Documente Academic

Documente Profesional

Documente Cultură

Fs 9006

Încărcat de

aiabbasi9615Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fs 9006

Încărcat de

aiabbasi9615Drepturi de autor:

Formate disponibile

g

Reuter-Stokes

-------------------------------------

FLAME TRACKER

SiC TWO WIRE FLAME SENSOR (4 - 20 mA)

OPERATION AND MAINTENANCE

MANUAL

MODEL RS-FS-9006 - GE 07482SOCNL44819P01

GE/REUTER-STOKES

8499 Darrow Rd.

Twinsburg, OH 44087

(330) 425-3755

FS-9006O&M

July 22, 2003

REV. A

Reuter-Stokes

------------------------------------ATTENTION

The FS-9006 Flame Tracker sensor complies with the following standards:

ETL and ETL Canada listed for Class I, Division 2, Groups A, B, C, and D, normally

non-arcing components. Control number 9900287

Conforms to UL standard 1604

Certified to CAN/CSA standard C22.2 No. 213

ATEX

II 3 G EEx nL IIC T3 , self protected energy limited apparatus.

CE Mark

EN 61000-4-1 - EMC basic immunity test

EN 61000-4-4 - EMC transient/burst immunity

EN 50140 - EMC radiated immunity

EN 50141 - EMC conducted immunity

GE Aircraft Engine Specification M50TF 1828 CL-B

The FS-9006 Flame Sensor is classified as non-incendive. The Flame Sensor is grounded

through the cable. The green wire must be grounded at the conduit junction box. All wiring is to

be in grounded conduit.

WARNING

Do not disconnect connector while circuit is energized (or live), unless area is known to be nonhazardous.

Certifications are based on the use of approved cables only. Currently available approved cables

are GE Reuter-Stokes RS-E2-0279 and GE 362A1053.

Do not attempt to disassemble the sensor. Sensor are not repairable. Breaching the seal of the

sensor will cause lose of the inert fill gas and render the sensor unusable.

Do not remove the sensor by wrenching on the body. Always use the 1 3/8 inch mounting nut.

Wrenching on the body may breach the seal. Breaching the seal of the sensor will cause lose of

the inert fill gas and render the sensor unusable.

CAUTION

The operating temperature range of the Flame Sensor is -30C to 150C. The operating

temperature range of the cable is -20C to 260C. Do not attempt to work on the Flame Sensor

or the cable until they have cooled to a safe handling temperature.

Reuter-Stokes

------------------------------------TABLE OF CONTENTS

SECTION 1.0 - Introduction..........................................................................................3

1.1 - Specifications.................................................................................3

Non-incendive wiring diagram. .................................................6

Sensor drawing...........................................................................7

1.2 - General Description.......................................................................8

SECTION 2.0 - Sensor ..................................................................................................8

SECTION 3.0 - Installation .........................................................................................10

3.1 - Mechanical...................................................................................10

3.2 - Electrical......................................................................................12

3.3 - Sensor checkout...........................................................................13

3.4 - Controller setup ...........................................................................14

SECTION 4.0 - Maintenance.......................................................................................14

SECTION 5.0 - Troubleshooting.................................................................................14

Reuter-Stokes

------------------------------------FLAME TRACKER

SiC TWO WIRE FLAME SENSOR SYSTEM

OPERATION AND MAINTENANCE MANUAL

1.0

INTRODUCTION

1.1

SPECIFICATIONS

Flame Tracker -RS-FS-9006

Mechanical

Body Mount:

AISI316 Stainless Steel

Housing:

AISI304 Stainless Steel (sealed and Argon filled)

Connector

Process:

3/4 NPT female

Electrical:

MIL-C-38999 Series III size 15 (5 pin)

Sensor:

Silicon Carbide photodiode

Window:

Sapphire

Operating

Sensitivity:

>5 mA @ 1x1010 photons/in2/sec. @ 310 nm

Output:

4 - 20 mA dc, Max < 21 mA

Response Time:

<25 milliseconds

Power Requirements:

12 - 30 vdc @ 100 mA

Temperature Range

(ambient):

-40F to 302F (-40C to 150C)

Temperature at mount:

800F (427C) Max.

Relative Humidity

100%

Process Pressure

400 psig (2.8 Mpa)

Vibration

0.1 inches DA 10 40 Hz

8 G continuous 40 2000 Hz

14 G Peak

455F (235C) with specified air cooling

Reuter-Stokes

------------------------------------Certifications

ETL and ETL Canada listed for Class I, Division 2, Groups A, B, C and D

normally non-arcing components. Control number 9900287

Conforms to UL Standard 1604

Certified to CAN/CSA (Canadian Standards) C22.2 No. 213

ATEX

II 3 G EEx nL IIC T3 , self protected energy limited apparatus.

CE Mark

EN 61000-4-1 - EMC basic immunity test

EN 61000-4-4 - EMC transient/burst immunity

EN 50140 - EMC radiated immunity

EN 50141 - EMC conducted immunity

REUTER-STOKES

TWINSBURG, OH 44087

UV FLAME SENSOR

07482SOCNL44819P01

24911-RS-FS-9006

SERIAL NUMBER

II 3 G

EEx nL IIC T3

ITS03 ATEX 41271X

990028

Class I, Div. 2, Gps. A, B, C & D T3

-30C Ta 150C

30V

25mA MAX

See instructions FS-9006O&M

First two digits of the serial number indicate year of manufacture.

i.e. 03 = 2003

Reuter-Stokes

------------------------------------INTERCONNECTING CABLE RS-E2-0279 OR 07482SOCNL44820

Mechanical

Wire:

18 gauge (1.02 mm), 19 strand nickel plated copper

Insulation:

Teflon PFA

Shield:

36 gauge (0.127 mm) nickel plated copper braid

Armor:

Stainless steel braid flexible conduit

Connector:

MIL-C-38999 series III, shell size 15, 5 #16 pins

(only 3 pins are used)

Color code

Signal:

Red Positive, Black Negative

Ground:

Green or Orange

Operating

Voltage (max):

300 vrms

Temperature (max):

500F (260C)

Reuter-Stokes

-------------------------------------

Reuter-Stokes

-------------------------------------

Reuter-Stokes

-------------------------------------

1.2

GENERAL DESCRIPTION

On Liquid Dry Low Nox Applications as well as those applications with

significant levels of water and steam injection, the ultra-violet light sensed by the

Geiger Mueller tube based flame detectors is absorbed by the fog of fuel, steam or

water. GEs research center invented a silicon carbide (SiC) photodiode which is

significantly more sensitive to the longer wavelength components of the UV light

generated by the flame. This longer wavelength light does penetrate the fog of oil

quite well and therefore the SiC based sensor is significantly more sensitive to the

presence of flame. A flame sensor utilizing the SiC photodiode is being produced

by GE Reuter Stokes, and has been successfully operated on a number of GE gas

turbine installations.

2.0

SENSOR

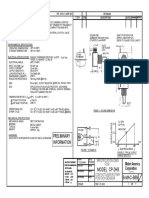

Figure 1 is a block diagram of the SiC Flame Sensor. The sensor has a sapphire

window that is transparent to UV light and can withstand the compressor

discharge temperature and pressure. It has a lens inside that focuses the light on a

silicon carbide photodiode in a sealed package. The photodiode is wired to a

MOSFET input amplifier. The amplifier has a high initial gain, which

automatically shifts to a lower gain in order to accommodate a wide range of input

light level without saturating. The sensor regulates the supply current in

proportion to the amount of UV light present. Both power and signal are

transmitted on the same two wires. The sensor can be powered from a dc voltage

between 12 and 30 volts. The whole transducer is sealed and filled with dry

argon.

Reuter-Stokes

-------------------------------------

FIGURE 1 SiC FLAME SENSOR WIRING DIAGRAM

Reuter-Stokes

------------------------------------3.0

INSTALLATION

3.1

MECHANICAL

The maximum operating temperature for the flame sensor is 302 F (150 C). If

the peak operating temperature at the location of the sensor exceeds this then

cooling will be required. There are two methods available for cooling. These are

air cooling with ambient air, and air cooling with pressurized air.

Air cooling with ambient air can be used in installations were the enclosure is

cooled with forced air. This would be typical of LM2500 and LM6000 aircraft

engine applications. The air velocity at the sensor must be 5 ft/sec (1.5 m/sec), or

greater, at a temperature of 50 F (10 C), or less, above outside ambient. Under

these conditions the sensors will operate at outside ambient temperatures up to

140 F (60 C).

Air cooling with pressurized air requires the use of air cooling can GEAE Part

Number 07482SOCNL44821P01. The air-cooing can is installed as shown in the

following drawing. The air-cooling can requires 25 psi (170 kPa) minimum at

120 F (49 C) maximum. Under these conditions the sensors will operate at

ambient temperatures up to 302 F (150 C)

Do not complete step 2 of the following instructions at this time. Leave the

sensors installed hand tight until after the sensor checkout described in Section

3.3.

10

Reuter-Stokes

-------------------------------------

11

Reuter-Stokes

-------------------------------------

3.2

ELECTRICAL

The sensors are connected to the turbine junction box with a connector cable as

specified in Section 1.1. All wiring must be in grounded conduit or armored. The

green wire must be connected to earth ground at the junction box. Do not connect

the shields over the twisted pair signal leads to each other or to earth ground at

any location. The inner shields should be individually jumpered through all

junction boxes and connected to the proper ground terminal at the Controller. The

polarity of the cable is: red wire is positive and black wire is negative. The

polarity is shown in the drawings. Reverse polarity will not damage the sensor.

Signal cable from the junction box to the Controller should be 18 gauge (1.02

mm) twisted shielded pair. The extension cable from the junction box to the

Controller is the customers responsibility.

FIGURE 2 - MAXIMUM RESISTANCE VS. OPERATING VOLTAGE

900

800

700

600

500

400

300

200

100

0

12

14

16

18

20

22

24

OPERATING VOLTAGE

12

26

28

30

32

Reuter-Stokes

-------------------------------------

The Flame Tracker is connected to the controller as a typical two wire current

transmitter. It can be operated from any well-filtered dc supply from 12 volts to

30 volts. The supply should be capable of supplying 100 milliamps. The power

supply must be protected to prevent the supply voltage from exceeding 30 volts in

normal use and more than 42 volts under transient conditions. The sensor is

protected against reverse polarity. The maximum value for the sense resistor plus

the wire resistance is dependent on the supply voltage. At 24 volts this value is

560 ohms. Resistance values for other voltages can be determined from the chart

in Figure 2.

Drawing FS-9001-NWD on Page 6 shows the preferred wiring for the sensor with

the Rsense of the controller in the return line of the sensor. This configuration can

be used with controllers that have single ended inputs (one side of the input

grounded) or differential inputs (neither side of the input grounded).

3.3

SENSOR CHECKOUT

Disconnect the sensors and unscrew them from the turbine. Plug the sensor cables

back in to each of the sensors. Apply power to the sensors. Check the current

values at the controller for each of the sensors. The sensors are sensitive to light,

and may have some reading, depending on the ambient light level. Test each

sensor by covering the port to see zero flame intensity signal, and with a flashlight

or flame to see a positive reading. With no light the reading should be 3.70 to 3.95

milliamps, while with a good flashlight the reading should be above 8 milliamps.

If a sensor is outside these rough check limits see Section 5.0.

Disconnect the sensor cables, and reinstall the sensors according to the instruction

in Section 3.1. At this time step 2 of Section 3.1 should be completed and the

sensor cables reconnected. Make sure that the sapphire window is clean; if it

needs cleaning, do this according to the maintenance instructions in Section 4.0.

Check that all sensors are reading less than 4.00 milliamps.

13

Reuter-Stokes

-------------------------------------

3.4

CONTROLLER SETUP

The Flame Sensor provides a minimum output of 5 milliamps when exposed to the

minimum flame intensity specified in GE specification number 362A1052. The set point

for flame off should be set to 6.25% which is equal to 5 milliamps. The set point for

flame on should be 10% of full scale, which equals 5.6 milliamps. If the intensity levels

are to low for these settings their may be other problems. Low intensity levels may be a

sign of other problems. Refer to Section 5.0 - Troubleshooting.

4.0

MAINTENANCE

WARNING

Do not disconnect connector while circuit is energized (or live), unless area is known to

be non-hazardous.

CAUTION

The operating temperature range of the Flame Sensor is -30C to 150C. The operating

temperature range of the cable is -20C to 260C. Do not attempt to work on the Flame

Sensor or the cable until they have cooled to a safe handling temperature.

The Flame Sensor output will deteriorate as the lens becomes dirty. It is recommended,

when initially installed, that the signal level be recorded during normal operation. During

subsequent running, the signal level should be compared with the initial values. If a

significant reduction in the signal level is noticed, then it is recommended that the lens be

cleaned at the next opportunity (with the turbine shut down and cold). Clean the lens with

isopropyl alcohol or other residue free solvent compatible with Sapphire. In order to

reduce the risk of galling, an anti seize compound should be applied to the mounting

thread prior to reinstallation of the sensor.

5.0

TROUBLESHOOTING

WARNING

Do not disconnect connector while circuit is energized (or live), unless area is known to

be non-hazardous.

14

Reuter-Stokes

------------------------------------CAUTION

The operating temperature range of the Flame Sensor is -30C to 150C. The operating

temperature range of the cable is -20C to 260C. Do not attempt to work on the Flame

Sensor or the cable until they have cooled to a safe handling temperature.

PROBLEM

CAUSE

SOLUTION

No current flows

Low sensitivity during

checkout or operation

Low flame intensity signal

during operation

Reversed polarity

Dirty lens

Grounded cable

Misalignment of the sensor

mount

Change polarity

Clean lens (Section 4.0)

Check cable for grounds

Check the squareness of all

flanges and pipes of the

sensor mount. Verify that

the senor has a clear view of

the flame.

Look for washers, or valves

that may restrict the diameter

of the sight tube.

Over cooling can cause

moisture to condense on the

lens and reduce the signal.

Reduce the cooling until the

condensation clears up and

the signal returns to normal.

Obstructions in the line of

sight

Condensation on the lens

15

S-ar putea să vă placă și

- SAP-1 Simple As Possible Computer Schematic DiagramDocument1 paginăSAP-1 Simple As Possible Computer Schematic Diagrampong74ls100% (5)

- DTV2760CDocument57 paginiDTV2760Cplasmapete100% (1)

- Fanlite ManualDocument29 paginiFanlite ManualMark NallickÎncă nu există evaluări

- Man Turbo THM Gas TurbineDocument51 paginiMan Turbo THM Gas Turbineaiabbasi9615100% (1)

- 173089Document22 pagini173089aiabbasi9615100% (1)

- MW20FP1Document103 paginiMW20FP1scotnelsonÎncă nu există evaluări

- FlexEJ Brochure 10 2011Document86 paginiFlexEJ Brochure 10 2011harlyganÎncă nu există evaluări

- TCR-2511 Product Datasheet enDocument3 paginiTCR-2511 Product Datasheet enNorberto NetoÎncă nu există evaluări

- Sony HCD-CP100 PDFDocument50 paginiSony HCD-CP100 PDFvideosonÎncă nu există evaluări

- Led TV: ServiceDocument106 paginiLed TV: ServiceSamuel Lopes100% (1)

- 15 - Pressure Relay For OLTC - (AKM - 35600 - Qualitrol)Document5 pagini15 - Pressure Relay For OLTC - (AKM - 35600 - Qualitrol)Trần Minh TríÎncă nu există evaluări

- DS Ycs-230v 2.0Document4 paginiDS Ycs-230v 2.0Bogdan AmarieiÎncă nu există evaluări

- Manual Service Tektronix 2712Document692 paginiManual Service Tektronix 2712TECSISCOM100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Responsibility Matrix - V00Document7 paginiResponsibility Matrix - V00Huseyin Sengul100% (1)

- Motors and Drives A Practical Technology Guide Dave PolkaDocument387 paginiMotors and Drives A Practical Technology Guide Dave Polkamurad6a9100% (9)

- TSR DatasheetDocument4 paginiTSR DatasheetJesus N RodriguezÎncă nu există evaluări

- Inet Scu1284 1280 1200 A4Document4 paginiInet Scu1284 1280 1200 A4Mihai ConstantinescuÎncă nu există evaluări

- NetzteilUser ManualDocument4 paginiNetzteilUser ManualErick IñiguezÎncă nu există evaluări

- UE3003 Instruction ManualDocument8 paginiUE3003 Instruction ManualAngelus Vincent Guilalas100% (1)

- LEC1Document17 paginiLEC1christophermrequintoÎncă nu există evaluări

- At 120Document19 paginiAt 120khcheungÎncă nu există evaluări

- ESM740G TiristorDocument2 paginiESM740G Tiristorjosenicolas12000Încă nu există evaluări

- Opa381 PDFDocument19 paginiOpa381 PDFVictoria Guerrero100% (1)

- BLDC 5015aDocument5 paginiBLDC 5015aroozbehxoxÎncă nu există evaluări

- 34100Document10 pagini34100Fahrul Songgolangit MangkubumiÎncă nu există evaluări

- MassflowmetersandcontrollersDocument19 paginiMassflowmetersandcontrollersMilectron Ion100% (1)

- Catalog Perry 2010 EngDocument120 paginiCatalog Perry 2010 Engl_dumitruÎncă nu există evaluări

- TBoxLITE Installation ManualDocument7 paginiTBoxLITE Installation ManualbrettmayÎncă nu există evaluări

- CERAVAC Transmitter: Operating Manual 17200257 - 002 - 02Document32 paginiCERAVAC Transmitter: Operating Manual 17200257 - 002 - 02mayito12093120Încă nu există evaluări

- Gas Detection Combi Mate PDFDocument2 paginiGas Detection Combi Mate PDFamirouche15Încă nu există evaluări

- Me2 O2Document3 paginiMe2 O2Amirsyah PsÎncă nu există evaluări

- Uk048e New Range LediDocument16 paginiUk048e New Range LediSayed HashemÎncă nu există evaluări

- Rubber Insulated Cable NSSHÖU Acc. To VDE 0250 T. 812Document2 paginiRubber Insulated Cable NSSHÖU Acc. To VDE 0250 T. 812corsini999Încă nu există evaluări

- General Purpose NPN Transistor Array Applications: FN483.6 Data Sheet December 15, 2011Document7 paginiGeneral Purpose NPN Transistor Array Applications: FN483.6 Data Sheet December 15, 2011Leidy Ferro100% (1)

- Lc-32le350m enDocument70 paginiLc-32le350m encandraÎncă nu există evaluări

- Sensor de CorrenteDocument3 paginiSensor de Correntejcarlos710Încă nu există evaluări

- LM3174Document8 paginiLM3174batka1Încă nu există evaluări

- DNR Duct Detector Installation DetailsDocument6 paginiDNR Duct Detector Installation DetailsBinu SulochananÎncă nu există evaluări

- Metal Detector BrochureDocument7 paginiMetal Detector Brochurenedim986Încă nu există evaluări

- Lnlet ValveDocument9 paginiLnlet ValveZewduErkyhunÎncă nu există evaluări

- Emerson Lc320em8Document66 paginiEmerson Lc320em8Edilberto Avila100% (1)

- Panasonic TX-25lk1p TX-28lk1p Chassis z8Document22 paginiPanasonic TX-25lk1p TX-28lk1p Chassis z8drrebyÎncă nu există evaluări

- 2712 Service PDFDocument692 pagini2712 Service PDFsimionovski100% (1)

- LG 50pt250na-Pd13kDocument72 paginiLG 50pt250na-Pd13kCarlos AzañedoÎncă nu există evaluări

- KX-TDA0174XJ KX-TDA0174X: 16port Single Line Telephone Extension CardDocument55 paginiKX-TDA0174XJ KX-TDA0174X: 16port Single Line Telephone Extension Cardjuanka_ing_2010Încă nu există evaluări

- PTC ReissmannDocument8 paginiPTC ReissmannAndré Carlos CorenzanÎncă nu există evaluări

- Level Monitor DATUM SCU500 LOOPDocument20 paginiLevel Monitor DATUM SCU500 LOOPJose Manuel Vazquez ZarcoÎncă nu există evaluări

- Fuente Goldstar PDFDocument11 paginiFuente Goldstar PDFdirectÎncă nu există evaluări

- Parts List 4" Model T-18 and T-27 Mark II Turbo-MeterDocument6 paginiParts List 4" Model T-18 and T-27 Mark II Turbo-MeterAnonymous OOZw87rg5Încă nu există evaluări

- Dokumentation Energoutil 2015-35370 - enDocument37 paginiDokumentation Energoutil 2015-35370 - enbrctlnÎncă nu există evaluări

- Magnecraft RelaysDocument210 paginiMagnecraft RelaysMohamed ElsayedÎncă nu există evaluări

- Upc-838 Plasma CutterDocument5 paginiUpc-838 Plasma Cutteramirouche15Încă nu există evaluări

- GT30 ManualDocument83 paginiGT30 ManualJerry ReddenÎncă nu există evaluări

- Samsung173Pplus ServiceManualDocument64 paginiSamsung173Pplus ServiceManualcheongiÎncă nu există evaluări

- Chroma 23291 User ManualDocument162 paginiChroma 23291 User ManualChristo PherlambertÎncă nu există evaluări

- PMM 8030 User ManualDocument48 paginiPMM 8030 User ManualMarco Vinicio BazzottiÎncă nu există evaluări

- Toyocom Cristal OscillatorsDocument58 paginiToyocom Cristal Oscillatorsb33g33100% (1)

- SwitzerDocument4 paginiSwitzerJove MultisystemsÎncă nu există evaluări

- Fs 9001Document16 paginiFs 9001Mauricio GuanellaÎncă nu există evaluări

- fs9001 PDFDocument16 paginifs9001 PDFforoÎncă nu există evaluări

- Rs-fs-9001 GT Flame SensorDocument18 paginiRs-fs-9001 GT Flame Sensorzakarianoui35Încă nu există evaluări

- D D D D D D: Description/ordering InformationDocument12 paginiD D D D D D: Description/ordering InformationRao FarhanÎncă nu există evaluări

- D D D D D D: Description/ordering InformationDocument12 paginiD D D D D D: Description/ordering InformationNavleen NaviÎncă nu există evaluări

- Variable Area Flow Meter Data Sheet mt3750 enDocument16 paginiVariable Area Flow Meter Data Sheet mt3750 enaiabbasi9615Încă nu există evaluări

- MarkVie SIS Evaulation ExidaDocument31 paginiMarkVie SIS Evaulation Exidaaiabbasi9615Încă nu există evaluări

- CPPA Annual Report - pdf-180305214924155Document96 paginiCPPA Annual Report - pdf-180305214924155aiabbasi9615Încă nu există evaluări

- CM A&F Mod 0 V13 - 1 - 0Document10 paginiCM A&F Mod 0 V13 - 1 - 0aiabbasi9615Încă nu există evaluări

- Afghanistan - Alternative Futures and Their Implications: Brigadier Naveed Mukhtar Pakistan ArmyDocument38 paginiAfghanistan - Alternative Futures and Their Implications: Brigadier Naveed Mukhtar Pakistan Armyaiabbasi9615Încă nu există evaluări

- 002 - ManualC - G - 47-50 - ING Rev.2 20.10.11Document13 pagini002 - ManualC - G - 47-50 - ING Rev.2 20.10.11aiabbasi9615Încă nu există evaluări

- 173295Document3 pagini173295aiabbasi9615Încă nu există evaluări

- 173400Document211 pagini173400aiabbasi9615Încă nu există evaluări

- FSLDMDocument5 paginiFSLDMaiabbasi9615Încă nu există evaluări

- Scofield Bldg. Addition Project Manual (503-6925), 2011-09-0Document903 paginiScofield Bldg. Addition Project Manual (503-6925), 2011-09-0aiabbasi9615Încă nu există evaluări

- Adm1000 035264Document8 paginiAdm1000 035264aiabbasi9615Încă nu există evaluări

- High Performance FSK/ASK Transceiver IC: Data SheetDocument45 paginiHigh Performance FSK/ASK Transceiver IC: Data Sheetআশিক পালোয়ানÎncă nu există evaluări

- Lecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorDocument5 paginiLecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorZ_JahangeerÎncă nu există evaluări

- Grade Thresholds - November 2022: Cambridge International AS & A Level Biology (9700)Document2 paginiGrade Thresholds - November 2022: Cambridge International AS & A Level Biology (9700)arhamrafique42Încă nu există evaluări

- Signal TransmissionDocument25 paginiSignal TransmissionKumbati SupertiksÎncă nu există evaluări

- Sensor Smarteye Spb-InstructionsDocument8 paginiSensor Smarteye Spb-InstructionsGerardo Espinosa EspinosaÎncă nu există evaluări

- Multiplexers and DemultiplexersDocument10 paginiMultiplexers and Demultiplexersamury kgÎncă nu există evaluări

- Sifian Ben Khalifa - ErDocument6 paginiSifian Ben Khalifa - ErSofian Ben KhalifaÎncă nu există evaluări

- FAN6921MR Integrated Critical Mode PFC and Quasi-Resonant Current Mode PWM ControllerDocument25 paginiFAN6921MR Integrated Critical Mode PFC and Quasi-Resonant Current Mode PWM ControllereduardskÎncă nu există evaluări

- Project ReportDocument50 paginiProject ReportHassaan ChÎncă nu există evaluări

- Study of Commercial RTOSDocument16 paginiStudy of Commercial RTOSnespijorziÎncă nu există evaluări

- TH D74ae IdmDocument64 paginiTH D74ae Idmudal64Încă nu există evaluări

- General System ArchitectureDocument28 paginiGeneral System ArchitectureroshsaumÎncă nu există evaluări

- Lab Manual: Electric Circuit Analysis I EEE-121Document22 paginiLab Manual: Electric Circuit Analysis I EEE-121earn moneyÎncă nu există evaluări

- JSPL Line-2 Erection BOMDocument11 paginiJSPL Line-2 Erection BOMRakesh Karan SinghÎncă nu există evaluări

- SM-A730F DS SVC Guide - F PDFDocument27 paginiSM-A730F DS SVC Guide - F PDFsafi alsafiÎncă nu există evaluări

- John Sheliak TWZ FormalizationDocument49 paginiJohn Sheliak TWZ Formalizationgalaxy5111Încă nu există evaluări

- HVDCDocument20 paginiHVDCChloé Sid FILLEURÎncă nu există evaluări

- Preliminary Information: B-MAC-B69 Model Cp-2HbDocument1 paginăPreliminary Information: B-MAC-B69 Model Cp-2HbCykhong KhongÎncă nu există evaluări

- Models - Acdc.helmholtz CoilDocument14 paginiModels - Acdc.helmholtz CoilAlvaro RivasÎncă nu există evaluări

- Lab-8 BPSK Modulation and DemodulationDocument11 paginiLab-8 BPSK Modulation and DemodulationNima Vahidian BaraniÎncă nu există evaluări

- Example Settings For Applying The SEL-487B To A Six-Breaker BusDocument24 paginiExample Settings For Applying The SEL-487B To A Six-Breaker Busu2andresÎncă nu există evaluări

- Traction Control of Electric Vehicle Based On The Estimation of Road Surface ConditionDocument8 paginiTraction Control of Electric Vehicle Based On The Estimation of Road Surface ConditionMahta SafrullahÎncă nu există evaluări

- Optimal Pin Fin Heat Exchanger SurfaceDocument123 paginiOptimal Pin Fin Heat Exchanger Surfaceteguh hady aÎncă nu există evaluări

- SX 36 ManualDocument16 paginiSX 36 ManualAndreyna BreaÎncă nu există evaluări

- Thermal Paste Banana Peel.Document15 paginiThermal Paste Banana Peel.Carlos ClimacoÎncă nu există evaluări

- Genergy Battery - NS12 28Document2 paginiGenergy Battery - NS12 28Alessandro Silva100% (1)

- ST Journal of Research 4.1 - Wireless Sensor NetworksDocument164 paginiST Journal of Research 4.1 - Wireless Sensor Networksclara_colombo1996Încă nu există evaluări