ControlDocument65 paginiUSP <1115> Impact on Bioburden ControlBlank Backtobasic100% (1)

- Sesv8002 PDFDocument97 paginiSesv8002 PDFali100% (2)

- نرخ نامه1Document7 paginiنرخ نامه1Farhad KaweshÎncă nu există evaluări

- Chemistry Jun 2010 Mark Scheme Unit 4Document22 paginiChemistry Jun 2010 Mark Scheme Unit 4dylandonÎncă nu există evaluări

- Multi Component DistillationDocument120 paginiMulti Component DistillationSamuel Espinoza GarciaÎncă nu există evaluări