Documente Academic

Documente Profesional

Documente Cultură

Bolt Torque Chart

Încărcat de

Marco BacianDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bolt Torque Chart

Încărcat de

Marco BacianDrepturi de autor:

Formate disponibile

17/12/2016

HOME

BoltTorqueChart

PROJECTS

REPAIR SERVICES DIRECTORY

Repair Techniques

TIPS

DATA

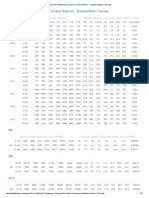

Bolt Torque Chart

Video Library

Shaft Straightening

Thread Repair

Repair Projects

Differential Repair

Impeller Repair

PTO Housing Repair

Failure Analysis

Cavitation

Product Info

E-Z LOK

HeliCoil

Keensert

Time-Sert

Repair Data

Bolt Torque Chart

Coeffic-Thermal Exp.

Density Data

Tap/Drill Chart-Inch

Repair Industry

Repair Search Engine

Repair News

http://www.repairengineering.com/bolttorquechart.html

1/7

17/12/2016

http://www.repairengineering.com/bolttorquechart.html

BoltTorqueChart

2/7

17/12/2016

http://www.repairengineering.com/bolttorquechart.html

BoltTorqueChart

3/7

17/12/2016

BoltTorqueChart

There are several factors that determine a proper bolt torque specification. Some of them are listed below...

Material containing the external thread (bolt)

Most bolt torque charts, including this one, are based on the material strength of the bolt - the

component containing the

external thread.

Reference 2 below recommends a fastener preload in the range of 60% - 90% of the bolt material proof

load. This RepairEngineering bolt torque chart was created assuming a value at the mid-point of that

range... at 75% of the material proof strength.

Bolt proof load is defined as the maximum force that the material can support without experiencing

permanent deformation. Although material properties vary, an approximate estimate of proof strength is

85% - 90% of its yield strength.

As noted in the chart, bolt proof strength varies depending on the fastener

diameter in some cases.

http://www.repairengineering.com/bolttorquechart.html

grade and also upon its

4/7

17/12/2016

BoltTorqueChart

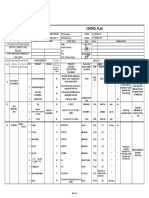

Material containing the internal thread (nut)

In order to determine the torque value of a bolt and nut assembly based on just the material strength of

the bolt itself, the materials of the assembly should follow this guideline...

The proof strength of the nut (the material containing the internal thread)

should be equal or greater than the

ultimate tensile strength of the bolt (the material with the external thread).

If the

nut material is the limiting factor in the fastening system, then obviously increasing the material

bolt will have no effect on increasing the clamping capability of the assembly.

strength of the

Also, if the nut material is the limiting factor, the maximum clamping capability (and corresponding bolt

torque) of the assembly needs to be de-rated accordingly.

Unlike most bolt torque charts, this particular chart also lists clamp loads and torque values that

correspond with bolt material stresses of 10,000 and 25,000 psi... regardless of fastener grade. This

listing may be useful when determining an appropriate de-rated torque value when engaging with lower

proof-strength materials.

Thread Engagement

Obviously, regardless of the material strength of the bolt and the nut, an effective clamping system will

not occur unless proper fastener thread engagement exists.

The objective is to assure that the engaging threads will not strip under the loading that the bolt is able

to apply.

At first, it would seem logical to simply increase the length of thread engagement by as much as required

to overcome the limitations of engaging with a material of limited proof strength. In reality, however,

only the first few threads of a threaded connection are actually involved in sharing the fastener clamping

force. This is due to thread form error and slight differences in thread size and pitch that result in an

inconsistent make-up between the male and female threads.

A common rule-of-thumb is to provide a minimum length of thread

engagement equal to the (major) diameter of the fastener.

A more conservative rule-of-thumb is to use a thread engagement

length of 1-1/2 times diameter.

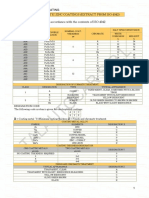

Bolt Thread Tensile Stress Area

The tensile stress area of the threaded portion of a fastener is determined by the

bolt and by the

thread pitch (spacing), as follows...

size (diameter) of the

As = 0.7854 x [d - (0.9743/n)]2

http://www.repairengineering.com/bolttorquechart.html

5/7

17/12/2016

BoltTorqueChart

where:

As = Bolt Thread Tensile Stress Area (in2)

d = Nominal Bolt Diameter (in.)

n = Thread Pitch (Threads Per Inch)

Bolt Clamp Pre-Load Force

Bolt clamp pre-load force is calculated using the bolt material

It is calculated using the following formula...

proof strength and its tensile stress area.

Fi = 0.75 x Sp x As

where:

Fi = Bolt Clamp Pre-Load Force (lbf)

.75 = Percentage of bolt material proof strength... 75% in this example

Sp = Bolt material Proof Strength (lbf / in2)

As = Bolt Thread Tensile Stress Area (in2)

Nut "K Factor"

There are several factors that affect the relationship between the applied bolt torque and the resulting

bolt tension. All of those factors are summarized in single variable that is known as the nut "K Factor".

The table below lists a typical range for the "K Factor" as well as the values used in calculating the

RepairEngineering Bolt Torque Chart.

Note that the "K Factor" values used to calculate the RepairEngineering Bolt Torque Chart were picked

somewhat arbitrarily. Any other "K Factor" value in the range could be equally valid depending on the

specific requirements of a particular application.

Bolt Condition

"K Factor"

Typical Range

"K Factor" value as used in the

RepairEngineering Bolt Torque Chart

Lubricated

0.12-0.16

0.15

Zinc Plated

0.17-0.22

0.18

Plain-Dry

0.19-0.25

0.20

Bolt Torque Calculation

The relationship between bolt

following formula...

torque and its corresponding pre-load force (tension) is given in the

T = K Fi d

where:

http://www.repairengineering.com/bolttorquechart.html

6/7

17/12/2016

BoltTorqueChart

T = Torque required to create a desired bolt pre-load (in-lb)

K = Nut "K Factor" (dimensionless)

Fi = Bolt Pre-Load Force (lbf)

d = Bolt Nominal Diameter (in)

Bolt torque provides only an indirect approximation of material stress.

It is estimated that only about 10% of the tightening torque actually

results in useful bolt tensioning. The remaining 90% is lost due

various forms of friction that occur during the tightening process.

In addition, a proper bolt torque value can be inconsistent from

fastener-to-fastener due to several factors including variations in

material, coatings, surface finishes, fit tolerances, installation method,

etc.

For these reasons, it is not practical to provide a single bolt torque

chart or formula that is accurate for all situations. This information is

voluntary, and is intended only for general-purpose reference as

explained in this

disclaimer.

Testing of actual fastener components is recommended to

determine appropriate torque values for all critical-use

applications.

This Bolt Torque Chart was created using reference information from various sources, including the

following...

1. Machinery's Handbook - 24th Edition

2. Mechanical Engineering Design - 4th Edition

Return to Bolt Torque Chart Top

Home

Disclaimer

Copyright 2016 RepairEngineering.com. All rights reserved.

Content and images may not be reproduced in any way without permission.

Saturday, December 17, 2016

http://www.repairengineering.com/bolttorquechart.html

7/7

S-ar putea să vă placă și

- ASTM & SAE Grade Markings For Bolts and ScrewsDocument2 paginiASTM & SAE Grade Markings For Bolts and ScrewsDavid D'AgostinoÎncă nu există evaluări

- Bolt Torquing AnalysisDocument7 paginiBolt Torquing AnalysisEleonor MaderazoÎncă nu există evaluări

- Material Specification: Specification: Revision Date: Revision LevelDocument2 paginiMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- BS Iso 1817-2011Document30 paginiBS Iso 1817-2011David JacksonÎncă nu există evaluări

- Bolt Torque FormulaDocument24 paginiBolt Torque Formulaماهر زارعي100% (1)

- Hitachi EX5600Document2 paginiHitachi EX5600Marco BacianÎncă nu există evaluări

- A Guide To Specifying Torque Values For FastenersDocument3 paginiA Guide To Specifying Torque Values For FastenersSÎncă nu există evaluări

- Bolt Torque ChartDocument7 paginiBolt Torque ChartMuhammad AslamÎncă nu există evaluări

- VDA Classification - Material - List - 205 - EN PDFDocument31 paginiVDA Classification - Material - List - 205 - EN PDFgogger100% (1)

- Din En12020-2001Document15 paginiDin En12020-2001Ricardo VitorianoÎncă nu există evaluări

- 18-1102 enDocument15 pagini18-1102 enhkatzerÎncă nu există evaluări

- Reinforcement CalculationDocument2 paginiReinforcement CalculationVekaymech100% (9)

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 paginăJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáÎncă nu există evaluări

- 757-767 Study GuideDocument117 pagini757-767 Study Guideviegas123100% (1)

- MIL Aa 58092Document6 paginiMIL Aa 58092sanjay_aranakeÎncă nu există evaluări

- Torque Pernos ZapatasDocument150 paginiTorque Pernos ZapatasMarco Bacian100% (1)

- VW 011 03Document22 paginiVW 011 03Alexandre UrquizaÎncă nu există evaluări

- Jis G 3466 - 2006 (JP)Document11 paginiJis G 3466 - 2006 (JP)HongHaiDuongÎncă nu există evaluări

- Bolt Thread and Head Fillet StressDocument6 paginiBolt Thread and Head Fillet StressBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Project InitiationDocument34 paginiProject InitiationJ. VinceÎncă nu există evaluări

- DM30Document6 paginiDM30Marco BacianÎncă nu există evaluări

- JPL Bolt TorqueDocument24 paginiJPL Bolt TorquegotstogoÎncă nu există evaluări

- TL 52622 en 07-2012Document12 paginiTL 52622 en 07-2012Juan Carlos Jaramillo LariosÎncă nu există evaluări

- N33 9 4 2015-04-15Document7 paginiN33 9 4 2015-04-15Anonymous 7ZTcBnÎncă nu există evaluări

- Ferrous Processing & Trading Co. Company OverviewDocument5 paginiFerrous Processing & Trading Co. Company OverviewfptscrapÎncă nu există evaluări

- Get Parts Caterpillar PDFDocument1.398 paginiGet Parts Caterpillar PDFMarco BacianÎncă nu există evaluări

- Paint Film Quality of Plastic Parts and Chrome Plated Parts: M5081 - 2020-N Nissan Engineering StandardDocument14 paginiPaint Film Quality of Plastic Parts and Chrome Plated Parts: M5081 - 2020-N Nissan Engineering StandardCARLOS A.N. LANZILLOTTO100% (1)

- AGMA 925-A03 - Effect of Lubrification On Gear Surface Distress PDFDocument58 paginiAGMA 925-A03 - Effect of Lubrification On Gear Surface Distress PDFAnonymous uL3JlWfh100% (6)

- Geomet 500 PDFDocument2 paginiGeomet 500 PDFKaran Chadha100% (1)

- Geomet 321Document2 paginiGeomet 321Satnam Rachna FastenersÎncă nu există evaluări

- Torque Tension ControlDocument5 paginiTorque Tension ControlAchmad DamarÎncă nu există evaluări

- AkzoNobel - Colloidal Silica For Adhesives BrochureDocument6 paginiAkzoNobel - Colloidal Silica For Adhesives BrochureCarlos GuerreroÎncă nu există evaluări

- A276 PDFDocument8 paginiA276 PDFsingaravelan narayanasamyÎncă nu există evaluări

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsDocument5 paginiCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsDocument3 paginiPre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjÎncă nu există evaluări

- Chapter 3 Qualitative Process AnalysisDocument27 paginiChapter 3 Qualitative Process AnalysisJesica RafananÎncă nu există evaluări

- SEBF8271 - Salvage of Tapered Steering Bores (4301, 4305, 4310) PDFDocument32 paginiSEBF8271 - Salvage of Tapered Steering Bores (4301, 4305, 4310) PDFMarco BacianÎncă nu există evaluări

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDocument9 paginiFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresÎncă nu există evaluări

- Toyota Engineering Standard PDFDocument10 paginiToyota Engineering Standard PDFrinusÎncă nu există evaluări

- As 1897-1976 Electroplated Coatings On Threaded Components (Metric Coarse Series)Document11 paginiAs 1897-1976 Electroplated Coatings On Threaded Components (Metric Coarse Series)SAI Global - APACÎncă nu există evaluări

- Screws With External Hexalobular Driving Feature: Mercedes-Benz MBN 10 142Document6 paginiScrews With External Hexalobular Driving Feature: Mercedes-Benz MBN 10 142achin123Încă nu există evaluări

- ISO 3601 Metric Size O-Rings Quick Reference ChartDocument6 paginiISO 3601 Metric Size O-Rings Quick Reference ChartHarryÎncă nu există evaluări

- Blackodizing CPDocument1 paginăBlackodizing CPx yÎncă nu există evaluări

- Fastener PDFDocument12 paginiFastener PDFdiegomilitojÎncă nu există evaluări

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 paginiTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- Ford Wa 960-2004Document1 paginăFord Wa 960-2004DanielMa0% (1)

- General Twin Seal 4 Way Diverter Iom 2007 PDFDocument20 paginiGeneral Twin Seal 4 Way Diverter Iom 2007 PDFtxlucky80Încă nu există evaluări

- Tata Steel IS - S275JR+AR - HR Data Sheet EN PDFDocument2 paginiTata Steel IS - S275JR+AR - HR Data Sheet EN PDFArnimala DewiÎncă nu există evaluări

- TL245 English 2004Document8 paginiTL245 English 2004Elliott RussellÎncă nu există evaluări

- Ralin Group Brochure 2013Document3 paginiRalin Group Brochure 2013n1ghtfallÎncă nu există evaluări

- Material SpecificationDocument9 paginiMaterial SpecificationMuthu GaneshÎncă nu există evaluări

- General Tolerances For MTB: July 2012 Accuracy of ShapeDocument9 paginiGeneral Tolerances For MTB: July 2012 Accuracy of ShapeAkmal NizametdinovÎncă nu există evaluări

- Coating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetDocument6 paginiCoating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetROHITÎncă nu există evaluări

- (Bolt Science) BOLTCALC Program Brochure PDFDocument3 pagini(Bolt Science) BOLTCALC Program Brochure PDFAbdulrahman Al HuribyÎncă nu există evaluări

- VW 50019 PDFDocument4 paginiVW 50019 PDFSujay Nahalde100% (1)

- Guia de Materiales - MatricesDocument11 paginiGuia de Materiales - MatricesGracielaÎncă nu există evaluări

- M6x1.0x23 Long HHS Control PlanDocument2 paginiM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsÎncă nu există evaluări

- GM500M - September 2010Document8 paginiGM500M - September 2010JOVANY LOPEZÎncă nu există evaluări

- Zinc/Aluminum Corrosion Protective Coatings For FastenersDocument3 paginiZinc/Aluminum Corrosion Protective Coatings For FastenersDarwin DarmawanÎncă nu există evaluări

- Is.7001.1989 0 PDFDocument14 paginiIs.7001.1989 0 PDFJotheeswaranÎncă nu există evaluări

- Alform 700 MCDocument9 paginiAlform 700 MCCarlos Nombela PalaciosÎncă nu există evaluări

- TL-52132 2021Document3 paginiTL-52132 2021Ronald Araujo100% (1)

- Zinc Plating InformationDocument4 paginiZinc Plating Informationankur panwarÎncă nu există evaluări

- Bossard CatalogueDocument150 paginiBossard CataloguethomaswangkoroÎncă nu există evaluări

- Electrolytic Zinc Coating PDFDocument2 paginiElectrolytic Zinc Coating PDFzoran100% (1)

- Hes B008-03 Hexagon NutsDocument5 paginiHes B008-03 Hexagon NutsPreetam KumarÎncă nu există evaluări

- Rotordynamics Analysis Using Abaqus/StandardDocument5 paginiRotordynamics Analysis Using Abaqus/Standardsüleyman tazebayÎncă nu există evaluări

- Data Sheet HV-HR ItDocument3 paginiData Sheet HV-HR ItKemo TufoÎncă nu există evaluări

- Rev 8Document2 paginiRev 8api-273257329Încă nu există evaluări

- Machinedesign 3417 Specifying Fastener TorqueDocument5 paginiMachinedesign 3417 Specifying Fastener TorqueStarlord PlazaÎncă nu există evaluări

- Bolt PretesnsionDocument2 paginiBolt PretesnsionAbhilash ChatterjeeÎncă nu există evaluări

- Bolt Preload CalculationDocument3 paginiBolt Preload Calculationmihai90Încă nu există evaluări

- Ex5600 BarandaDocument10 paginiEx5600 BarandaMarco BacianÎncă nu există evaluări

- Datasheet - Metric: Pick & Carry Crane at 20-3Document16 paginiDatasheet - Metric: Pick & Carry Crane at 20-3Marco BacianÎncă nu există evaluări

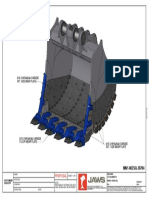

- Blindaje Balde Hitachi 5500 - 5600Document1 paginăBlindaje Balde Hitachi 5500 - 5600Marco BacianÎncă nu există evaluări

- ASTM A514 GR B Data Sheet 2012 04 01 PDFDocument2 paginiASTM A514 GR B Data Sheet 2012 04 01 PDFMarco BacianÎncă nu există evaluări

- Equipos para Revirado de BujesDocument18 paginiEquipos para Revirado de BujesMarco BacianÎncă nu există evaluări

- 06 Undercarriage Tools PDFDocument108 pagini06 Undercarriage Tools PDFMarco BacianÎncă nu există evaluări

- Track Link Assembly D475Document1 paginăTrack Link Assembly D475Marco BacianÎncă nu există evaluări

- Track Carrier Roller Remove and Install... 349F Excavator Machine Systems CaterpillarDocument4 paginiTrack Carrier Roller Remove and Install... 349F Excavator Machine Systems CaterpillarMarco BacianÎncă nu există evaluări

- Track - Separate: Table 1Document4 paginiTrack - Separate: Table 1Marco BacianÎncă nu există evaluări

- Cerrar SIS: Wheel Loader 994 Wheel Loader 9yf 994 Wheel Loader 9YF00001-UP (MACHINE) POWERED BY 3516 EngineDocument2 paginiCerrar SIS: Wheel Loader 994 Wheel Loader 9yf 994 Wheel Loader 9YF00001-UP (MACHINE) POWERED BY 3516 EngineMarco BacianÎncă nu există evaluări

- Torno - Bb5000Document8 paginiTorno - Bb5000Marco BacianÎncă nu există evaluări

- Plataforma Bulldozer 3D Opción N°2Document1 paginăPlataforma Bulldozer 3D Opción N°2Marco BacianÎncă nu există evaluări

- Torque Pernos 9w3619 ExcavadorasDocument1 paginăTorque Pernos 9w3619 ExcavadorasMarco BacianÎncă nu există evaluări

- Excavator Track Adjuster AssembliesDocument2 paginiExcavator Track Adjuster AssembliesMarco BacianÎncă nu există evaluări

- Refrentador de Caras - Bb5000Document4 paginiRefrentador de Caras - Bb5000Marco BacianÎncă nu există evaluări

- Machine Manual TP-400 (I)Document47 paginiMachine Manual TP-400 (I)Marco BacianÎncă nu există evaluări

- Quiz QuestionsDocument8 paginiQuiz QuestionsSai NathÎncă nu există evaluări

- Part Numbering ConventionDocument69 paginiPart Numbering ConventionHasan PashaÎncă nu există evaluări

- Dell Precision 670 SpecsDocument2 paginiDell Precision 670 SpecsRayirth DghÎncă nu există evaluări

- A Brief History of Aviation: Lighter-Than-AirDocument11 paginiA Brief History of Aviation: Lighter-Than-Airpsppunk7182Încă nu există evaluări

- IBM TemplateDocument9 paginiIBM Templategfgdfg7579Încă nu există evaluări

- Schrenk's Curve and V-N DiagramDocument9 paginiSchrenk's Curve and V-N DiagramLogesh Sadhasivam100% (1)

- GDST 1241 ManualDocument24 paginiGDST 1241 ManualLida PerezÎncă nu există evaluări

- BS en 00259-1-2001Document14 paginiBS en 00259-1-2001Harun ARIKÎncă nu există evaluări

- J S Auto Cast Foundry India PVT LTD.,: Tool LayoutDocument24 paginiJ S Auto Cast Foundry India PVT LTD.,: Tool Layoutkishore RavindranÎncă nu există evaluări

- What Is Free/Open-Source Software (FOSS) ?Document24 paginiWhat Is Free/Open-Source Software (FOSS) ?Marko SchuetzÎncă nu există evaluări

- Report For Action: Date: April 16, 2019 To: City Council From: City Manager Wards: AllDocument20 paginiReport For Action: Date: April 16, 2019 To: City Council From: City Manager Wards: AllToronto StarÎncă nu există evaluări

- Digital India1Document19 paginiDigital India1RamanÎncă nu există evaluări

- 74LCX125 Low Voltage Quad Buffer With 5V Tolerant Inputs and OutputsDocument13 pagini74LCX125 Low Voltage Quad Buffer With 5V Tolerant Inputs and Outputsfenixtec1Încă nu există evaluări

- Weldedmesh Adets B500a b500bDocument4 paginiWeldedmesh Adets B500a b500bFiraz Kaot'zÎncă nu există evaluări

- 11g Partitioning Features Part2Document4 pagini11g Partitioning Features Part2Ashok ThiyagarajanÎncă nu există evaluări

- Astm-B601 Temper TerminologyDocument5 paginiAstm-B601 Temper TerminologyAloke BhaduriÎncă nu există evaluări

- Peram Sreenivasulu Reddy: M.C.A Form Velenkanni Institute of Computer Science, Nellore Under S.V.U WithDocument3 paginiPeram Sreenivasulu Reddy: M.C.A Form Velenkanni Institute of Computer Science, Nellore Under S.V.U WithperamsrinivasuluÎncă nu există evaluări

- Job Description For QA Automation EngineerDocument1 paginăJob Description For QA Automation EngineerRam RaiÎncă nu există evaluări

- MINERA IRL Project Gold OllacheaDocument230 paginiMINERA IRL Project Gold OllacheaJhonCordovaCruz100% (1)

- Question Paper Code: X71451: K. Ramakrishnan College of Technology (Autonomous)Document2 paginiQuestion Paper Code: X71451: K. Ramakrishnan College of Technology (Autonomous)Madhankumar .JÎncă nu există evaluări

- PowerCenter Level1 Unit03Document18 paginiPowerCenter Level1 Unit03Christian AcostaÎncă nu există evaluări

- JasperReports Server CP Install GuideDocument68 paginiJasperReports Server CP Install GuideDavid LoaisigaÎncă nu există evaluări

- LET Zamboanga Room AssignmentDocument84 paginiLET Zamboanga Room AssignmentPhilNewsXYZ100% (1)