Documente Academic

Documente Profesional

Documente Cultură

Saic B 2001 Wasit

Încărcat de

Anonymous 4e7GNjzGWTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Saic B 2001 Wasit

Încărcat de

Anonymous 4e7GNjzGWDrepturi de autor:

Formate disponibile

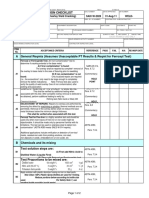

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

Rev 4

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Proprietary Fireproofing System & Procedure

(Intumescent Epoxy Mastics & Lightweight Concretes)

PROJECT TITLE

SAIC-B-2001

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

A

A1

A2

A3

ACCEPTANCE CRITERIA

REFERENCE

General Requirements

Proprietary Fireproofing Material System was approved by the Chief

Fire Prevention Engineer as follows:

A) Qualifying documentation of fireproofing material was submitted to the

Chief Fire Prevention Engineer for approval.

B) Refer to Attachment 1 for proprietary fireproofing mat'l list for various

applications in SA facilities.

Proprietary fireproofing shall be approved by the Chief Fire Prevention

Engineer. The material shall be applied in a manner approved by the

fireproofing manufacturer and by the Manager, Inspection Department,

Application of intumescent mastics or other approved proprietary

fireproofing shall be performed only by personnel trained and certified by

the material manufacturer.

SAES-B-006,

Para. 8.2.1

SAES-B-006,

Para. 8.2.1

SAES-B-006,

Para. 8.2.2

A4

Application shall be made in strict accordance with the manufacturer's

guidelines regarding ambient temperature, storage temperature,

materials, proportioning, and mixing.

SAES-B-006,

Para. 8.2.3

A5

Quality control procedures and hold points for inspection of surface

preparation and reinforcement shall be approved by the Manager,

Inspection Department, Dhahran.

SAES-B-006,

Para. 8.2.4

A6

Steel surfaces that are to be insulated per 8.3, fireproofed with

cementitious materials or covered with intumescent or other proprietary

fireproofing such as lightweight concrete, shall be coated in accordance

with SAES-H-101, APCS-1B.

The surface preparation and coating system specified shall be

referenced on all applicable construction drawings.

SAES-B-006,

Para. 8.4

A7

Procedure application for intumescent material specifies a minimum wet

thickness that will yield the required dry thickness (DFT).

(API PUBL 2218, Para. 7.3.3.1) Note: Procedure details extent &

location of checks to ensure adequate DFT (evaporation loss).

SAES-B-006,

Para. 5.2 & 8.2.3

A8

Procedure details top coating requirements & manner of application:

See Attachment 1 (Cementitious per Para. 8.5 and (Intumescent Epoxy

per Para. 8.6)

SAES-B-006,

Sect. 8.5 & 8.6

A9

Top-coating for proprietary fireproofing other than an intumescent epoxy

mastic shall be approved by the fireproofing manufacturer and the Chief

Fire Prevention Engineer. The coating shall be applied in a manner

approved by the fireproofing manufacturer and by the Manger, Inspection

Department, Dhahran.

SAES-B-006,

Para. 8.6.4

A10

Procedure Definition Section lists applicable SAES-B-006 & API

Publication 2218 applicable definitions:

A) Intumescent mastic:

B) Fire-hazardous equipment:

C) Fire-hazardous zone:

D) Other applicable definitions (SAES-B-006, API 2218).

SAES-B-006,

Section 4,

Definitions

Page 1 of 6

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

A11

Procedure Mat'l Section lists applicable materials selected and states

or infers (data sheet inference) their limits for application:

A) Intumescent epoxy mastics (equipment or supports) such as

Chartek 4, 7 (Int'l Coatings, Ltd.), Thermo-Lag 440 (Thermal Sci, Inc),

Pitt-Char XP (PPG Industries, Inc.), or other approved material.

B) Proprietary Intumescent epoxy coatings (Valve Actuators) like KMass (Thermal Designs, Inc) or FR Coating (MOV Limited)

C) Other proprietary coatings that meets Company requirements

See also Sections B & C for specific application reqmts

Page 2 of 6

SAES-B-006,

Appendix 1

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

Rev 4

SAUDI ARAMCO INSPECTION CHECKLIST

Review Proprietary Fireproofing System & Procedure

(Intumescent Epoxy Mastics & Lightweight Concretes)

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-B-2001

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

A12

Procedure Material Section lists material testing requirements for

material qualification:

A) Intumescent materials have been subjected to a test furnace

environment per UL 1709 or equivalent fire exposure test procedure

B) Fireproofing manufacturer has demonstrated no peel-back at edges

or terminations in a fire situation for intended application.

C) Other applicable tests performed to qualify materials

SAES-B-006,

Para. 7.2

A13

Procedure Material Section covers Top coating considerations (as

required by Manufacturer). These are identified in procedure & Material

Data sheet (two options):

A) FP must be clean, dry & free of contaminants prior to top-coat.

B) FP must be cured per mfg. recommendations prior to top-coat

C) Top-coat with SA Stock No 1000194797 or 1000194960 applied to a

dry-film thickness of 75 to 125 microns. (Option 1)

D) Top-coat for proprietary fireproofing other than intumescent epoxy

mastic as approved by fireproofing manufacturer & Company

SAES-B-006,

Section 8.6

A14

Material APPLICATION section is specific and breaks down the

elements of the documentation package from manufacturer:

A) Mfg. Data Sheet lists material's physical properties

B) Mfg. Data Sheet lists specific applications & limits for materials

C) Certified Report (fireproofing & environmental exposure tests)

D) Material Safety Data Sheet (MSDS) listing hazards & precautions

SAES-B-006,

Para. 8.2.1

A15

Procedure details API Publication 2218 material application

considerations (ensure checks by those responsible) as follows:

A) Shelf life is determined and maintained.

B) Material storage is per manufacturers recommendations.

C) Temperature-sensitive material storage and shipping.

D) Fireproofing materials are applied directly from original sealed

containers to avoid contamination and changes in their formulation.

E) Materials requiring controlled curing periods are identified

F) Appliers & inspectors understand specified thickness is dry thickness,

not wet thickness. Cured mastics shrink up to 30% .

SAES-B-006,

Section 3.2

A16

Procedure details or infers API Publication 2218 material application

Quality Control responsibilities/considerations:

A) Qualified personnel familiar with job specs monitor mixing, density,

substrate preparation, application thickness and finishing.

B) Materials are applied per manufacturers recommendations for dry

thickness. Small variations are significant to the fire-resistance of the

finished coating when using thin mastics, and are most often found in

parts of a structure that are congested or difficult to reach.

C) Inspection is aware of user & applier agreements regarding the

extent of random sampling necessary to verify coat thickness, proper

bond, lack of voids & specific evaluation procedures used.

SAES-B-006,

Section 3.2

Specific Requirements (Equipment & Supports)

B1

Intumescent materials have been subjected to a test furnace

environment per UL 1709 or equivalent fire exposure test procedure

accepted by the SA Chief Fire Prevention Engineer.

SAES-B-006,

Para. 7.2

B2

Fireproofing manufacturer has demonstrated no peel-back at edges or

fireproofing terminations in fire situation for intended application.

SAES-B-006,

Para. 7.2

Specific Requirements (Actuators)

Page 3 of 6

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

Rev 4

SAUDI ARAMCO INSPECTION CHECKLIST

Review Proprietary Fireproofing System & Procedure

(Intumescent Epoxy Mastics & Lightweight Concretes)

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-B-2001

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

C1

Fireproofing protects valve actuators for a minimum of 20 minutes when

subjected to test furnace environment per the full-scale test method of

UL 1709 or an equivalent "rapid-rise" fire test procedure

SAES-B-006

Para. 6.3.4

C2

Newly constructed Emergency Isolation Valves (EIVs) that require

actuator fireproofing have a vendor shop-applied intumescent

fireproofing per 21-SAMSS-014 requirements as follows:

A) Material is rated to withstand environmental conditions below:

UV irradiation by direct sunlight.

Relative humidity of 0 to 100% (condensing).

Wind velocity to 36 m/sec (130 km/h), gusts to 44 m/sec (160km/h)

Ambient temperatures range from 0C (minimum for EIV actuators) to

50C (for sheltered actuators), to max 80C (exposed actuators)

SAES-B-006

Para. 6.3.4

C3

The fireproofing fully covers the actuator body, excluding:

A) Indicator lights

B) Stem protector on top of the actuator

C) Handwheel or declutch lever.

Shaft extenders (where specified) are Type 316 SS

Controls & Indicators shall be accessible for maintenance

C4

Actuator outer surface of fireproofing is a distinctive color or colors

21-SAMSS-014,

(agreeable to Chief Fire Prevention Engineer) to identify this special

Section 7.4

coating as fireproofing. The color is not a Safety color (per SAES-B-067).

For example, purple is one acceptable color used.

Quality Control (QC) Requirements (Procedure)

D1

QC Equipment listed in SAES-H-100 Attachment A is listed for

inspection of surface preparation & coatings application.

SAES-H-100,

Para 9.1

D2

QC Records section lists requirements & responsibility as follows:

A) Equipment Check Sheet (Attachment B)

B) In-process Inspection Sheet (Attachment C)

C) Paints/Coatings & Equipment Log (Att D)

D) Daily Job Log

SAES-H-100,

Para 9.2

D3

Final Acceptance Report is listed. Report includes four (4) QC

documents (Attachments B, C, D, Daily Logs) above.

SAES-H-100,

Para 9.2.5

D4

Non Conformance Report is listed. Issued whenever any defect from

coating material deficiency or/ and application malfunctioning. Remedial

action & method of repair are defined & agreed upon.

SAES-H-100,

Para 9.2.6

Safety during Applications (SAES-H-102, Section 4)

E1

Safety Requirements are detailed in procedure as follows:

A) Fire and Explosion Prevention covers Smoking, hot work,

designated areas, welding/heating coil use, electrical items (lighting

equipment & connections), solvent/paint application, & work permits

B) Ventilation (forced, natural) & equipment used covers fresh air inlets,

discharge, added fans, confined spaces, air-fed hoods.

C) Health Hazards cover Alkaline catalysts, skin contact, chemical

burns, washing facilities, personnel protection equipment & MSDS

Page 4 of 6

21-SAMSS-014,

Section 7.2

SAES-H-102,

Section 4

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

Rev 4

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Proprietary Fireproofing System & Procedure

(Intumescent Epoxy Mastics & Lightweight Concretes)

SAIC-B-2001

PROJECT TITLE

ITEM

No.

E2

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

Safety Requirements (Equipment) are detailed in procedure:

A) Airless spray gun basic safety, tip guards, leather glove use, trigger

safety catches, pressure ratings (Hoses, pumps, etc) for operations,

5000 psi line limit, pump pressure relief valves, pump shut down & fluid

pressure bleed before servicing/cleaning parts (clogged spray tips, etc),

hose ground (anti-static type), equipment ground (AWG-4), equipment

pressure component condition, solvent flushing safety, & emergency

care for high pressure fluid injuries.

B) Power Tool Equipment Hazards covers grounding, operation

speeds, safety guards, hearing protection

C) Vessel use (air receivers, surge tanks, etc) are code vessels

stamped per ASME SEC VIII D1, hydrotested at 250 psig annually with

vessel test certificates submitted to SA Inspector for review.

D) Pressure relief valves, gauges & devices are tested/tagged

E) Blasting/coating equipment grounding (electrostatic disch.)

31-Mar-10

DATE APPROVED

QR NUMBER

31-Aug-11

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAES-H-102,

Section 4

REMARKS: *Always use latest approved revision of B-Std, not the Cut-off stds.

REFERENCE DOCUMENTS:

1. SAES-B-006, Fireproofing for Plants, (18 July, 2006)

2. SAES-H-100, Coating Materials & Application Requirements for Industrial Facilities (31 July 2004)

3. SAES-H-102, Safety Requirements for Coating Applications (11 Aug 2007)

4. API Publication 2218 - Fireproofing Practices in Petroleum & Petrochemical Processing Plants (Latest Edition)

5. 21-SAMSS-014 - Intumescent Fireproofing for Valve Actuators (15 April 2009)

ATTACHMENTS:

1. SAES-B-006 Appendix 1 - Approved Proprietary Fireproofing Materials

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 5 of 6

N = NO F = FAILED

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

SAUDI ARAMCO INSPECTION CHECKLIST

Review Proprietary Fireproofing System & Procedure

(Intumescent Epoxy Mastics & Lightweight Concretes)

Rev 4

SAIC NUMBER

SAIC-B-2001

31-Mar-10

DATE APPROVED

QR NUMBER

31-Aug-11

MECH-

Attachment 1 -- Approved Proprietary FP Materials

Appendix 1 (Use SAES-B-006, July 2006 or latest revision)

Ordinary dense concrete is the preferred fireproofing of structures and supports because of its proven economy,

durability, and effectiveness in hydrocarbon fires. However, for some applications, alternative proprietary fireproofing

mat'ls may be justified. This listing is intended to provide useful information on the available proprietary fireproofing

materials to requisition originators and others responsible for the development and evaluation of bids. This is not

intended to list all acceptable materials, nor are requisition originators restricted to the products of manufacturers or

vendors on this list. Fireproofing may be purchased from any qualified source that can comply with the mandatory

requirements. Verification of compliance shall be the responsibility of the requisition originator. Approval shall be

received from Chief Fire Prevention Engineer for each product unless it is already listed. See Section 8 reqmts.

A) Approved Material ... Is it on the list?

B) Approved Manufacturer ... Is it on the list?

C) Approved Material Supplier & Installer ... Are they on the list?

Note: Any item "not on list" shall be appv'd by Chief Fire Prevention Engineer

8.5 Top-Coating of Cementitious Fireproofing

8.5.1 All cementitious fireproofing (whether dense or lightweight concrete) shall be provided with a top coat under any of

the following conditions:

When top-coating is required by the manufacturer.

When fireproofing is installed within 3 m vertically from grade.

When fireproofing is installed on equipment that is protected by a fixed firewater spray or deluge system.

When fireproofing is installed below atmospheric drains or vents that are used during normal operations.

8.5.2 When cementitious fireproofing is to be provided with a top coat, the following shall apply:

Surface shall be dry & loose contaminants shall have been removed by brushing (stiff bristle brush) & vacuuming.

Fireproofing must be fully cured in accordance with manufacturer's technical reqmts, prior to top-coat application.

First top coat, SA Stock # 1000194629 thinned 10% to 15% & applied to a dry-film thickness of 50 to 90 microns.

Second top coat, SA Stock Number 1000194797 shall be applied to dry-film thickness of 75 to 125 microns.

8.6 Top-Coating of Intumescent Epoxy Mastic Proprietary Fireproofing

Intumescent epoxy mastic and other noncementitious proprietary fireproofing shall be top-coated when it is required by

the fireproofing manufacturer.

8.6.1 Fireproofing must be clean, dry, and free of contaminants prior to top-coating.

8.6.2 Fireproofing must be cured in accordance with the manufacturer's recommendations prior to top-coating.

8.6.3 Top-coating of Saudi Aramco Stock Number 1000194797 or 1000194960 shall be applied to a dry-film thickness of

75 to 125 microns.

8.6.4 Top-coating for proprietary fireproofing other than an intumescent epoxy mastic shall be approved by the

fireproofing manufacturer and the Chief Fire Prevention Engineer. The coating shall be applied in a manner approved by

the fireproofing manufacturer and by the Manger, Inspection Department, Dhahran.

APPLICATION NOTE (DESIGN):

8.3 Process Insulation

Vessels, exchangers, & equipment externally insulated for process reasons shall be considered to be fireproofed if

process insulation per SAES-N-001, as a composite system, satisfies FP performance Stds in Section 7 below.

7.1 Dense concrete meeting the material requirements of Section 8 and applied with a minimum thickness of 50 mm is

accepted as complying with the performance requirements for fireproofing without further testing. Dense concrete is the

preferred fireproofing for onshore facility structures & supports because of its proven economy, durability, and

effectiveness in hydrocarbon fires.

7.2 Minimum thickness of fireproofing mat'ls for structural members & vessel supports, other than qualifying dense

concrete, shall be installed with a thickness to provide a minimum fire-resistance rating of two (2) hours when subjected

to a test furnace environment in accordance with UL 1709 or an equivalent fire exposure test procedure accepted by the

Chief Fire Prevention Engineer.All materials and methods of fireproofing shall also be listed to meet the ASTM E119

Hose Test. Fireproofing manufacturer shall also demonstrate that there is no peel-back at the edges or terminations of

the fireproofing in a fire situation for the intended application. Certified test reports shall be submitted to the Chief Fire

Prevention Engineer for his approval. Refer to Appendix 1 for more info.

Page 6 of 6

S-ar putea să vă placă și

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 paginiExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Kafou Health Safety Loss Prevention ProgramDocument117 paginiKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWÎncă nu există evaluări

- Asme Ix QW PDFDocument183 paginiAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- Natural Gas IMS Essar - 8.8.2022Document61 paginiNatural Gas IMS Essar - 8.8.2022Jitendra Sharma100% (1)

- Corrosion AuditDocument4 paginiCorrosion AuditGopal RamalingamÎncă nu există evaluări

- Ethylenediamine Complexes of ChromiumDocument5 paginiEthylenediamine Complexes of ChromiumMatt PraterÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 paginiSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Corrosion Survey - Maintenance Painting ProjectDocument8 paginiCorrosion Survey - Maintenance Painting ProjectAmit NimbalkarÎncă nu există evaluări

- Hydrostatic Test (Log) : Quality Control FormDocument22 paginiHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- GasketsDocument20 paginiGasketsParthiban NagarajanÎncă nu există evaluări

- G. Std. ITP For Pipeline Job PDFDocument4 paginiG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Oisd 142Document55 paginiOisd 142sandeep MÎncă nu există evaluări

- Corrosion and Asset Integrity Management in Oil and Gas Production, Process, Transportation and Storage FacilitiesDocument12 paginiCorrosion and Asset Integrity Management in Oil and Gas Production, Process, Transportation and Storage FacilitiesRASHEED YUSUF100% (1)

- PROJECT STANDARD and SPECIFICATIONS Fire Proofing Vessels and Supports Rev01webDocument4 paginiPROJECT STANDARD and SPECIFICATIONS Fire Proofing Vessels and Supports Rev01webAzeem50% (2)

- Welding Procedure Specification FormatDocument3 paginiWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 paginiSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 paginiSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWÎncă nu există evaluări

- Endothermic and Exothermic Reactions WorksheetDocument4 paginiEndothermic and Exothermic Reactions Worksheetabdulhakim100% (1)

- Rna Qualitative TestsDocument5 paginiRna Qualitative TestsPeter Paul RecaboÎncă nu există evaluări

- KOC-MP-011 Part 1Document49 paginiKOC-MP-011 Part 1Akhil VasÎncă nu există evaluări

- Icorr Certification Scheme: Icorr Training Courses (Itc)Document5 paginiIcorr Certification Scheme: Icorr Training Courses (Itc)sheikbbaÎncă nu există evaluări

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 paginăFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 paginăFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- API 571 Comparison Sheet API 570Document3 paginiAPI 571 Comparison Sheet API 570HARDIK PATELÎncă nu există evaluări

- R P RP O501 E W P S: Ecommended RacticeDocument43 paginiR P RP O501 E W P S: Ecommended RacticeSaqib AliÎncă nu există evaluări

- FBE Coating PDFDocument12 paginiFBE Coating PDFthadikkaran100% (1)

- PD19-25 Norsok-M-503-Ed-2007cathodic-ProtectionDocument16 paginiPD19-25 Norsok-M-503-Ed-2007cathodic-ProtectionSonya Mamani ChambiÎncă nu există evaluări

- Welding Defect - MACRO PDFDocument5 paginiWelding Defect - MACRO PDFAnonymous 4e7GNjzGWÎncă nu există evaluări

- Materials SelectionDocument1 paginăMaterials SelectionAnonymous P9TMWcGÎncă nu există evaluări

- SKTCO ISO 9001 2008 Gap Analysis ChecklistDocument17 paginiSKTCO ISO 9001 2008 Gap Analysis ChecklistAnonymous 4e7GNjzGWÎncă nu există evaluări

- Durapol UHT (Spray Grade) - 2014 PDFDocument2 paginiDurapol UHT (Spray Grade) - 2014 PDFEngTamerÎncă nu există evaluări

- 07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementDocument8 pagini07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementSamuel JohnÎncă nu există evaluări

- FloatingDocument12 paginiFloatingrobson2015Încă nu există evaluări

- Garnet SpecificationDocument2 paginiGarnet SpecificationskÎncă nu există evaluări

- Keyword For API 580 PDFDocument9 paginiKeyword For API 580 PDFRaymundo ACÎncă nu există evaluări

- Meccoct18 12573Document9 paginiMeccoct18 12573Malik Ansar HayatÎncă nu există evaluări

- PPL Su 2005 PDFDocument11 paginiPPL Su 2005 PDFresp-ect100% (1)

- Study of Corrosion Behavior and Mechanism of Carbon Steel in The Presence of Chlorella VulgarisDocument11 paginiStudy of Corrosion Behavior and Mechanism of Carbon Steel in The Presence of Chlorella VulgarisAnh Quang PoÎncă nu există evaluări

- History Thermal SprayingDocument5 paginiHistory Thermal Sprayingmaverick_cvc100% (1)

- Publication - Painting, Coating & Corrosion Protection - Alfsen Og Gunderson - Dehumidifiers For The Oil and Gas ApplicationsDocument4 paginiPublication - Painting, Coating & Corrosion Protection - Alfsen Og Gunderson - Dehumidifiers For The Oil and Gas Applicationszinha_alÎncă nu există evaluări

- Publication - Painting, Coating & Corrosion Protection - Aremco Inc - High Temperature Materials - Coatings and AdhesivesDocument56 paginiPublication - Painting, Coating & Corrosion Protection - Aremco Inc - High Temperature Materials - Coatings and Adhesiveszinha_alÎncă nu există evaluări

- QCF316 Cold Insulation Inspection Report For Vessel / MachineryDocument1 paginăQCF316 Cold Insulation Inspection Report For Vessel / MachineryminhnnÎncă nu există evaluări

- Cosasco RBS - Rbsa Retriever MaintenanceDocument44 paginiCosasco RBS - Rbsa Retriever MaintenanceSeip SEIPÎncă nu există evaluări

- Fire Proofing QtyDocument1 paginăFire Proofing QtyMidhun K ChandraboseÎncă nu există evaluări

- BS 7910:2013 in Brief: International Journal of Pressure Vessels and Piping July 2018Document12 paginiBS 7910:2013 in Brief: International Journal of Pressure Vessels and Piping July 2018Arnab DebÎncă nu există evaluări

- Cathodic Protection TechnologistDocument1 paginăCathodic Protection TechnologistBaharin HashimÎncă nu există evaluări

- Clad and Lined Pipe Specification: Company SpecificationsDocument59 paginiClad and Lined Pipe Specification: Company SpecificationsrachedÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 paginiSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan MohammadÎncă nu există evaluări

- Corrosion Loop - Wikipedia PDFDocument10 paginiCorrosion Loop - Wikipedia PDFEndhy Wisnu NovindraÎncă nu există evaluări

- Material Selection Tutorial 1Document16 paginiMaterial Selection Tutorial 1hschoi12Încă nu există evaluări

- Corrosion Application Library ManualDocument230 paginiCorrosion Application Library ManualMiguel Angel Holguin MontañoÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 MechDocument2 paginiSaudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 Mechpookkoya thangalÎncă nu există evaluări

- RC 17015Document4 paginiRC 17015Shubham MoreÎncă nu există evaluări

- 06189G FrontmatterDocument11 pagini06189G FrontmatterEd Marti100% (1)

- NACE International Publication 31215 - 2014Document17 paginiNACE International Publication 31215 - 2014Mohammed ArnawootyÎncă nu există evaluări

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pagini8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Ut PittingDocument7 paginiUt PittingmmÎncă nu există evaluări

- KOC-P-004 Part 4Document38 paginiKOC-P-004 Part 4Hari KrishnanÎncă nu există evaluări

- 3PS Gaw 008Document14 pagini3PS Gaw 008ravi00098100% (1)

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pagini8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- GRP Pipe Case History - Revised Shoiaba Eng Large DiaDocument4 paginiGRP Pipe Case History - Revised Shoiaba Eng Large DiaA.Subin DasÎncă nu există evaluări

- An Electrochemical Study of Cathodic Protection of Steel Used For Marine StructuresDocument6 paginiAn Electrochemical Study of Cathodic Protection of Steel Used For Marine StructureshamidÎncă nu există evaluări

- Deep Anode SystemsDocument26 paginiDeep Anode Systemsaliyildizx17730Încă nu există evaluări

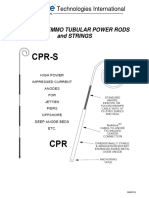

- Tubular Vent BinderDocument12 paginiTubular Vent BinderbayuÎncă nu există evaluări

- Delta FerriteDocument4 paginiDelta FerriteRavindra ErabattiÎncă nu există evaluări

- Datasheet Briosil Primer 6-7360P - Eng - 25-08-11Document3 paginiDatasheet Briosil Primer 6-7360P - Eng - 25-08-11SUBODHÎncă nu există evaluări

- 7T04-CS-00-TS-018 R01 Project Specificationfor Cleaning Reequirements For Piping SystemsDocument9 pagini7T04-CS-00-TS-018 R01 Project Specificationfor Cleaning Reequirements For Piping Systemsel_sharkawy2011100% (1)

- I HRSGDocument7 paginiI HRSGJayanath Nuwan SameeraÎncă nu există evaluări

- Potential Damage PKTDocument7 paginiPotential Damage PKTFebri Ramdani NugrahaÎncă nu există evaluări

- API 510 PC 5mar05 Case Study 2 Thickness CalculationsDocument3 paginiAPI 510 PC 5mar05 Case Study 2 Thickness CalculationsSameh AminÎncă nu există evaluări

- NewbuildingUniversalPrimers WhitePaperDocument4 paginiNewbuildingUniversalPrimers WhitePapermkccm100% (1)

- Durapol Coating For Amines EtcDocument2 paginiDurapol Coating For Amines EtckermadaxÎncă nu există evaluări

- Ses-Pgb-Co-Itp-0058 Itp For HRSG SystemDocument4 paginiSes-Pgb-Co-Itp-0058 Itp For HRSG SystemzhangÎncă nu există evaluări

- 1-Pit To Crack Transition and Corrosion Fatigue Lifetime Reduction Estimations by Means of A Short Crack Microstrutural ModelDocument12 pagini1-Pit To Crack Transition and Corrosion Fatigue Lifetime Reduction Estimations by Means of A Short Crack Microstrutural ModelGilmar Menegotto100% (1)

- Risk Based Inspection A Complete Guide - 2020 EditionDe la EverandRisk Based Inspection A Complete Guide - 2020 EditionÎncă nu există evaluări

- SAIC-B-2003 Rev 2Document2 paginiSAIC-B-2003 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- Name Name Name Name: To: CCDocument1 paginăName Name Name Name: To: CCAnonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 paginiSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 paginăSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWÎncă nu există evaluări

- Warrior Tech Spare Parts List 2Document1 paginăWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWÎncă nu există evaluări

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 paginiShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWÎncă nu există evaluări

- Weld Joint Preparation Weld Joint PreparationDocument1 paginăWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWÎncă nu există evaluări

- Bio Data-01.07.13Document2 paginiBio Data-01.07.13Anonymous 4e7GNjzGWÎncă nu există evaluări

- Numbering Format: Project DocumentationDocument1 paginăNumbering Format: Project DocumentationAnonymous 4e7GNjzGWÎncă nu există evaluări

- Notes-Api Exams-Prathap DhasDocument7 paginiNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWÎncă nu există evaluări

- Request For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionDocument2 paginiRequest For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionAnonymous 4e7GNjzGWÎncă nu există evaluări

- QW484Document1 paginăQW484Anonymous 4e7GNjzGWÎncă nu există evaluări

- HSMC Employee Induction Procedure (Offices)Document3 paginiHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWÎncă nu există evaluări

- AEtrium-2 Brochure V7 PDFDocument4 paginiAEtrium-2 Brochure V7 PDFThomas DylanÎncă nu există evaluări

- SigmazincDocument8 paginiSigmazincHaresh BhavnaniÎncă nu există evaluări

- DNA-protein Interactions: Methods For Detection and AnalysisDocument31 paginiDNA-protein Interactions: Methods For Detection and AnalysisAhsan Arshad BSIT-F16-LC-008Încă nu există evaluări

- Proposed OS&E Requirement - Measuring Ozone DosageDocument3 paginiProposed OS&E Requirement - Measuring Ozone DosageProteina QuitinaseÎncă nu există evaluări

- Protein Characterization/Purification: Dr. Kevin AhernDocument34 paginiProtein Characterization/Purification: Dr. Kevin AhernkelpachurpaÎncă nu există evaluări

- Determination of Contents in Cold DrinksDocument12 paginiDetermination of Contents in Cold DrinksMayank AggarwalÎncă nu există evaluări

- Effect of Flake Ice On Concrete CoolingDocument1 paginăEffect of Flake Ice On Concrete CoolingGianni TogniÎncă nu există evaluări

- Zhang 2022Document10 paginiZhang 2022Statistics LearningÎncă nu există evaluări

- Finals ReviewerDocument5 paginiFinals ReviewerARIAR, Jyllianne Kyla C.Încă nu există evaluări

- Dielectric Strength of Transformer OilDocument2 paginiDielectric Strength of Transformer OilAnil VarriÎncă nu există evaluări

- Experiments 11 15 NotesDocument16 paginiExperiments 11 15 Notesforisko05Încă nu există evaluări

- Project Report Final-1Document33 paginiProject Report Final-1Sahil ChelatÎncă nu există evaluări

- Rev004Document3 paginiRev004Issam LahlouÎncă nu există evaluări

- 11 Iajps11072017Document7 pagini11 Iajps11072017Baru Chandrasekhar RaoÎncă nu există evaluări

- Experilab Breinwave: Bubble BlowersDocument4 paginiExperilab Breinwave: Bubble BlowersHirenkumarÎncă nu există evaluări

- Isensee Robert W1943Document17 paginiIsensee Robert W1943DŨNG VŨ NGUYỄN TUẤNÎncă nu există evaluări

- WasherDocument80 paginiWasherbugdapugÎncă nu există evaluări

- Panchakanya Structural SteelDocument5 paginiPanchakanya Structural Steelkabira12Încă nu există evaluări

- Metals From Ores: An Introduction: CRI SONDocument8 paginiMetals From Ores: An Introduction: CRI SONSaumya Subhra NandiÎncă nu există evaluări

- Fast Blue BDocument1 paginăFast Blue BAchuthanand MukundanÎncă nu există evaluări

- GATE-2018 - Mechanical Engineering Online Test Series ENGINEERING THERMODYNAMICSDocument10 paginiGATE-2018 - Mechanical Engineering Online Test Series ENGINEERING THERMODYNAMICSDebashis NayakÎncă nu există evaluări

- Heat Capacity of Sodium Silicate Liquids: Pascal RichetDocument3 paginiHeat Capacity of Sodium Silicate Liquids: Pascal RichetDaniel SetyadiÎncă nu există evaluări

- Product Information: Synpower™ Motor Oil Sae 5W-40Document2 paginiProduct Information: Synpower™ Motor Oil Sae 5W-40Iulia DanaÎncă nu există evaluări

- 3G Metric A4 Overview PDFDocument8 pagini3G Metric A4 Overview PDFDiadam SharmaÎncă nu există evaluări

- GPRSDocument6 paginiGPRSRoberto CapchaÎncă nu există evaluări