Documente Academic

Documente Profesional

Documente Cultură

204-01 Front Suspension

Încărcat de

Miguel AngelDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

204-01 Front Suspension

Încărcat de

Miguel AngelDrepturi de autor:

Formate disponibile

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

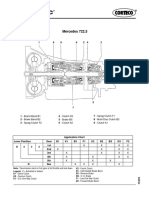

Front Suspension Coil Spring Suspension

Item

Specification

Front

Conventional coil spring with a twin tube damper and a high stress stabilizer bar

Road Spring Identification

Part Number

LR 001131

Specification

Isolator

LR 001145

Green/Yellow/Orange.

Torque Specifications

Description

Damper locknut*

Front subframe crossbrace:

M10*

M16*

Front subframe to body bolts*

Front ride height sensor

Halfshaft to hub bolt*

Lower control arm front bolt

Lower control arm rear nut and bolt

Lower control arm taper ball joint locknut*

Spring and damper assembly top mounting nuts

Stabilizer bar clamp bolts

Stabilizer bar link nuts*

Wheel knuckle to damper clamp bolt

* New nuts/bolts must be fitted

1 of 1

Nm

lb-ft

80

59

45

140 + 240

140 + 240

10

45 + 80

140 + 45

175

100

30

175

60

110

33

103 + 240

103 + 240

7

33 + 80

104 + 45

129

74

22

129

44

81

23/02/2012 7:30 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Part Number

-

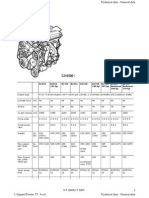

Front Suspension - Front Suspension

Description and Operation

COMPONENT LOCATION

Item

Part Number

Right Hand (RH) spring and damper assembly

Stabilizer bar link

Stabilizer bar

Left Hand (LH) spring and damper assembly

Wheel knuckle

Hub and bearing assembly

Lower control arm

Subframe

Description

OVERVIEW

The front suspension features long travel McPherson struts to optimize on and off road performance.

1 of 5

23/02/2012 7:30 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

The suspension components are mounted on a subframe. The subframe is mounted on 4 bushes which have differing

compression rates to absorb lateral and longitudinal loading. This provides a rigid platform for front suspension cornering

loads, frontal impact absorption and also provides a towing point for off-road recovery.

SPRING AND DAMPER

Item

Description

Boot

Bolts - Top mount (3 off)

Upper top mount plate

Lower top mount plate

Bump washer

Top mount bearing

Spring isolator

Spring

Spring Isolator

10

Damper body

11

Spring seat

12

Damper piston rod

13

Locknut

14

Spring aid

The spring and damper assembly is a twin tube design with the conventional coil spring located on a welded spring seat on

the damper tube. The lower end of the damper body locates in the wheel knuckle which is clamped with a bolt.

The damper functions by restricting the flow of hydraulic fluid through internal galleries within the damper. The damper rod

moves axially within the damper, its movement limited by the flow of fluid through the galleries, providing damping of

undulations in the terrain. The damper rod is sealed at its exit point from the damper body to maintain the fluid within the

unit and to prevent the ingress of dirt and moisture. The seal also incorporates a wiper to keep the rod clean.

The damper rod is located through a central hole in the top mount assembly. The rod is threaded at its outer end. A

self-locking nut secures the top mount to the damper rod. A spring aid is fitted to the damper rod to prevent the top mount

contacting the top of the damper during full suspension compression and also assists the suspension tune. A boot is fitted

between the damper body and the top mount and protects the damper piston rod from damage.

The coil spring fitted differs with vehicle specification. Each spring is colour coded to identify its rating and fitment

2 of 5

23/02/2012 7:30 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

requirements.

The coil spring is located in a spring seat which is an integral part of the damper body and contains a spring isolator. The

design of the spring seat prevents the spring rotating. The spring has a linear rate compression and is inclined to counter

cornering forces. The opposite end of the coil spring is also located in a spring isolator which is fitted in the top mount

assembly. Both spring isolators are made from rubber and prevent any noise produced during damper and spring

compression/extension from being transmitted to the vehicle body.

The top mount is fitted with a top mount bearing which is located between the 2 top mount plates and the damper rod. A self

locking nut secures the damper rod to the top mount. The top mount bearing reduces steering resistance by preventing the

spring from 'winding' up when the steering in turned. The top mount attaches to a strengthened turret on the chassis with 3

integral studs and self-locking nuts.

Two brackets are welded to the damper body. One bracket provides for the attachment of the stabilizer link. The second

bracket provides for the attachment of the brake hose and wheel speed sensor cable. This bracket also positively locates the

damper into the wheel knuckle and its location is critical to controlling the vehicle trim height.

LOWER CONTROL ARM

Item

Description

Subframe

Ball bush

Bolt - front attachment

Bolt - rear attachment (2 off)

Nut - rear attachment (2 off)

Hydrabush

Locknut

Taper ball joint

The lower control arm assembly comprises the control arm, a rubber bush, a hydrabush and a ball joint.

The control arm is a pressed steel fabrication. The outer end is fitted with a non-serviceable taper ball joint which mates with

the wheel knuckle.

The 2 inner attachments locate in the subframe. The forward attachment is a non-serviceable rubber bush which is pressed

into the control arm. This joint locates in a slot in the subframe and is secured with a bolt which is screwed into a threaded

boss on the subframe.

The rearward attachment is a hydrabush which is located on a spigot on the control arm. The hydrabush has 2 welded

3 of 5

23/02/2012 7:30 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

brackets which provides for its attachment to the subframe with 2 bolts and nuts. The hydrabush contains hydraulic fluid and

valves which allow controlled displacement of the bush to improve bump and handling characteristics and also reduce road

noise transmission. The bush becomes progressively stiffer as the forces on it increase, such as severe braking.

WHEEL KNUCKLE AND HUB ASSEMBLY

Item

Description

Clamp bolt

Wheel knuckle

Anti-lock Brake System (ABS) wheel speed sensor mounting

Steering tie-rod attachment

ABS wheel speed sensor pulse ring

Seal

Wheel bearing

Hub

Wheel stud

10

Disc shield attachment

11

Brake caliper attachment

The cast steel wheel knuckle provides the attachment for the lower control arm, spring and damper assembly, wheel hub and

bearing assembly and the steering tie-rod.

The extended lower boss on the knuckle provides for the attachment of the steering gear tie-rod ball joint. The ball joint is a

taper fitting and is secured with a locknut. The tie-rod allows for the adjustment of the front wheel toe angle.

The upper section of the wheel knuckle has a location hole for the damper body. The damper body slides into the hole and

locates against an abutment. The rear face of the hole is split and allows the damper body to be secured in the wheel knuckle

with a clamp bolt.

Mounting locations are provided for the brake caliper and the brake disc shield. A hole in the top face of the wheel knuckle

provides the location for the ABS wheel speed sensor which is secured with a bolt.

STABILIZER BAR

4 of 5

23/02/2012 7:30 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Item

Description

Locknut (hidden)

Ball joint

Link

Ball joint

Locknut

Clamp

Bush

Stabilizer bar

Bolt (2 off)

The stabilizer bar is attached to the rear of the subframe with bushes and mounting brackets. The pressed steel brackets

locate over the bushes and are attached to the cross member with bolts screwed into threaded locations in the subframe. The

stabilizer bar has 'anti-shuffle' collars pressed in position on the inside edges of the bushes. The collars prevent sideways

movement of the stabilizer bar.

The stabilizer bar is manufactured from 20.5 mm diameter, manganese steel bar. Each end of the stabilizer bar curves

forwards to attach to a ball joint on a stabilizer link. Each stabilizer link is secured to a bracket on the damper body with a

locknut. The links, which are not handed, allow the stabilizer bar to move with the wheel travel providing maximum

effectiveness.

The stabilizer bar bushes are the compression type which grip the bar under compression by the mounting brackets. When

fitting replacement bushes, it is important to ensure the bushes are correctly orientated to the bar. Failure to correctly align

the bushes will result in excessive pre-load (wind-up) in the bushes when the suspension is at its nominal ride height.

5 of 5

23/02/2012 7:30 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Front Suspension

Diagnosis and Testing

For additional information.

REFER to: Suspension System (204-00 Suspension System - General Information, Diagnosis and Testing).

1 of 1

23/02/2012 7:30 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Front Wheel Bearing

Removal and Installation

Special Tool(s)

204-348/3

Remover/Installer, Wheel Hub/Wheel Bearing

204-348-01

Adapter for 204-348

204-528/1

Remover/Installer, Bushing

204-536/2

Remover/Installer, Bushing

205-802/5

Remover, Wheel Hub/Bearing

Removal

NOTE: The wheel bearing is supplied as part of the drive flange assembly.

1.

WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Remove the wheel knuckle.

Refer to: Wheel Knuckle (204-01 Front Suspension, Removal and

Installation).

1 of 2

23/02/2012 7:33 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

3.

Position the wheel knuckle assembly in a press

and support on special tool.

Special Tool(s): 205-802/5

Using the special tool, press the drive flange

assembly out of the wheel knuckle.

Special Tool(s): 204-536/2

Installation

1.

CAUTION: Make sure that a new drive flange

assembly is installed.

Position the new drive flange assembly in the

special tools.

Special Tool(s): 204-348/3, 204-348-01

Using the special tool, press the drive flange

assembly into the wheel knuckle.

Special Tool(s): 204-528/1

2. Install the wheel knuckle.

Refer to: Wheel Knuckle (204-01 Front Suspension, Removal and

Installation).

2 of 2

23/02/2012 7:33 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Lower Arm

Removal and Installation

Special Tool(s)

204-619

G-Clamp

205-857

Remover, Halfshaft

211-316

Separator, Ball Joint

Removal

1. Remove the plenum chamber panel.

Refer to: Plenum Chamber (412-01 Climate Control, Removal and

Installation).

2. Release the hood support struts and secure the hood in

an upright position.

3.

WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

4. Remove the wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

1 of 4

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

5. NOTE: This step requires the aid of another technician.

Compress the spring and damper assembly.

Special Tool(s): 204-619

6. Remove and discard the front halfshaft bolt.

7. Partially release the front halfshaft from the wheel

knuckle.

Special Tool(s): 205-857

8.

CAUTION: Do not allow halfshafts to hang

unsupported at one end or joint damage will occur.

Partially release the front halfshaft from the wheel

knuckle.

2 of 4

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

9.

WARNING: Make sure that a new lower arm ball

joint nut is installed.

CAUTION: Make sure that the ball joint ball does

not rotate.

10. Special Tool(s): 211-316

11. Remove and discard the lower arm bolts.

Installation

1. NOTE: Make sure that new nuts and bolts are installed.

Install the lower suspension arm.

Tighten bolt 1.

Torque:

Stage 1:140 Nm

Stage 2:45

Tighten bolt 2 to

Torque: 175 Nm

Tighten bolt 3 to

Torque: 175 Nm

3 of 4

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

2.

WARNING: Make sure that a new lower arm ball

joint nut is installed.

CAUTION: Make sure that the ball joint ball does

not rotate.

Torque: 100 Nm

3.

CAUTION: Do not allow halfshafts to hang unsupported at one

end or joint damage will occur.

Fully insert the front halfshaft into the wheel knuckle.

4. NOTE: This step requires the aid of another technician.

Release the tension from the spring and damper assembly and

remove the special tool.

5. CAUTIONS:

Make sure that a new bolt is installed.

Make sure that the brake hose is not twisted and is

correctly located.

Install a new front halfshaft bolt.

Torque:

Stage 1:45 Nm

Stage 2:80

6. Install the wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

7. Lower the hood and secure the support struts with the clips.

8. Install the plenum chamber panel.

Refer to: Plenum Chamber (412-01 Climate Control, Removal and

Installation).

4 of 4

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Front Stabilizer Bar

Removal and Installation

Removal

CAUTION: Nuts and bolts must be tightened with the weight of the vehicle on the suspension.

NOTE: Only use clean water as a lubricant for the bushing, if required.

NOTE: Removal steps in this procedure may contain installation details.

1.

WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Remove the front wheels and tires.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

3. Remove the driveshaft.

Refer to: Driveshaft - Vehicles Without: Diesel Particulate Filter (DPF)

(205-01 Driveshaft, Removal and Installation).

4. Remove the catalytic converters.

Refer to: Catalytic Converter (309-00A Exhaust System - I6 3.2L

Petrol, Removal and Installation).

5.

CAUTION: Make sure that the ball joint ball does

not rotate.

Disconnect both stabilizer bar links.

Torque: 60 Nm

Discard the nuts.

6.

WARNING: Make sure that new nuts are installed.

Tighten in the sequence shown.

Torque: 175 Nm

Repeat the above procedure for the other side.

1 of 2

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

7. NOTE: Do not disassemble further if the component is

removed for access only.

Remove the stabilizer bar bushings.

Installation

1.

CAUTION: Nuts and bolts must be tightened with the weight of

the vehicle on the suspension.

To install, reverse the removal procedure.

2 of 2

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Front Stabilizer Bar Bushing

Removal and Installation

Removal

1.

WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Remove the front wheels and tires.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

3. Remove the engine undershield.

Refer to: Engine Undershield (501-02 Front End Body Panels, Removal

and Installation).

4.

CAUTION: Make sure that the ball joint ball does

not rotate.

Disconnect both front stabilizer bar links from the

stabilizer bar.

Discard the nuts.

1 of 3

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

5.

WARNING: Make sure that new nuts are installed.

Remove the stabilizer bar bushing.

Installation

WARNING: Make sure that new nuts are installed.

1.

Install the stabilizer bar bushings.

Torque: 175 Nm

2.

WARNING: Make sure that new nuts are installed.

CAUTION: Make sure that the ball joint ball does not rotate.

Install the stabilizer link bar.

Torque: 60 Nm

3. Install the engine undershield.

Refer to: Engine Undershield (501-02 Front End Body Panels, Removal

and Installation).

4. Install the wheels and tires.

2 of 3

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

3 of 3

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Front Stabilizer Bar Link

Removal and Installation

Removal

1.

WARNING: Do not work on or under a vehicle supported only by

a jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the front wheel.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

3.

WARNING: Make sure that new nuts are installed.

CAUTION: Use an Allen key to prevent the ball joint

rotating whilst removing the nut.

Torque: 60 Nm

Installation

1. To install, reverse the removal procedure.

1 of 1

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Wheel Knuckle

Removal and Installation

Special Tool(s)

204-159

Lever, Wheel Knuckle

204-619

G-Clamp

205-754A

Splitter, Ball Joints

205-857

Remover, Halfshaft

211-316

Separator, Ball Joint

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Remove the plenum chamber panel.

Refer to: Plenum Chamber (412-01 Climate Control, Removal and

Installation).

1 of 6

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

2. Release the hood support struts and secure the hood in

an upright position.

3.

WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

4. Remove the wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

5. CAUTIONS:

Discard the bolt.

Do not use air tools to install the bolt. Failure to

follow this instruction may result in damage to the

component.

Torque:

Stage 1:45 Nm

Stage 2:60

6.

CAUTION: Do not use a hammer to detach the

halfshaft from the hub assembly, failure to follow this

instruction may result in damage to the halfshaft.

Partially release the front halfshaft from the wheel

knuckle.

Special Tool(s): 205-857

2 of 6

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

7.

WARNING: Make sure that a new nut is installed.

CAUTION: Make sure that the ball joint ball does

not rotate.

Torque: 60 Nm

8. Torque: 5 Nm

9.

WARNING: Make sure that a new tie-rod end nut is

installed.

CAUTION: Make sure that the ball joint ball does

not rotate.

Torque: 80 Nm

10. Special Tool(s): 211-316

3 of 6

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

11.

CAUTION: Make sure that no load is placed on the

brake hose.

Torque: 200 Nm

12. Torque: 35 Nm

13. Torque: 10 Nm

14. NOTE: This step requires the aid of another technician.

Special Tool(s): 204-619

4 of 6

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

15. Torque: 110 Nm

16. Special Tool(s): 204-159

17. CAUTIONS:

Do not allow halfshafts to hang unsupported at one

end or joint damage will occur.

Do not use a hammer to detach the halfshaft from

the hub assembly, failure to follow this instruction may

result in damage to the halfshaft.

5 of 6

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

18.

WARNING: Make sure that a new lower arm ball

joint nut is installed.

CAUTION: Make sure that the ball joint ball does

not rotate.

Special Tool(s): 205-754A

Torque: 100 Nm

Installation

1. CAUTIONS:

Make sure that the brake hose is not twisted and is correctly

located.

Nuts and bolts must be tightened with the weight of the vehicle

on the suspension.

Install the halfshaft bolt finger tight.

NOTE: Make sure that all the component mating faces are clean.

To install, reverse the removal procedure.

6 of 6

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Front Shock Absorber

Removal and Installation

Removal

WARNINGS:

Ensure the spring compressor Safe Working Load (SWL) meets or exceeds the spring rating quoted in the Specifcations

section.

Always follow the spring compressor manufacturer's instructions.

1.

WARNING: Do not work on or under a vehicle supported only by

a jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the road wheel.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

3. Remove the spring and damper assembly.

Refer to: Shock Absorber and Spring Assembly (204-01 Front

Suspension, Removal and Installation).

4. Install the spring compressor in a vise.

5. Install the shock absorber and spring assembly in the spring

compressor.

6.

WARNING: Make sure that a new nut is installed.

Installation

1 of 2

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

1. WARNINGS:

Make sure that a new nut is installed.

It is imperative that the timing marks are aligned

as shown in illustration.

Torque: 80 Nm

2. Release the tension from the spring and damper assembly and

remove from the special tool.

3. Remove the spring compressor from a vise.

4. Install the spring and damper assembly.

Refer to: Shock Absorber and Spring Assembly (204-01 Front

Suspension, Removal and Installation).

5. Install the road wheel.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

2 of 2

23/02/2012 7:34 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Shock Absorber and Spring Assembly

Removal and Installation

Special Tool(s)

204-159

Lever, Wheel Knuckle

204-619

G-Clamp

Removal

1. Remove the plenum chamber panel.

Refer to: Plenum Chamber (412-01 Climate Control, Removal and

Installation).

2. Release the hood support struts and secure the hood in

an upright position.

3.

WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

4. Remove the wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

1 of 3

23/02/2012 7:35 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

5.

WARNING: Make sure that a new nut is installed.

Torque: 60 Nm

6. Torque: 110 Nm

7. NOTE: This step requires the aid of another technician.

Compress the spring and damper assembly.

Special Tool(s): 204-619

2 of 3

23/02/2012 7:35 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

8. Release the damper from the knuckle assembly.

Special Tool(s): 204-159

9. NOTE: This step requires the aid of another technician.

Release the tension from the spring and damper assembly and

remove the tool.

10. Remove the spring and damper assembly.

Torque: 30 Nm

Installation

1. CAUTIONS:

Make sure that the brake hose is not twisted and is correctly

located.

Nuts and bolts must be tightened with the weight of the vehicle

on the suspension.

NOTE: Make sure that the component is clean, free of foreign material

and lubricant.

To install, reverse the removal procedure.

3 of 3

23/02/2012 7:35 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Published: 11-May-2011

Front Suspension - Spring

Removal and Installation

Removal

WARNINGS:

Ensure the spring compressor Safe Working Load (SWL) meets or exceeds the spring rating quoted in the Specifcations

section.

Always follow the spring compressor manufacturer's instructions.

1.

WARNING: Do not work on or under a vehicle supported only by

a jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the road wheel.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

3. Remove the spring and damper assembly.

Refer to: Shock Absorber and Spring Assembly (204-01 Front

Suspension, Removal and Installation).

4. Install the spring compressor in a vise.

5. Install the shock absorber and spring assembly in the spring

compressor.

6.

1 of 3

WARNING: Make sure that a new nut is installed.

23/02/2012 7:35 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

7. Remove old spring from the spring compressor.

Installation

1. Install the new spring to the compressor and compress sufficiently.

2. WARNINGS:

Make sure that a new nut is installed.

It is imperative that the timing marks are aligned

as shown in illustration.

Torque: 80 Nm

3. Release the tension from the spring and damper assembly and

remove from the special tool.

4. Remove the spring compressor from a vise.

5. Install the spring and damper assembly.

Refer to: Shock Absorber and Spring Assembly (204-01 Front

Suspension, Removal and Installation).

6. Install the road wheel.

2 of 3

23/02/2012 7:35 AM

http://topix.landrover.jlrext.com/topix/service/procedure/146634/OD...

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and

Installation).

3 of 3

23/02/2012 7:35 AM

S-ar putea să vă placă și

- 206-03 Front Disc BrakeDocument13 pagini206-03 Front Disc BrakeMiguel AngelÎncă nu există evaluări

- 206-04 Rear Disc BrakeDocument17 pagini206-04 Rear Disc BrakeMiguel AngelÎncă nu există evaluări

- 204-02 Rear SuspensionDocument44 pagini204-02 Rear SuspensionMiguel AngelÎncă nu există evaluări

- 211-02 Power SteeringDocument23 pagini211-02 Power SteeringMiguel AngelÎncă nu există evaluări

- Land Rover Discovery 3 Wheels and Tires ManualDocument86 paginiLand Rover Discovery 3 Wheels and Tires ManualService Manual100% (1)

- 206-00 General InfoDocument16 pagini206-00 General InfoMiguel AngelÎncă nu există evaluări

- 204-05 Vehicle Dynamic SuspensionDocument2 pagini204-05 Vehicle Dynamic SuspensionMiguel AngelÎncă nu există evaluări

- Driveline System - General Information - Driveline System: Principles of OperationDocument4 paginiDriveline System - General Information - Driveline System: Principles of OperationMiguel AngelÎncă nu există evaluări

- 205 01 DriveshaftDocument13 pagini205 01 DriveshaftMiguel AngelÎncă nu există evaluări

- 206-06 Hydraulic Brake ActuationDocument16 pagini206-06 Hydraulic Brake ActuationMiguel AngelÎncă nu există evaluări

- 206-07 Power Brake ActuationDocument12 pagini206-07 Power Brake ActuationMiguel AngelÎncă nu există evaluări

- 801S - 2000 PDFDocument360 pagini801S - 2000 PDFclcasalÎncă nu există evaluări

- Timing Belt: Service and Repair Timing Belt, AssemblingDocument5 paginiTiming Belt: Service and Repair Timing Belt, AssemblingGustavo Guzuck Gutierrez GonzalezÎncă nu există evaluări

- Fitting The Bell Auto Services TDV6 EGR Blanking Kit To A MY06 TDV6Document6 paginiFitting The Bell Auto Services TDV6 EGR Blanking Kit To A MY06 TDV6Stathis MoumousisÎncă nu există evaluări

- D3 Suspension DiagnosticsDocument8 paginiD3 Suspension DiagnosticsPrudencio Serviano IIIÎncă nu există evaluări

- 2006 LAND ROVER RANGE ROVER HSE, SALME15456A199143 - Premium Report 44 Historical RecordsDocument4 pagini2006 LAND ROVER RANGE ROVER HSE, SALME15456A199143 - Premium Report 44 Historical RecordsJosephÎncă nu există evaluări

- Pin Out Volvo Radio Parrot AdaptDocument4 paginiPin Out Volvo Radio Parrot AdaptteknautomotiveÎncă nu există evaluări

- 4WD System Specs & Service GuideDocument35 pagini4WD System Specs & Service GuideZM OhnÎncă nu există evaluări

- 2588 - 10 EnglishDocument7 pagini2588 - 10 EnglishkallatisÎncă nu există evaluări

- Laf 0091-10-1e Towbar Electrics 13 Pin Vplft0077Document7 paginiLaf 0091-10-1e Towbar Electrics 13 Pin Vplft0077Miguel AngelÎncă nu există evaluări

- 156 PDFDocument208 pagini156 PDFAlexandru Catalin Negru100% (1)

- Engine Throtle FailureDocument2 paginiEngine Throtle FailuremarcglebÎncă nu există evaluări

- 205-02 Rear Drive Axle DifferentialDocument50 pagini205-02 Rear Drive Axle DifferentialMiguel Angel100% (1)

- LA413001 PDC Intermittant Operation PDFDocument2 paginiLA413001 PDC Intermittant Operation PDFGino PierÎncă nu există evaluări

- Land Rover Specific Diagnostic Trouble CodesDocument96 paginiLand Rover Specific Diagnostic Trouble CodesBRUCE QUAREÎncă nu există evaluări

- Contents and Components of the Parking Brake SystemDocument15 paginiContents and Components of the Parking Brake SystemRaphael Francisco PuttiniÎncă nu există evaluări

- GDI Engines VolkswagonDocument9 paginiGDI Engines VolkswagonNikhil KattiÎncă nu există evaluări

- Volvo XC70 2.5L Fuel Pump Control Module Relocation GuideDocument11 paginiVolvo XC70 2.5L Fuel Pump Control Module Relocation GuideGiedrius VainiusÎncă nu există evaluări

- Benz722 5powerpathDocument8 paginiBenz722 5powerpathGypsyRÎncă nu există evaluări

- Saab 9-3ss Fuel Tank R& RDocument14 paginiSaab 9-3ss Fuel Tank R& Rraquettelaker2100% (1)

- Replace front & rear brake padsDocument6 paginiReplace front & rear brake padsVenomKill18Încă nu există evaluări

- SKANDIX Pricelist Volvo S40 V40 (-2004)Document701 paginiSKANDIX Pricelist Volvo S40 V40 (-2004)Tudosie Alexey100% (1)

- 960 - 1996 Owner's ManualDocument254 pagini960 - 1996 Owner's ManualhucnÎncă nu există evaluări

- Mitchell Collisionshop Catalog 2082Document16 paginiMitchell Collisionshop Catalog 2082Leslie Rebecca Serrano JiménezÎncă nu există evaluări

- Land Rover V8: and ToolDocument56 paginiLand Rover V8: and ToolAntonio OliveiraÎncă nu există evaluări

- XC90 OwnersManual MY16 en-GB TP20376Document564 paginiXC90 OwnersManual MY16 en-GB TP20376Florin VilceaÎncă nu există evaluări

- Abs 1-16Document16 paginiAbs 1-16Vasile SilvioÎncă nu există evaluări

- 51035020running Gear PDFDocument626 pagini51035020running Gear PDFGeorge DimitroulisÎncă nu există evaluări

- English DS150E WIN7 User Guide V1.0Document128 paginiEnglish DS150E WIN7 User Guide V1.0Mirsad SalihovićÎncă nu există evaluări

- H 100Document8 paginiH 100api-199203074Încă nu există evaluări

- Electro Shema Range Rover 1999onDocument611 paginiElectro Shema Range Rover 1999onАлексей ЛопаткоÎncă nu există evaluări

- L314 Freelander 2004 LHDDocument165 paginiL314 Freelander 2004 LHDDubois BoxÎncă nu există evaluări

- Airbag Cayenne DefautDocument4 paginiAirbag Cayenne Defautmayet100% (1)

- LR2 2009 3.2LDocument348 paginiLR2 2009 3.2LRamsez Leonel100% (1)

- Wilson Gear BoxDocument20 paginiWilson Gear Boxsonirocks100% (1)

- DOHC Engine: Chapter 2 Part BDocument18 paginiDOHC Engine: Chapter 2 Part BMurgaÎncă nu există evaluări

- Timing Kit: Application Guide For: EngineDocument12 paginiTiming Kit: Application Guide For: EngineAnonymous wpUyixsjÎncă nu există evaluări

- 2005 9-5 EnginesDocument2 pagini2005 9-5 Enginessnappydressedotter100% (1)

- Freelander 2 TopixDocument5 paginiFreelander 2 TopixKelee KuulauÎncă nu există evaluări

- MY12 Electric Reference LibraryDocument772 paginiMY12 Electric Reference LibraryJose Maria Castro Pazos100% (2)

- Vehicle Specifications: ContentsDocument146 paginiVehicle Specifications: ContentsnanaÎncă nu există evaluări

- E1050 CAN Connection LinesDocument10 paginiE1050 CAN Connection LinesalexxmanuÎncă nu există evaluări

- DP 0Document4 paginiDP 0Vlad Blk100% (1)

- Volvo XC70 - 2006 Late Version - Rear Seat Entertainment System (RSE WIRING DIAGRAMDocument8 paginiVolvo XC70 - 2006 Late Version - Rear Seat Entertainment System (RSE WIRING DIAGRAMsen tilÎncă nu există evaluări

- Cutting-Edge Automotive Diagnostic Equipment Functions ManualDocument4 paginiCutting-Edge Automotive Diagnostic Equipment Functions ManualRichard Andrianjaka LuckyÎncă nu există evaluări

- VQ37HR Oil Consumption TSB - Nissan 370zDocument8 paginiVQ37HR Oil Consumption TSB - Nissan 370zcheshirecat79Încă nu există evaluări

- Jaguar XF Service PDFDocument1 paginăJaguar XF Service PDFtheprof55Încă nu există evaluări

- 206-00 General InfoDocument16 pagini206-00 General InfoMiguel AngelÎncă nu există evaluări

- RR Classic 87-91 Workshop Manual Part SRR652USWMADocument864 paginiRR Classic 87-91 Workshop Manual Part SRR652USWMAEmmanuel Romero0% (1)

- Laf 0091-10-1e Towbar Electrics 13 Pin Vplft0077Document7 paginiLaf 0091-10-1e Towbar Electrics 13 Pin Vplft0077Miguel AngelÎncă nu există evaluări

- 204-05 Vehicle Dynamic SuspensionDocument2 pagini204-05 Vehicle Dynamic SuspensionMiguel AngelÎncă nu există evaluări

- 206-09B Anti-Lock Control - Traction ControlDocument1 pagină206-09B Anti-Lock Control - Traction ControlMiguel AngelÎncă nu există evaluări

- 204-04 Wheels and TyresDocument20 pagini204-04 Wheels and TyresMiguel Angel100% (1)

- 205-02 Rear Drive Axle DifferentialDocument50 pagini205-02 Rear Drive Axle DifferentialMiguel Angel100% (1)

- 205 01 DriveshaftDocument13 pagini205 01 DriveshaftMiguel AngelÎncă nu există evaluări

- 204-06 Ride and Handling OptimizationDocument7 pagini204-06 Ride and Handling OptimizationMiguel AngelÎncă nu există evaluări

- 205-06 Rear Drive HalfshaftsDocument22 pagini205-06 Rear Drive HalfshaftsMiguel AngelÎncă nu există evaluări

- 205-04 Front Drive HalfshaftsDocument18 pagini205-04 Front Drive HalfshaftsMiguel AngelÎncă nu există evaluări

- Driveline System - General Information - Driveline System: Principles of OperationDocument4 paginiDriveline System - General Information - Driveline System: Principles of OperationMiguel AngelÎncă nu există evaluări

- 206-09C Anti-Lock Control - Stability AssistDocument18 pagini206-09C Anti-Lock Control - Stability AssistMiguel AngelÎncă nu există evaluări

- 204-00 General InfoDocument6 pagini204-00 General InfoMiguel AngelÎncă nu există evaluări

- 206-06 Hydraulic Brake ActuationDocument19 pagini206-06 Hydraulic Brake ActuationMiguel AngelÎncă nu există evaluări

- 211-04 Steering ColumnDocument14 pagini211-04 Steering ColumnMiguel AngelÎncă nu există evaluări

- 206-06 Hydraulic Brake ActuationDocument16 pagini206-06 Hydraulic Brake ActuationMiguel AngelÎncă nu există evaluări

- 206-07 Power Brake ActuationDocument12 pagini206-07 Power Brake ActuationMiguel AngelÎncă nu există evaluări

- 206 09A Anti Lock ControlDocument11 pagini206 09A Anti Lock ControlMiguel AngelÎncă nu există evaluări

- 211-00 General InfoDocument8 pagini211-00 General InfoMiguel AngelÎncă nu există evaluări

- 211-05 Steering Column SwitchesDocument13 pagini211-05 Steering Column SwitchesMiguel AngelÎncă nu există evaluări

- 211-03 Steering LinkageDocument5 pagini211-03 Steering LinkageMiguel AngelÎncă nu există evaluări

- 41 - Method Statements For Erection of Steel PDFDocument1 pagină41 - Method Statements For Erection of Steel PDFAbdul RahmanÎncă nu există evaluări

- Surface CareDocument18 paginiSurface CareChristi ThomasÎncă nu există evaluări

- Isuzu Service BookDocument32 paginiIsuzu Service BookJames100% (1)

- Companies DirectoryDocument137 paginiCompanies DirectorySiddhartha Govil75% (4)

- Rema Tip Top Automotive 2012Document380 paginiRema Tip Top Automotive 2012PTT XXKÎncă nu există evaluări

- Business Case AnalysisDocument7 paginiBusiness Case AnalysisEugenia JinÎncă nu există evaluări

- Suspension SystemDocument16 paginiSuspension SystemDebayan Dhar ChoudhuryÎncă nu există evaluări

- Tfelc We 0111Document0 paginiTfelc We 0111miguelx69Încă nu există evaluări

- Toyota R150 R151Document4 paginiToyota R150 R151Christian Rhadames Barkley Chavez100% (1)

- Vdocuments - MX Caterpillar 926e Manuals Volu Caterpillar Wheel Loader Powershift ManualDocument7 paginiVdocuments - MX Caterpillar 926e Manuals Volu Caterpillar Wheel Loader Powershift ManualAbdelbagi100% (1)

- Top Drive Drilling System Parts ListDocument105 paginiTop Drive Drilling System Parts ListAjay Singh RathaurÎncă nu există evaluări

- Software Engineering ProjectDocument27 paginiSoftware Engineering Projectcharity diolaÎncă nu există evaluări

- 2 (1) - HR PresentationDocument49 pagini2 (1) - HR Presentationpranav100% (1)

- Financial Statements Analysis TechniquesDocument83 paginiFinancial Statements Analysis TechniquesArunKumar100% (4)

- OTR Load InflationDocument77 paginiOTR Load InflationAchmad AnwarÎncă nu există evaluări

- Maruti Supply ChainDocument23 paginiMaruti Supply ChainRishabh ChaureÎncă nu există evaluări

- The Business Of... Managing Uptime (2015)Document8 paginiThe Business Of... Managing Uptime (2015)giovanniÎncă nu există evaluări

- 2013 Catalog # FLSC240P-SO Updated Date: August 15, 2013 Expiry Date: December 30, 2013Document7 pagini2013 Catalog # FLSC240P-SO Updated Date: August 15, 2013 Expiry Date: December 30, 2013Ashraf MostafaÎncă nu există evaluări

- Credigy Final PresentationDocument24 paginiCredigy Final Presentationapi-548833147Încă nu există evaluări

- Dom Unit I Imp QuestionsDocument1 paginăDom Unit I Imp QuestionsSree MurthyÎncă nu există evaluări

- Truck Load-Out ChecklistDocument3 paginiTruck Load-Out ChecklistIsaac Anthony100% (2)

- G. H. Raisoni College of EngineeringDocument5 paginiG. H. Raisoni College of EngineeringAsif MansuriÎncă nu există evaluări

- Diesel Progress June 2012Document21 paginiDiesel Progress June 2012Mauricio RamirezÎncă nu există evaluări

- Volkswagen Group: Adapting in The Age of AiDocument10 paginiVolkswagen Group: Adapting in The Age of AiAditi SoniÎncă nu există evaluări

- LeBlond Regal Lathes Manuals AvailableDocument60 paginiLeBlond Regal Lathes Manuals Availablejulie2420140% (1)

- Honda Accord 2007 Incl v6Document7.372 paginiHonda Accord 2007 Incl v6Kale Arbrough90% (10)

- File 001977Document3 paginiFile 001977julio binedaÎncă nu există evaluări

- Component Location Index: 2007 Acura RL 2007 Acura RLDocument5 paginiComponent Location Index: 2007 Acura RL 2007 Acura RLmkisa70Încă nu există evaluări

- PI PartsDocument417 paginiPI PartsRoberto Perez100% (1)

- Design and Implementation of Kinetic EnergyDocument2 paginiDesign and Implementation of Kinetic EnergysheikhÎncă nu există evaluări