Documente Academic

Documente Profesional

Documente Cultură

SmartPlant PID Engineering Integrity Top 10 Rules

Încărcat de

DavidAcostaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SmartPlant PID Engineering Integrity Top 10 Rules

Încărcat de

DavidAcostaDrepturi de autor:

Formate disponibile

WHITE PAPER

SmartPlant P&ID

Engineering

Integrity

10 Example Rules

SmartPlant P&ID Engineering Integrity

SmartPlant P&ID Engineering Integrity

SmartPlant P&ID Engineering Integrity checks that SmartPlant P&IDs comply with engineering

standards and company best practices for safety and operations. The system is delivered with

more than 3,000 rules developed based on the API 14C standard and typical company engineering

practices. Or the customer can quickly develop their own using the supplied simple engineering

interface. You dont need a background in computer programming to customize the software.

Generally, rules can be divided into the

following categories:

Topology verification

Data check

Standard verification, such as safety

and operational practices

Visual verification, for example, if

labels are placed on the P&ID

Combinations of the above

10 Example Rules

Instrumentation checks

1. Check that equipment is correctly instrumented. For example, all pressure vessels must

have a relief system and a pressure indicator.

Frequently repeated checks

Some checks continually take time to manually check again and again. For example:

2. All control valves must have a fail position defined with the label on the P&ID.

3. There should be no restrictions between a pressure vessel and its relief valve. But if there

is a valve, it must be labeled car sealed open.

Note that the results from SmartPlant P&ID Engineering Integrity are versioned so that the user can

check just the changes since the last version.

SmartPlant P&ID Engineering Integrity

Configurations

SmartPlant P&ID Engineering Integrity can check for more complex configurations. Although SmartPlant

P&ID has assemblies, there is no guarantee that the right assembly has been selected by the user or has

not been modified in some way. Examples of configuration checks include:

4. Control stations should always be configured with:

Bypass takeoff

Block valve

Drain

Reducer

Control valve

Reducer

Drain

Block valve

Bypass takeoff

And the pipe size must change either side of the control valve.

5. Block valves are required for each exchanger cooling water supply and return line when several

units are in common service and the ability to take one or more out of service during operation is

required to avoid shutdown. Block valves shall be:

Gate valve for lines 200 mm

Butterfly valve for lines > 200 mm

6. For cooling water service, provide winterization bypass for all exchangers. The bypass will be

open when the exchanger is out of service and the temperature is below freezing. Provide the

following bypass line sizes to maintain adequate velocities in the supply and return headers:

CW line size

Bypass size

8 or less

10 to 18

1 1/2

20 or more

2"

SmartPlant P&ID Engineering Integrity

7. Drain/Vent/Steam-out Nozzle Size Check

Vessel volume, m

Drain

Vent

Steam-out

Less than 17.0

17.0 70.0

Greater than 70.0

3"

Engineering rules

8. Check for high-pressure and low-pressure interfaces where the high pressure can get locked in

by valves closing.

9. Check that the relief valve is set to 110 percent of the maximum allowable working pressure of

the vessel and is less than the design pressure.

10. Positive isolation assemblies must be used when toxic fluids are present in the pipework and

shall consist of double block and bleed arrangement with both a vent and drain connection

between the double block valves. The vent and drain connection shall have double isolation

valves.

SmartPlant P&ID Engineering Integrity

User Interface Examples

Engineer Stays in Control

If the rule is failing, the engineer can always override the results and accept a configuration as-is.

This will then be recorded in the system for later audits.

For more information about Intergraph, visit our website at

www.intergraph.com.

Intergraph, the Intergraph logo, and SmartPlant are registered

trademarks of Intergraph Corporation or its subsidiaries in the

United States and in other countries. Other brands and product

names are trademarks of their respective owners. Intergraph

believes that the information in this publication is accurate as

of its publication date. Such information is subject to change

without notice. Intergraph is not responsible for inadvertent

errors. 2012 Intergraph Corporation. All Rights Reserved.

3/12 PPM-US-0162-ENG

S-ar putea să vă placă și

- Significant Zeros Worksheet AnswersDocument6 paginiSignificant Zeros Worksheet AnswersEthan Heinzel100% (5)

- SPAutomation Course Labs V2009Document149 paginiSPAutomation Course Labs V2009yan liu100% (1)

- SPPID - Procedure To Create New Line StyleDocument23 paginiSPPID - Procedure To Create New Line StyleShahfaraz Ahmad100% (2)

- Export To PDMS User's Guide PDFDocument145 paginiExport To PDMS User's Guide PDFlnacerÎncă nu există evaluări

- Add Custom View Style Type SM3D SP3D SP3D MHEDocument2 paginiAdd Custom View Style Type SM3D SP3D SP3D MHEjeffÎncă nu există evaluări

- EE Raceway IntroductionDocument10 paginiEE Raceway Introductiontranhuy3110100% (1)

- Creating Intergraph Smart 3D DataBases and ConfiguringDocument7 paginiCreating Intergraph Smart 3D DataBases and ConfiguringpedromiguelÎncă nu există evaluări

- Isometrics Generated in SP3DDocument2 paginiIsometrics Generated in SP3Drahult19Încă nu există evaluări

- SP3D Smart PlantDocument14 paginiSP3D Smart PlantahmedalishÎncă nu există evaluări

- Plant Design SystemDocument16 paginiPlant Design Systemsairam_ysr75% (4)

- SPPID Training - 01 Logging in Through Drawing Manager PDFDocument31 paginiSPPID Training - 01 Logging in Through Drawing Manager PDFANAND KALEPÎncă nu există evaluări

- 05 - SP3DNetAPI - Business ObjectDocument3 pagini05 - SP3DNetAPI - Business Objectyan liuÎncă nu există evaluări

- SPP&ID Training - 00 Logging Through VMwareDocument4 paginiSPP&ID Training - 00 Logging Through VMwareKarthik0% (1)

- Interactive Section Tables: Reference GuideDocument64 paginiInteractive Section Tables: Reference GuideKannaphat Wattanaphan100% (1)

- Smartplant P&Id: Installation and Upgrade GuideDocument130 paginiSmartplant P&Id: Installation and Upgrade GuideHdkdbdksÎncă nu există evaluări

- RIS SQL User's GuideDocument312 paginiRIS SQL User's GuidemÎncă nu există evaluări

- 04 - SP3DNetAPI - Client ServicesDocument13 pagini04 - SP3DNetAPI - Client Servicesyan liuÎncă nu există evaluări

- TSPL1002 V2009 Course LabsDocument182 paginiTSPL1002 V2009 Course Labsdharan kumar100% (1)

- SmartPlant PIDDocument2 paginiSmartPlant PIDavailmeÎncă nu există evaluări

- SmartPlant Electrical Basic Users TrainiDocument238 paginiSmartPlant Electrical Basic Users TrainiVictor RamirezÎncă nu există evaluări

- 02 - SP Instrumentation On Oracle PDFDocument57 pagini02 - SP Instrumentation On Oracle PDFSd Weds DsÎncă nu există evaluări

- Intergraph SmartPlant P&ID User Tips and Tricks For SpeedDocument5 paginiIntergraph SmartPlant P&ID User Tips and Tricks For Speedking1470100% (1)

- Configuring Intergraph Smart 3D Application Servers and Databases CreationsDocument20 paginiConfiguring Intergraph Smart 3D Application Servers and Databases CreationsAnonymous WCG2HjPybJÎncă nu există evaluări

- TSMP3002 - SmartPlant 3D Equipment Reference Data Labs v7Document20 paginiTSMP3002 - SmartPlant 3D Equipment Reference Data Labs v7Gopi BÎncă nu există evaluări

- 3D-08-13F1-601 - SP3D Pipe Support Setup Procedure - Rev4 PDFDocument12 pagini3D-08-13F1-601 - SP3D Pipe Support Setup Procedure - Rev4 PDFsoedirboysÎncă nu există evaluări

- How To Install SmartPlant 3DDocument5 paginiHow To Install SmartPlant 3Dshiva_ssk17Încă nu există evaluări

- In ToolsDocument2 paginiIn ToolsamarnethaÎncă nu există evaluări

- TSMP3002 - Smart 3D Piping Reference Data LabsDocument143 paginiTSMP3002 - Smart 3D Piping Reference Data Labssateesh pindiÎncă nu există evaluări

- Howto Configurethe Authoringand DWHModelsDocument156 paginiHowto Configurethe Authoringand DWHModelsAnand KumarÎncă nu există evaluări

- 3D Bulkload ProcessDocument5 pagini3D Bulkload Processpingu365Încă nu există evaluări

- Marine S3d Citrix GuideDocument39 paginiMarine S3d Citrix Guidesenthilsp3dÎncă nu există evaluări

- Schem SPI Symbol Editor Users GuideDocument78 paginiSchem SPI Symbol Editor Users GuideRamasubramanian SÎncă nu există evaluări

- SmartPlant® P&ID Benefits For Owner Operators - A ResumeDocument29 paginiSmartPlant® P&ID Benefits For Owner Operators - A ResumeNoman Abu-FarhaÎncă nu există evaluări

- SPP&ID Training - 02c Engineering Data Editor OverviewDocument12 paginiSPP&ID Training - 02c Engineering Data Editor OverviewANAND KALEPÎncă nu există evaluări

- TSMP3002 - Smart 3D Equipment Reference Data LabsDocument27 paginiTSMP3002 - Smart 3D Equipment Reference Data Labssateesh pindiÎncă nu există evaluări

- PDS NotesDocument107 paginiPDS NotesLijo P VargheseÎncă nu există evaluări

- 11 SQL Config SP3DDocument39 pagini11 SQL Config SP3DgoodmorningfredÎncă nu există evaluări

- Manual - 3D SymbolDesigner (En)Document64 paginiManual - 3D SymbolDesigner (En)Álvaro Rodríguez BÎncă nu există evaluări

- SP 3 Dprogguide 082014-1Document70 paginiSP 3 Dprogguide 082014-1scleeÎncă nu există evaluări

- PDS Translation User Guide PDFDocument63 paginiPDS Translation User Guide PDFerikestrelaÎncă nu există evaluări

- 3d 07 13f1 129sp3d Operator Training Guide Lab2 System Hierarchy Settingenrev0watermark PDFDocument13 pagini3d 07 13f1 129sp3d Operator Training Guide Lab2 System Hierarchy Settingenrev0watermark PDFrajendraÎncă nu există evaluări

- PDS Admin ManualDocument26 paginiPDS Admin ManualAndy Garcia100% (1)

- Intergraph Smart Interop Publisher: System RequirementsDocument8 paginiIntergraph Smart Interop Publisher: System RequirementsRamilÎncă nu există evaluări

- SP 3 D Upgrade GuideDocument51 paginiSP 3 D Upgrade GuideKannaphat WattanaphanÎncă nu există evaluări

- SP3D2011 Equipment Tutorial PDFDocument145 paginiSP3D2011 Equipment Tutorial PDFdharmendra_kanthariaÎncă nu există evaluări

- PDS 3dtheory PDFDocument300 paginiPDS 3dtheory PDFSwarup Ghosh100% (2)

- SP3D Object Search User Manual Rev4 PDFDocument44 paginiSP3D Object Search User Manual Rev4 PDFSrinivasan SeenuÎncă nu există evaluări

- 12 SPF ModelingDocument5 pagini12 SPF Modelingbladek1016-10% (1)

- Autoplant Modeler V8: I (Selectseries 5)Document2 paginiAutoplant Modeler V8: I (Selectseries 5)ingjavierginezÎncă nu există evaluări

- Autocad Plant3d Quick Reference GuideDocument2 paginiAutocad Plant3d Quick Reference GuideashrafÎncă nu există evaluări

- AVEVA DiagramsInfo PDFDocument4 paginiAVEVA DiagramsInfo PDFMayur MandrekarÎncă nu există evaluări

- Global Work Share Guide SQL ServerDocument83 paginiGlobal Work Share Guide SQL Serverfsuclupe4671Încă nu există evaluări

- SP3D Client InstallationDocument2 paginiSP3D Client InstallationKodali Naveen KumarÎncă nu există evaluări

- SmartPlant License ManagerDocument86 paginiSmartPlant License Managerbarcelata_antonioÎncă nu există evaluări

- TSMP3002 - SmartPlant 3D Equipment Reference Data Labs v7Document20 paginiTSMP3002 - SmartPlant 3D Equipment Reference Data Labs v7Shahfaraz Ahmad100% (1)

- Intergraph Smart Interop Publisher Mapping ResolutionDocument9 paginiIntergraph Smart Interop Publisher Mapping ResolutionQiuniuÎncă nu există evaluări

- Pds IsogenDocument575 paginiPds IsogenbalajivangaruÎncă nu există evaluări

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- 10 Example Rules: Intergraph Smart Engineering IntegrityDocument7 pagini10 Example Rules: Intergraph Smart Engineering IntegrityVăn Tuấn NguyễnÎncă nu există evaluări

- Wearable Antennas For Biomedical Applications A Revolution in HealthcareDocument2 paginiWearable Antennas For Biomedical Applications A Revolution in Healthcareفادي الجبوريÎncă nu există evaluări

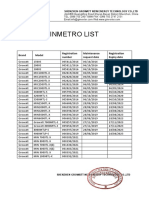

- 5 - Certificado InmetroDocument5 pagini5 - Certificado InmetroDanilo MarinhoÎncă nu există evaluări

- Industrial Security Management February 20 LessonDocument15 paginiIndustrial Security Management February 20 LessonjeysonmacaraigÎncă nu există evaluări

- 5 Paragraph EssaysDocument45 pagini5 Paragraph Essaysxumuqvwhd100% (2)

- Manual Lab BookDocument57 paginiManual Lab BookNeo TarunÎncă nu există evaluări

- LESSON 2-Data Collection ActivityDocument20 paginiLESSON 2-Data Collection ActivityBERNARDITA NICOLASÎncă nu există evaluări

- H2 PACE Plugpower 1Document6 paginiH2 PACE Plugpower 1Deepak GehlotÎncă nu există evaluări

- The Prepper Phone PDFDocument7 paginiThe Prepper Phone PDFStanÎncă nu există evaluări

- HVAC Designing, Drafting, Estimation and Installation 2023Document20 paginiHVAC Designing, Drafting, Estimation and Installation 2023MANISH KUMARÎncă nu există evaluări

- Subject: English Class: Ii: 1) My English Reader 2) Practice Book 1 Evaluation (April To August)Document34 paginiSubject: English Class: Ii: 1) My English Reader 2) Practice Book 1 Evaluation (April To August)Itismita PriyadarshiÎncă nu există evaluări

- LiftMaster SL3000 Specification English 1 1 18Document5 paginiLiftMaster SL3000 Specification English 1 1 1828larrysjunkmailÎncă nu există evaluări

- Capitulo 3 - NIST SP 800-63 Digital Identity GuidelinesDocument3 paginiCapitulo 3 - NIST SP 800-63 Digital Identity GuidelinesCristiane LimaÎncă nu există evaluări

- Omnikey 3021 USB Reader: Logical Access SolutionsDocument2 paginiOmnikey 3021 USB Reader: Logical Access SolutionsHowTo HackÎncă nu există evaluări

- A New Inrush Current Detection Method For PDFDocument14 paginiA New Inrush Current Detection Method For PDFMilovan LukovacÎncă nu există evaluări

- Bug Games 2023Document10 paginiBug Games 2023orbit bangdeÎncă nu există evaluări

- GK Holiday Homework For Class 6Document5 paginiGK Holiday Homework For Class 6ere50xvb100% (1)

- 1F80-361 1F80-361 1F80-361 1F80-361 1F80-361: Description Description Description Description DescriptionDocument8 pagini1F80-361 1F80-361 1F80-361 1F80-361 1F80-361: Description Description Description Description DescriptiononeÎncă nu există evaluări

- RGT Engineering & Technology Business ProfileDocument13 paginiRGT Engineering & Technology Business ProfileMONA TECHÎncă nu există evaluări

- DP Monitor 13115 DriversDocument1.047 paginiDP Monitor 13115 DriversAndyS WicaksonoÎncă nu există evaluări

- Colbeck AffidavitDocument3 paginiColbeck AffidavitThe Epoch Times100% (5)

- Amipox - SUBMITTAL 52Document1 paginăAmipox - SUBMITTAL 52norman moralesÎncă nu există evaluări

- High Horsepower Hydraulics (Auxiliary Hydraulics) - (S - N 514450945, 514651254 & Below) - 863Document5 paginiHigh Horsepower Hydraulics (Auxiliary Hydraulics) - (S - N 514450945, 514651254 & Below) - 863Partagon PowÎncă nu există evaluări

- L1 11.2.2 Airframe Structures - Construction Concepts A-1Document7 paginiL1 11.2.2 Airframe Structures - Construction Concepts A-1mohan reddyÎncă nu există evaluări

- Wenge Minimalist Luxury Interior Design Instagram StoryDocument3 paginiWenge Minimalist Luxury Interior Design Instagram StoryJustine PadillaÎncă nu există evaluări

- Think l5 Test7 1678725402 PDFDocument2 paginiThink l5 Test7 1678725402 PDFМакс ИвановÎncă nu există evaluări

- Online Bus Ticket Reservation System: Statistics and Computing January 2015Document18 paginiOnline Bus Ticket Reservation System: Statistics and Computing January 2015muhdÎncă nu există evaluări

- Scope Split Matrix For Agitator (Project-A010-HIIPL)Document6 paginiScope Split Matrix For Agitator (Project-A010-HIIPL)Tushar MangratiÎncă nu există evaluări

- Test Report (Pump) : Nekad Development Engineering SDN BHD (329894-M)Document1 paginăTest Report (Pump) : Nekad Development Engineering SDN BHD (329894-M)خير العابدينÎncă nu există evaluări

- Project Information:: ACECOMS GEAR: RC Column Section Design Version: 3.0 (Rev. 1)Document3 paginiProject Information:: ACECOMS GEAR: RC Column Section Design Version: 3.0 (Rev. 1)Maria Rose Giltendez - BartianaÎncă nu există evaluări