Documente Academic

Documente Profesional

Documente Cultură

Method Statement 2 - Spraytek Plaster

Încărcat de

Mohammad Arif RasheedTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Method Statement 2 - Spraytek Plaster

Încărcat de

Mohammad Arif RasheedDrepturi de autor:

Formate disponibile

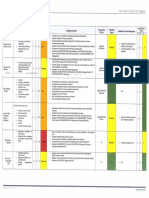

METHOD STATEMENT

FOR

SPRAYTEK PLASTER

Revisions Details:

Rev.

Date of

Issue

06.03.05

Prepared

M. Asaad

Reviewed

Engineering

QA/QC

Manager

Manager

Dr. Nabil

T. Hozayen

Approved

Project

Director

Ziad Ammous

Description

1st Issue

CONTENTS

Sr.

Subject

Page No.

Originator:

HEE

Date of issue: 06.03.2005

Page No. 1 of 6

Identification

Document Number

Contract No.

Tower/ location

Discipline

Issuer

Doc. Type

Number

Rev.

4505

General

HEE

MS

00062

/var/www/apps/conversion/tmp/scratch_5/339763491.doc

Document No.: 00062

Rev.: 0

Date of Issue: march 06, 2005

Page No.: No. 2 of 6

METHOD STATEMENT FOR

SPRAYTEK PLASTER

1.0

Scope

3

2.0

References

3

3.0

General

3

4.0

4.1

Resources

Materials

3

4.2

Equipment

3

4.3

Personnel

3

5.0

6.0

6.1

Definitions & Abbreviations

3

Procedure

Pre-application

4

6.2

7.0

Application of Spray Plaster

4

Quality Control

5

8.0

Safety

5

9.0

Attachments

5

METHOD STATEMENT FOR

SPRAYTEK PLASTER

1.

Document No.: 00062

Rev.: 0

Date of Issue: march 06, 2005

Page No.: No. 3 of 6

SCOPE: -

This Method Statement provides the control sequence of construction and methodology that will be

used for the application of Spraytek Plaster of ceiling in overall project site as an alternative for Terraco

material.

2. REFERENCES: o Project Specifications Volume II, Part 2 of 5, Section 09200.

o Drawings issued for construction.

3. GENERAL: The Spraytek Plaster shall be applied to the concrete ceilings only, in accordance with the drawings,

project specifications and the product manufacturers recommendations.

4. RESOURCES: 4.1. Materials:

Spraytek Extra Coarse Spraytek Fine, approved as per SCAR 00019.

4.2. Equipment:

Spray machine

Compressor

Measuring containers

Leveling tools

Finishing tools

4.3. Personnel:

5.

Project Engineer

Site Engineer

QA/QC Engineer

Site Foreman

Masons (Applicators)

Helpers

DEFINITIONS & ABBREVIATIONS: PE

SE

QCE

FM

SO

Project Engineer

Site Engineer

Quality Control Engineer

Foreman

Safety Officer

METHOD STATEMENT FOR

SPRAYTEK PLASTER

Document No.: 00062

Rev.: 0

Date of Issue: march 06, 2005

Page No.: No. 4 of 6

6. PROCEDURE: Responsibility

6.1. Pre-application:

1.

2.

3.

4.

5.

Approved materials shall be used in accordance with the project,

specifications and manufacturers recommendations.

Before beginning with plastering, the following shall be ensured;

- First fix of Electrical Works connected with backgrounds

have been completed.

- Adjacent finish work is well protected to prevent any

damage to it or spots, marks and stains on it during the

progress of work.

The activity of plastering shall not commence unless the substrate

is suitable. Concrete debris, binding wire, any ridges and traces of

form oil or release agents shall be removed from the surface.

Dust, dirt and foreign matter shall be brushed away and the

surface shall be ensured to be clean and dry.

Any joints of uneven level shall be grinded.

Spraytek spray plaster doesnt require any key coat haking prior

to plaster.

PE/SE

PE/SE/MEP

SE/FM

SE/FM

6.2. Application of Spraytek Plaster:

1.

2.

3.

4.

5.

6.

7.

8.

7. QUALITY:

Fill the joints with Spraytek Extra Coarse to level the uneven

joints.

Apply one coat of Spraytek Fine and level the surface with 60 Cm.

spatulla.

After 24 hours touch up the surface using Spraytek Fine and

obtain a smooth surface.

the surface is ready to receive texture to the desired size using

spraytek Fine.

Over Spraytek Spray Plaster smooth surface 2 coats of paint can

be done.

Before applying Final coat, it shall be ensured that final fix of

Electrical Works is completed.

Curing is not required for the Spray Plaster system.

Accessories (lath, corner beads, stop beads etc.) are not required

for the Spraytek plastering of ceilings.

SE/FM

SE/FM

SE/FM

SE/FM

SE/FM

PE/SE/FM

SE/FM

METHOD STATEMENT FOR

SPRAYTEK PLASTER

Document No.: 00062

Rev.: 0

Date of Issue: march 06, 2005

Page No.: No. 5 of 6

Significant stages of work shall be ensured by Project Engineer/Site

Engineer to be conforming to the drawings, specifications and

manufacturers recommendations, including;

-

PE/SE/QCE

Substrate preparation

Application of different coats of spraytek plaster

Clearance of MEP before covering up the work

QA/QC Engineer shall monitor all these stages.

First completed example of installed plaster not less than 10 meter

square shall be submitted to Consultant to establish the required

standard before proceeding with the remainder of work.

PE/SE/QCE

Inspection Request (IR) shall be submitted to Consultant for the

following stages of work;

PE/SE/QCE

o First completed example of installed work on-site

o Routine inspection of spraytek works:

- Inspection of substrate condition

- Inspection of Completed work.

8.

9.

PE/SE/QCE

Check sheet attached as Appendix. 1 shall be used at each

Inspection stage.

SAFETY:

Proper scaffolding shall be used and safety harness to be used and

secured, if required.

PE/SE/FM/SO

Proper and safe working platforms shall be used, wherever

required.

PE/SE/FM/SO

All personal protective equipment shall be used as appropriate

according to the nature of the job.

SE/FM/SO

Housekeeping shall be of good standard and all off cuts and spills

shall be removed.

SE/FM/SO

ATTACHMENTS: Appendix. 1.

application.

Appendix. 2.

QC/FIN/3-583, Rev. 1 Check Sheet for Ceiling plaster

Brochure of Spraytek Plaster system.

METHOD STATEMENT FOR

SPRAYTEK PLASTER

Document No.: 00062

Rev.: 0

Date of Issue: march 06, 2005

Page No.: No. 6 of 6

S-ar putea să vă placă și

- WMS (Method Statement For Pouring Concrete On Slab On Grade)Document4 paginiWMS (Method Statement For Pouring Concrete On Slab On Grade)PUI CHEE KHIANÎncă nu există evaluări

- Method Statement For Casting of Cement Based ScreedDocument8 paginiMethod Statement For Casting of Cement Based Screedmd_rehan_2100% (1)

- Method Statement: Soil Replacement Under FoundationsDocument1 paginăMethod Statement: Soil Replacement Under FoundationsMohamed SalahÎncă nu există evaluări

- Method of Statement (Concrete Repair)Document3 paginiMethod of Statement (Concrete Repair)Sa3id HassanÎncă nu există evaluări

- Method of Statement For Tile Laying Work-Qc-RvlDocument9 paginiMethod of Statement For Tile Laying Work-Qc-Rvljohn paul100% (1)

- Method Statement FOR Concreting Work: ProjectDocument6 paginiMethod Statement FOR Concreting Work: ProjectKelvin LauÎncă nu există evaluări

- Renderoc FC (1) Fairing Coat PDFDocument4 paginiRenderoc FC (1) Fairing Coat PDFPrashant MankarÎncă nu există evaluări

- Renderoc TGDocument4 paginiRenderoc TGBalasubramanian Ananth100% (1)

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 paginiCV-0013-005 - Method Statement For Concrete Work (Revised)한상호Încă nu există evaluări

- Casting of RC Slab MosDocument2 paginiCasting of RC Slab MosEngr Badz de DiosÎncă nu există evaluări

- Method Statement For Raft FootingDocument5 paginiMethod Statement For Raft FootingLokesh SaranÎncă nu există evaluări

- Method Statement For Cement Board Dry Wall PartitionsDocument10 paginiMethod Statement For Cement Board Dry Wall PartitionsComet GroupÎncă nu există evaluări

- AAC Block Masonary - Method StatementDocument2 paginiAAC Block Masonary - Method StatementdawoodnagnurÎncă nu există evaluări

- 2 Finishing Works Method Statement For Building ConstructionDocument15 pagini2 Finishing Works Method Statement For Building ConstructionElxao XanÎncă nu există evaluări

- Epoxy Painting MethodDocument3 paginiEpoxy Painting MethodKaram MoatasemÎncă nu există evaluări

- Installation On: Tiles Dado DryDocument35 paginiInstallation On: Tiles Dado Drylokesh.kukadiyaÎncă nu există evaluări

- Work Method StatementDocument2 paginiWork Method StatementSetyawanÎncă nu există evaluări

- Method Statement of Brick Masonary WorkDocument6 paginiMethod Statement of Brick Masonary WorkMihirduttaÎncă nu există evaluări

- BlockworkDocument5 paginiBlockworkVikram DhabaleÎncă nu există evaluări

- Method Statement For Tiliing Works: Method Statement No.: ONEIC/MS/C/08 Page 1 of 3Document3 paginiMethod Statement For Tiliing Works: Method Statement No.: ONEIC/MS/C/08 Page 1 of 3Presanna RajasekaranÎncă nu există evaluări

- Kerbstones Installation GuidelinesDocument4 paginiKerbstones Installation Guidelinespartha_svnitÎncă nu există evaluări

- Terrazzo Tiles ChecklistDocument1 paginăTerrazzo Tiles Checklistahmed samirÎncă nu există evaluări

- Code of Practice Construction SSW PDocument117 paginiCode of Practice Construction SSW PRafael FonsecaÎncă nu există evaluări

- Method Statement For AAC Block Masonry: Material RequiredDocument2 paginiMethod Statement For AAC Block Masonry: Material RequiredEyutt HghghÎncă nu există evaluări

- 29 Method Statement BRICK WORKDocument6 pagini29 Method Statement BRICK WORKSusil Kumar SahooÎncă nu există evaluări

- Method Statement For Cement Board Dry Wall PartitionsDocument10 paginiMethod Statement For Cement Board Dry Wall PartitionsComet GroupÎncă nu există evaluări

- Method Statement FOR Embedded Conduits, Boxes and Fittings InstallationDocument6 paginiMethod Statement FOR Embedded Conduits, Boxes and Fittings InstallationWalidÎncă nu există evaluări

- Method of Statement Template For Marble InstallationDocument6 paginiMethod of Statement Template For Marble InstallationumitÎncă nu există evaluări

- Method Statement For Retaining Wall Work ExecutionDocument3 paginiMethod Statement For Retaining Wall Work ExecutionSujeet SarukÎncă nu există evaluări

- Waterproof Planiseal 288Document3 paginiWaterproof Planiseal 288Chezy629Încă nu există evaluări

- Method Statement - Concreting WorkDocument4 paginiMethod Statement - Concreting WorkArnold Roy ManaloÎncă nu există evaluări

- Methodology For Floor Tiling.Document2 paginiMethodology For Floor Tiling.murali100% (2)

- MS For Form - WorksDocument8 paginiMS For Form - WorksImho Tep100% (1)

- DSE Assessment DT TemplateDocument11 paginiDSE Assessment DT TemplateJulien CambonÎncă nu există evaluări

- Cem Tec White PuDocument2 paginiCem Tec White Pupravi3434Încă nu există evaluări

- Method Statement For Casting of Cement Based Screed-Checked by Const - TeamDocument8 paginiMethod Statement For Casting of Cement Based Screed-Checked by Const - Teammd_rehan_2100% (1)

- Method Statement For Painting WorksDocument5 paginiMethod Statement For Painting WorksDavid SeeÎncă nu există evaluări

- Ceramic Tile Fixing StatementDocument5 paginiCeramic Tile Fixing StatementAmit KhazanchiÎncă nu există evaluări

- Screeding WorksDocument1 paginăScreeding WorksCindy AmyzaÎncă nu există evaluări

- Method Statement For Planter WaterproofingDocument8 paginiMethod Statement For Planter WaterproofingMonali Varpe0% (1)

- Method Statement of Plastering: Pembinaan Infra E&J SDN BHDDocument5 paginiMethod Statement of Plastering: Pembinaan Infra E&J SDN BHDChezy629Încă nu există evaluări

- Method Statement of Installing I-BeamDocument1 paginăMethod Statement of Installing I-BeamfaizbukhariÎncă nu există evaluări

- Wall and Floor Tiles Method Statment PDFDocument4 paginiWall and Floor Tiles Method Statment PDFAli SaifÎncă nu există evaluări

- Method StatementDocument4 paginiMethod StatementSagar ParabÎncă nu există evaluări

- Fire Stop Work Installation & Application Method Statement: ScopeDocument22 paginiFire Stop Work Installation & Application Method Statement: ScopeWahid HusainÎncă nu există evaluări

- Method Statement Striking FormworkDocument3 paginiMethod Statement Striking FormworkSurya HeriwijayaÎncă nu există evaluări

- KAPSARC-MRK-Concrete Repair work-METHOD STATEMENTDocument4 paginiKAPSARC-MRK-Concrete Repair work-METHOD STATEMENTsherwin suarezÎncă nu există evaluări

- Method Statement For Coring WorkDocument6 paginiMethod Statement For Coring Workadeniyi abiolaÎncă nu există evaluări

- Method Statement: Interiors Sources Decor LLCDocument10 paginiMethod Statement: Interiors Sources Decor LLCaayasirÎncă nu există evaluări

- 1 MS - Pouring of ConcreteDocument8 pagini1 MS - Pouring of ConcreteFauzi MastamÎncă nu există evaluări

- ML-KW-MST-001 R1 False Ceiling WorksDocument7 paginiML-KW-MST-001 R1 False Ceiling WorksprithivirajÎncă nu există evaluări

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Document19 paginiMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinÎncă nu există evaluări

- CONQUAS Ver 2editDocument3 paginiCONQUAS Ver 2editbyleekkÎncă nu există evaluări

- Lysaght Klip-Lok OptimaDocument12 paginiLysaght Klip-Lok OptimaZaid AzmiÎncă nu există evaluări

- Flat Concrete Floor Work Method - FindotekDocument16 paginiFlat Concrete Floor Work Method - FindotekTAHER AMMARÎncă nu există evaluări

- Synthetic Grass DIY Installation GuideDocument26 paginiSynthetic Grass DIY Installation GuideNirav PathakÎncă nu există evaluări

- Method StatementDocument7 paginiMethod StatementTenuki JapanÎncă nu există evaluări

- Civil Engineering Draftsman II: Passbooks Study GuideDe la EverandCivil Engineering Draftsman II: Passbooks Study GuideÎncă nu există evaluări

- Work Methodology For Epoxy Flooring Coating WorkDocument2 paginiWork Methodology For Epoxy Flooring Coating WorkKripesh Kumar DubeyÎncă nu există evaluări

- Plastering Works Method StatementDocument7 paginiPlastering Works Method StatementYan Belarmino33% (6)

- Whole Building Commissioning Process ManualDocument155 paginiWhole Building Commissioning Process ManualSayed HashemÎncă nu există evaluări

- Project Risk RegisterDocument9 paginiProject Risk RegisterMohammad Arif Rasheed100% (1)

- SBJ H2 HSE PlanDocument51 paginiSBJ H2 HSE PlanMohammad Arif RasheedÎncă nu există evaluări

- Trail No 198 - M50 BHARATHI + CHRYSO: Concrete Mix Proportioning Details A. Stipulations For ProportioningDocument4 paginiTrail No 198 - M50 BHARATHI + CHRYSO: Concrete Mix Proportioning Details A. Stipulations For ProportioningMohammad Arif RasheedÎncă nu există evaluări

- Chapter 02 - Introduction To Quality Management-Sep 2010 PDFDocument13 paginiChapter 02 - Introduction To Quality Management-Sep 2010 PDFMohammad Arif RasheedÎncă nu există evaluări

- MS-101 REv. 01 - Overall Construction Method Statement-UPLOADDocument30 paginiMS-101 REv. 01 - Overall Construction Method Statement-UPLOADMohammad Arif Rasheed100% (3)

- RA Termite PDFDocument1 paginăRA Termite PDFMohammad Arif RasheedÎncă nu există evaluări

- METHOD STATEMENT OF Excavation Pile Cutting Rev 1 UPLOADDocument7 paginiMETHOD STATEMENT OF Excavation Pile Cutting Rev 1 UPLOADMohammad Arif RasheedÎncă nu există evaluări

- METHOD STATEMENT OF Excavation Pile Cutting Rev 1 UPLOADDocument7 paginiMETHOD STATEMENT OF Excavation Pile Cutting Rev 1 UPLOADMohammad Arif RasheedÎncă nu există evaluări

- Itp - Rebar & Concrete-UploadDocument4 paginiItp - Rebar & Concrete-UploadMohammad Arif RasheedÎncă nu există evaluări

- Itp - Rebar & ConcreteDocument4 paginiItp - Rebar & ConcreteMohammad Arif RasheedÎncă nu există evaluări

- Construction Management PalnDocument25 paginiConstruction Management PalnMohammad Arif RasheedÎncă nu există evaluări

- Pioneer pdp-424mv Pdp-42mve1 (ET)Document122 paginiPioneer pdp-424mv Pdp-42mve1 (ET)Manuel PeraltaÎncă nu există evaluări

- A01 04 Assessmentk UndercarriageDocument7 paginiA01 04 Assessmentk UndercarriageMARIO DEL PINO MUÑOZÎncă nu există evaluări

- BLTouch Setup ManualDocument7 paginiBLTouch Setup ManualBobbyÎncă nu există evaluări

- Co-Ordinate Measuring Machines & It's Applications: Introduction ToDocument65 paginiCo-Ordinate Measuring Machines & It's Applications: Introduction Toshiva dÎncă nu există evaluări

- 90 61 085 Transportation ValvesDocument18 pagini90 61 085 Transportation ValvesarrikanÎncă nu există evaluări

- Manual Yamaha Clavinova P100Document69 paginiManual Yamaha Clavinova P100Nelon Rocha100% (1)

- ERPtips SAP Training Manual SAMPLE CHAPTER From Basic PayrollDocument20 paginiERPtips SAP Training Manual SAMPLE CHAPTER From Basic Payrollravibabu1620Încă nu există evaluări

- Algorithmic Versus Human AdviceDocument31 paginiAlgorithmic Versus Human AdviceDaqiang ChenÎncă nu există evaluări

- Sabor CaseDocument3 paginiSabor CaseTushar LaroiyaÎncă nu există evaluări

- Acornejo Southmayd ProfileDocument11 paginiAcornejo Southmayd Profileapi-242543114Încă nu există evaluări

- ASTM Pumping TestDocument125 paginiASTM Pumping TestErnesto Heinze100% (1)

- SAP Workflow Interview Questions - MindmajixDocument25 paginiSAP Workflow Interview Questions - MindmajixsudhÎncă nu există evaluări

- Invoice Cod Invoice Cod: Agen Pos Agen PosDocument4 paginiInvoice Cod Invoice Cod: Agen Pos Agen Poswahids0204Încă nu există evaluări

- Types of CCTVDocument12 paginiTypes of CCTVpradeeplava950Încă nu există evaluări

- Assignment 3 - 2 Microcontrollers With DatasheetsDocument2 paginiAssignment 3 - 2 Microcontrollers With Datasheetsapi-42328551276% (45)

- Performance Analysis of Cooperative Communication For Wireless NetworksDocument164 paginiPerformance Analysis of Cooperative Communication For Wireless NetworksIhtesham JadoonÎncă nu există evaluări

- Transport ModellingDocument37 paginiTransport ModellingRiza Atiq Abdullah Rahmat100% (6)

- Sony Blitz h36 - ManualDocument212 paginiSony Blitz h36 - ManualBohorc Ivica JerryÎncă nu există evaluări

- StetindDocument6 paginiStetindGiovanniÎncă nu există evaluări

- Akta Satelit On Astra 4A at 4Document6 paginiAkta Satelit On Astra 4A at 4Amirul AsyrafÎncă nu există evaluări

- Pawan Kumar Dubey: ProfileDocument4 paginiPawan Kumar Dubey: Profilepawandubey9Încă nu există evaluări

- Cu Ext 2015Document4 paginiCu Ext 2015mohammedzuluÎncă nu există evaluări

- SP2000 COD Testkits 2014Document5 paginiSP2000 COD Testkits 2014Andres FalmacelÎncă nu există evaluări

- Duty Engineer: Grand Mercure & Ibis Yogyakarta Adi SuciptoDocument1 paginăDuty Engineer: Grand Mercure & Ibis Yogyakarta Adi Suciptoali maulana yuthiaÎncă nu există evaluări

- TM 9-792 M21 AMMUNITION TRAILERDocument128 paginiTM 9-792 M21 AMMUNITION TRAILERAdvocate100% (1)

- Lewmar Marine Equipment Guide Ed 14Document224 paginiLewmar Marine Equipment Guide Ed 14Renato Fonseca100% (1)

- B. Tech. Electrical and Electronics EngineeringDocument105 paginiB. Tech. Electrical and Electronics EngineeringKarthik NagarajanÎncă nu există evaluări

- Web Content Management SystemsDocument30 paginiWeb Content Management SystemsTharmi KÎncă nu există evaluări

- Sap BarcodesDocument59 paginiSap BarcodesDarmin MemiševićÎncă nu există evaluări

- Creation of Customer From Business PartnerDocument9 paginiCreation of Customer From Business PartnerParag SoniÎncă nu există evaluări