Documente Academic

Documente Profesional

Documente Cultură

Plumbing Piping

Încărcat de

DONGTA123Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plumbing Piping

Încărcat de

DONGTA123Drepturi de autor:

Formate disponibile

SECTION 22 1005

PLUMBING PIPING

PART 1 GENERAL

1.01 SECTION INCLUDES

A.

Pipe, pipe fittings, specialties, and connections for piping systems.

1. Sanitary sewer.

2. Domestic water.

3. Storm water.

4. Flanges, unions, and couplings.

5. Pipe hangers and supports.

6. Valves.

7. Flow controls.

8. Check.

9. Water pressure reducing valves.

10. Relief valves.

11. Strainers.

1.02 RELATED REQUIREMENTS

A.

Section 22 0553 - Identification for Plumbing Piping and Equipment.

B.

Section 22 0719 - Plumbing Piping Insulation.

1.03 REFERENCE STANDARDS

A.

TCVN 2980-79 Steel pipes and fittings for Hater piping - Technical requirements

B.

ASME B16.1 - Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250; 2010.

C.

ASME BPVC-IX - Boiler and Pressure Vessel Code, Section IX - Welding, Brazing, and Fusing

Qualifications; 2015.

D.

ASTM A53/A53M - Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated,

Welded and Seamless; 2012.

E.

ASTM C14 - Standard Specification for Nonreinforced Concrete Sewer, Storm Drain, and

Culvert Pipe; 2015a.

F.

ASTM C14M - Standard Specification for Nonreinforced Concrete Sewer, Storm Drain, Culvert

Pipe and (Metric); 2015a.

G.

ASTM C76 - Standard Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer

Pipe; 2015a.

H.

TCVN 6151-Pipes and fittings made of unplasticized poly(vinyl chloride) (PVC-U) for water

supply Specifications - Part 2: Pipes (with or without integral sockets)

I.

ASTM D1785 - Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules

40, 80, and 120; 2015.

J.

ASTM D2239 - Standard Specification for Polyethylene (PE) Plastic Pipe (SIDR-PR) Based on

Controlled Inside Diameter; 2012a.

K.

ASTM D2241 - Standard Specification for Poly (Vinyl Chloride) (PVC) Pressure-Rated Pipe

(SDR Series); 2015.

L.

ASTM D2466 - Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings,

Schedule 40; 2015.

M. ASTM D2661 - Standard Specification for Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40

Plastic Drain, Waste, and Vent Pipe and Fittings; 2014.

N.

ASTM D2665 - Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and

Vent Pipe and Fittings; 2014.

O.

TCVN 7305-3:2008 Plastics piping systems Polyethylene (PE) pipes and fittings for water

supply Part 3: Fittings

xxx / BOYDENSVN MASTER

SPEC

22 1005 - 1

PLUMBING PIPING

P.

DIN 8078 Polypropylene (PP) pipes PP-H, PP-B, PP-R, PP-RTC General quality requirement

and testing.

Q.

NSF 61 - Drinking Water System Components - Health Effects; 2014 (Errata 2015).

R.

NSF 372 - Drinking Water System Components - Lead Content; 2011.

1.04 SUBMITTALS

A.

See Section 01 3000 - Administrative Requirements, for submittal procedures.

B.

Product Data: Provide data on pipe materials, pipe fittings, valves, and accessories. Provide

manufacturers catalog information. Indicate valve data and ratings.

C.

Welder Certificate: Include welders certification of compliance with ASME BPVC-IX.

D.

Shop Drawings: For non-penetrating rooftop supports, submit detailed layout developed for this

project, with design calculations for loadings and spacings.

E.

Sustainable Design Documentation: For soldered copper joints, submit installer's certification

that the specified installation method and materials were used.

F.

Project Record Documents: Record actual locations of valves.

G.

Maintenance Materials: Furnish the following for Owner's use in maintenance of project.

1. See Section 01 6000 - Product Requirements, for additional provisions.

1.05 QUALITY ASSURANCE

A.

Perform work in accordance with applicable codes.

B.

Valves: Manufacturer's name and pressure rating marked on valve body.

C.

Welding Materials and Procedures: Conform to ASME BPVC-IX and applicable state labor

regulations.

D.

Welder Qualifications: Certified in accordance with ASME BPVC-IX.

E.

Identify pipe with marking including size, ASTM material classification, ASTM specification,

potable water certification, water pressure rating.

1.06 DELIVERY, STORAGE, AND HANDLING

A.

Accept valves on site in shipping containers with labeling in place. Inspect for damage.

B.

Provide temporary protective coating on cast iron and steel valves.

C.

Provide temporary end caps and closures on piping and fittings. Maintain in place until

installation.

D.

Protect piping systems from entry of foreign materials by temporary covers, completing sections

of the work, and isolating parts of completed system.

1.07 FIELD CONDITIONS

A.

Do not install underground piping when bedding is wet or frozen.

PART 2 PRODUCTS

2.01 GENERAL REQUIREMENTS

A.

Potable Water Supply Systems: Provide piping, pipe fittings, and solder and flux (if used), that

comply with NSF 61 and NSF 372 for maximum lead content; label pipe and fittings.

END OF SECTION

xxx / BOYDENSVN MASTER

SPEC

22 1005 - 2

PLUMBING PIPING

S-ar putea să vă placă și

- Alfa Laval TL3: Gasketed Plate-And-Frame Heat ExchangerDocument2 paginiAlfa Laval TL3: Gasketed Plate-And-Frame Heat ExchangerDONGTA123Încă nu există evaluări

- G Bag Brochure NewDocument5 paginiG Bag Brochure NewDONGTA123Încă nu există evaluări

- Plate Heat Exchanger Type Tl3-Bfg: Pvcals™Document2 paginiPlate Heat Exchanger Type Tl3-Bfg: Pvcals™DONGTA123Încă nu există evaluări

- Klauke Emerson UAP-4L Press Tool Technical SheetDocument2 paginiKlauke Emerson UAP-4L Press Tool Technical SheetDONGTA123Încă nu există evaluări

- Catalogue Calorex Heat Pump 2018Document16 paginiCatalogue Calorex Heat Pump 2018DONGTA123Încă nu există evaluări

- IMax Leaflet Grey W PDocument2 paginiIMax Leaflet Grey W PDONGTA123Încă nu există evaluări

- International Trade Sale Contract CrackiDocument31 paginiInternational Trade Sale Contract CrackiDONGTA123Încă nu există evaluări

- Technical Brochure - En: Enerblue - ItDocument8 paginiTechnical Brochure - En: Enerblue - ItDONGTA123Încă nu există evaluări

- Hot Water Heat Pump: TH EditionDocument12 paginiHot Water Heat Pump: TH Editiongeorge100% (1)

- Hot Water Storage Tank VintekDocument12 paginiHot Water Storage Tank Vintekh2odavidÎncă nu există evaluări

- Germany Referenceslist 2021Document11 paginiGermany Referenceslist 2021DONGTA123Încă nu există evaluări

- Lipujet-P-Oap Extension Stage 3: Product Information For The Product GroupDocument3 paginiLipujet-P-Oap Extension Stage 3: Product Information For The Product GroupDONGTA123Încă nu există evaluări

- Free-Standing InstallationDocument4 paginiFree-Standing InstallationDONGTA123Încă nu există evaluări

- Vitocell 300: Domestic Hot Water TanksDocument2 paginiVitocell 300: Domestic Hot Water TanksDONGTA123Încă nu există evaluări

- Dissimilar Metal Weldingv2 HERBST PDFDocument23 paginiDissimilar Metal Weldingv2 HERBST PDFAnonymous q2HC0zyfa2Încă nu există evaluări

- KEMPER Combitek HCMC 20191015 - p003Document1 paginăKEMPER Combitek HCMC 20191015 - p003DONGTA123Încă nu există evaluări

- Lipujet-P-Oap Extension Stage 3: Product Information For The Product GroupDocument3 paginiLipujet-P-Oap Extension Stage 3: Product Information For The Product GroupDONGTA123Încă nu există evaluări

- Austenitic Stainless Steel Welded PipesDocument1 paginăAustenitic Stainless Steel Welded PipesDONGTA123Încă nu există evaluări

- Bedard2015 Table S1-S2 Temperature DiagnosticDocument8 paginiBedard2015 Table S1-S2 Temperature DiagnosticDONGTA123Încă nu există evaluări

- KEMPER Combitek HCMC 20191015 - p007Document1 paginăKEMPER Combitek HCMC 20191015 - p007DONGTA123Încă nu există evaluări

- KEMPER Combitek HCMC 20191015 - p005Document1 paginăKEMPER Combitek HCMC 20191015 - p005DONGTA123Încă nu există evaluări

- So Do May Do Nong Do Bun ModelDocument1 paginăSo Do May Do Nong Do Bun ModelDONGTA123Încă nu există evaluări

- Water Safety in Buildings - WHODocument164 paginiWater Safety in Buildings - WHOTercio Estudiantil Famurp100% (2)

- KEMPER Combitek HCMC 20191015 - p004Document1 paginăKEMPER Combitek HCMC 20191015 - p004DONGTA123Încă nu există evaluări

- Kemper - A Global Manufacturer Since 1864Document1 paginăKemper - A Global Manufacturer Since 1864DONGTA123Încă nu există evaluări

- WSP Roadmap PDFDocument4 paginiWSP Roadmap PDFDONGTA123Încă nu există evaluări

- Potable Water Hygiene System: A Novel Approach For Drinking Water InstallationsDocument35 paginiPotable Water Hygiene System: A Novel Approach For Drinking Water InstallationsDONGTA123Încă nu există evaluări

- Water Heating Design Guide Final FNi DisclaimerDocument43 paginiWater Heating Design Guide Final FNi DisclaimerAhmed JabirÎncă nu există evaluări

- 2Document1 pagină2DONGTA123Încă nu există evaluări

- Best Environmental Management Practice In: The Tourism SectorDocument13 paginiBest Environmental Management Practice In: The Tourism SectorDONGTA123Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- FCVL 10 - 520 P 020220 enDocument2 paginiFCVL 10 - 520 P 020220 enAnonymous Xz3PgZR8100% (1)

- TDS 11 Hydraulic AnimationDocument17 paginiTDS 11 Hydraulic Animationahmed.kareem.khanjerÎncă nu există evaluări

- Directional Control Valve FundamentalsDocument18 paginiDirectional Control Valve Fundamentalsdoan lucÎncă nu există evaluări

- Bloco-Cilindro grua-L1-LUEN-SINGLE-OVERCENTRE-VALVES - 001Document43 paginiBloco-Cilindro grua-L1-LUEN-SINGLE-OVERCENTRE-VALVES - 001MARCO PAULO OLIVEIRAÎncă nu există evaluări

- Electropneumatically Operated Valves Series 3 and 4Document18 paginiElectropneumatically Operated Valves Series 3 and 4Diana DrutaÎncă nu există evaluări

- Section 3 Hydraulic System Group 1 Circuit DiagramDocument82 paginiSection 3 Hydraulic System Group 1 Circuit DiagramYonder RodríguezÎncă nu există evaluări

- ManualsDocument9 paginiManualsUmar SaeedÎncă nu există evaluări

- Kelas: D-Iv SKL 1E No Absen: 13: Nama: Mahrus HapidiDocument1 paginăKelas: D-Iv SKL 1E No Absen: 13: Nama: Mahrus HapidiJTE POLINEMAÎncă nu există evaluări

- DX55W Main Pump AP2D28 Technical ManualDocument14 paginiDX55W Main Pump AP2D28 Technical ManualZawminhtun100% (1)

- O.M.F.B Motores PWDocument4 paginiO.M.F.B Motores PWMasparts MaspartsÎncă nu există evaluări

- KSB LCC MDocument126 paginiKSB LCC MAlexander Alonso FernándezÎncă nu există evaluări

- High volume foam monitor datasheetDocument6 paginiHigh volume foam monitor datasheetMAHMUDÎncă nu există evaluări

- Hydraulic Schematic 6050 FS: Old Hydraulikschaltplan 6050 LSDocument1 paginăHydraulic Schematic 6050 FS: Old Hydraulikschaltplan 6050 LSJHONATAN ESTEBAN VALENZUELA ALBIÑOÎncă nu există evaluări

- Reciprocating Pump: Group 3Document13 paginiReciprocating Pump: Group 3Ariel GamboaÎncă nu există evaluări

- Pumping StationDocument54 paginiPumping Stationharipooyam100% (2)

- Nashirabad Et, Battali Hill Reservoir Phase-2Document1 paginăNashirabad Et, Battali Hill Reservoir Phase-2gawtomÎncă nu există evaluări

- BPE Catalog 2017 PDFDocument160 paginiBPE Catalog 2017 PDFIvailo ZapryanovÎncă nu există evaluări

- Construction Instrument Tubing Pressure & Leak Test ProcedureDocument9 paginiConstruction Instrument Tubing Pressure & Leak Test Procedurezack zeeartÎncă nu există evaluări

- Plumbing Notes:: LegendDocument1 paginăPlumbing Notes:: LegendjanelleÎncă nu există evaluări

- Spare Part ListDocument645 paginiSpare Part ListJose luis VargasÎncă nu există evaluări

- Fordson Dexta Workshopmanual Part 2 of 2Document97 paginiFordson Dexta Workshopmanual Part 2 of 2sunny dhaliwalÎncă nu există evaluări

- Idoc - Pub - Bs 6700 2006 Water Supply Services FormulatedDocument2 paginiIdoc - Pub - Bs 6700 2006 Water Supply Services FormulatedAmbi TionÎncă nu există evaluări

- MTech Machine DesignDocument41 paginiMTech Machine DesignAkshay Singh0% (1)

- Hydraulic Pumps FAQDocument5 paginiHydraulic Pumps FAQJatadhara GSÎncă nu există evaluări

- Festo-Hydraulics Advanced LevelDocument164 paginiFesto-Hydraulics Advanced Levelarm43994% (16)

- Format No SWPL-0221-QA-FRMT-010Document53 paginiFormat No SWPL-0221-QA-FRMT-010Swathy Nath PÎncă nu există evaluări

- Pumping Stations Design GuideDocument45 paginiPumping Stations Design GuideNestor Augusto Oyarce100% (2)

- REXROTH Service Manual PVC PSSFDocument6 paginiREXROTH Service Manual PVC PSSFRaghavendra DeshpandeÎncă nu există evaluări

- Hi-Force Hydrostatic PDFDocument6 paginiHi-Force Hydrostatic PDFWong Chung MengÎncă nu există evaluări

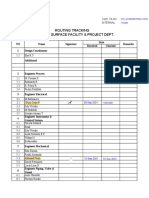

- Routing Tracking Operation Surface Facility & Project Dept.: 015 - JX-200238-PHG-LI-VD-21 TA-026Document8 paginiRouting Tracking Operation Surface Facility & Project Dept.: 015 - JX-200238-PHG-LI-VD-21 TA-026aurinkokelloÎncă nu există evaluări