Documente Academic

Documente Profesional

Documente Cultură

SAG10 Manual

Încărcat de

Sarfaraz Ahmed BrohiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SAG10 Manual

Încărcat de

Sarfaraz Ahmed BrohiDrepturi de autor:

Formate disponibile

To jump directly to a chapter simply click on a chapter title within the index.

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

New Features of Alcoa Sag10 for Windows Version 3.0 ......................................................3

Features of Alcoa Sag10 for Windows Version 2.0 ..............................................................4

Features of Alcoa Sag10 for Windows Version 1.1...............................................................5

Differences Between SAG10 for Windows and SAG10 for DOS..........................................6

Features of Current & Previous Versions..............................................................................7

History ...................................................................................................................................8

License Agreement Information ............................................................................................8

Installation .............................................................................................................................9

1.8.1 Minimum Equipment Required:.............................................................................9

1.8.2 Installation - Single User .......................................................................................9

1.8.3 Installing and Using SAG10 On a Network ...........................................................9

1.8.4 Installation of SAG10 on a Network Server...........................................................9

1.8.5 Installation of SAG10 on a Workstation ................................................................9

1.8.6 Using SAG10 on a Network ..................................................................................10

1.8.7 Printing over a Network .........................................................................................10

1.9 Getting Started with SAG10 ..................................................................................................10

2.1 Entry Screen..........................................................................................................................11

2.2 Main Menu.............................................................................................................................12

2.3 Create/Edit Problem File .......................................................................................................12

2.3.1 Headings ...............................................................................................................12

2.3.2 Conductor Selection..............................................................................................13

2.3.2.1 ADSS Cable ..........................................................................................13

2.3.2.2 OPGW...................................................................................................14

2.3.2.3 ACSS Conductors .................................................................................14

2.3.2.4 Pre-stressing ACSS Conductors...........................................................14

2.3.2.5 Copper Conductors ...............................................................................15

2.3.2.6 Conductor Lookup List ..........................................................................15

2.3.2.8 User Bookmarks ...................................................................................16

2.3.2.9 Add New Conductor to Database..........................................................16

2.3.2.10 View Existing Stress-Strain Chart in Sag10.Pgm Database ...............16

2.3.2.11 Add New Stress-Strain Chart to Sag10.Pgm Database......................16

2.3.2.12 Delete User Added Stress-Strain Chart from Sag10.Pgm Database .17

2.3.3 Loadings Table......................................................................................................17

2.3.4 Ruling Spans .........................................................................................................21

2.3.5 Output Redirection ................................................................................................21

3.1 File Commands (Main Menu)................................................................................................22

3.1.1 File New (Main Menu) ...........................................................................................22

3.1.2 File Open (Main Menu) .........................................................................................22

3.1.3 File Save (Main Menu) ..........................................................................................22

3.1.4 File Save As ..........................................................................................................22

3.1.5 File eXit (Main Menu) ............................................................................................22

3.2 Options ...................................................................................................................................23

3.2.1 Elevated Temperatures, Input (default = unchecked)..........................................23

3.2.2 Elevated Temperatures, Output Strain (default = unchecked).............................23

3.2.2.1 Elevated Temperature Creep................................................................23

3.2.3 Account for Aluminum Compression ....................................................................25

3.2.4 Separate AL & STL Tension .................................................................................25

3.2.5 Tensions Avg Vert (At Supports) Horiz (At Sag) .............................................25

3.2.6 Display Extra Column No % RTS H/W Horz & Vert Sag ..............................25

3.2.7 Units English English-to-Kg Kilogram Newton ..............................................25

3.2.8 NESC K New Old Old (Steel & Cu) ................................................................26

3.2.9 T-2TM Conductor ...................................................................................................26

3.2.10 Attachments to Wire No Marker Balls Cables PLP Spoiler ........................26

3.2.10.1 Marker Balls ........................................................................................26

3.2.10.2 Non-supporting spacer cable, installed after stringing ........................27

3.2.10.3 Non-supporting cable, pre-assembled or lashed ................................28

3.2.10.4 PLP Spoilers .......................................................................................29

3.2.10.5 Estimated Cast Rod Creep ...............................................................29

Chapter 1

Introduction

3.2.10.6 Creep Time at Stress ........................................................................29

3.3 Setup Commands (Main Menu) ............................................................................................29

3.3.1 Setup - Print Setup................................................................................................29

3.3.2 Setup - Page Setup...............................................................................................30

3.3.3 Setup - Fonts.........................................................................................................30

3.4 Run Commands (Main Menu) ...............................................................................................31

3.4.1 Run - Sag & Tension.............................................................................................31

3.4.2 Run - Pause between Spans ................................................................................31

3.4.3 Inclined Spans.......................................................................................................31

3.4.4 Run - Ruling Span Calc.........................................................................................32

3.4.5 Run IEEE738 .....................................................................................................32

3.5 Help for Sag10 ......................................................................................................................32

4.1 Output Screen ........................................................................................................................33

4.1.1 Creep .....................................................................................................................33

4.2 Gallop ....................................................................................................................................34

4.3 Sag Curves ...........................................................................................................................36

4.4 Stringing Sag Tables .............................................................................................................38

4.4.1 Stringing Spans .....................................................................................................38

4.4.2 Stringing Temperatures ........................................................................................38

4.6 Ruling Span Variation............................................................................................................40

4.7 Clash .....................................................................................................................................42

4.8 Vibrec ....................................................................................................................................45

4.9 Output ...................................................................................................................................46

Alcoa SAG10 Manual

Page 2

Chapter 1

Introduction

TM

TM

1.1 New Features of Alcoa Sag10 for Windows Version 3.0

Vibration Analysis and Damper Selection Calculations

Perform your own Vibration Analysis and Select your own Dampers for ACSR, AAC, AAAC, ACAR, Alumoweld,

Steel, OPGW, and ACSS cables.

Clash analysis w/graphic solution for ADSS

Check loaded & unloaded swing & static clearances between Conductor and ADSS supported on the same

structure, for both initial and final state. Conductor suspension insulator string length is taken into consideration.

The loading cases, swing angles, horizontal and vertical offsets between the two cables and conductor ADSS

clearances are presented in a Report. Graphically view the results in both Tranverse and Longitudinal Views.

Graphic views may be saved to a .BMP file for emailing or viewing in other graphic software.

Compiled for 32 bit operation for Win2000

Compiled to run with all of the latest Windows 2000 generation operating systems. Support of longer file names.

ACSS/TW and BPA TW Conductors

The Conductor Database has been expanded to include the ACSS/TW and BPA TW Cables.

IEEE 738 Calculations

Perform Thermal Rating analysis with IEEE738 calculations.

Allow deletion of user created charts

The Conductor Selection area has been improved to allow deletion of user created charts

Estimated cast rod creep

Sag & Tension data may be calculated for either factory Cast or Rolled aluminum rod.

Calculation of Creep for varying time periods

Creep can now be calculated for time periods greater or less than the 10 year time period that is currently used to

calculate final sags & tensions within Sag10. Check to see if your conductor has any additional creep after 20 or

30 years, or use for confirming sag information on a conductor that has been in service for less than 10 years.

Save sag curve to .BMP File & Display Catenary Constant

Sag Curves can be Saved to a .BMP file, for emailing or viewing in other Graphics software. The Catenary

constant is now displayed with the Sag Curve.

Help Screens

Help Screens have been added to Sag10 for user convenience.

Root Failure message explanation

When a Sag & Tension run fails due to a Root Failure, an explanation recommends possible solutions to allow

proper output.

User's manual on CD

The entire Sag10 Manual and Appendices will be provided on CD to allow the user ready access to the

Instructions.

Use of command line parameters when entering Sag10

Command Line parameters may be used to preload a Problem File while initially entering Sag10.

Pretensioning of ACSS Conductors

A complete set of instructions are provided to allow the user to calculate conductor sags during and after an ACSS

Conductor has been pre-stressed.

Spoiler Loading on Cable

A routine to allow calculation of the loads created by adding PLP spoilers to the cable, and their affect on the Sag

& Tension output.

Alcoa SAG10 Manual

Page 3

Chapter 1

Introduction

TM

TM

1.2 Features of Alcoa Sag10 for Windows Version 3.0

Adjustment of High Temperature Creep

Optional calculations can be performed that account for the effect of aluminum compression at elevated

temperature conditions. The program provides default values for built in aluminum stress, ASTM strand lay ratios

and allows user entry of optional values.

Adding New Conductors to the Data files

The Add new conductors feature has been integrated into the Windows program, making it much easier to use.

Data from other conductors may be prompted onto the screen and edited to create a new conductor, or entered as

entirely new data.

Adding New Stress-Strain Charts

The ADD new Stress-Strain charts ( Sag10.Pgm ) feature has been integrated into the Windows program, making

it much easier to use. Data from other chart #s may be prompted onto the screen and edited to create a new

chart, or entered with entirely new chart data.

Conductor Selection Lookup List

It is now possible to find the conductor that you are looking for by scrolling thru a pulldown list. This is especially

handy if you do not remember the name and/or stranding of the conductor that you need.

Custom Conductor Database

A custom conductor database has been created that allows the user to add his favorite conductors to a his own

custom list. The user may then use a pulldown menu to select a conductor from his own custom selection list.

Copper and Copperweld Conductor Databases

Hard drawn Copper and Copperweld Conductor Databases have been added to the list of available conductors.

Old NESC K Factor for Copper and Steel

The old NESC K factor for copper and steel calculations has been added to allow proper simulation of older NESC

calculations.

Graphic Display of Galloping Ellipses between 2 Different Structure Types

The user may optionally enter different attachment points and insulator types and/or lengths for structures at either

end of a galloping span and generate resulting ellipses.

Gallop Button for Load Table

A Gallop command button has been added to the Load Table area to ensure the Load Table includes the

appropriate Load conditions required for calculation of graphic Galloping Ellipses.

Medium Ice Load added

The new NESC Medium loading condition of 32 Deg F, .25-inch ice, no wind has been added to the Medium

Loading Default conditions.

Quantity of Conductors Displayed in the Galloping Ellipses

The quantity of conductors graphically displayed in the Galloping Ellipses may be varied between 1 and 4

conductors.

Ruling Span Calculation

Spans within a ruling span can now be entered into a table. The spans within the table can then be calculated for

ruling span, saved as a file for future recall and editing, and transferred to the stringing sag tables.

Calculation of Total Conductor Length

When a list of spans are provided for Stringing Sag Tables, the Total Conductor Catenary Length is calculated for

those spans over level ground and for the range of selected stringing temperatures and corresponding horizontal

tension (one length for each temperature and tension). The calculated ruling span for those spans may also be

displayed.

Year 2000 Compliant

Alcoa SAG10 Manual

Page 4

Chapter 1

Introduction

The output files are dated with a 4 digit year that will allow dated output for the year 2000 and beyond.

ADSS Cable - Variable Coefficient of Thermal Expansion

The Calculations for ADSS cables now allow the user to enter the Cofficient of Thermal Expansion as a variable

rather than as a fixed value.

ADSS Cable - Three Moduli of Elasticity: Initial, Final, 10 Years Creep

The Calculations for ADSS cables now allow the user to enter three moduli of elasticity, that will exactly

characterize the stress-strain chart for each individual AFL-ADSS cable.

Grid Lines for Sag Curves

Grid lines may optionally be added to the Sag Curve Graphic output, to allow easier alignment of the curve with the

users background grid.

Printing of Inclined Spans

The Inclined Span output may now be printed via a print command in the Inclined Span Calculation area.

Stringing Sag Table Output in Inches

The Stringing Sag Table output may be shown in Inches only, rather than Feet & Inches.

Calculation of Ruling Span Variations

Each span within a ruling span has a variation from the ruling span sag & tension caused by change in span

length. Ruling Span Variation calculates the amount of that variation.

1.3 Features of Alcoa Sag10 for Windows Version 1.1

ADSS, OPGW, & ACSS Cable calculations

Calculates Sag & Tension, Stringing Sag Tables, Clipping Offsets, Catenary Curve and Galloping Ellipses for

Alcoa Fujikura Ltd.s (AFL) All Dieletric Self Supporting Cables (ADSS), Optical Ground Wire & Aluminum

Conductor Steel Supported.

New Options for Formatting of the Output

Horizontal and Vertical Sag may optionally be displayed as separate columns in lieu of Resultant Sag. This

allows calculation of horizontal conductor blowout and actual ground clearance sag under wind load conditions.

Adjustment of Rime Ice density

Allows the calculated Rime Ice density to be selected by the user rather than always using a preset rime ice

density of 37 lb/ft^3.

Spacer Cable Calculations

Input and output for spacer cable were modified for greater conformity with Hendrix Wire & Cable calculation

methods. NESC K Factor may be applied to all cables or only the messenger cable at the users discretion.

New Metric Features

Galloping calculations and graphic display of the galloping ellipses is now available for metric calculations.

The Marker Ball and Spacer calculations have been improved for metric calculations.

British Sag Demo

A Demo version of Sag10 is available with the British conductors of Centipede and Zebra.

SAG10 is a reg. TM of Alcoa Fujikura Ltd.

Windows is a reg. TM of Microsoft Corp.

Alcoa SAG10 Manual

Page 5

Chapter 1

Introduction

1.4 Differences Between SAG10 for Windows and SAG10 for DOS

1-Create File is replaced with selecting each of the 4 command buttons on the Main Menu.

2-Retrieve File has been replaced by File - Open (Main Menu)

3-Modify Menu is replaced with selecting each of the 4 command buttons on the Main Menu.

4-Default Parameters is divided into several areas:

Options (Main Menu) contains the majority of the previous defaults.

Setup - Page Setup (Main Menu) contains the options for output display of headings, with many other choices

added.

Output to Screen, Printer or File is now located on the Main Menu for convenience, and always defaults to

screen output.

Run - Sag & Tension (Main Menu) contains a menu selection for Stringing Sag Tables. This selection is now

made after viewing the sag & tension output.

5-Save Problem File has been replaced by File - Save or File - Save As (Main Menu)

6-Process Problem File has been replaced by Run - Sag & Tension (Main Menu)

7-Other Calculations, Inclined Spans has been replaced by Run - Inclined Spans (Main Menu)

7-Other Calculations, Offset Clipping has been replaced by Offset Clipping accessed from the Output Screen

( Run - Sag & Tension )

8-Quit has been replaced by File - eXit (Main Menu)

Printing and plotting of the Galloping Ellipses and Sag Curves is now done from within SAG10 or by switching

between applications to another graphics program of choice, rather than exiting to SagPlot. This is supplemented

by the DXF file option.

For individual data entry boxes, the TAB key is used to move from entry box to entry box, rather than the ENTER

key used previously. Each box is entered in the type over mode as a highlighted cell. If an ARROW, HOME or

END key are pressed, the entry box switches to the edit mode.

For data tables, standard spreadsheet table commands are used. The TAB, ENTER, or ARROW keys are used to

move from cell to cell. Each cell is entered in the type over mode. The F2 key will highlight the cell and initiate

editing of the cell. A row is inserted with Insert, a row is deleted with Delete. The Table is cleared with Clear.

Selecting a conductor is now an interactive process, where a conductor may be selected and reviewed as many

times as the user wishes prior to leaving the conductor selection area. After picking the Conductor Selection

(Main Menu) command, enter the conductor type, and codeword or other required data such as size and

stranding. Pressing the Lookup Wire Data command will search the database for the required data and display it

on the form. The Lookup Wire Data command will then become disabled until a modification is made in the

conductor request. If Main Menu or OK is picked and the requested entry data has been modified, the program

will lookup the new request prior to exiting the form.

The data output is displayed in a sizable window with scrolling capabilities. If Run - Pause between Spans (Main

Menu) is checked, the spans will display one at a time, to allow for reviewing Galloping, Sag Curves, Stringing Sag

Tables, and/or Clipping Offsets. If Run - Pause between Spans (Main Menu) is unchecked, all of the requested

spans will calculate and display in the sizable window at one time.

Alcoa SAG10 Manual

Page 6

Chapter 1

Introduction

1.5 Features of Current & Previous Versions

Alcoa's SAG10TM Computer Program* designed for use with the IBM PC contains:

Alcoa Graphic Method

Sag and Tension with Creep

Elevated Temperature Creep

Inclined Span Calculation

Stringing Sag Tables

Offset Clipping

Processing Highlights include:

User Friendly

Menu Driven

Screen Oriented Editing

Use of enhanced video and keyboard function

Problem features are:

Create, Save, and Open Problem File

Built-in Temperature and Loadings

Choice of Bare Wire Limits

Modify Defaults and Problem File

Automatic Creep Check

Single Entry Increments Temperature-Spans

Automatic Conductor Data

Automatic Stress-Strain Chart Selection

Problem Output Designates Inputs

Graphic Output Galloping Ellipses and Sag Curves

Calculation of Marker Ball and Non-supporting Cable additions

The processing and problem features work together to make an easy to use self-prompting software

package. Data furnished includes:

Stress-Strain Coefficients

Conductor Data Base

(Area, Dia., Wgt., RTS, SS Chart No.)

ACSR's:

Standard & British

/AW

/TW

/SD

AAC ......British

AAAC .....British

ACAR

AW-Alumoweld

ST-Steel

Multiplex Wires

Covered Line Wires

T-2 Conductors

ADSS cable

OPGW cable

ACSS

ACSS / AW

CopperWeld

CopperWeld - Copper

Hard drawn Copper

User Bookmarks

* Copyright 1986 Aluminum Company of America

Alcoa SAG10 Manual

Page 7

Chapter 1

Introduction

1.6 History

The Alcoa Graphic Method of sag-tension calculations was developed in 1926 by H. H. Rodee. Analysis of the

stress-strain behavior of the complete conductor and its component parts form the basis for the method. It is

applicable for composite conductors (ACSR's, OPGW's) or those consisting of one metal - aluminum, copper, or

steel. SAG10 is an enhancement of the mainframe Alcoa SAGTEN program available since 1963. The

enhancements include conductor data bases, for accurate and up-to-date data retrieval of most cataloged

conductors and overhead ground wires; elevated temperature creep, an important consideration today when

electrical demand taxes old designs; inclined span calculations, at times a perplexing mathematical problem;

offset clipping, a solution to a stringing problem; and use of screen editing and keyboard functions inherent to the

IBM-PC. In 1992, SAG10 Version 5 and SAGPLOT Version 1 were released. In 1994, SAG10 for Windows was

released. In 1997, Windows was updated with Version 1.1. In 1998, Windows was updated with Version 2.0. In

2001, Windows was updated with Version 3.0. The new features are listed on page 1 of this manual.

1.7 License Agreement Information

The software program is furnished to the original purchaser under the license agreement written. The software

may be used or copied only in accordance with the terms of the agreement. It is against the law to copy the

software on any medium except as specifically allowed in the license agreement. The only warranty on this

software is on the CD-ROM, which Alcoa warrants to be free from defects in materials and workmanship. If within

90 days from date of purchase the defective CD-ROM is returned, a replacement will be made at no charge. Also

within 90 days of purchase technical questions regarding operation of the programs will be answered by calling

Tech Support at

1-800-866-7385.

Definitions as they apply to SAG10 licensing:

SITE-a physical location, a headquarters building where many users conduct every day business. A SITE

is not various divisions within a city, operating district, or company wide operation with multiple subsidiaries. Up to

25 users is permitted.

LAN-local area network which is specific to a site. It is not a network covering a companys operating

divisions within a geographic area. A minimum of three concurrent SAG10 users is required.

Concurrent User-software is available that monitors and controls the number of users of software at any

one time.

CLIENT SERVER-a hardware/software host centrally located to serve multiple locations. Mergers of

utilities to form huge companies has fostered the client server operation as a means of sharing expensive

software. A minimum of six concurrent SAG10 users is required.

To purchase or upgrade SAG10 contact customer service at 1-800-925-4815.

Technical Support is offered for the lifetime of the current version and can be obtained at the 3 locations listed

below. For the most prompt responses, it is recommended that you email directly or email from the Website with a

complete explanation of the problem or information required.

Email: Support @ Sag10.com

Website: www.Sag10.com/support.htm

Phone: 800-866-7385

Alcoa SAG10 Manual

Page 8

Chapter 1

Introduction

1.8 Installation

SAG10 Package Contents:

1. Installation Guide and License Agreement

2. Installation CD-ROM

3. Registration User ID and Password Card

1.8.1 Minimum Equipment Required:

1. IBM compatible Pentium 90 or greater with at least 16 MB of RAM memory.

2. Microsoft Windows 95 or higher.

3. CD-Rom drive

4. Hard disk with at least 20 MB of free space (5 MB used by program for file storage).

5. VGA or better monitor

1.8.2 Installation - Single User

1.Uninstall all previous versions of SAG10.

2.Close any open applications running in Windows.

3. Insert SAG10 CD-ROM into the CD-ROM drive.

4.If the Startup Menu does not launch automatically locate the file

StartUpMenu.exe on the CD-ROM and open the file.

5.From the Sag10 Startup Menu, pick Install Sag10 3.0.

6.Make sure all other programs are not running, then click OK.

7.When setup is complete, choose the OK button to return to

Startup Menu.

8.If the user is upgrading SAG10, and has previously modified any of the

conductor data files, copy the required data files from the previous SAG10 directory to the new Sag10w directory

using Windows Explorer.

If a previous user has used ADD.EXE to modify the conductor charts, then copy the stress-strain chart file from

the previous SAG10 directory to the default Sag10w directory, or your custom SAG10v 3.0 directory location,

using Windows Explorer. If the user has NOT modified these files, then do NOT copy them.

9. Any additional instructions that were too late to put in this manual will be stored in a file named README.1ST.

The instructions may be viewed from the CD-Rom Menu, Windows Notepad, or any text editor or word processor.

10. Continue on to "Getting Started with SAG10" below.

1.8.3 Installing and Using SAG10 On a Network

On a network, many users can share the SAG10 program and data files. Once SAG10 is set up on the network,

the program can be run from the network server, or it can be installed onto the hard disks of individual

workstations. This document assumes that you know how to use network software to connect to network drives

and how to find files stored on network computers.

Note: Every SAG10 user must either have a SAG10 Single User License, or the user's company must have a

LAN/Client Server license or a Site License.

Before you set up SAG10

The network must be operational, and you must have read-write access to the network directory in which you want

to install SAG10. For more information, see your network software documentation.

Setting up SAG10 on a network is a two-step process. You first install SAG10 on the network server. Then you set

up the workstations, either by setting up the workstations to run SAG10 from the server or by installing SAG10 on

each workstation's hard disk. Note: Each workstation should have at least 16 MB of RAM in order to run the

SAG10 program.

1.8.4 Installation of SAG10 on a Network Server

1. Follow steps 1 thru 5 for 1.8.2 Installation - Single User, with the exception that the drive is likely to some letter

higher than C:, such as R:\Sag10Net3\.

Although the SAG10 program directory on the server (the directory containing Sag10w3.EXE) can be either readwrite or read-only, you should make it read-only after installing SAG10 to prevent users from unintentionally

overwriting files. For more information, see your operating system documentation.

1.8.5 Installation of SAG10 on a Workstation

Alcoa SAG10 Manual

Page 9

Chapter 1

Introduction

You can install SAG10 onto local workstations so that users run the program from the network server, or you can

install so that users run the program from their local workstation's hard drive. You perform the following

procedures from the local workstation on which you are installing SAG10.

1. Follow steps 1 thru 5 for 1.8.2 Installation - Single User at each workstation licensed to use SAG10. This will

place the appropriate files in the \Windows\System directories for each workstation.

2a. If the intention of the user is to access SAG10 from his own hard disk, and use the network only for printing

and plotting and perhaps sharing common problem files, then the installation is complete.

-or2b. If the intention of the user is to access SAG10 from the network drive, then perform the steps below.

3. In Windows Explorer, Pick Start, Programs and highlight Sag10 from the list.

4. Click on the right mouse button, select Properties, Shortcut.

5. Change the Target: from the name of the local drive to the name of the server drive, such as from C:\Program

Files\Sag10w3\Sag10w3.EXE to R:\SAG10Net\Sag10w3.EXE if C is the local drive and R is the server drive.

6. Change the Start In: from the name of the local drive to the name of the server drive, such as from C:\Program

Files\Sag10w3 to R:\Sag10Net (or similar).

7. Select OK to close the Properties form.

8. Use Windows Explorer to delete the SAG10 files in the local drive, such as DELETE C:\Program

Files\Sag10w3\*.*.

1.8.6 Using SAG10 on a Network

Using SAG10 on a network is essentially the same as using SAG10 from a hard disk on an individual computer.

On the network, you can make a data file available to other users and allow them to make changes to the file, or

you can protect the file from changes. You can use the network server to store and exchange data files between

users, and many people can use a printer attached to the network server.

1.8.7 Printing over a Network

For information on setting up printers, see your Windows documentation. The procedures for printing over a

network generally are the same as printing procedures for an individual computer. You use the Windows Setup

program to set up all printers available to you. Then you choose the Page Setup command on the Setup menu in

SAG10 and choose the Printer Setup button to select a printer for use with SAG10 and to change the settings for

the active printer. If you have installed more than one printer, when you start SAG10 for the first time, make sure

you select the printer you will be using for your documents. If you select one printer when you format a document

and a different printer when you print the document, some fonts, point sizes, and other character formatting

options may not be available when you print.

Note: Your network software may require you to issue a system command to make a network printer available to

your computer. For specific procedures for your network, see your network software documentation.

TM

Special Note for Bates TLCADD users:

Refer to Appendix, Notes for Bates Spotting Program" for installation and additional information.

1.9 Getting Started with SAG10

1. To begin using SAG10, click on the Alcoa SAG10 icon:

2. The SAG10 Entry Screen appears with information on licensing of SAG10. Read the information. If you have

met the terms of the agreement, press OK to continue to the SAG10 Main Menu

3. Refer to Chapter 2 for more information on each Command and Menu option.

TLCADD is a registered trademark of LineSoft

Alcoa SAG10 Manual

Page 10

Chapter 2

Introduction

2.1 Entry

Screen

Double clicking on the

SAG10 icon loads the

program and the entry

screen shown in Fig.

2-1 appears. The user

has 30 days in which

to register the program

by going online to the

Alcoa website:

www.sag10.com/

register.htm. The user

is asked to complete

the registration form

for company

information and will

then receive an email

with his registration

number to enter into

Sag10.

Fig. 2-1

Alcoa SAG10 Manual

If an error message

appears, refer to the

Appendix on Error

Messages".

Page 11

Chapter 2

Main Menu - Pulldown Menus

2.2 Main Menu

After selecting OK at the Entry Screen, the

following menu in Fig. 2-2 appears. New

Problem Files are created, or existing

Problem Files are edited, directly from the

Main Menu. The 4 command buttons are

used to access the required data entry

areas discussed below.

2.3 Create/Edit Problem File

To create a new or edit an existing Problem

file, select each of the command buttons:

Headings, Conductor Selection,

Loadings Table and Ruling SPans from

the Main Menu. Each of the commands is

discussed separately below.

2.3.1 Headings

Fig.2-2

Alcoa SAG10 Manual

The first step is to select the Headings

command. You will be prompted to enter

two lines of heading. Each line of the

heading may be up to 72 characters. These

2 lines will appear at the top of the first page

of the sag & tension output, and optionally,

at the top of each additional page and for

Stringing Sag Tables and Clipping Offsets.

Page 12

Chapter 2

Main Menu - Pulldown Menus

2.3.2 Conductor Selection

Selecting the Conductor Selection (Main

Menu) command displays the form shown

in Fig. 2-3. The conductor selections are

broken down into 24 categories. Select the

appropriate category for your conductor

type. If none of these have the conductor

needed, select 15- Other.

Fig.2-3

After a conductor type is selected, the user

will be prompted for additional information,

which will vary, depending on which

conductor type is picked. In most cases,

the user may just enter the Codeword, and

the rest of the necessary conductor data

will be automatically searched and entered

from the SAG10 database. If Select by:

Size/Strand option is picked, a different

prompt will appear in lieu of the Codeword

prompt. For 2- ACSR British, 13Multiplex and 14- Covered Line Wire,

the only valid option is to enter the correct

codeword.

When the Lookup Wire Data command is picked, the program will search the data base for the conductor

characteristics and stress-strain Chart #, and display the values for Area, Diameter, Weight, Rated Tensile

Strength (RTS), and stress-strain Chart #. The User may then optionally modify either the Weight or Chart #. A

listing of charts commonly used is shown in Appendix, List of Stress - Strain Charts".

If it is necessary to use the 15- Other option, it is possible to enter that information permanently into the SAG10

conductor database by using the Add to Database command. Conductor data may also be viewed thru this utility.

Refer to the Section on User Bookmarks for more information.

2.3.2.1 ADSS Cable

Sag10 calculations now include AFLs All

Dielectric Self Supporting (ADSS) cable.

AFL (Alcoa Fujikura Ltd) does not

recommend attempting to use Sag10 to

calculate data for dielectric cable from other

manufacturers.

In order to perform ADSS calculations, first

choose Conductor Selection from the Main

Menu. After selecting 16- ADSS, the

displayed form will appear as shown in Fig.

2-4. Type in the proper values requested on

the form. These values may be obtained

from AFL for your particular cable. The

MRCL stands for Maximum Rated

Conductor Limit and RTS stand for Rated

Tensile Strength, or Rated Breaking

Strength. It is important that both MRCL

and RTS values be accurate in order to

allow stringing the cable to the proper

design tensions. Sag10 obtains the allowed

Fig. 2-4

percentage of RTS by dividing the MRCL by

the RTS. This percentage is often 50%, but may range from 45% to 63+%, depending on the particular cable. The

allowable percentage is increasing as new designs are developed. It is important that Conductor Selection be set

to ADSS prior to entering the Load Table data, in order to initiate the proper Load Table limits. The ADSS input

now prompts for the Thermal Coefficient of Expansion and for 3 Moduli: Initial, 10 Years Creep, Final, so the

Alcoa SAG10 Manual

Page 13

Chapter 2

Main Menu - Pulldown Menus

program can simulate the exact stress-strain chart for that particular design. The proper values for these

parameters can also be obtained from your AFL representative.

2.3.2.2 OPGW

Sag10 calculations now include AFLs

Optical Ground Wire cables. AFL does not

recommend attempting to use Sag10 to

calculate data for OPGW cable from other

manufacturers.

Selecting 17- OPGW will display the form

shown in Fig. 2-5 or 2-6. Selecting by:

Catalog #: allows the user to type in AFLs

catalog #, such as GW0815. Selecting by:

Size/Strand allows the user to enter data

by cable designation. If the cable does not

have alloy stranding, enter the single

leading value into the first entry cell as

shown in Fig. 2-6.

Fig. 2-5

2.3.2.3 ACSS Conductors

The selection of conductor databases now include Aluminum Conductor, Steel Supported (ACSS). This is the

conductor formerly called SSAC by Reynolds Metal Co. Both ACSS/AW and ACSS/TW cables are also included.

2.3.2.4 Pre-stressing ACSS Conductors

Alcoa has been asked to provide some guidance for the pretensioning of ACSS conductors. These instructions

were put together for that purpose. Be sure to also read the note below instructions (1)-(20):

1) Create or Open a Problem File. Only one ruling span may be run at a time.

2) Pick Load Table from the Main Menu

3) Pick a Load Zone from one of the 5 available at the bottom of the form, or enter your own values.

4) Enter an additional row with a stringing temperature in the 1st column.

5) Tab over and enter an increased weight in the 3rd column for wind as a Negative number, generally about 4

times that of the conductor weight.

6) Tab over and enter a 1 in the 5th column for Code.

7) Pick OK to return to the Main menu.

8) Pick Run, Sag & tension calcs from the Main Menu.

9) Note the initial tension for the common point in the Sag & Tension output and return to the Loading Table and

adjust the negative value in the Wind column 3 if more or less pretension is desired. Repeat steps (5), (7), (8) &

(9) until the desired Pretension is achieved in the Sag & Tension output.

10) From the Sag & Tension Data Menu, pick Stringing

11) Enter spans and Pick OK to continue.

12) Pick Final Condition.

13) For the Starting Temperature, enter the same temperature that was used in (4) above. Leave Increment and

Ending Temperature as 0. Pick OK to continue.

14) Record the single temperature Stringing Sag data.

15) Return to the Load Table and replace the stringing temperature with another stringing temperature.

16) Tab over to the 3rd column for wind and adjust the value to a smaller negative number for a higher stringing

temperature or to a larger negative number for a lower stringing temperature.

17) Pick OK to return to the Main menu.

18) Pick Run, Sag & tension calcs from the Main Menu.

Alcoa SAG10 Manual

Page 14

Chapter 2

Main Menu - Pulldown Menus

19) Note the Sag & tension output and Return to the Loading Table, adjusting the negative value in the Wind

column 3 until the initial and final values for all of the conditions, other than the stringing temperature common

point, match those of the output in step (9) above.

20) Repeat steps (15) thru (19) and steps (10) thru (14) for each stringing temperature.

Note: If the user intends to pretension an ACSS conductor, it is important that he consider the following items :

a) The structure design engineer must be informed of the additional loads created by pre-stressing so that he can

review the entire line for those loads.

b) The design engineer needs to review in particular the additional horizontal and vertical loads applied to the

structures adjacent to the tensioner and puller during the stringing process. The engineer should design and

specify the temporary guy attachment locations for these structures, and specify minimum level ground distances

allowed between the puller and tensioner and the adjacent structures.

c) The line crew manager needs to be informed of the additional loads as it may be necessary to use larger

pullers and tensioners than would be used otherwise. Cable pulling may require different pulling clamps than

normally used. Additional time may be required during stringing, and will require throwing lines over the conductor

to pull the conductor back into a uniform sag. The line crew may need to budget for these additional costs.

2.3.2.5 Copper Conductors

The selection of conductor databases now include separate databases for Copperweld cables,

Copperweld-Copper cables and Hard Drawn (HD) Copper.

2.3.2.6 Conductor Lookup List

It is now possible to scroll thru a list of

available conductors for each conductor

type, and thereby select the appropriate

conductor without having to type the name

or remember the exact spelling.

In order to select a conductor from the

lookup list, first select the proper conductor

type from the left column. Then click the

arrow on the right side of the dropdown box

to display a list of cables as shown in Fig. 27. Select the applicable conductor by

highlighting and <Enter> or by doubleclicking the conductor. Then press Lookup

Wire Data to fill in the conductor data

boxes.

In order to save the time of scrolling thru

the conductor list for future lookups, refer to

Section 2.3.2.7 in order to add the

conductor to set a bookmark for the

conductor.

2.3.2.7 Sort Selection List

Fig. 2-7

A check box has been provided just below

the Optional Conductor Selection List box. Checking the box will sort the conductor databases in alphabetical

order for conductor types 1 to 9, 13, 14, 18, and 19. This is helpful if you wish to lookup the conductor by ordered

by conductor name, rather than the normal order by conductor size.

Alcoa SAG10 Manual

Page 15

Chapter 2

Main Menu - Pulldown Menus

2.3.2.8 User Bookmarks

You can now use bookmarks to store a list

of the most common conductors used. The

list of favorite conductors are then available

for quick recall when setting up future

problem files. The steps to do this are:

1. Select a conductor and then press

Lookup Wire Data to fill in the conductor

data boxes.

2. Press the Add to Database button to

display the red form shown in Fig. 2-8.

3. Press the Add Bookmark button. The

conductor is added to the User Bookmarks.

4. Press the EXit button to return to the

Conductor Selection area.

2.3.2.9 Add New Conductor to

Database

This replaces the previous DOS based

ADD.EXE program, simplifying the process

of adding new conductors to the existing databases. In order to add a new conductor, follow the steps below:

1. If the conductor is similar to an existing conductor, select that conductor and then press Lookup Wire Data to

fill in the conductor data boxes. Otherwise, proceed to step 2.

2. Press the Edit Data checkbox. This allows the user to enter new data or edit existing data in the data boxes

provided.

3. Press the Add to Database button shown in Fig. 2-7 to display the red form shown in Fig. 2-8.

4. Press the Add to Type N button, where N equals the conductor type requested. The conductor is added to the

database for that conductor type.

5. You may also bookmark the new conductor at this time by pressing the Add Bookmark button. The conductor

is added to the User Bookmarks.

6. Press the EXit button to return to the Conductor Selection area.

Fig. 2-8

2.3.2.10 View Existing StressStrain Chart in Sag10.Pgm

Database

Fig. 2-9

This replaces the previous DOS based

ADD.EXE program, simplifying the

process of viewing existing stress-strain

charts in the Sag10.Pgm database. In

order to view an existing chart, follow the

steps below:

1. Press the New S-S Chart button

shown in Fig. 2-7. This will display the

Form shown in Fig. 2-9.

2. Click on the Chart # lookup box to

present a list of existing chart #s. Select

a Chart #.

3. Press the View Chart button. The

stress-strain data for that chart will fill in the data boxes.

2.3.2.11 Add New Stress-Strain Chart to Sag10.Pgm Database

This replaces the previous DOS based ADD.EXE program, simplifying the process of adding new stress-strain

charts to the existing Sag10.Pgm database. In order to add a new chart, follow the steps below:

1. Press the New S-S Chart button shown in Fig. 2-7. This will display the Form shown in Fig. 2-9.

2. Fill in all of the data boxes provided in the form. The required data may be obtained thru your AFL

representative.

Alcoa SAG10 Manual

Page 16

Chapter 2

Main Menu - Pulldown Menus

3. Press the Add Chart button. The data will be added to the Sag10.Pgm database. Warning: If the chart already

exists in Sag10.Pgm, the earlier data will be retrieved rather than the most recent entry.

2.3.2.12 Delete User Added Stress-Strain Chart from Sag10.Pgm Database

This new feature allows the user to remove any Stress-Strain Charts from Sag10.Pgm that he has added in

himself and would now like to remove for various reasons. In order to delete a chart, follow the steps below:

1. Click on the Chart # lookup box to present a list of existing chart #s. Select a Chart #.

2. Press the View Chart button. The stress-strain data for that chart will fill in the data boxes.

3. Press the Delete Chart button. The data will be removed from the Sag10.Pgm database. If the chart is an core

AFL chart, the Delete Chart button will show as disabled.

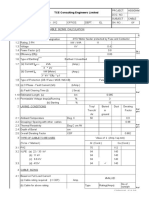

2.3.3 Loadings Table

Selecting the Loadings Table

command displays the form shown

in Fig. 2-10. The table is ready for

individual inputs or automatic

loadings. An initial record entry of

60 F, 0, 0, 0, 2 is automatically

generated. This is the standard

check for creep. Any entry with a

zero value for the tension entry

and a 2 for code entry, will allow

the program to check for creep. If

all such entries are removed,

creep will not be checked, and

incorrect data may result. In such

a case, the output also will read

Creep is NOT Considered. If

the final sag is controlled by creep,

the output will read Creep IS a

Factor. If the final sag is

controlled by the ice and wind from

one of the load cases, the output

will read Creep is NOT a

Factor. Fig. 2-10 shows a typical

Fig. 2-10

load case after additional loads

have been added. If metric units have been selected in the Options section, units will appear as Deg C, mm Ice,

2

2

Kg/M or N/M wind, Kg or N tension.

The command buttons at the bottom left of the form will generate various standard load conditions. Selecting any

of them will generate the Design Limits form shown in Fig. 2-11 & Fig. 2-12. The following pages list the load

conditions generated for each of the standard Loadings and Design Limit options possible. The load condition

limits differ for ADSS in that both Alcoa and NESC limits generate a maximum limit of 50% of RTS.

Clear Loads will clear all loads from the table and generate a creep condition of 60 F, 0, 0, 0, 2.

Insert Row will insert one row at the current cursor location.

Delete Row will delete one row at the current cursor location.

Auto Temp Incr. prompts for a Temperature to increment. When the down arrow is used in the 1st column, any

blank rows will be incremented by the entered amount.

Save Load File allows you to store your loadings, and reuse them for creating or editing other problem files. You

will be prompted for a file name. Enter a file name, using .LOD as the extension.

Open Load File allows you to then retrieve any previously saved load files. You will be prompted for a file name.

Selecting OK will clear out any previous entries and retrieve the loadings in the .LOD file.

Additional entries may be made in any order up to a total of 50. A sorting process will organize the problem file into

proper temperature/load order. Temperature (Deg F or C), radial thickness of ice (in. or mm. or negative value for

2

2

Rime ice or wet Snow), horizontal wind load (Psf, Kg/M , or N/M ), tension limit (Lb, Kg, or N) or % RTS or

negative value for sag, and limit code values are placed within fields.

Alcoa SAG10 Manual

Page 17

Chapter 2

Main Menu - Pulldown Menus

Glaze ice is based on a density of 57 Lbs/ft3. Rime ice or wet Snow is assigned a default value of 37 Lbs/ft3. One

of the new features for Sag10 is the ability to adjust the density of the Rime ice by selecting the Rime Ice Density

command button or press <Alt>-R. Type in the new value and press <Tab> to return to the Load Table.

Tensions may be inserted as % of RTS (Ex: .5 for 50% RTS) or in Lbs. Limit Code 1,2 or 3 is used in the far right

column. 1 is used for initial, 2 for final. Limit entries may be tensions or sags. Sags are entered as negative

numbers. Code 3 designates elevated temperature.

Bare weights are supplied and loaded weights are calculated based on data from conductor files (or user input)

and are displayed in report printout. Negative wind values may not be used in problem files with Marker Balls or

Cables added.

Pressing the GalloP Loads button will insert the loads required to calculate the Galloping Ellipses. These load

conditions are normally only inserted if NESC Heavy Loads are selected. Refer to section 4.2 Gallop for more

information on galloping calculations.

There are 2 recommended methods for printing the Loadings Table. In either case, select the Loadings Table

form, with the desired load conditions in the table.

Method A) Press <Alt>-<Print Screen> from the Loadings Table form. Then, activate a graphic word processor,

such as MS Wordpad or Word, and press <Cntrl>-V. The Loadings Table form will paste into the word processor.

Print from the word processor.

Method B) Press "Save Load File" in the Loadings Table form. Enter a file name, such as MYLOADS.LOD and

press OK. The extension for load files are .LOD. Activate a word processor, such as MS Wordpad or Word. Open

the MYLOADS.LOD file. Highlight the text and select a fixed pitch font such as Courier New. If you want the table

headings, you will have to type them in manually. Print from the word processor.

Selecting one of the Loading commands at the left bottom area of the form will

generate NESC Heavy, Medium, and Light Loading, respectively, as shown in the

loadings that follow. These function keys will erase any data previously entered.

Tension limits shown are % RTS. However, % RTS, Lbs. tension or amount of

Sag may be used. NESC Limits indicate maximum tensions allowed by code.

Alcoa Limits are more conservative and are recommended for maximum wire

and line durability. Selection of one these Function keys prompts the user with the

form shown in Fig. 2-11 :

Fig. 2-11

NESC Heavy Load

Alcoa Limits

NESC Medium Load

Alcoa Limits

TEMP

ICE

WIND

TENSION

Deg F

0

32

-20

0

0

0

30

60

90

120

167

212

Inch

.5

.5

Lb/Ft2

4

% or Lb

.5

.333

.25

1

2

Alcoa SAG10 Manual

CODE

TEMP

ICE

WIND

TENSION

Deg F

15

32

0

15

15

15

30

60

90

120

167

212

Inch

.25

.25

Lb/Ft2

4

% or Lb

.5

NESC Light Load

Alcoa Limits

CODE

1

2

TEMP

ICE

WIND

TENSION

CODE

Deg F

30

30

30

30

60

90

120

167

212

Inch

Lb/Ft2

9

% or Lb

.5

.333

.25

1

1

2

2

Page 18

Chapter 2

Main Menu - Pulldown Menus

NESC Heavy Load

NESC Limits

TEMP

ICE

WIND

TENSION

Deg F

0

32

-20

0

30

60

60

60

90

120

167

212

Inch

.5

.5

Lb/Ft2

4

% or Lb

.6

.35

.25

NESC Medium Load

NESC Limits

CODE

1

2

2

TEMP

ICE

WIND

TENSION

Deg F

15

32

0

15

30

60

60

60

90

120

167

212

Inch

.25

.25

Lb/Ft2

4

% or Lb

.6

NESC Heavy Load

No Limits

TEMP

ICE

WIND

TENSION

.35

.25

NESC Light Load

NESC Limits

CODE

1

2

2

TEMP

ICE

WIND

TENSION

CODE

Deg F

30

30

60

60

60

90

120

167

212

Inch

Lb/Ft2

9

% or Lb

.6

NESC Medium Load

No Limits

ICE

WIND

TENSION

Deg F

Inch

Lb/Ft2

% or Lb

Deg F

Inch

0

.5

4

.5

1

15

.25

32

.5

32

.25

-20

0

0

15

30

30

60

2

60

90

90

120

120

167

167

212

212

* NESC Limits are reduced to .50 (50%) for ADSS cables

CODE

TEMP

Lb/Ft2

4

% or Lb

.5

.35

.25

1

2

2

NESC Light Load

No Limits

CODE

TEMP

ICE

WIND

TENSION

CODE

Deg F

30

30

60

90

120

167

212

Inch

Lb/Ft2

9

% or Lb

.5

1

2

Pressing the GalloP Loads button will insert the 2 loads below into the current load case, in order to allow

calculation of the Lissajous ellipses. This is required for all load cases except NESC Heavy, which already include

these 2 load conditions.

GalloP Loads

TEMP

ICE

WIND

TENSION

Deg F

32.0

30.0

Inch

.50

Lb/Ft2

% or Lb

Alcoa SAG10 Manual

CODE

Page 19

Chapter 2

Main Menu - Pulldown Menus

Selecting the Calif. HeaVy or Calif. LiGht commands generate California Heavy Loading and California Light

Loading, respectively, as shown in the loadings that follow. These commands will erase any data previously

entered. Tension limits shown are % RTS. However, % RTS, Lbs. tension or

amount of Sag may be used. NESC Limits indicate maximum tensions allowed by

the California GO 95 code limits. Alcoa Limits are more conservative and are

recommended for maximum wire and line durability. Selection of one these

commands prompts the user with the Design Limits form. Selection of one these

Function keys prompts the user with the form shown in Fig. 2-12 :

Fig. 2-12

California Heavy Load

Alcoa Limits

California Light Load

Alcoa Limits

TEMP

ICE

WIND

TENSION

Deg F

0

32

-20

0

0

0

30

60

90

120

130

167

212

Inch

.5

.5

Lb/Ft2

6

% or Lb

.5

CODE

.333

.25

1

2

TEMP

ICE

WIND

TENSION

CODE

Deg F

25

25

25

25

60

90

120

167

212

Inch

Lb/Ft2

8

% or Lb

.5

.333

.25

1

1

2

California Heavy Load

NESC Limits

TEMP

ICE

WIND

TENSION

Deg F

0

32

-20

0

30

60

60

60

90

120

130

167

212

Inch

.5

.5

Lb/Ft2

6

% or Lb

.6

.35

.25

California Light Load

NESC Limits

CODE

1

2

2

TEMP

ICE

WIND

TENSION

CODE

Deg F

25

25

60

60

60

90

120

167

212

Inch

Lb/Ft2

8

% or Lb

.6

California Heavy Load

No Limits

TEMP

ICE

WIND

TENSION

Deg F

0

32

-20

0

30

60

90

120

130

167

212

Inch

.5

.5

Lb/Ft2

6

% or Lb

.5

.25

.25

California Light Load

No Limits

CODE

TEMP

ICE

WIND

TENSION

CODE

Deg F

25

25

60

90

120

167

212

Inch

Lb/Ft2

8

% or Lb

.5

1

2

NESC Limits are reduced to .50 (50%) for ADSS cables

Alcoa SAG10 Manual

1

2

2

Page 20

Chapter 2

Main Menu - Pulldown Menus

2.3.4 Ruling Spans

Selecting the Run, Ruling SPans command from the Main Menu

displays the form shown in Fig. 2-13.

Up to 50 spans may be entered. Spans may be generated singly, or

in increments. Units are Feet or Meters, depending on option

selected. The common editing keys are similar to typical Windows

spreadsheets. Keystrokes specific for the Span table are explained

below:

Main Menu or OK ends the current span entry/edit session and

returns to the Main Menu.

Fig. 2-13

Insert Span will insert one span

Delete Span will delete one span

Clear Span will clear all of the spans in the table

<F2> will switch from type over mode to edit cell mode

Series of Spans command prompts for the input shown in Fig. 2-14 below

and then generates the requested values for the span table.

Fig. 2-14

2.3.5 Output Redirection

The data output option box previously on the Main Menu screen has now been replaced with Print options on the

Sag & Tension data menu bar. Refer to Section 4.9 Output for details.

Alcoa SAG10 Manual

Page 21

Chapter 3

Main Menu - Pulldown Menus

3.1 File Commands (Main Menu)

Selecting File (Main Menu) displays the sub menu shown in Fig. 3-1.

3.1.1 File New (Main Menu)

is selected to clear all previous file problem data.

3.1.2 File Open (Main Menu)

Fig 3-1

is selected to open a problem file. The standard

Windows file opening form is displayed as shown in

Fig. 3-1. A sample file named SAMPLE.PRF has

been included and may be opened for practice. It is

recommended that all problem files be given a .PRF

extension.

3.1.3 File Save (Main Menu)

is selected to save a new or an existing

problem file. If the problem has not yet been

assigned a name, a standard Windows file

saving form similar to Fig. 3-2 will display. It is

recommended that all problem files be given a

.PRF extension.

3.1.4 File Save As

is selected from the Main Menu to save a

problem file under a new name. The standard

Windows file saving form is used, similar to Fig.

Fig. 3-2

3-2.

It is recommended that all problem files be given a .PRF extension.

3.1.5 File eXit (Main Menu)

is selected to close SAG10 and return to Windows.

Alcoa SAG10 Manual

Page 22

Chapter 3

Main Menu - Pulldown Menus

3.2 Options

Selecting Options will display the form shown

in Fig. 3-3. This is similar to the 'Defaults' area

in the DOS versions of SAG10. The format has

been rearranged, however, for convenience

and to better meet the standard Windows

format. The following options have been

moved to other areas:

1. The Stringing Sag options have been moved

to the Sag & Tension Output Screen. It is no

longer necessary to decide ahead of time

whether or not to view the Stringing Sag

Tables. See Section 4.4.

2. Headings for 2nd page have been moved to

Setup - Page Setup. See Section 3.3.2.

Fig. 3-3

For the current Options area, the default

values or the last selected option is displayed.

Use the Tab key to move through the optional

groups. The alternate choices may be selected

by using the right or left ARROW keys. Check

boxes may be toggled with the spacebar. Main

Menu or OK returns to Main Menu. The

Options set by the user are saved as part of

the problem file.

Below is a detailed explanation of each default selection.

3.2.1 Elevated Temperatures, Input (default = unchecked)

When Elevated Temperature Input box is checked, the message shown below appears on the Options form. This

message is a reminder that it is still necessary to indicate what temperatures to check, and for what time intervals.

Refer to Elevated Temperature Creep below for complete information on elevated temperature entry. Fig. 3-5

also appears.

Note: Elevated Temperature Points Require

Code = 3 in Loading Table

** Modify Load Table before running **

3.2.2 Elevated Temperatures, Output Strain (default = unchecked)

This default is only considered if the Elevated Temperature Input Default shown above in Section 3.2.1 equals

"Yes". If so, then the output will include a line of data at the first elevated temp creep point, indicating normal (EC)

and elevated temperature creep (ECRP). This is shown in Fig. 3-4 below, followed by 60 Deg F temperature

w/creep output. Refer to Section 3.2.2.1 for complete information on elevated temperature entry.

Ec = 468.26 Ecrp = 1159.04

60.# .00 .00 .00 1.075 28.31 4766.

Fig. 3-4

Creep is a function of time and temperature. The time/temperature that will cause the maximum micro strain

increase in elongation is selected and converted to a temperature differential.

3.2.2.1 Elevated Temperature Creep

The following steps are required to generate elevated temperature calculations. If any of the steps are left out, the

output will not reflect the proper output:

1. Select Options (Main Menu).

2. Under Elevated Temperatures, mark the Input checkbox. Optionally, mark the Output Strain check box.

Refer to Section 3.2.2 for explanation of Output Strain.

Alcoa SAG10 Manual

Page 23

Chapter 2

Main Menu - Pulldown Menus

3. The Elevated Temperature Creep form shown in Fig. 3-5 will appear. Enter the length of time at which the

conductor is expected to experience elevated temperatures over the life of the line is required. Entries are in hours

and Deg C. Typical entries might be:

4. Select RoLLed or CAst Rod from the option box as shown

in Fig. 3-5. Creep characteristics between rolled and cast rod

are different. Cast rod exhibits less creep than rolled rod.

Conductors manufactured prior to the early 1970s are likely to

have been made with rolled rod.

5. If the conductor selected is all-aluminum (AAC, AAAC,

ACAR) or an ACSR with strands of 84/19, 84/7, 45/7, 20/7,

18/1, 42/7, 76/19, 72/7, and 36/1 (ACSR's with less than 71/2% steel by area), the values entered into the table shown in

Fig. 3-5 will be used in the elevated temperature calculations.

(The actual times and temperatures shown in table are entered

by user).

Fig. 3-5

Elevated temperature creep of ACSR's with more than 7-1/2%

steel by area is less than room temperature creep and can be

ignored.1 If the user has chosen an ACSR with more than 7 1/2% steel, the program will issue a warning

message, toggle the Elevated Temp Input Default to "No", and the Elevated Temp Table will be bypassed.

6. Select Loadings Table from the Main Menu. Select a standard load from the 5 command buttons and the

proper entries will be automatically generated. An additional record (row) will be generated for each temperature at

or above 60 Deg F. (16 Deg C.), and assigned a code value of 3. The temperatures from the Elevated

Temperature Table in Fig. 3-5 will be converted to Deg F, and included in the Loadings Table also, with a code

value of 3. If temperatures less than 16 Deg C. were added, SAG10 will ignore them as they are not affected by

elevated temperature.

If the user is entering a non-standard loading, it is then necessary to enter the Elevated Temperatures manually.

All temperature values in the table at or above 60 Deg F should have a 2nd entry with a code value of 3. Each of

the temperatures in the Elevated Temperature Table in Fig. 3-5 should be converted to Deg F, and included in the

Loadings Table also, with a code value of 3. As an example, if the Elevated Temperature Table has a temperature

of 125 Deg C included, then the Loadings Table should have an equivalent entry of 257 Deg F, with and without a

code value of 3. This is shown below in Fig. 3-6.

This creates in the output the comparison of sag at 257 Deg F. with and without elevated temperature creep. In

the Sag & Tension Output, the elevated temperature creep line is identified by a # sign.

Creep is a function of time and temperature. The

time/temperature that will cause the maximum micro strain

increase in elongation is selected and converted to a

temperature differential. A printout of normal creep (EC)

and elevated temperature creep (ECRP) is available by

requesting Output Strain in the Options menu area. The

program ETCR.EXE on your SAG10 diskette is based on

the papers described below and will provide the

temperature differential used by SAG10 in determining

Fig. 3-6

elevated temperature sag values. For background on

elevated temperature creep the following papers may be researched:

l. J. R. Harvey, R. E. Larson - Use of Elevated Temperature Creep Data in Sag-Tension Calculations, IEEE Paper 69 TP 674-PWR.

2. J. R. Harvey, R. E. Larson - Creep Equations of Conductors for Sag-Tension Calculations, IEEE Paper C 72 190-2.

3. J. R. Harvey, R. E. Larson - Technique to Include Elevated Temperature Creep in Sag-tension Calculations, IEEE T&D Conference and

Exposition April 1-9, 1979.

4. W. B. Zollars - Aluminum Conductor Elevated Temperature Considerations, Seminar sponsored by Georgia Power Co., the Aluminum

Association, and EPRI on the Effects of Elevated Temperature Operation on Overhead Conductors and Accessories - May 20, 1986, Atlanta

Georgia.

Alcoa SAG10 Manual

Page 24

Chapter 3

Main Menu - Pulldown Menus

3.2.3 Account for Aluminum Compression

SAG10 Vers. 2.0 corrects an error in the previous version relating to effects of creep at elevated temperatures.

The error caused the increases in sag at elevated temperatures to be overestimated. It occurred only under

conditions where the aluminum in ACSR was slack.

This error arose from the method used in previous versions for representing effects of creep at elevated

temperatures. The elevated temperature increment in creep was simulated by a fictitious increment in conductor

temperature. The method in effect assigned a significant part of the creep increment to the steel core, actually one

part creep strain to the steel for each two parts assigned to the aluminum. In actuality, there is little or no creep of

the steel. The method is accurate for conditions where the aluminum in ACSR is not slack. However, it leads to an

estimate of the so-called kneepoint temperature that is too high, and that leads to overestimates of increases in

sags. In Vers. 2.0, all of the elevated creep strain increment is assigned to the aluminum, so that sags are correct

even when the aluminum is slack. Refer to Appendix, Theory of Compressive Stress in Aluminum of ACSR and

Appendix, Some Effects of Mill Practice on the Stress Strain Behavior of ACSR.

3.2.4 Separate AL & STL Tension

The basis for the Alcoa Graphic-Method of sag and tension is stress- strain testing. When stress-strain tests are

performed on ACSR, composite data (aluminum combined with steel) and single data (that of the steel only) are

possible. The Graphic Method, when dealing with ACSR derives the stress-strain data of the aluminum portion by

subtracting the available steel data from that of the composite. Whenever different temperatures are considered in

a sag and tension problem, transposition of the steel and aluminum portion by use of coefficient of linear

expansion is used. At each temperature, therefore, the components are added vectorially to form the composite.

Since the separate aluminum and steel tensions are always available, the default option of separate aluminum and

steel tensions is offered. Separate tensions can be a valuable tool when evaluating operation of ACSR's at high

temperatures. ACSR's with large percentage steel will exhibit zero tension on the aluminum

strands at high temperatures. This means added sag will be attributable only to the elongation of the steel - a

lower value since the coefficient of expansion of steel is half that of aluminum.

3.2.5 Tensions Avg Vert (At Supports) Horiz (At Sag)

The default used for tension is the average value. This is the tension the conductor "sees". Options for tension

components at the support or at the "belly" of the sag are available. The support value (vertical) includes the

weight of wire whereas the sag value (horizontal) subtracts out the weight of the wire. Tension at support is used

in tower design calculations. Horizontal tension is used in offset clipping and inclined span options. Formulas used

for leveled spans are as follows:

T = P + WD/2

H = P - WD/2

Where: T = Tension at support, Lbs.

H = Horizontal tension at center of span, Lbs.

P = Average tension, Lbs.

W = Conductor weight, Lbs./ft.

D = Sag, ft.

For the incline span case formulas are presented in Appendix () Inclined Span Sag Example.

3.2.6 Display Extra Column No % RTS H/W Horz & Vert Sag

This option adds columns to the Sag & Tension Output for Final & Initial tension as either

% RTS refers to Percentage of Rated Tensile Strength or

H / W is the Horizontal Tension divided by Weight. This is often referred to as the "Catenary Constant" or "C"

value or

Horz & Vert Sag displays the resultant sag as horizontal and vertical components.

An example is shown in "Appendix G13, Percent RTS, H / W or Horz & Vert Sag Example ".

3.2.7 Units English English-to-Kg Kilogram Newton

There are four options available for Units:

English - English Input and Output in Pounds, Feet or Inches, and Deg. Fahrenheit.

English-to-Kg - English Input and Metric Output in Kilograms, Meters or Millimeters, and Deg. Centigrade.

Kilogram - Both Input and Output are in Kilograms, Meters or Millimeters, and Deg. Centigrade.

Newtons - Both Input and Output are in Newtons, Meters, & Deg. Centigrade.

Alcoa SAG10 Manual

Page 25

Chapter 3

Main Menu - Pulldown Menus

The Sag Curves and Galloping Ellipses are now displayed and printed in both English and Metric Units. Refer to

Appendix, Notes for Metric Users' for more information.

3.2.8 NESC K New Old Old (Steel & Cu)

Occasionally it is necessary to distinguish between NESC 5th or 6th Edition and the rounded-off K factor of the

NESC 7th Edition. The Old designates 5th or 6th. The Old (Steel & Cu) should be used as required to match

calculations for steel or copper cable for the older NESC manuals.

3.2.9 T-2TM Conductor

Any of the ACSR, AAC, AAAC, or ACAR may be calculated as T-2 conductor, also referred to as TTwo. The

weight, strength, and area of the wire are doubled, the diameter is considered to be 1.637 times as large as the

single wire for wind resistance calculations. If the T-2 selection is made, the conductor description will indicate use

of T-2. This option is not available for Line Wire or Multiplex, attempting to run such a combination will reset TTwo

to unchecked. The TTwo option may also be set in the Conductor Selection area.