Documente Academic

Documente Profesional

Documente Cultură

Kaiser Aluminum Soft Alloy Tube PDF

Încărcat de

gerrzen64Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Kaiser Aluminum Soft Alloy Tube PDF

Încărcat de

gerrzen64Drepturi de autor:

Formate disponibile

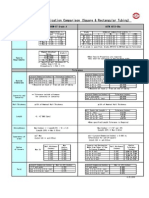

SOFT ALLOY TUBE & PIPE

EXTRUDED SEAMLESS ALUMINUM TUBE CAPABILITIES

STANDARD ALLOYS & TEMPERS

1100

O

3003

O

H112

6061

O

T4, T4511

T6, T6511

6063

O

T4

T5

T6

STANDARD ALLOYS & SPECIFICATIONS

1100

ASTM B241

ASTM B221

3003

ASTM B241

ASTM B221

6061

ASTM B241

ASTM B221

AMS 4150

ASME SB241

MIL-P-25995

AMS-QQ-A-200/8

6063

ASTM B241

ASTM B221

Notes

Press minimums vary from 500 3,000 lbs. Call for availability.

www.kaiseraluminum.com

| KA-TPS-PC1-1.09

SOFT ALLOY TUBE & PIPE

EXTRUDED SEAMLESS ALUMINUM TUBE CAPABILITIES

Wall

Thickness

(in.)

0.000-0.049

0.050-0.065

0.066-0.074

0.075-0.084

0.085-0.100

0.101-0.124

0.125-0.149

0.150-0.174

0.175-0.199

0.200-0.224

0.225-0.249

0.250-0.274

0.275-0.299

0.300-0.324

0.325-0.349

0.350-0.374

0.375-0.399

0.400-0.449

0.450-0.499

0.500-0.549

0.550-0.599

0.600-0.649

0.650-0.699

0.700-0.749

0.750-0.799

0.800-0.849

0.850-0.899

0.900-0.949

0.950-1.000

>1.000

= Capable

DIMENSIONAL RANGES - ALLOYS 1100, 3003

Outside Diameter (in.)

<1.000 1.000 1.250 1.500 1.750 2.000 2.250 2.500 2.750 3.000 3.250 3.500 3.750 4.000 4.250 4.500 4.750

This area identies available

Extruded Seamless Aluminum Tube

dimensional ranges.

STI

STI

STI

STI

STI

STI

STI

STI = Subject to inquiry

www.kaiseraluminum.com

| KA-TPS-PC2-1.09

SOFT ALLOY TUBE & PIPE

EXTRUDED SEAMLESS ALUMINUM TUBE CAPABILITIES

Wall

Thickness

(in.)

0.000-0.049

0.050-0.065

0.066-0.074

0.075-0.084

0.085-0.100

0.101-0.124

0.125-0.149

0.150-0.174

0.175-0.199

0.200-0.224

0.225-0.249

0.250-0.274

0.275-0.299

0.300-0.324

0.325-0.349

0.350-0.374

0.375-0.399

0.400-0.449

0.450-0.499

0.500-0.549

0.550-0.599

0.600-0.649

0.650-0.699

0.700-0.749

0.750-0.799

0.800-0.849

0.850-0.899

0.900-0.949

0.950-1.000

>1.000

= Capable

DIMENSIONAL RANGES - ALLOYS 1100, 3003

Outside Diameter (in.)

5.000 5.250 5.500 5.750 6.000 6.250 6.500 6.750 7.000 7.250 7.500 7.750 8.000 8.250 8.500 8.625 >8.625

This area identies available

Extruded Seamless Aluminum Tube

dimensional ranges.

STI

STI

STI

STI

STI

STI

STI = Subject to inquiry

www.kaiseraluminum.com

| KA-TPS-PC3-1.09

SOFT ALLOY TUBE & PIPE

EXTRUDED SEAMLESS ALUMINUM TUBE CAPABILITIES

Wall

Thickness

(in.)

0.000-0.049

0.050-0.065

0.066-0.074

0.075-0.084

0.085-0.100

0.101-0.124

0.125-0.149

0.150-0.174

0.175-0.199

0.200-0.224

0.225-0.249

0.250-0.274

0.275-0.299

0.300-0.324

0.325-0.349

0.350-0.374

0.375-0.399

0.400-0.449

0.450-0.499

0.500-0.549

0.550-0.599

0.600-0.649

0.650-0.699

0.700-0.749

0.750-0.799

0.800-0.849

0.850-0.899

0.900-0.949

0.950-1.000

>1.000

= Capable

DIMENSIONAL RANGES - ALLOY 6061

Outside Diameter (in.)

<1.000 1.000 1.250 1.500 1.750 2.000 2.250 2.500 2.750 3.000 3.250 3.500 3.750 4.000 4.250 4.500 4.750

This area identies available

Extruded Seamless Aluminum Tube

dimensional ranges.

STI

STI

STI

STI

STI

STI

STI

STI = Subject to inquiry

www.kaiseraluminum.com

| KA-TPS-PC4-1.09

SOFT ALLOY TUBE & PIPE

EXTRUDED SEAMLESS ALUMINUM TUBE CAPABILITIES

Wall

Thickness

(in.)

0.000-0.049

0.050-0.065

0.066-0.074

0.075-0.084

0.085-0.100

0.101-0.124

0.125-0.149

0.150-0.174

0.175-0.199

0.200-0.224

0.225-0.249

0.250-0.274

0.275-0.299

0.300-0.324

0.325-0.349

0.350-0.374

0.375-0.399

0.400-0.449

0.450-0.499

0.500-0.549

0.550-0.599

0.600-0.649

0.650-0.699

0.700-0.749

0.750-0.799

0.800-0.849

0.850-0.899

0.900-0.949

0.950-1.000

>1.000

= Capable

DIMENSIONAL RANGES - ALLOY 6061

Outside Diameter (in.)

5.000 5.250 5.500 5.750 6.000 6.250 6.500 6.750 7.000 7.250 7.500 7.750 8.000 8.250 8.500 8.625 >8.625

This area identies available

Extruded Seamless Aluminum Tube

dimensional ranges.

STI

STI

STI

STI

STI

STI

STI = Subject to inquiry

www.kaiseraluminum.com

| KA-TPS-PC5-1.09

SOFT ALLOY TUBE & PIPE

EXTRUDED SEAMLESS ALUMINUM TUBE CAPABILITIES

Wall

Thickness

(in.)

0.000-0.049

0.050-0.065

0.066-0.074

0.075-0.084

0.085-0.100

0.101-0.124

0.125-0.149

0.150-0.174

0.175-0.199

0.200-0.224

0.225-0.249

0.250-0.274

0.275-0.299

0.300-0.324

0.325-0.349

0.350-0.374

0.375-0.399

0.400-0.449

0.450-0.499

0.500-0.549

0.550-0.599

0.600-0.649

0.650-0.699

0.700-0.749

0.750-0.799

0.800-0.849

0.850-0.899

0.900-0.949

0.950-1.000

>1.000

= Capable

DIMENSIONAL RANGES - ALLOY 6063

Outside Diameter (in.)

<1.000 1.000 1.250 1.500 1.750 2.000 2.250 2.500 2.750 3.000 3.250 3.500 3.750 4.000 4.250 4.500 4.750

This area identies available

Extruded Seamless Aluminum Tube

dimensional ranges.

STI

STI

STI

STI

STI

STI

STI = Subject to inquiry

www.kaiseraluminum.com

| KA-TPS-PC6-1.09

SOFT ALLOY TUBE & PIPE

EXTRUDED SEAMLESS ALUMINUM TUBE CAPABILITIES

Wall

Thickness

(in.)

0.000-0.049

0.050-0.065

0.066-0.074

0.075-0.084

0.085-0.100

0.101-0.124

0.125-0.149

0.150-0.174

0.175-0.199

0.200-0.224

0.225-0.249

0.250-0.274

0.275-0.299

0.300-0.324

0.325-0.349

0.350-0.374

0.375-0.399

0.400-0.449

0.450-0.499

0.500-0.549

0.550-0.599

0.600-0.649

0.650-0.699

0.700-0.749

0.750-0.799

0.800-0.849

0.850-0.899

0.900-0.949

0.950-1.000

>1.000

= Capable

DIMENSIONAL RANGES - ALLOY 6063

Outside Diameter (in.)

5.000 5.250 5.500 5.750 6.000 6.250 6.500 6.750 7.000 7.250 7.500 7.750 8.000 8.250 8.500 8.625 >8.625

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

STI

This area identies available

Extruded Seamless Aluminum Tube

dimensional ranges.

STI

STI

STI

STI

STI

STI

STI = Subject to inquiry

www.kaiseraluminum.com

| KA-TPS-PC7-1.09

Technical Data

TUBE & PIPE ALLOY 1100

ALLOY DESCRIPTION 1

The purest of the aluminum alloys. This alloy is typically used in applications requiring maximum ductility and relatively low strength.

Good corrosion resistance, workability and weldability.

1 Alloy subject to cast lot quantity restriction

TYPICAL MECHANICAL PROPERTIES

Temper

Tensile (.0625 Dia. Specimen)

Ultimate

0

H14

H18

KSI

13

18

24

MPa

90

125

165

Yield

KSI

5

17

22

Elongation/4D

MPa

35

115

150

Hardness

Shear

Fatigue

Modulus

Brinell

500kg

10 mm

Ultimate

Shearing

Strength

Endurance Limit R.R. Moore Type

Modulus of

Elasticity

%

35

9

5

23

32

44

KSI

9

11

13

MPa

60

75

90

KSI

5

7

9

MPa

35

50

60

KSI x 10

10.0

10.0

10.0

Gpa

69

69

69

COMPARATIVE CHARACTERISTICS

Temper

O

H14

H18

Corrosion Resistance

General1

A

A

A

Stress2

A

A

A

Cold Workability3

Machinability3

Anodize Response3

Brazeability4

A

A

C

E

D

D

A

A

A

A

A

A

Weldability4

Gas

A

A

A

Arc Spot

A

B

A

A

A

A

1 Ratings A through E are relative ratings in decreasing order of merit, based on exposures to sodium chloride solution by intermittent spraying or immersion.

Alloys with A and B ratings can be used in industrial and seacoast atmospheres without protection. Alloys with C, D and E ratings generally should be protected

at least on faying surfaces.

2 Stress-corrosion cracking ratings are based on service experience and on laboratory tests of specimens exposed to the 3.5% sodium chloride alternate

immersion test.

A= No known instance of failure in service or in laboratory tests.

B= No known instance of failure in service; limited failures in laboratory tests of short transverse specimens.

C= Service failures with sustained tension stress acting in short transverse direction relative to grain structure; limited failures in laboratory tests of long

transverse specimens.

D= Limited service failures with sustained longitudinal or long transverse areas.

3 Ratings A through D for Workability (cold), A through E for Machinability and A through C for Anodize Response, are relative ratings in decreasing order of merit.

4 Ratings A through D for Weldability and Brazeability are relative ratings dened as follows:

A= Generally weldable by all commercial procedures and methods.

B= Weldable with special techniques or for specic applications that justify preliminary trials or testing to develop welding procedure and weld performance.

C= Limited weldability because of crack sensitivity or loss in resistance to corrosion and mechanical properties.

D= No commonly used welding methods have been developed.

www.kaiseraluminum.com

| KA-TPS-1100-1.09

Technical Data

TUBE & PIPE ALLOY 1100

APPLICABLE SPECIFICATIONS

Cold Drawn

Extruded

ASTM B210

AMS 4062

AMS-T-700/1

ASTM B221

ASTM B241

CHEMICAL COMPOSITION LIMITS

Others

Weight %

Minimum

Maximum

Si

Fe

0.95 Si + Fe

Cu

0.05

0.20

Mn

Mg

0.05

Cr

Ni

Zn

0.10

Ti

Each

Total

0.05

0.15

TYPICAL PHYSICAL PROPERTIES

Characteristic

English

Metric

Nominal Density (68 F / 20 C)

Melting Range

0.099 lbs./in.3

1190 F - 1215 F

2.71 g/cm3

640 C - 655 C

13.1 micro in./in. - F

23.6 micro m/m - K

1540 BTU/ft. - hr. - F

1510 BTU/ft. - hr. - F

59% IACS

57% IACS

194% IACS

187% IACS

222 W/m - K

218 W/m - K

34 MS/m

33 MS/m

113 MS/m

108 MS/m

Coefcient of Thermal Expansion

Thermal Conductivity (68 F / 20 C)

Electrical Conductivity (68 F / 20 C)

Linear

68 F - 212 F

20 C - 100 C

O

H18

Equal Volume

Equal Weight

O Temper

H18

O Temper

H18

Technical Data

TUBE & PIPE ALLOY 3003

ALLOY DESCRIPTION 1

One of the non-heat treatable manganese alloys. Typically used for condensers and heat exchangers in chemical equipment and

pressure vessels. Good corrosion resistance, workability and weldability.

1 Alloy subject to cast lot quantity restriction

TYPICAL MECHANICAL PROPERTIES

Temper

Tensile (.0625 Dia. Specimen)

Ultimate

0

H14

KSI

16

22

MPa

110

152

Yield

KSI

6

21

Elongation/4D

MPa

40

145

Hardness

Shear

Fatigue

Modulus

Brinell

500kg

10 mm

Ultimate

Shearing

Strength

Endurance Limit R.R. Moore Type

Modulus of

Elasticity

%

30

16

28

40

KSI

11

14

MPa

75

96

KSI

7

9

MPa

50

62

KSI x 10

10.0

10.0

Gpa

69

69

COMPARATIVE CHARACTERISTICS

Temper

O

H14

Corrosion Resistance

General1

A

A

Stress2

A

A

Cold Workability3

A

A

Machinability3

E

D

Anodize Response3

A

A

Brazeability4

A

A

Weldability4

Gas

A

A

Arc Spot

A

B

A

A

1 Ratings A through E are relative ratings in decreasing order of merit, based on exposures to sodium chloride solution by intermittent spraying or immersion.

Alloys with A and B ratings can be used in industrial and seacoast atmospheres without protection. Alloys with C, D and E ratings generally should be protected

at least on faying surfaces.

2 Stress-corrosion cracking ratings are based on service experience and on laboratory tests of specimens exposed to the 3.5% sodium chloride alternate

immersion test.

A= No known instance of failure in service or in laboratory tests.

B= No known instance of failure in service; limited failures in laboratory tests of short transverse specimens.

C= Service failures with sustained tension stress acting in short transverse direction relative to grain structure; limited failures in laboratory tests of long

transverse specimens.

D= Limited service failures with sustained longitudinal or long transverse areas.

3 Ratings A through D for Workability (cold), A through E for Machinability and A through C for Anodize Response, are relative ratings in decreasing order of merit.

4 Ratings A through D for Weldability and Brazeability are relative ratings dened as follows:

A= Generally weldable by all commercial procedures and methods.

B= Weldable with special techniques or for specic applications that justify preliminary trials or testing to develop welding procedure and weld performance.

C= Limited weldability because of crack sensitivity or loss in resistance to corrosion and mechanical properties.

D= No commonly used welding methods have been developed.

www.kaiseraluminum.com

| KA-TPS-3003-1.09

Technical Data

TUBE & PIPE ALLOY 3003

APPLICABLE SPECIFICATIONS

Cold Drawn

Extruded

ASTM B210 ASTM 234

AMS 4067/AMS 4065

AMS-T-700/2

ASTM B221

ASTM B241

CHEMICAL COMPOSITION LIMITS

Others

Weight %

Minimum

Maximum

Si

Fe

0.60

0.70

Cu

0.05

0.20

Mn

1.0

1.5

Mg

Cr

Ni

Zn

0.10

Ti

Each

Total

0.05

0.15

TYPICAL PHYSICAL PROPERTIES

Characteristic

English

Metric

Nominal Density (68 F / 20 C)

Melting Range

0.099 lbs./in.3

1190 F - 1210 F

2.73 g/cm3

640 C - 655 C

12.9 micro in./in. - F

23.2 micro m/m - K

1340 BTU/ft. - hr. - F

50% IACS

163% IACS

193 W/m - K

29 MS/m

92 MS/m

Coefcient of Thermal Expansion

Thermal Conductivity (68 F / 20 C)

Electrical Conductivity (68 F / 20 C)

Linear

68 F - 212 F

20 C - 100 C

O Temper

Equal Volume

Equal Weight

O Temper

O Temper

Technical Data

TUBE & PIPE ALLOY 6061

ALLOY DESCRIPTION

A good all purpose alloy for applications requiring good corrosion resistance, medium strength, and good machining characteristics.

Appearance after anodizing is excellent.

TYPICAL MECHANICAL PROPERTIES

Temper

Tensile (.0625 Dia. Specimen)

Ultimate

0

T4

T6

KSI

18

35

45

MPa

124

241

310

Yield

KSI

8

21

40

Elongation/4D

MPa

55

145

276

Hardness

Shear

Fatigue*1

Modulus*2

Brinell

500kg

10 mm

Ultimate

Shearing

Strength

Endurance Limit R.R. Moore Type

Modulus of

Elasticity

%

25

22

12

30

65

95

KSI

12

24

30

MPa

83

165

207

KSI

9

14

14

MPa

62

97

97

KSI x 10

10.0

10.0

10.0

Gpa

68.3

68.3

68.3

*1 - 5 x 10E8 cycles of reversed stress, *2 Average Tension and Compression

COMPARATIVE CHARACTERISTICS

Temper

0

T4

T6

Corrosion Resistance

General1

B

B

B

Stress2

A

B

A

Cold Workability3

Machinability3

Anodize Response3

Brazeability4

A

B

C

D

C

C

A

A

A

A

A

A

Weldability4

Gas

A

A

A

Arc Spot

A

B

A

A

A

A

1 Ratings A through E are relative ratings in decreasing order of merit, based on exposures to sodium chloride solution by intermittent spraying or immersion.

Alloys with A and B ratings can be used in industrial and seacoast atmospheres without protection. Alloys with C, D and E ratings generally should be protected

at least on faying surfaces.

2 Stress-corrosion cracking ratings are based on service experience and on laboratory tests of specimens exposed to the 3.5% sodium chloride alternate

immersion test.

A= No known instance of failure in service or in laboratory tests.

B= No known instance of failure in service; limited failures in laboratory tests of short transverse specimens.

C= Service failures with sustained tension stress acting in short transverse direction relative to grain structure; limited failures in laboratory tests of long

transverse specimens.

D= Limited service failures with sustained longitudinal or long transverse areas.

3 Ratings A through D for Workability (cold), A through E for Machinability and A through C for Anodize Response, are relative ratings in decreasing order of merit.

4 Ratings A through D for Weldability and Brazeability are relative ratings dened as follows:

A= Generally weldable by all commercial procedures and methods.

B= Weldable with special techniques or for specic applications that justify preliminary trials or testing to develop welding procedure and weld performance.

C= Limited weldability because of crack sensitivity or loss in resistance to corrosion and mechanical properties.

D= No commonly used welding methods have been developed.

www.kaiseraluminum.com

| KA-TPS-6061-1.09

Technical Data

TUBE & PIPE ALLOY 6061

APPLICABLE SPECIFICATIONS

Cold Drawn

Extruded

ASTM B210, B234, B241, B483

ASME SB210

AMS 4079, 4080, 4081, 4082, 4083

AMS-T-700/6, AMS-T-7081

MIL-P-25995

ASTM B221

ASTM B241

ASME SB241

AMS-QQ-A-200/8

CHEMICAL COMPOSITION LIMITS

Others

Weight %

Minimum

Maximum

Si

0.40

0.80

Fe

0.70

Cu

0.15

0.40

Mn

0.15

Mg

0.80

1.20

Cr

0.04

0.35

Zn

Ti

Each

Total

0.25

0.15

0.05

0.15

TYPICAL PHYSICAL PROPERTIES

Characteristic

English

Nominal Density (68 F / 20 C)

Melting Range

Specic Heat (212 F / 100 C)

0.098 lbs./in.

1080 F - 1206 F

0.214 BTU/lb. - F

2.70 g/cm3

582 C - 652 C

0.896 J/kg - K

13.1 micro in./in. - F

23.6 micro m/m - K

1250 BTU/ft. - hr. - F

1070 BTU/ft. - hr. - F

1160 BTU/ft. - hr. - F

47% IACS

40% IACS

43% IACS

155% IACS

132% IACS

142% IACS

180 W/m - K

154 155 W/m - K

167 W/m - K

27 MS/m

23 MS/m

25 MS/m

90 MS/m

77 MS/m

82 MS/m

Coefcient of Thermal Expansion

Thermal Conductivity (68 F / 20 C)

Metric

3

Linear

68 F - 212 F

20 C - 100 C

O Temper

T4

T6

Equal Volume

Electrical Conductivity (68 F / 20 C)

Equal Weight

O Temper

T4

T6

O Temper

T4

T6

Technical Data

TUBE & PIPE ALLOY 6063

ALLOY DESCRIPTION

Magnesium/Silicon alloy. One of the most popular of the Heat Treatable alloy group. Excellent corrosion resistance and weldability.

Finer grain structure than 6061 lends itself to more aesthetically pleasing anodize results. Target applications include air cylinder

tubing, electrical bus conductor and architectural applications.

TYPICAL MECHANICAL PROPERTIES

Temper

Tensile (.0625 Dia. Specimen)

Ultimate

O

T1

T4

T5

T52

T6

T832

Yield

Elongation/4D

KSI

13

22

25

27

MPa

90

150

170

185

KSI

7

13

13

21

MPa

50

90

90

145

20

22

12

35

42

240

290

31

39

215

270

12

12

Hardness

Shear

Fatigue

Modulus

Brinell

500kg

10 mm

Ultimate

Shearing

Strength

Endurance Limit R.R. Moore Type

Modulus of

Elasticity

25

42

KSI

10

14

MPa

70

95

KSI

8

9

MPa

55

60

60

17

115

10

70

73

95

22

27

150

185

10

70

KSI x 10

10.0

10.0

10.0

10.0

Gpa

69

69

69

69

10.0

10.0

69

69

COMPARATIVE CHARACTERISTICS

Temper

T1

T4

T6

Corrosion Resistance

General1

A

A

A

Stress2

A

A

A

Cold Workability3

Machinability3

Anodize Response3

Brazeability4

B

B

C

D

D

C

A

A

A

A

A

A

Weldability4

Gas

A

A

A

Arc Spot

A

A

A

A

A

A

1 Ratings A through E are relative ratings in decreasing order of merit, based on exposures to sodium chloride solution by intermittent spraying or immersion.

Alloys with A and B ratings can be used in industrial and seacoast atmospheres without protection. Alloys with C, D and E ratings generally should be protected

at least on faying surfaces.

2 Stress-corrosion cracking ratings are based on service experience and on laboratory tests of specimens exposed to the 3.5% sodium chloride alternate

immersion test.

A= No known instance of failure in service or in laboratory tests.

B= No known instance of failure in service; limited failures in laboratory tests of short transverse specimens.

C= Service failures with sustained tension stress acting in short transverse direction relative to grain structure; limited failures in laboratory tests of long

transverse specimens.

D= Limited service failures with sustained longitudinal or long transverse areas.

3 Ratings A through D for Workability (cold), A through E for Machinability and A through C for Anodize Response, are relative ratings in decreasing order of merit.

4 Ratings A through D for Weldability and Brazeability are relative ratings dened as follows:

A= Generally weldable by all commercial procedures and methods.

B= Weldable with special techniques or for specic applications that justify preliminary trials or testing to develop welding procedure and weld performance.

C= Limited weldability because of crack sensitivity or loss in resistance to corrosion and mechanical properties.

D= No commonly used welding methods have been developed.

www.kaiseraluminum.com

| KA-TPS-6063-1.09

Technical Data

TUBE & PIPE ALLOY 6063

APPLICABLE SPECIFICATIONS

Cold Drawn

Extruded

ASTM B210

ASTM B483

ASTM B221

ASTM B241

ASTM B345

ASTM B429

CHEMICAL COMPOSITION LIMITS

Others

Weight %

Minimum

Maximum

Si

.020

0.60

Fe

Cu

Mn

0.35

0.10

0.10

Mg

0.45

0.90

Cr

Zn

Ti

Each

Total

0.10

0.10

0.10

0.05

0.15

TYPICAL PHYSICAL PROPERTIES

Characteristic

English

Nominal Density (68 F / 20 C)

Melting Range

0.097 lbs./in.

1140 F - 1210 F

2.70 g/cm3

615 C - 655 C

13.0 micro in./in. - F

23.4 micro m/m - K

1510 BTU/ft. - hr. - F

1340 BTU/ft. - hr. - F

1390 BTU/ft. - hr. - F

58% IACS

50% IACS

55% IACS

53% IACS

191% IACS

165% IACS

181% IACS

175% IACS

218 W/m - K

193 W/m - K

201 W/m - K

34 MS/m

29 MS/m

32 MS/m

31 MS/m

111 MS/m

96 MS/m

105 MS/m

102 MS/m

Coefcient of Thermal Expansion

Thermal Conductivity (68 F / 20 C)

Metric

3

Linear

68 F - 212 F

20 C - 100 C

O

T1

T6

Equal Volume

Electrical Conductivity (68 F / 20 C)

Equal Weight

O Temper

T1

T5

T6

O Temper

T1

T5

T6

SOFT ALLOY EXTRUDED

TUBE & PIPE DEPOT

EFFECTIVE 1-09 (2)

Alloy

Temper

6063

6063

6063

6063

6063

6061

6061

6061

6061

T52

T52

T52

T52

T52

T6

T6

T6

T6

Shape

A Dim

Extruded Square Tube (1)

1.000

Extruded Square Tube (1)

1.500

Extruded Square Tube (1)

2.000

Extruded Rectangular Tube (1) 1.000

Extruded Rectangular Tube (1) 2.000

Extruded Structural Pipe (1) 1 NPS 40

Extruded Structural Pipe

1.25 NPS 40

Extruded Structural Pipe

1.5 NPS 40

Extruded Structural Pipe (1) 2 NPS 40

B Dim

T Dim

1.000

1.500

2.000

2.000

3.000

Wall

Length

0.125

0.125

0.125

0.125

0.125

211

211

211

211

211

20

20

20

20

Stock #

East of

Rockies

050

053

055

058

065

286

288

289

290

Stock #

West of

Rockies

288

289

Bundle

Weight

(lbs.)

537

507

691

507

700

500

503

507

506

Notes

(1) Available East of Rockies ONLY.

(2) Orders received by the cut-off time shown below will ship the following day provided available stock exists and we have a regularly scheduled truck.

Stocking Depot - Noon Eastern / Los Angeles (local) - 1:00 PM Pacic / Los Angeles (Outside LA area) - 11:30 AM Pacic

All items are subject to a maximum withdrawal of 4M# per week per Ship To location.

Kaiser Aluminum produces many standard shapes not shown in this depot list.

Please contact your Kaiser sales ofce for more information.

www.kaiseraluminum.com

| KA-TPS-DEP-1.09

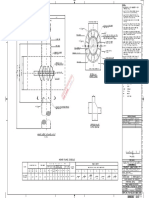

SELECTED STANDARD TUBE DIE

AVAILABILITIES / EXTRUSIONS

STRUCTURAL SQUARE TUBE WITH ROUNDED CORNERS

Inches

Estimated

Weight Per

Foot Pounds

Circle

Size

.091

.156

.165

.125

.125

.100

.010

.015

.125

.281

.015

.062

.375

.063

.375

.250

.062

.250

.275

.283

.337

.526

.476

.498

.424

1.109

1.076

1.636

2.502

3.240

5.190

2.293

3.214

4.221

2.867

5.397

1-2

1-2

1-2

1-2

1-2

1-2

1-2

2-3

2-3

2-3

4-5

4-5

4-5

5-6

5-6

5-6

7-8

6-7

R-1

R-2

Inches

Inches

Inches

1.000

1.000

1.000

1.000

1.000

1.250

1.500

2.000

2.000

2.000

3.000

3.000

3.500

4.000

4.000

4.000

5.000

5.000

.065

.067

.085

.125

.125

.094

.062

.125

.125

.188

.188

.250

.375

.125

.175

.250

.125

.250

.156

.156

.250

.125

.250

.180

.062

.125

.250

.281

.188

.250

.750

.188

.375

.500

.062

.500

Notes

(1)

STRUCTURAL RECTANGULAR TUBE WITH ROUNDED CORNERS

X

R-1

R-2

Inches

Inches

Inches

Inches

Inches

4.000

4.000

4.000

2.000

2.500

3.000

.188

.125

.188

.188

.062

.188

.094

.062

.015

Estimated

Weight Per

Foot Pounds

2.511

1.874

2.989

Circle

Size

Notes

4-5

4-5

5-6

STRUCTURAL SQUARE TUBE

X

Inches

Inches

Estimated Weight

Per Foot Pounds

Circle

Size

Notes

.750

.750

1.000

1.000

1.250

1.500

1.500

1.500

1.750

2.000

2.000

2.000

.062

.125

.062

.125

.125

.062

.187

.125

.125

.125

.187

.250

.208

.374

.280

.524

.676

.428

1.179

.826

.975

1.126

1.631

2.100

1-2

1-2

1-2

1-2

1-2

2-3

1-2

2-3

2-3

2-3

2-3

2-3

(1)

(1)

(1)

(1)

Notes

(1) Available in 6063 alloy only.

Hollow structural sections manufactured with porthole or bridge-type dies may not be suitable for applications involving internal pressure.

Applications requiring internal pressure subject to special inquiry.

www.kaiseraluminum.com

| KA-TPS-TDIES1-1.09

SELECTED STANDARD TUBE DIE

AVAILABILITIES / EXTRUSIONS

STRUCTURAL SQUARE TUBE

X

Inches

Inches

Estimated Weight

Per Foot Pounds

Circle

Size

2.500

2.500

2.500

3.000

3.000

3.000

3.000

3.500

4.000

4.000

4.000

.125

.188

.250

.125

.188

.219

.250

.125

.125

.250

.313

1.426

2.087

2.700

1.726

2.531

2.923

3.300

2.025

2.326

4.500

5.539

3-4

3-4

3-4

4-5

4-5

4-5

4-5

4-5

5-6

5-6

5-6

Notes

(1)

(1)

STRUCTURAL RECTANGULAR TUBE

X

Inches

Inches

Inches

1.000

1.500

1.500

1.750

2.000

2.000

2.250

2.500

2.500

3.000

3.000

3.000

3.000

3.000

3.000

3.500

4.000

4.000

4.000

4.000

4.000

4.500

5.000

5.000

5.000

5.000

6.000

6.000

6.000

.500

.750

1.000

2.000

1.000

1.500

1.750

1.250

2.000

1.000

1.500

1.500

1.750

2.000

2.000

1.750

1.750

1.750

2.000

3.000

3.000

1.750

1.750

1.750

2.000

3.000

2.000

2.000

4.000

.125

.125

.125

.125

.125

.125

.125

.125

.250

.125

.125

.188

.125

.125

.250

.125

.094

.125

.125

.125

.188

.125

.125

.188

.125

.125

.125

.250

.250

Estimated

Weight Per Foot

Pounds

.374

.600

.674

1.050

.826

.976

1.126

1.050

2.400

1.126

1.274

1.861

1.350

1.426

2.700

1.500

1.255

1.650

1.726

2.026

2.989

1.800

1.950

2.876

2.026

2.326

2.326

4.410

5.700

Circle

Size

1-2

1-2

1-2

2-3

2-3

2-3

2-3

2-3

3-4

3-4

3-4

3-4

3-4

3-4

3-4

3-4

4-5

4-5

4-5

4-5

4-5

4-5

5-6

5-6

5-6

5-6

6-7

6-7

7-8

Notes

(1)

(1)

(1)

(1)

(1)

(1)

Notes

(1) Available in 6063 alloy only.

Hollow structural sections manufactured with porthole or bridge-type dies may not be suitable for applications involving internal pressure.

Applications requiring internal pressure subject to special inquiry.

www.kaiseraluminum.com

| KA-TPS-TDIES2-1.09

SELECTED STANDARD PIPE DIE

AVAILABILITIES / EXTRUSIONS

SCHEDULE PIPE

X

O.D.

.675

.840

1.050

1.050

1.315

1.315

1.315

1.315

1.660

1.660

1.660

1.660

1.660

1.900

1.900

1.900

1.900

1.900

2.375

2.375

2.375

2.375

2.375

2.875

2.875

2.875

2.875

2.875

3.500

3.500

3.500

3.500

3.500

Nominal Dimensions

(in.)

Y

I.D.

.493

.622

.824

.742

1.097

1.049

.957

.615

1.530

1.442

1.380

1.278

1.160

1.770

1.682

1.610

1.500

1.338

2.245

2.157

2.067

1.939

1.687

2.709

2.635

2.469

2.323

2.125

3.334

3.260

3.068

2.900

2.624

T

Wall

.080

.109

.113

.154

.109

.133

.179

.250

.065

.109

.140

.191

.250

.065

.109

.145

.200

.281

.065

.109

.154

.218

.344

.083

.120

.203

.276

.375

.083

.120

.216

.300

.438

Estimated

Weight

Per Foot

Pounds

.179

.294

.391

.510

.486

.581

.751

.984

.383

.625

.786

1.037

1.302

.441

.721

.940

1.256

1.681

.555

.913

1.264

1.737

2.581

.856

1.221

2.004

2.650

3.464

1.048

1.498

2.621

3.547

4.955

USAS Pipe Sizes

Schedule Pipe

Size

(in.)

.375

.500

.750

.750

1.000

1.000

1.000

1.000

1.250

1.250

1.250

1.250

1.250

1.500

1.500

1.500

1.500

1.500

2.000

2.000

2.000

2.000

2.000

2.500

2.500

2.500

2.500

2.500

3.000

3.000

3.000

3.000

3.000

Schedule

Number

40

40

40

80

10

40

80

160

5

10

40

80

160

5

10

40

80

160

5

10

40

80

160

5

10

40

80

160

5

10

40

80

160

Available

As

Seamless

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Available

As

Structural

Notes

x

x

x

x

x

x

x

x

x

(1)

(1)

x

x

x

x

x

x

(1)

x

x

x

x

x

x

(1)

Notes

(1) Available in 6063 alloy only.

Hollow structural sections manufactured with porthole or bridge-type dies may not be suitable for applications involving internal pressure.

Applications requiring internal pressure subject to special inquiry.

www.kaiseraluminum.com

| KA-TPS-PDIES1-1.09

SELECTED STANDARD PIPE DIE

AVAILABILITIES / EXTRUSIONS

SCHEDULE PIPE

X

O.D.

4.000

4.000

4.000

4.000

4.500

4.500

4.500

4.500

4.500

4.500

5.563

5.563

5.563

5.563

5.563

6.625

6.625

6.625

6.625

6.625

6.625

8.625

8.625

8.625

8.625

8.625

Nominal Dimensions

(in.)

Y

I.D.

3.834

3.760

3.548

3.364

4.334

4.260

4.026

3.825

3.624

3.438

5.345

5.295

5.047

4.813

4.563

6.407

6.357

6.065

5.761

5.501

5.187

8.329

8.125

7.981

7.813

7.625

T

Wall

.083

.120

.226

.318

.083

.120

.237

.337

.438

.531

.109

.134

.258

.375

.500

.109

.134

.280

.432

.562

.719

.148

.250

.322

.406

.500

Estimated

Weight

Per Foot

Pounds

1.201

1.720

3.151

4.326

1.354

1.942

3.733

5.183

6.573

7.786

2.196

2.688

5.057

7.188

9.353

2.624

3.213

6.564

9.884

12.589

15.668

4.635

7.735

9.878

12.328

15.009

USAS Pipe Sizes

Schedule Pipe

Size

(in.)

3.500

3.500

3.500

3.500

4.000

4.000

4.000

4.000

4.000

4.000

5.000

5.000

5.000

5.000

5.000

6.000

6.000

6.000

6.000

6.000

6.000

8.000

8.000

8.000

8.000

8.000

Schedule

Number

5

10

40

80

5

10

40

80

120

160

5

10

40

80

120

5

10

40

80

120

160

10

20

40

60

80

Available

As

Seamless

Available

As

Structural

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Notes

(1)

(1)

(1)

(1)

x

x

(1)

x

x

(2)

(2)

(1)

(2)

(2)

(2)

(2)

Notes

(1) Available in 6063 alloy only.

(2) Length restrictions apply Subject to inquiry.

Hollow structural sections manufactured with porthole or bridge-type dies may not be suitable for applications involving internal pressure.

Applications requiring internal pressure subject to special inquiry.

www.kaiseraluminum.com

| KA-TPS-PDIES2-1.09

AIR BREATHER SEAMLESS

ROUND TUBE

AIR BREATHER QUALITY TUBE

Air Breather Seamless Round Tube is an extruded seamless thin wall tube (wall thickness from .050 to .124) that is suitable

for anodizing and is relatively free of dents, die lines and other types of surface imperfections. This higher quality tube is

commonly used for truck breather tubes, pneumatic tubes and swimming pool cover rolls.

SURFACE FINISH

Produced to 1/2 standard tolerance per Table 12.13 on page KA-TPS-AA4-1.09. Minor scuffs are allowed, scratches are not.

Surface is suitable for anodizing.

DENTS

Dents are less frequent and are held to approximately 1/2 standard tolerance per Table 12.14 on page KA-TPS-AA4-1.09.

No more than three isolated dents in a 6-foot section. For this reason it is recommended that orders be entered at the

end use length and not standard 20-foot lengths.

Note: O- temper is not covered by Table 12.14. Tolerances for O- temper shall be agreed upon at the time of

inquiry/purchase.

To gure dent tolerances using Table 12.14:

1. Divide wall thickness by O.D. x 100 which equals the factor percentage

2. Factor percentage x Table 12.2 column three Other Alloys (page KA-TPS-AA1-1.09)

3. Divide by two to determine 1/2 standard dent tolerance

Example: Using a 3.000 O.D. x .065 wall

1. .065 wall divided by 3.000 O.D. x 100 = 2.166%

2. Table 12.14 states for 2% to 2.5% exclusive - use 2.5 times tolerance

3. 2.5 times tolerance shown in Table 12.2 column 3, sub-column other alloys is .030, or 2.5 x .030 = .075

4. .075 divided by 2 = .0375 rounded to .038 for 1/2 standard dent tolerance

www.kaiseraluminum.com

| KA-TPS-AB1-1.09

AIR BREATHER SEAMLESS

ROUND TUBE

DENTS

The more common sizes are listed below showing the maximum dent depth.

O.D. (in.)

2.500

3.000

3.500

3.500

4.000

4.000

5.000

5.000

5.500

6.000

6.000

7.000

7.000

8.000

8.000

8.000

Wall (in.)

0.078

0.065

0.065

0.078

0.062

0.072

0.062

0.078

0.072

0.072

0.078

0.078

0.094

0.072

0.078

0.083

I.D. (in.)

Wt./Ft. (lbs.)

Max. Dent Depth (in.)

2.344

2.870

3.370

3.344

3.876

3.856

4.876

4.844

5.356

5.856

5.844

6.844

6.812

7.856

7.844

7.834

0.6908

0.6976

0.8165

0.9761

0.8929

1.0342

1.1196

1.4039

1.4292

1.5608

1.6892

1.9744

2.3739

2.0874

2.2597

2.4030

0.015

0.038

0.045

0.038

0.075

0.075

0.100

0.075

0.100

0.150

0.150

0.150

0.150

0.200

0.200

0.200

OVALITY

For walls less than 2.5% of the O.D., the ovality tolerances are TWO TIMES the tolerance shown on Table 12.2, column 3

Other Alloys (page KA-TPS-AA1-1.09).

For walls greater than 2.5% of the O.D., the ovality tolerances are as published in Table 12.2, column 3 Other Alloys.

Note: O- temper is not covered by Table 12.2 if wall thickness is less than 2.5% of outside diameter. The wall

thickness of most Air Breather Seamless Tube is less than 2.5% of outside diameter. Tolerances for these sizes in Otemper shall be agreed upon at the time of inquiry/purchase.

www.kaiseraluminum.com

| KA-TPS-AB2-1.09

AIR BREATHER SEAMLESS

ROUND TUBE

PACK

Standard pack is 300# and over AngleBoard Crate with paper interleave. Customers may request other packing and this

would be subject to inquiry.

Based on standard AngleBoard crate pack and 20 foot lengths, one truck can be loaded with 8 crates. Listed below are pieces per

crate and pieces per truckload by Outside Diameter of the tube.

Outside Diameter

Pieces Per Crate

Pieces Per Truckload

3.000

3.500

4.000

4.500

5.000

5.500

6.000

7.000

175

132

95

77

60

48

42

30

1400

1056

760

616

480

384

336

240

Maximum cut-to-length for vertical cell pack is 36. Box size is 40 x 40.

In most cases the $30.00/box minimum charge will apply since 300# minimum weight may not be achievable.

LENGTHS

Because of dent tolerances, the preferred length would be the customers end use length.

All information contained herein or related hereto is intended only for evaluation by technically skilled persons, with any use thereof

to be at their independent discretion and risk. Such information is believed to be reliable, but Kaiser Aluminum shall have no

responsibility or liability for results obtained or damages resulting from such use. Kaiser Aluminum grants no license under, and

shall have no responsibility or liability for infringement of, any patent or other proprietary right. Sales of Kaiser Aluminums products

shall be independent and subject exclusively to warranties set forth in Kaiser Aluminums order acknowledgment. The foregoing

may be waived or modied only in writing by Kaiser Aluminum.

www.kaiseraluminum.com

| KA-TPS-AB3-1.09

SOFT ALLOY EXTRUSIONS

PRODUCT ADDERS

Alloy / Temper

6061 T6, T6511 (ne grain)

6061, 6063 F

1100 F**

3003 H112**

1350 H111**

6070** all tempers

500 - 1,999 lbs.

2,000 - 4,999 lbs.

ALLOY & TEMPER ADDERS

Adder / Deductor

Alloy / Temper

+$.05 / lb. to 6061 base price

6101 all tempers**

-$.01 / lb. from alloy base price

6005 all tempers**

+$.25 / lb. to 6061 base price

6105 all tempers**

+$.35 / lb. to 6061 base price

7005 all tempers**

+$.25 / lb. to 6063 base price

6082 F, T6

+$.10 / lb. to 6061 base price

6061 T6B2, T6B11

O (annealed) temper

+$.20 / lb. to alloy base price

+$.12 / lb. to alloy base price

Adder / Deductor

+$.10 / lb. to 6061 base price

Use 6061 base price

+$.05 / lb. to 6061 base price

+$.25 / lb. to 6061 base price

+$.05 / lb. to 6061 base price

+$.05 / lb. to 6061 base price

5,000 - 9,999 lbs.

10,000 - 30,000 lbs.

+$.06 / lb. to alloy base price

+$.03 / lb. to alloy base price

*Excludes Drawn Tube / Tempers T61, T63, T64 & T65 are subject to 10,000# age oven minimums / **Select alloys - Subject to inquiry

SPECIFIED LENGTH ADDERS

Specied Length

.125 - .249

+$.055 / lb.

+$.025 / lb.

BASE

+$.025 / lb.

3 - 5

Over 5 - 7

Over 7 - 40

Over 40 - 48

Over 48

lbs. / ft.

.250 - .499

+$.040 / lb.

+$.020 / lb.

BASE

+$.020 / lb.

.500 - .999

+$.035 / lb.

+$.015 / lb.

BASE

+$.015 / lb.

1.00 & over

+$.030 / lb.

+$.010 / lb.

BASE

+$.010 / lb.

Subject to inquiry - may require special transportation with additional charge

PRODUCT ADDERS

Light Weight Adders

6061 Thin / Wide Bar Adders

Weight Per Foot

.100 to less than .150

.150 to less than .200

.200 to less than .400

.125 Thickness

Widths 5 to not including 6

Widths 6 to not including 7

Widths 7 and over

Adder

+$.10 / lb.

+$.07 / lb.

+$.05 / lb.

Adder

+$.10 / lb.

+$.15 / lb.

+$.20 / lb.

STANDARD SHIPPING TOLERANCE

10,000 lbs. & over

2,000 lbs. - 9,999 lbs.

500 lbs. - 1,999 lbs.

Under 500 lbs.

5%

8%

15%

35%

PACKAGING ADDERS

Paper or Stretch Wrap Bundle

Individual Paper Wrap

Chipboard Strip Layer Separation

Fiberboard Overwrap

Paper Layer Separation

Horizontal & Vertical Separation

Interleaving

Styrofoam Saddle Pack

$0.05 / lb.

$0.10 / lb.

$0.03 / lb.

$0.03 / lb.

$0.04 / lb.

$0.05 / lb.

$0.06 / lb.

$0.07 / lb.

Dustcover

Sling Board

Skid

Fiber Box

Tri-Wall Box

Angle Board Crate (300 lb. min.)

Wooden Box (300 lb. min.)

Export Treated Wood

$0.02 / lb.

$0.04 / lb.

$0.06 / lb.

$0.06 / lb.

$0.09 / lb.

$0.11 / lb.

$0.35 / lb.

$0.03 / lb.

Drop Ship Fee

Oiling

High Voltage Bus Pipe

Roll Contour - 50%

Roll Contour - 100%

$400 / load

$0.05 / lb.

$0.10 / lb. + Freight

$0.05 / lb.

$0.10 / lb.

OTHER ADDERS

Actual Chemistry

Mechanical Testing

100% Visual Inspection

Dimensional Checking

Exact Piece Count

Warehouse Restocking Fee

$100 / lot

$50 / item

$0.02 / lb.

$0.02 / lb.

$250 / item

$0.10 / lb. + Freight

www.kaiseraluminum.com

| KA-TPS-PA-1.09

SOFT ALLOY EXTRUSIONS

PRESS MINIMUMS

ROD & BAR PRODUCTS EXCLUDING MANIFOLD BAR*

Size Range

Up to 4.99 lbs. / ft.

5.00 Up to 14.99 lbs. / ft.

15.00 Up to 19.99 lbs. / ft.

20.00 Up to 44.99 lbs. / ft.

45.00 lbs. / ft. & greater

Press Minimum

1,000 lbs.

1,500 lbs.

2,000 lbs.

3,000 lbs.

4,000 lbs.

STANDARD STRUCTURALS

Size Range

Up to 5.99 Circle Size

6.00 Circle Size to 9.99 Circle Size

10.00 Circle Size & greater

Press Minimum

1,000 lbs.

2,000 lbs.

3,000 lbs.

SOLID SHAPES

Size Range

Up to 8.00 Circle Size

Over 8.00 Circle Size

Press Minimum

2,000 lbs.

3,000 lbs.

SEMI-HOLLOW/HOLLOW SHAPES

Size Range

Up to 5.99 Circle Size

6.00 Circle Size & greater

Press Minimum

2,000 lbs.

3,000 lbs.

STRUCTURAL TUBE/PIPE

Size Range

Up to 3.99 Circle Size

4.00 Circle Size to 5.99 Circle Size

6.00 Circle Size & greater

Press Minimum

1,000 lbs.

2,000 lbs.

3,000 lbs.

SEAMLESS TUBE/PIPE

Size Range

Press Minimum

Small Press (Thru 6.000 O.D. & 4.100 lbs. / ft.)

Large Press (Over 6.000 O.D. & 4.101 lbs. / ft.)

500 lbs.

1,000 lbs.

DRAWN SEAMLESS TUBE

Size Range

2.125 thru 6.250 O.D.

Press Minimum

2,000 lbs.

*MANIFOLD BAR

Size Range

Press Minimum

Manifold Bar - up to 44.99 lbs. / ft.

Manifold Bar - 45.00 lbs. / ft. & greater

3,000 lbs.

4,000 lbs.

Notes

The plant reserves the right to request a special press minimum on high difculty shapes.

The above applies to 6061, 6262 & 6063 only in standard tempers.

www.kaiseraluminum.com

| KA-TPS-PM-1.09

TABLE 12.2 DiameterRound Tube

EXCEPT FOR T3510, T4510, T6510, T73510, T76510 AND T8510 TEMPERS U

TOLERANCE Win. plus and minus

ALLOWABLE DEVIATION OF MEAN DIAMETER E

ALLOWABLE DEVIATION OF DIAMETER AT ANY POINT

FROM SPECIFIED DIAMETER (Size)

FROM SPECIFIED DIAMETER R

SPECIFIED

DIAMETER Q

in.

Difference between (AA+BB)

and specied diameter

Difference between AA or BB and specied diameter

Col. 2

Col. 1

5xxx 4.0

4.0

nominal Mg r

0.5000.999

1.0001.999

2.0003.999

4.0005.999

6.0007.999

.015

.018

.023

.038

.053

8.0009.999

10.00011.999

12.00013.999

14.00015.999

16.00017.999

18.00019.999

20.00021.999

22.00023.999

Col. 3

Other Alloys

5xxx 4.0

nominal Mg r

Other Alloys

.010

.012

.015

.025

.035

.030

.038

.045

.075

.113

.020

.025

.030

.050

.075

.068

.083

.098

.113

.128

.045

.055

.065

.075

.085

.150

.188

.225

.263

.300

.100

.125

.150

.175

.200

.143

.158

.173

.095

.105

.115

.338

.375

.413

.225

.250

.275

TABLE 12.3 Width and DepthSquare, Rectangular, Hexagonal and Octagonal Tube

EXCEPT FOR T3510, T4510, T6510, T73510, T76510 AND T8510 TEMPERS U

TOLERANCE Win. plus and minus

ALLOWABLE DEVIATION OF WIDTH OR DEPTH

AT CORNERS FROM SPECIFIED WIDTH OR

DEPTH

ALLOWABLE DEVIATION OF WIDTH OR DEPTH

NOT AT CORNERS FROM SPECIFIED WIDTH OR DEPTH R

SPECIFIED

WIDTH

OR

DEPTH

in.

Difference between AA and specied

width, depth, or distance across ats

Difference between AA and specied

width or depth

SQUARE, RECTANGULAR

SQUARE HEXAGONAL,

OCTAGONAL

RECTANGULAR

Col. 3

Col. 4

Col. 2

Col. 1

5xxx 4.0

4.0

nominal Mg r

Other

Alloys

5xxx 4.0

4.0

nominal Mg r

Other

Alloys

0.5000.749

0.7500.999

1.0001.999

2.0003.999

4.0004.999

.018

.021

.027

.038

.053

.012

.014

.018

.025

.035

.030

.030

.038

.053

.068

.020

.020

.025

.035

.045

5.0005.999

6.0006.999

7.0007.999

8.0008.999

9.0009.999

.068

.083

.098

.113

.128

.045

.055

.065

.075

.085

.083

.098

.108

.123

.143

.055

.065

.075

.085

.095

10.00010.999

11.00012.999

.143

.158

.095

.105

.158

.173

.105

.115

All

Alloys

The tolerance for the width

is the value in the previous

column for a dimension equal

to the depth, and conversely,

but in no case is the tolerance

less than at the corners.

Example: The width tolerance

of a 1 3 inch alloy 6061 rectangular tube is 0.025 inch

and the depth tolerance 0.035

inch.

For all numbered footnotes, see page KA-TPS-AA4-1.09

This data reprinted from Aluminum standards and data 2006 with permission from The Aluminum Association, Inc.

KA-TPS-AA1-1.09

TABLE 12.4 Wall ThicknessRound Extruded Tube

TOLERANCE Q Win. plus and minus

ALLOWABLE DEVIATION OF MEAN WALL THICKNESS T FROM

SPECIFIED WALL THICKNESS

ALLOWABLE DEVIATION

OF WALL THICKNESS

AT ANY POINT

FROM MEAN

WALL THICKNESS T

(Eccentricity)

SPECIFIED

WALL

THICKNESS

Y

in.

Difference between (AA + BB) and specied wall thickness

5.000 and over

Difference between

AA and mean

wall thickness

Col. 5

Col. 6

OUTSIDE DIAMETERIN.

Under 1.250

1.2502.999

3.0004.999

Col. 2

Col. 3

Col. 4

5xxx

4.0

4.0

nominal

Mg r

Other

Alloys

5xxx

4.0

4.0

nominal

Mg r

Under 0.047

0.0470.061

0.0620.077

0.0780.124

0.1250.249

0.2500.374

.009

.011

.012

.014

.014

.017

.006

.007

.008

.009

.009

.011

0.3750.499

0.5000.749

0.7500.999

1.0001.499

1.5002.000

..

..

..

..

..

2.0012.499

2.5002.999

3.0003.499

3.5004.000

..

..

..

..

Col. 1

Other

Alloys

5xxx

4.0

4.0

nominal

Mg r

Other

Alloys

5xxx

4.0

4.0

nominal

Mg r

Other

Alloys

..

.012

.012

.014

.014

.017

..

.008

.008

.009

.009

.011

..

.012

.014

.015

.020

.024

..

.008

.009

.010

.013

.016

..

.015

.018

.023

.030

.038

..

.010

.012

.015

.020

.025

..

..

..

..

..

.023

.030

..

..

..

.015

.020

..

..

..

.032

.042

.053

.068

..

.021

.028

.035

.045

..

.053

.068

.083

.098

.113

.035

.045

.055

.065

.075

max 0.060

min 0.010

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

.128

.143

.158

.173

.085

.095

.105

.115

0.120

All Alloys

Plus and

minus

10% of

mean

wall

thickness

TABLE 12.5 Wall ThicknessOther-Than-Round Extruded Tube

TOLERANCE Q Win. plus and minus

ALLOWABLE DEVIATION OF MEAN WALL

THICKNESS T FROM SPECIFIED WALL THICKNESS

ALLOWABLE DEVIATION OF WALL THICKNESS

AT ANY POINT FROM MEAN WALL

THICKNESS T (Eccentricity)

SPECIFIED

WALL

THICKNESS Y

in.

Difference between (AA + BB) and

specied wall thickness

Difference between AA and mean wall thickness

CIRCUMSCRIBING CIRCLE DIAMETER Pin.

Under 5.000

5.000 and over

Under 5.000

5.000 and over

Col. 2

Col. 3

Col. 4

Col. 5

All

Alloys

Col. 1

5xxx4.0

4.0

nominal Mg r

Other

Alloys

5xxx4.0

5xxx

4.0

nominal Mg r

Other

Alloys

All

Alloys

Under 0.047

0.0470.061

0.0620.124

0.1250.249

0.2500.374

.008

.009

.011

.012

.017

.005

.006

.007

.008

.011

.012

.014

.015

.023

.030

.008

.009

.010

.015

.020

.005

.007

.010

.015

.025

0.3750.499

0.5000.749

0.7500.999

1.0001.499

1.5002.000

.021

.038

.053

.068

..

.014

.025

.035

.045

..

.045

.060

.075

.090

.105

.030

.040

.050

.060

.070

.030

.040

.050

.060

..

Plus and

minus

10% of

mean

wall

thickness

max 0.060

min 0.010

For all numbered footnotes, see page KA-TPS-AA4-1.09

This data reprinted from Aluminum standards and data 2006 with permission from The Aluminum Association, Inc.

KA-TPS-AA2-1.09

TABLE 12.6 LengthExtruded Tube

TOLERANCEin. plus excepted as noted

ALLOWABLE DEVIATION FROM SPECIFIED LENGTH

SPECIFIED OUTSIDE

DIAMETER OR WIDTH

in.

0.5001.249

1.2502.999

3.0007.999

8.000 and over

STRAIGHT

COILED

SPECIFIED LENGTHft.

Up

thru

12

Over

12

thru

30

Over

30

thru

50

Over

50

Up

thru

100

Over

100

thru

250

Over

250

thru

500

Over

500

Q-i

Q-i

E-qy

T-qy

E-i

E-i

E-i

U-qy

1

1

1

1

+5%, 0%

..

..

..

10%

..

..

..

15%

..

..

..

20%

..

..

..

TABLE 12.7 Twist {Other-than-Round Extruded Tube

TOLERANCE ODegrees

ALLOWABLE DEVIATION FROM STRAIGHT

SPECIFIED

WIDTH

in.

TEMPER

SPECIFIED

THICKNESS

in.

Y (max.) in degrees

IN TOTAL LENGTH OR

IN ANY SEGMENT OF

ONE FT. OR MORE

OF TOTAL LENGTH

1 Measured length, ft.

Measured length, ft.

Measured length, ft.

All except O,

TX510, TX511 I

0.500 thru 1.499

1.5002.999

3.000 and over

All

All

All

O, TX510 I

0.500 and over

0.095 and over

TX511 I

0.5001.499

1.5002.999

3.000 and over

0.095 and over

0.095 and over

0.095 and over

TABLE 12.8 StraightnessExtruded Tube in

Straight Lengths

TOLERANCE O }in.

ALLOWABLE DEVIATION (D)

FROM STRAIGHT

TEMPER

SPECIFIED

WIDTH

in.

O, TX510 I

7

5

3

1 Measured length, ft.

Measured length, ft.

Measured length, ft.

7

5

3

TABLE 12.9 Flatness (Flat Surfaces)

Extruded Tube

EXCEPT FOR O, T3510, T4510, T6510, T73510, T76510 AND T8510

TEMPERS U

TOLERANCEin.

MINIMUM THICKNESS

OF METAL FORMING

THE SURFACE

in.

IN TOTAL LENGTH OR

IN ANY SEGMENT OF

ONE FT. OR MORE

OF TOTAL LENGTH

All except

O, TX510 I

MAXIMUM

FOR TOTAL

LENGTH

0.5005.999

6.000 and over

.010 Measured length, ft.

.020 Measured length, ft.

0.500

and over

Maximum Allowable Deviation Y

WIDTHS UP THRU

1 IN. OR ANY 1 IN.

INCREMENT

OF WIDER SURFACES

WIDTHS

OVER

1 IN.

THRU 5.999 IN.

0.006

0.004

0.006 W (inches)

0.004 W (inches)

Up thru 0.187

0.188 and over

For all numbered footnotes, see page KA-TPS-AA4-1.09

This data reprinted from Aluminum standards and data 2006 with permission from The Aluminum Association, Inc.

KA-TPS-AA3-1.09

TABLE 12.10 Squareness of Cut Ends

Extruded Tube

TABLE 12.13 Surface Roughness w t

Extruded Tube

Allowable deviation from square: 1 degree.

TABLE 12.11 Corner and Fillet RadiiExtruded

Tube

TOLERANCEin.

ALLOWABLE DEVIATION

FROM SPECIFIED

RADIUS

SPECIFIED RADIUS y

in.

Specied

Outside

Diameter

in.

Specied

Wall

Thickness

in.

Allowable

Depth of

Conditions q

in., max.

Up thru

12.750

Up thru 0.063

0.0640.125

0.1260.188

0.1890.250

0.2510.500

0.501 and over

0.0025

0.003

0.0035

0.004

0.005

0.008

12.75115.000

Up thru 0.500

0.501 and over

0.010

0.012

15.00120.000

Up thru 0.500

0.501 and over

0.012

0.015

Up thru 0.500

0.501 and over

0.015

0.020

20.001 and over

Difference between radius

A and specied radius

Sharp corners

0.0160.187

0.188 and over

+

+Q-yr

Q-yr

10%

TABLE 12.12 AngularityExtruded Tube

TABLE 12.14 Dents eExtruded Tube

Depth of dents shall not exceed twice the tolerances specied in Table 12.2

for diameter at any point from specied diameter, except for tube having a

wall thickness less than 2.5 percent of the outside diameter, in which case

the following multipliers apply:

2% to 2% exclusive2.5 tolerance (max.)

1% to 2% exclusive3.0 tolerance (max.)

1% to 1% exclusive4.0 tolerance (max.)

Allowable deviation from square: 2 degrees.

Footnotes for Tables 12.2 through 12.14

Q When outside diameter, inside diameter, and wall thickness (or their

equivalent dimensions in other than round tube) are all specied, standard

tolerances are applicable to any two of these dimensions, but not to all three.

When both outside and inside diameters or inside diameter and wall thickness are specied, the tolerance applicable to the specied or calculated

O.D. dimension shall also apply to the I.D. dimension.

W When a dimension tolerance is specied other than as an equal bilateral

tolerance, the value of the standard tolerance is that which applied to the

mean of the maximum and minimum dimensions permissible under the tolerance for the dimension under consideration.

E Mean diameter is the average of two diameter measurements taken at

right angles to each other at any point along the length.

R Not applicable in the annealed (O) temper of if wall thickness is less than

2 percent of outside diameter of a circle having a circumference equal to

the perimeter of the tube.

T The mean wall thickness of round tube is the average of two measurements taken opposite each other. The mean wall thickness of other-thanround tube is the average of two measurements taken opposite each other

at approximate center line of tube and perpendicular to the longitudinal axis

of the cross section.

Y When dimensions specied are outside and inside, rather than wall thickness itself, allowable deviation at any point (eccentricity) applies to mean

wall thickness.

U Tolerances for O, T3510, T4510, T6510, T73510, T76510 and T8510

tempers shall be as agreed upon between purchaser and vendor at the time

the contract or order is entered.

I TX510 and TX511 are general designations for the following stressrelieved tempers: T3510, T4510, T6510, T8510, T73510, T76510; and

T3511, T4511, T6511, T8511, T73511, T76511, respectively.

O When weight of piece on at surface minimizes deviation.

P The circumscribing circle diameter is the diameter of the smallest circle

that will completely enclose the cross section of the extruded product.

{ Twist is normally measured by placing the extruded tube on a at surface

and at any point along its length measuring the maximum distance between

the bottom surface of the extruded tube and the at surface. From this measurement, the actual deviation from straightness of the extruded tube at that

point is subtracted. The remainder is the twist. To convert the standard twist

tolerance (degrees) to an equivalent linear value, the sine of the standard

tolerance is multiplied by the width of the surface of the section that is on

the at surface. The following values are used to convert angular tolerances

to linear deviation:

Maximum allowable

Tolerance,

linear deviation

degrees

inch per inch of width

1

1

3

5

7

9

15

21

0.004

0.009

0.017

0.026

0.052

0.087

0.122

0.156

0.259

0.358

} Tolerances not applicable to TX510, or TX511 temper tube having a wall

thickness less than 0.095 in.

q Conditions include die lines, mandrel lines and handling marks.

w For tube over 12.750 in. O.D. the 2000 and 7000 series alloys and 5000

series alloys with nominal magnesium content of 3 percent or more are

excluded.

e Not applicable to O temper tube.

r Tolerances apply to 5xxx alloys with 4.0% Mg.

t Not applicable to 2219 alloy tube. Most tubes in 2219 alloy will have die

lines about twice the depth shown in the table; however, for each tube size

the supplier should be contacted for the roughness value to apply.

y If unspecied, the radius shall be Q-ew in. maximum including tolerances.

This data reprinted from Aluminum standards and data 2006 with permission from The Aluminum Association, Inc.

KA-TPS-AA4-1.09

TABLE 12.55 Diameters, Wall Thicknesses, WeightsPipe

NOMINAL

PIPE

SIZE Q

IN.

OUTSIDE DIAMETER

in.

SCHEDULE

NUMBER

INSIDE

DIAMETER

in.

WALL THICKNESS

in.

WEIGHT PER FOOT

lb.

Nom. Q

Min W R

Max. W R

Nom.

Nom. Q

Min W

Max. W

Nom. E

Max. W E

Q-i

40

80

0.405

0.405

0.374

0.374

0.420

0.420

0.269

0.215

0.068

0.095

0.060

0.083

..

..

0.085

0.109

0.091

0.118

40

80

0.540

0.540

0.509

0.509

0.555

0.555

0.364

0.302

0.088

0.119

0.077

0.104

..

..

0.147

0.185

0.159

0.200

E-i

40

80

0.675

0.675

0.644

0.644

0.690

0.690

0.493

0.423

0.091

0.126

0.080

0.110

..

..

0.196

0.256

0.212

0.276

5

10

40

80

160

0.840

0.840

0.840

0.840

0.840

0.809

0.809

0.809

0.809

0.809

0.855

0.855

0.855

0.855

0.855

0.710

0.674

0.622

0.546

0.464

0.065

0.083

0.109

0.147

0.188

0.053

0.071

0.095

0.129

0.164

0.077

0.095

..

..

..

0.186

0.232

0.294

0.376

0.453

..

..

0.318

0.406

0.489

5

10

40

80

160

1.050

1.050

1.050

1.050

1.050

1.019

1.019

1.019

1.019

1.019

1.065

1.065

1.065

1.065

1.065

0.920

0.884

0.824

0.742

0.612

0.065

0.083

0.113

0.154

0.219

0.053

0.071

0.099

0.135

0.192

0.077

0.095

..

..

..

0.237

0.297

0.391

0.510

0.672

..

..

0.422

0.551

0.726

5

10

40

80

160

1.315

1.315

1.315

1.315

1.315

1.284

1.284

1.284

1.284

1.284

1.330

1.330

1.330

1.330

1.330

1.185

1.097

1.049

0.957

0.815

0.065

0.109

0.133

0.179

0.250

0.053

0.095

0.116

0.157

0.219

0.077

0.123

..

..

..

0.300

0.486

0.581

0.751

0.984

..

..

0.627

0.811

1.062

5

10

40

80

160

1.660

1.660

1.660

1.660

1.660

1.629

1.629

1.629

1.629

1.629

1.675

1.675

1.675

1.675

1.675

1.530

1.442

1.380

1.278

1.160

0.065

0.109

0.140

0.191

0.250

0.053

0.095

0.122

0.167

0.219

0.077

0.123

..

..

..

0.383

0.625

0.786

1.037

1.302

..

..

0.849

1.120

1.407

5

10

40

80

160

1.900

1.900

1.900

1.900

1.900

1.869

1.869

1.869

1.869

1.869

1.915

1.915

1.915

1.915

1.915

1.770

1.682

1.610

1.500

1.338

0.065

0.109

0.145

0.200

0.281

0.053

0.095

0.127

0.175

0.246

0.077

0.123

..

..

..

0.441

0.721

0.940

1.256

1.681

..

..

1.015

1.357

1.815

5

10

40

80

160

2.375

2.375

2.375

2.375

2.375

2.344

2.344

2.351

2.351

2.351

2.406

2.406

2.399

2.399

2.399

2.245

2.157

2.067

1.939

1.687

0.065

0.109

0.154

0.218

0.344

0.053

0.095

0.135

0.191

0.301

0.077

0.123

..

..

..

0.555

0.913

1.264

1.737

2.581

..

..

1.365

1.876

2.788

5

10

40

80

160

2.875

2.875

2.875

2.875

2.875

2.844

2.844

2.846

2.846

2.846

2.906

2.906

2.904

2.904

2.904

2.709

2.635

2.469

2.323

2.125

0.083

0.120

0.203

0.276

0.375

0.071

0.105

0.178

0.242

0.328

0.095

0.135

..

..

..

0.856

1.221

2.004

2.650

3.464

..

..

2.164

2.862

3.741

5

10

40

80

160

3.500

3.500

3.500

3.500

3.500

3.469

3.469

3.465

3.465

3.465

3.531

3.531

3.535

3.535

3.535

3.334

3.260

3.068

2.900

2.624

0.083

0.120

0.216

0.300

0.438

0.071

0.105

0.189

0.262

0.383

0.095

0.135

..

..

..

1.048

1.498

2.621

3.547

4.955

..

..

2.830

3.830

5.351

5

10

40

80

4.000

4.000

4.000

4.000

3.969

3.969

3.960

3.960

4.031

4.031

4.040

4.040

3.834

3.760

3.548

3.364

0.083

0.120

0.226

0.318

0.071

0.105

0.198

0.278

0.095

0.135

..

..

1.201

1.720

3.151

4.326

..

..

3.403

4.672

For all numbered footnotes, see page KA-TPS-AA6-1.09

This data reprinted from Aluminum standards and data 2006 with permission from The Aluminum Association, Inc.

KA-TPS-AA5-1.09

TABLE 12.55 Diameters, Wall Thicknesses, WeightsPipe (concluded)

NOMINAL

PIPE

SIZE Q

IN.

OUTSIDE DIAMETER

in.

SCHEDULE

NUMBER

INSIDE

DIAMETER

in.

WALL THICKNESS

in.

WEIGHT PER FOOT

lb.

Nom. Q

Min W R

Max. W R

Nom.

Nom. Q

Min W

Max. W

Nom. E

Max. W E

5

10

40

80

120

160

4.500

4.500

4.500

4.500

4.500

4.500

4.469

4.469

4.455

4.455

4.455

4.455

4.531

4.531

4.545

4.545

4.545

4.545

4.334

4.260

4.026

3.826

3.624

3.438

0.083

0.120

0.237

0.337

0.438

0.531

0.071

0.105

0.207

0.295

0.383

0.465

0.095

0.135

..

..

..

..

1.354

1.942

3.733

5.183

6.573

7.786

..

..

4.031

5.598

7.099

8.409

5

10

40

80

120