Documente Academic

Documente Profesional

Documente Cultură

ISO/WD xxxxx-1: © ISO 2010 - All Rights Reserved

Încărcat de

Ananda Ganesh MadheswaranTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ISO/WD xxxxx-1: © ISO 2010 - All Rights Reserved

Încărcat de

Ananda Ganesh MadheswaranDrepturi de autor:

Formate disponibile

ISO/WD xxxxx-1

Contents

Page

Scope................................................................................................................................................1

Normative references .......................................................................................................................2

Designation system..........................................................................................................................2

Examples of designations..............................................................................................................11

Annex A (normative) Definition and designation of polyamides...............................................................14

ISO 2010 All rights reserved

iii

ISO/WD xxxxx-1

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO xxxxx-1 was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 9, Thermoplastic

materials.

This second/third/... edition cancels and replaces the first/second/... edition (), [clause(s) / subclause(s) /

table(s) / figure(s) / annex(es)] of which [has / have] been technically revised.

ISO xxxxx consists of the following parts, under the general title Plastics Polyamide (PA) moulding and

extrusion materials:

Part 1: Designation system and basis for specification

Part 2: Preparation of test specimens and determination of properties

Annex A forms an integral part of this part of ISO XXXXX.

iv

ISO 2010 All rights reserved

ISO/WD xxxxx-1

Introduction

The ISO 1874-1: 1992 - Polyamides Designation system and basis for specification is complex and does not

fit with daily practice anymore. In practice ISO 1043 and ISO 11469 are, in combination, 'improperly' being

used as a designation system for e.g. marking. The aim of this revision is to simplify the data block system

and to connect more to ISO 1043 and ISO 11469, where the first two blocks are used for generic identification

and marking of products.

The revised designation system needs a new ISO number, as many existing documents refer to ISO 1874-1.

If the existing ISO 1874-1 would be replaced by the new designation system, these documents would refer to

the incorrect designation system. Therefore, after publication of the new designation system ISO 1874-1 need

to be phased out in 5 to 10 years. During that period of time ISO 1874-2; Preparation of test specimens and

determination of properties, will serve as the part 2 for as well ISO 1874-1 as the new ISO PA-designation

standard.

ISO 2010 All rights reserved

WORKING DRAFT

ISO/WD xxxxx-1

Plastics Polyamide (PA) moulding and extrusion materials

Part 1: Designation system, marking of products and basis for

specification

Scope

This part of ISO xxxxx establishes a system of designation for polyamide (PA) thermoplastic materials which

is based on ISO 1043 and is intended to coordinate with the marking document ISO 11469.

The designation system may be used as the basis for specifications.

It covers Polyamide homopolymers, copolymers and blends of various compositions for moulding and

extrusion.

The types of polyamide plastic are differentiated from each other by a classification system based on

appropriate levels of the designatory properties

a) viscosity number,

b) tensile modulus of elasticity and

and on information about chemical structure, method of processing, important properties, additives, colour,

fillers and reinforcing materials

The designation system is applicable to all polyamide homopolymers, copolymers and blends. It applies to

materials ready for normal use, unmodified and modified by colorants, additives, fillers, reinforcing materials,

polymer modifiers, etc.

This part of ISO xxxxx does not apply to monomer casting-type polyamides of PA6 and PA12.

It is not intended to imply that materials having the same designation give necessarily the same performance.

This part of ISO xxxxx does not provide engineering data, performance data or data on processing conditions

which may be required to specify a material for a particular application and/or method of processing. If such

additional properties are required, they shall be determined in accordance with the test methods specified in

part 2 of ISO 1874, if suitable.

In order to specify a thermoplastic material for a particular application or reproducible processing, additional

requirements shall be given in Data Block 5 (3.1, 3.6).

ISO 2010 All rights reserved

ISO/WD xxxxx-1

Normative references

The following normative documents contain provisions, which through reference in this text, constitute

provisions of this part of ISO 1874. For dated references, subsequent amendments to, or revisions of, any of

these publications do not apply. However, parties to agreements based on this part of ISO 1874 are

encouraged to investigate the possibility of applying the most recent editions of the normative documents

indicated below. For undated references, the latest edition of the normative document referred to applies.

Members of ISO and IEC maintain registers of currently valid International Standards.

ISO 307; Plastics - Polyamides Determination of viscosity number

ISO 472; Plastics - Vocabulary

ISO 527-1; Plastics Determination of tensile properties Part 1:General principles

ISO 527-2; Plastics Determination of tensile properties

plastics

Part 2:Test conditions for moulding and extrusion

ISO 1043-1; Plastics Symbols and abbreviated terms Part 1: Basic polymers and their special

characteristics

ISO 1043-2; Plastics -- Symbols and abbreviated terms - Part 2: Fillers and reinforcing materials

ISO 1874-2; Plastics Polyamide (PA) moulding and extrusion materials Part 2: Preparation of test

specimens and determination of properties

ISO 3451-4; Plastics Determination of ash Part 4: Polyamides

ISO 11469; Plastics Generic identification and marking of plastics products Determination of ash

Part 4: Polyamides

3

3.1

Designation system

General

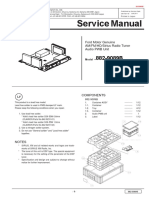

The designation system for polyamides is based on the following standardized pattern (fig 1).

Designation

Identity Block

Description

block

(optional)

International

Standard

Block

Individual Item Block

Data Block 1

Data Block 2

Data Block 3

Data Block 4

Data Block 5

Figure 1 Data block designation system

The designation consists of an optional Description Block, reading Thermoplastics, and an Identity Block

comprising the International Standard number and an Individual Item Block. For unambiguous designation, the

Individual Item Block is subdivided into five Data Blocks comprising the following information.

ISO 2010 All rights reserved

ISO/WD xxxxx-1

Data block 1 (3.2)

Identification of the Plastic by its abbreviated symbol (PA), in accordance with

ISO 1043-1, and information about the chemical structure and composition,

including information on the use of plasticizer or impact modifier.

Agreed P (Plasticizer) and I (Impact modifier)

Data block 2 (3.3)

- Fillers reinforcement incl summarized nominal content

- Important properties, impact modified flame retardant

- declaration of recyclate: Agreed only R followed by a number

Data block 3 (3.4)

Position 1: method of processing (3.3).

Positions 2 and further: additives, supplementary information and other

characteristics (3.3).

Data block 4 (3.5)

designatory properties (3.5).

- viscosity

- Emodulus

Data block 5 (3.6)

For the purpose of specifications, a fifth Data Block containing additional

information may be used (3.6).

The first character of the individual Item Block shall be a hyphen.

The five Data Blocks shall be separated from each other by a comma.

If a Data Block is not used, this shall be indicated by doubling the separation sign, i.e. by two commas (,,).

Terminal commas may be omitted.

For part marking the first two blocks of the designation are used, connected with a hyphen, and placed

between the punctuation marks '>' and '<', where no spaces are used between the codes.

EXAMPLE

See page 5

DESIGNATION

Identity Block

Individual Item Block

Description

block

(optional)

Thermoplastics

ISO

Standard

XXXXX

Data

Block 1

Data

Block 2

Data

Block 3

Data

Block 4

Data

Block 5

Polymer

Performance & Origin

Application &

Processing

Properties

Additional

information

Type

Additive

Filler

Flame

retardant

Recyclate

Moulding

Chracteristics

-PA6

-P

GF+MD

25

FR(30)

(R50)

60-14

>Part marking<

No

No

Yes

Yes

No

Designation:

ISO 1XXXXX-PA6-P,(GF+MD)25 FR(30) (RC50),MA,60-14,,

Part marking:

>PA6-P(GF+MD)25FR(30)(R50)<

ISO 2010 All rights reserved

No

No

ISO/WD xxxxx-1

3.2

Data Block 1

In this Data Block, after the hyphen, the polyamide (PA) is identified by using the symbols and designations

listed in tables 1 and 2.

Polyamides containing a plasticizer may be designated by adding the letter P after the symbol, separated from

it by a hyphen (example: PA610-P).

Polyamides containing an impact modifier may be designated by adding the letter I after the symbol,

separated from it by a hyphen (example: (PA6-I).

Table 1 Symbols indicating the chemical structure of polyamide materials in Data Block 1

Symbol

Name and chemical structure

Aliphatic - One monomer (AA)

PA6

Polyamide 6; homopolymer based on -caprolactam

PA11

Polyamide 11; homopolymer based on 11-aminoundecanoic acid

PA12

Polyamide 12; homopolymer based on

-aminododecanoic acid or on laurolactam

Aliphatic Two monomers Diamine / dicarboxylic acid

PA46

Polyamide 46; homopolymer based on tetramethylenediamine and adipic acid

PA410

Polyamide 410; homopolymer based on tetramethylenediamine and hexamethylenediamine

PA66

Polyamide 66; homopolymer based on hexamethylenediamine and adipic acid

PA69

Polyamide 69; homopolymer based on hexamethylenediamine and azelaic acid

PA610

Polyamide 610; homopolymer based on hexamethylenediamine and sebacic acid

PA612

Polyamide 612; homopolymer based on hexamethylenediamine and dodecanedioic acida

PA1212

Polyamide 1212; homopolymer based on dodecanediamine and dodecanedioic acida

Semi aromatic Two monomers (aromatic) Diamine /(aromatic) dicarboxylic acid

PA4T

Polyamide 4T; homopolymer based on tetramethylenediamine and terephthalic acid

PA6T

Polyamide 6T; homopolymer based on hexamethylenediamine and terephthalic acid

PA9T

Polyamide 9T; homopolymer based on nonamethylenediamine and terephthalic acid

PAMXD6

Polyamide MXD6; homopolymer based on m-xylylenediamine and adipic acid

PA6I

Polyamide 6I; homopolymer based on hexamethylenediamine and isophthalic acid

1,10-Decanedicarboxylic acid

ISO 2010 All rights reserved

ISO/WD xxxxx-1

Table 2 Examples of symbols indicating the chemical structure of copolyamide materials in Data

Block1

Symbola

Chemical structure

PA66/610

Polyamide copolymers based on hexamethylenediamine, adipic acid and sebacic acid

PA6/12

Polyamide copolymers based on -caprolactam and laurolactam

PA6/66/PACM6

Polyamide ternary copolymers based on -caprolactam, hexamethylenediamine, adipic acid,

bis( -aminocyclohexyl)methane and adipic acid

PA12/IPDI

Polyamide copolymers of laurolactam, isophorone diamine and isophthalic acid

PA46/6

Polyamide copolymers based on tetramethylenediamine, adipic acid and -caprolactam

PA4T/6T

Polyamide copolymers based on tetramethylenediamine, terephthalic acid and hexamethylenediamine

PA6T/XT

Polyamide copolymers based on hexamethylene diamine, terephthalic acid and an unspecified diamine

PA6T/66

Polyamide copolymers based on hexamethylene diamine, terephthalic acid and adipic acid

PA6T/6I

Polyamide copolymers based on hexamethylene diamine, terephthalic acid and isophthalic acid

PA6T/6I/66

Polyamide copolymers based on hexamethylene diamine, terephthalic acid, isophthalic acid and adipic

acid

PA66/6I

Polyamide copolymers based on hexamethylene diamine, adipic acid, and isophthalic acid

PANDT/INDT

Polyamide copolymers based on 1,6 diamino-2,2,4-trimethylenehexane, 1,6 diamino-2,4,4trimethylenehexane and terephthalic acid

PA12/IPDI

Polyamide copolymers based on laurolactam, isophoronediamine, and isophthalic acid

The following two designations include an indication of the mass content ratio (Annex A).

PA66/6 (90/10)

Polyamide copolymers based on 90% (m/m) hexamethylenediamine and adipic acid and 10% (m/m)

-caprolactam

PA6/66 (80/20)

Polyamide copolymers based on 80% (m/m) -caprolactam and 20% (m/m) hexamethylenediamine and

adipic acid

PA66/6 (80/20)

Polyamide copolymers based on 80% (m/m) hexamethylenediamine and adipic acid and 20% (m/m)

-caprolactam

Semi-crystalline Polyamides, designated as PA6T/xx/yy may also be called Polyphthalamides (PPA) if the residues of terephthalic acid

or isophthalic acid or a combination of the two comprise at least 55 mole percentage of the dicarboxylic acid portion of the repeating

structural units of the polymer chain (ASTM D 5336)

ISO 2010 All rights reserved

ISO/WD xxxxx-1

Blends.

Blends can be made from materials mentioned in both tables and/or other polymers (ISO 1043).

For polymer blends or alloys use the abbreviated terms for the basic polymers, with the main component in

first place followed by the other components in descending order according to their mass fractions, separated

by a plus sign and no space before or after the plus sign.

EXAMPLE

3.3

A blend of Polyamide12 and Polypropylene is designated: PA12+PP.

Data Block 2

In this data block, the type of filler or reinforcing material is represented by one code-letter and its physical

form by a second code-letter (Table 3, ISO 1043-2). Subsequently (without a space), the mass content may

be given by a two-figure code-number.

Mixtures of filler materials or forms may be indicated by combining the relevant codes using the sign "+" within

parenthesis followed by the total filler content outside the parenthesis. For example, a mixture of 25 % (m/m)

glass fibre (GF) and 10 % (m/m) mineral powder (MD) would be indicated by (GF+MD)35.

Separated from the reinforcement code by a space, the addition of a flame retardant or flame retardant

behaviour is represented by the code FR, where the type of flame retardant according ISO 1043-4 is given by

a two letter code between parenthesis.

Separated by a space from the flame retardant or the reinforcement code if no flame retardant code is used,

the declaration of recyclate is represented by the code RC between parenthesis (RC). Following the code RC

the mass content may be given between the parenthesis without a space. For example, a PA66 containing

20% glass fibres resulting from an overall minimum 70% of weight recyclate and 30% of virgin material would

be indicated PA66 GF20 (RC70).

Table 3 Coding system for fillers and reinforcing materials in Data Block 2

Code-letter

Material

(Position 1)

Boron

Carbona

Powder; dry blend

Fiber

Glass

Granules; ground

Whiskers

Form

(Position 2)

Balls; beads; spheres

Calcium Carbonate (CaCO3)

Minerala; metal b

Organic; synthetica

Talcum

Not specified

Not specified

Othersa

Others

These materials may be identified after the code-letter, e.g. by chemical symbol or additional codes to be agreed upon.

Metal filler shall be identified by the chemical symbol (in capital letters) after the mass content. For example, steel whickers may be

designated MH05FE.

EXAMPLE

ISO 1874-PA6-I,(GF+MD)25

ISO 2010 All rights reserved

ISO/WD xxxxx-1

3.4

Data Block 3

In this data block, information about the method of processing is represented by a code letter, followed by

code letters about additives, supplementary information, and other characteristics. The code-letters are

specified in table 4.

If no specific information is given on the method of processing the letter X shall be used as the first

code-letter.

Table 4 Codes used in Data Block 3

Code-Letter

First letter

Processing stabilized

A

B

Letters 2 to 8

Blow moulding

Antiblocking

C1

Coloured, transparent

C2

Coloured, non-transparent

Powder; dry blend

D

E

Extrusion of pipes, profiles and sheets

Extrusion of film and thin sheeting

Expandable

Pellets; granules

G

H

Coating

Cable and wire coating

Monofilament extrusion

Injection moulding

Heat-ageing stabilized

Light and/or weather stabilized

Natural (not coloured)

N

P

Multiple processing modes

Rotational moulding

Powder coating or sintering

Lubricated

Tape manufacture

Improved transparency

Stabilized against hydrolysis

W

X

No indication

Antistatic

3.5

Moulding release agent

Data block 4

In this data block, the viscosity number is represented by a two-figure code-number (3.5.1) and the tensile

modulus of elasticity by a three-figure code-number (3.5.2). The two codes are separated from each other by

a hyphen.

If no specific information is given in one of the two positions, the letter X shall be used.

If a property value falls on or near a range limit, the manufacturer shall state which range will designate the

material. If subsequent individual test values lie on, or either side of, the range limit because of manufacturing

tolerances, the designation is not affected.

NOTE

Not all combinations of the values of the designatory properties are provided by currently available m aterials.

ISO 2010 All rights reserved

ISO/WD xxxxx-1

3.5.1

Viscosity number

The viscosity number shall be determined in accordance with ISO 307, using the solvent specified in table 5.

The average value of the viscosity number is represented by a two-figure code-number as specified in table 5.

For copolyamides, 96% (m/m) sulfuric acid should preferably be used as solvent, but some copolyamides

dissolve better in m-cresol or phenol/1,1,2,2-tetrachloroethane (60/40%). Information concerning the most

suitable solvent can be obtained from the supplier of copolyamides and homopolyamides which are not

covered in the last column of table 5.

Table 5 Code-numbers used for viscosity number in Data Block 4

Code-number

Range of viscosity number

Solvent

96% (m/m)

sulfuric acid

09

Solvent

m-cresol

Applicable to

Solvent

phenol/1,1,2,2tetrachloroethane

(60/40%)

PA6,

90

PA66,

10

>90 to 110

12

>110 to 130

PA69,

14

>130 to 160

PA610,

18

>160 to 200

PA612,

22

>200 to 240

MXD6 and

27

>240 to 290

Copolyamides

32

>290 to 340

34

>340

11

110

PA1212,

12

>110 to 130

PA11,

14

>130 to 150

PA12 and

16

>150 to 170

Copolyamides

18

>170 to 200

22

>200 to 240

24

>240

12

120

PA6T/66,

13

>120 to 140

PA6I/66, PA6I/6T,

15

>140 to 160

PA6T/6I/66,

17

>160 to 180

PA6T/6I,

19

>180 to 200

PA6I/6T/66, PPA

20

>200

and

Copolyamides

ISO 2010 All rights reserved

ISO/WD xxxxx-1

NOTE

Viscosity numbers determined with 90 % (m/m) formic acid as solvent can be converted into viscosity

numbers determined in 96 % (m/m) sulfuric acid using the following equations (ISO 307: 2007).

For PA6:

For PA66:

In y = 0,416 1 + 0,927 6 In x

In y = 0,454 1 + 0,926 1 In X

For PA69:

In y = 0,463 4 + 0,909 5 In x

For PA610:

In y = 0,982 3 + 0,793 2 In x

Where

x is the viscosity number in 90 % (m/m) formic acid;

y is the viscosity number in 96 % (m/m) sulfuric acid.

For the viscosity number of PA612, which may be determined in accordance with ISO 307: 2007 in either m-cresol or 96

% (m/m) sulfuric acid, the following conversion formula applies:

ln y = 0,285 7 + 0,985 9 ln x

where

x is the viscosity number in 96 % (m/m) sulfuric acid;

y is the viscosity number in m-cresol.

The above conversion formulae have been calculated from the results of an interlaboratory investigation carried out in

1982 ( ISO 307:2007). The accuracy of the conversions depends on both the size of the viscosity number and the type of

PA, the latter resulting from the fact that different numbers of the different PA-types were included in the investigation. The

95 % confidence intervals for the values of the nominal viscosity number in 96 % (m/m) sulfuric acid, converted from

different values of the nominal viscosity number in the other solvent, are given in table 5.

Table 6 Confidence intervals

Nominal viscosity

numbera

95% confidence intervals for converted nominal viscosity numbers in

96% (m/m) sulfuric acid

100

140

180

220

260

300

340

a

PA6

PA66

PA69

PA610

PA612

0.8

0,8

0,7

0,7

0,8

1,0

1.3

1,6

1,4

1,2

1.3

1,7

2,4

3,3

2,0

1.9

2.9

4.7

6.9

9.3

11,9

4,7

4,1

5,8

9,0

12,9

17,2

21,8

4.4

4,9

10,2

17,6

26.0

35,3

45.3

Solvents: 90 % (m/m) formic acid for PA6, PA66, PA69 and PA610; m-cresol for PA612

ISO 2010 All rights reserved

ISO/WD xxxxx-1

3.5.2

Tensile modulus of elasticity

The tensile modulus of elasticity shall be determined in the dry state in accordance with ISO 527 under the

test conditions specified in ISO 1874-2. The average value of the tensile modulus of elasticity is represented

by a three-figure code-number as specified in table 7.

Table 7 Codes used for tensile modulus of elasticity in Data Block 4

Tensile modulus of elasticity

Code-number

001

3.6

Range MPa

150

002

> 150 to 250

003

> 250 to 350

004

> 350 to 450

005

> 450 to 600

007

> 600 to 800

010

> 800 to 1 500

020

> 1 500 to 2 500

030

> 2 500 to 3 500

040

> 3 500 to 4 500

050

> 4 500 to 5 500

060

> 5 500 to 6 500

070

> 6 500 to 7 500

080

> 7 500 to 8 500

090

> 8 500 to 9 500

100

> 9 500 to 10 500

110

> 10 500 to 11 500

120

> 11 500 to 13 000

140

> 13 000 to 15 000

160

> 15 000 to 17 000

190

> 17 000 to 20 000

220

> 20 000 to 23 000

250

> 23 000

Data Block 5

Indication of additional requirements in optional data block 5 is a way of transforming the designation of a

material into a specification for a particular application. This may be done for example by reference to a

suitable national standard or to a standard-like, generally established specification (4.2).

10

ISO 2010 All rights reserved

ISO/WD xxxxx-1

Examples of designations

4.1

Designations without specification

An unfilled polyamide material PA6 for injection moulding (M), with moulding release agent (R), having a

viscosity of 150 ml/g (14) and a tensile modulus of elasticity of 2 700 MPa (030), and with a nucleating

additive (N), would be designated:

DESIGNATION

Identity Block

Individual Item Block

Description

block

(optional)

ISO

Standard

Data

Block 1

Data

Block 2

Data

Block 3

Data

Block 4

Data

Block 5

Polymer

Performance & origin related

information

Application &

Processing

Properties

Additional

information

Type

Thermoplastics

XXXXX

Modification

Filled

Flame

retardant

Recyclate

Moulding

Chracteristics

-PA6

14-030N

>Part marking<

No

No

Yes

Yes

No

No

No

Designation: Thermoplastics ISO XXXXX-PA6,,MR,14-030N,, or

ISO XXXXX-PA6,,MR,14-030N,, or

ISO XXXXX-PA6,,MR,14-030N

Part marking: >PA6<

A polyamide material (PA66) reinforced with 37 % glass fiber (GF) for injection moulding (M) containing

heat-ageing stabilizer (H), and having a viscosity number of 140 ml/g (14) and a tensile modulus of elasticity

of 10200 MPa (100), would be designated:

DESIGNATION

Identity Block

Individual Item Block

Description

block

(optional)

ISO

Standard

Type

Thermoplastics

XXXXX

Data

Block 1

Data

Block 2

Data

Block 3

Data

Block 4

Data

Block 5

Polymer

Performance & origin related

information

Application &

Processing

Properties

Additional

information

Modification

-PA66

Filled

Flame

retardant

Recyclate

GF37

Moulding

Chracteristics

14-100

>Part marking<

No

No

Yes

Yes

No

No

No

Designation: Thermoplastics ISO XXXXX-PA66,GF37 FR,MH,14-100,, or

ISO XXXXX-PA66,GF37,MH,14-100,, or

ISO XXXXX-PA66,GF37,MH,14-100

Part marking: >PA66GF37<

ISO 2010 All rights reserved

11

ISO/WD xxxxx-1

An unfilled polyamide material containing plasticizer (PA12-P) for extrusion (E), with a heat-ageing stabilizer

(H) and a light and weather stabilizer (L), and having a viscosity number of 210 ml/g (22) and a tensile

modulus of elasticity of 280 MPa (003), would be designated:

DESIGNATION

Identity Block

Individual Item Block

Description

block

(optional)

Thermoplastics

ISO

Standard

XXXXX

Data

Block 1

Data

Block 2

Data

Block 3

Data

Block 4

Data

Block 5

Polymer

Performance & origin related

information

Application &

Processing

Properties

Additional

information

Type

Modification

-PA12

-P

Filled

Flame

retardant

Recyclate

Moulding

Chracteristics

HL

22-003

>Part marking<

No

No

Yes

Yes

No

No

No

Designation: Thermoplastics ISO XXXXX-PA12-P,,EHL,22-003,, or

ISO XXXXX-PA12,,EHL,22-003,, or

ISO XXXXX-PA12,,EHL,22-003

Part marking: >PA12-P<

4.2

Designation transformed into a specification

This section provides examples of how to use this designation system and how to turn the designations into

specifications. When used only as designations, the pattern employs information from Data Blocks 1-4. When

converting the designation into a Specification, the pattern also includes information from Data Block 5

An unfilled polyamide material (PA6) for injection moulding (M), containing heat aging stabilizer (H), having a

viscosity of 150 ml/g (14), and a tensile modulus of 2 200 MPa (020), and meeting the requirements of ASTM

D6779 PA0213 would have the specification:

DESIGNATION

Identity Block

Individual Item Block

Description

block

(optional)

ISO

Standard

Type

Thermoplastics

XXXXX

Data

Block 1

Data

Block 2

Data

Block 3

Data

Block 4

Data

Block 5

Polymer

Performance & origin related

information

Application &

Processing

Properties

Additional

information

14-020

ASTM

D6779

PA0213

No

No

Modification

Filled

Flame

retardant

Recyclate

-PA6

Moulding

Chracteristics

>Part marking<

No

No

Yes

Yes

No

Specification:

Thermoplastics ISO XXXXX-PA6,,MH,14-020,ASTM D6779 PA0213 or

ISO XXXXX-PA6,,MH,14-020,ASTM D6779 PA0213

Part marking: >PA6<

12

ISO 2010 All rights reserved

ISO/WD xxxxx-1

A polyamide material (PA6T/6I) reinforced with 33% of glass fiber (GF) with special burning characteristics

(FR) for injection moulding (M), having a tensile modulus of elasticity of 8 000 MPa (080) and meeting the

requirements of ASTM D5336 PPA0121FL34 would have the specification:

DESIGNATION

Identity Block

Individual Item Block

Descriptio

n block

(optional)

ISO

Standard

Data

Block 1

Data

Block 2

Data

Block 3

Data

Block 4

Data

Block 5

Polymer

Performance & origin related

information

Application &

Processing

Properties

Additional

information

X-080

ASTM

D5336

PPA

012FL34

No

No

Type

Thermoplastics

XXXXX

Modification

-PA6T/6I

Filled

GF33

Flame

retardant

Recyclate

FR

Moulding

Chracteristics

>Part marking<

No

No

Yes

Yes

No

Specification:

Thermoplastics ISO XXXXX-PA6T/6I,GF33 FR,M,X-080,ASTM D5336 PPA012FL34 or

ISO XXXXX-PA6T/6I,GF33 FR,M,X-080,ASTM D5336 PPA012FL34

Part marking: >PA6T/6IGF33FR<

ISO 2010 All rights reserved

13

ISO/WD xxxxx-1

Annex A

(normative)

Definition and designation of polyamides

Polyamide materials are thermoplastic materials that contain carboxylic amide groups, -CONH-, at regular

intervals in the linear polymer chain.

Polyamide homopolymers may be built up from a single starting material (an aminocarboxylic acid or its

lactam); in this case, they are designated by a number corresponding to the number of carbon atoms in the

starting material (table A.1).

Table A.1 Designation of linear aliphatic polyamides of general formula [NH-(CH2)x -CO]n

Symbol

Value of x

Number of C atoms in the

starting material

PA6

PA11

10

11

PA12

11

12

However, polyamide homopolymers may also be built up from on starting material with amino groups plus one

starting material with carboxylic acid groups. These polyamides, based on diamines and dicaboxylic acids, are

designated by a two-digit, three-digit or four-digit number, respectively. In the case of the four digit number,

the first digit (or the first and second digits) corresponds to the number of C atoms in the linear aliphatic

diamine and the second digit (or with some materials the second and third or the third and fourth digits)

corresponds to the number f C atoms in the linear aliphatic dicarboxylic acid (table A.2).

Table A.2 Designation of linear aliphatic polyamides of general formula

[NH-(CH2)x-NH-CO-(CH2)y-CO]n/2

Value of

Symbol

X

PA46

PA66

PA610

PA612

10

PA1212

12

10

Copolymer polyamides, also called copolyamides, may be built up from various starting materials (lactams,

aminocarboxylic acids, equimolar amounts of diamines and dicarboxylilc acids). These copolyamides are

designated PA plus numbers representing the components of the copolyamide, the numbers being separated

by an oblique stroke (ISO 1043-1:2001 annex A, clause A.6). But copolyamides with the same numbers or

symbols can give quiet different properties, depending on the ratio of the starting materials. Therefore, if there

is a need for a more exact designation, the mass content ratio shall be included. If it is necessary to indicate

this ratio, the two figures, separated by an oblique stroke, may be placed in parentheses at the end of the

designation (table 2).

14

ISO 2010 All rights reserved

ISO/WD xxxxx-1

Starting materials (monomers) for copolyamides, as well as for homopolyamides, include not only linear

aliphatic compounds, but also branched aliphatic-aromatic, cyclo-aliphatic and aromatic compounds. The

monomer units of these non-linear aliphatic compounds may be derived from the substances listed, together

with their designations, in table A.3. Because of the large number of possible combinations of copolyamides,

only a few examples have been listed in table 2.

Table A.3 Symbols of aromatic and non-linear aliphatic monomer units

Symbol of

monomer unita

Monomer unit derived from

Terephthalic acid

Isophthalic acid

2,6-Naphthalenedicarboxylic acid

PACP

2,2-Bis(p-aminocyclohexyl)propane

MACM

3,3-Dimethyl-4,4-diaminodicyclohexylmethane

PACM

Bis(p-aminocyclohexyl)methane

IPD

Isophorone diamine

ND

1,6-Diamino-2,2,4-trimethylhexane)

IND

1,6-Diamino-2,4,4-trimethylhexane

PPGD

Polypropylene glycoldiamine

PBGD

Polybutylene glycoldiamine

MXD

m-Xylylene diamine

PXD

m-Xylylene diamine

PTD

p-Toluylene diamine

MTD

m-Toluylene diamine

PABM

Diphenylmethane-4,4-diamine

MC

1,3-Bis(aminomethyl)cyclohexane

MPMD

2-Methylpentamethylenediamine

XX

Not specified diamine

YY

Not specified diacid

ISO 2010 All rights reserved

15

S-ar putea să vă placă și

- VW 96005 enDocument5 paginiVW 96005 enpatborÎncă nu există evaluări

- VW 96006 enDocument6 paginiVW 96006 enpatborÎncă nu există evaluări

- GMW 15581-In (07.10)Document5 paginiGMW 15581-In (07.10)Rafael Prado Moraes100% (1)

- Agco - Cfsen04019 (2011 Yılı)Document7 paginiAgco - Cfsen04019 (2011 Yılı)CEMRE YAŞLIÎncă nu există evaluări

- CFSEN04018 Technical Requirements for Cab PartsDocument6 paginiCFSEN04018 Technical Requirements for Cab PartsCEMRE YAŞLIÎncă nu există evaluări

- TMS6900Document14 paginiTMS6900Josue Garcia QuiniÎncă nu există evaluări

- Agco - Cfsen04009 (2011 Yılı)Document6 paginiAgco - Cfsen04009 (2011 Yılı)CEMRE YAŞLIÎncă nu există evaluări

- Worldwide Engineering Standards: Polypropylene Expanded Bead FoamDocument5 paginiWorldwide Engineering Standards: Polypropylene Expanded Bead FoamLucas MlbÎncă nu există evaluări

- GMW15516Document13 paginiGMW15516Ed Ri0% (1)

- 9.55460-2009 - Needle Punched and Nonwoven Fabrics For Interior Vehicle LiningsDocument14 pagini9.55460-2009 - Needle Punched and Nonwoven Fabrics For Interior Vehicle Liningsclaudio5475Încă nu există evaluări

- M0132 2007 (N)Document8 paginiM0132 2007 (N)jenwitbunjongsatÎncă nu există evaluări

- Nissan Paint Film Quality Standard for Plastic and Chrome PartsDocument14 paginiNissan Paint Film Quality Standard for Plastic and Chrome PartsCARLOS A.N. LANZILLOTTO100% (1)

- 30 Automotive Applications of Plastics: Past, Present, and FutureDocument23 pagini30 Automotive Applications of Plastics: Past, Present, and FuturePatito Lisbhet Romero BuenoÎncă nu există evaluări

- VW 10500 enDocument17 paginiVW 10500 enIsabel Sierra0% (1)

- MBN 10761 2009-06Document91 paginiMBN 10761 2009-06tarakram2809Încă nu există evaluări

- BMS 0000147Document15 paginiBMS 0000147方綵樺Încă nu există evaluări

- DBL 4023 2012-08Document7 paginiDBL 4023 2012-08Fernando MartínÎncă nu există evaluări

- Jis D1201Document38 paginiJis D1201Han Win Aung50% (2)

- BN - 586437-115 - Acr 04Document15 paginiBN - 586437-115 - Acr 04oslat100% (1)

- Test of Ozone Resistance and Plastic Deformation: Group StandardDocument4 paginiTest of Ozone Resistance and Plastic Deformation: Group Standardali soydaşÎncă nu există evaluări

- TS.006 Rev09 PDFDocument28 paginiTS.006 Rev09 PDFalexa8888Încă nu există evaluări

- PV 3937 enDocument2 paginiPV 3937 enJoão Saldanha100% (1)

- GMW PQ140-250 PF144x72Document4 paginiGMW PQ140-250 PF144x72seriousguy2Încă nu există evaluări

- Sae - J576-1991 Astm D4364Document5 paginiSae - J576-1991 Astm D4364Thanh TruongÎncă nu există evaluări

- Coating Systems For Customised, Special Versions: January 2004Document14 paginiCoating Systems For Customised, Special Versions: January 2004Akmal NizametdinovÎncă nu există evaluări

- Norma 80900NDS00Document48 paginiNorma 80900NDS00Mayra Mtz100% (1)

- Jis D0205 1987 PDFDocument52 paginiJis D0205 1987 PDFsabaris ksÎncă nu există evaluări

- D493027 en PDFDocument39 paginiD493027 en PDFJose ValenciaÎncă nu există evaluări

- 1984 Bookmatter PVCTechnology PDFDocument105 pagini1984 Bookmatter PVCTechnology PDFGonzalo BenavidesÎncă nu există evaluări

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Document2 paginiPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaÎncă nu există evaluări

- AdvancesDocument20 paginiAdvancesZeeshan MohamedÎncă nu există evaluări

- Is53 Iso - 5836 - 1988Document8 paginiIs53 Iso - 5836 - 1988elvisonderÎncă nu există evaluări

- B65 4251 (Rev. D 2016.03) EN - SOUNDPROOFING ACOUSTIC ABSORBENTS SPECIFICATIONDocument25 paginiB65 4251 (Rev. D 2016.03) EN - SOUNDPROOFING ACOUSTIC ABSORBENTS SPECIFICATIONDiego CamargoÎncă nu există evaluări

- Worldwide Engineering Standards: General Specification HVAC & PT Cooling GMW15866Document11 paginiWorldwide Engineering Standards: General Specification HVAC & PT Cooling GMW15866Akmal NizametdinovÎncă nu există evaluări

- Astm D5930.1207343-1 Condutividade Termica PDFDocument5 paginiAstm D5930.1207343-1 Condutividade Termica PDFtadeuafÎncă nu există evaluări

- Burning behavior test for insulating materialsDocument7 paginiBurning behavior test for insulating materialserik0007Încă nu există evaluări

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedDocument7 paginiAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzÎncă nu există evaluări

- VW 50125 enDocument12 paginiVW 50125 enDan IlcaÎncă nu există evaluări

- TL 211 enDocument19 paginiTL 211 enCarlos AraujoÎncă nu există evaluări

- 32-00-008 enDocument40 pagini32-00-008 enJose ValenciaÎncă nu există evaluări

- Measuring The Force-Displacement of A Membrane Switch: Standard Test Method ForDocument5 paginiMeasuring The Force-Displacement of A Membrane Switch: Standard Test Method Formasoud132Încă nu există evaluări

- Title: Cover-Fr Under No. 75892 NDS01Document7 paginiTitle: Cover-Fr Under No. 75892 NDS01Diego Camargo100% (1)

- Test Method: Renault Automobiles Standardisation DQSC - S / Department 00621 Section Normes Et Cahiers Des ChargesDocument9 paginiTest Method: Renault Automobiles Standardisation DQSC - S / Department 00621 Section Normes Et Cahiers Des Chargesclaudio5475Încă nu există evaluări

- PV 3935 enDocument13 paginiPV 3935 enpatborÎncă nu există evaluări

- A125500Document53 paginiA125500Sukant GhoshÎncă nu există evaluări

- Sae Uscar45 - 2018Document22 paginiSae Uscar45 - 2018Salafi Mhmd100% (1)

- MIL-STD-193L Painting Procedures and Marking For Vehicles, Construction Equipment, Material Handling Equipment, and Spare PartsDocument47 paginiMIL-STD-193L Painting Procedures and Marking For Vehicles, Construction Equipment, Material Handling Equipment, and Spare PartsCemalÎncă nu există evaluări

- TL245 English 2004Document8 paginiTL245 English 2004Elliott RussellÎncă nu există evaluări

- E7021-00 - .8829089B FordDocument28 paginiE7021-00 - .8829089B FordAndre VPÎncă nu există evaluări

- Iso 14801 2016Document11 paginiIso 14801 2016robonrobertorrsÎncă nu există evaluări

- 05Document42 pagini05tt_aljobory3911Încă nu există evaluări

- B63 1100 (Rev. C 2006.07) EN - SOLID RUBBERS CATEGORY 1 COMPOUNDSDocument4 paginiB63 1100 (Rev. C 2006.07) EN - SOLID RUBBERS CATEGORY 1 COMPOUNDSDiego CamargoÎncă nu există evaluări

- DIN 55633 Recubrimiento anclajesDocument29 paginiDIN 55633 Recubrimiento anclajesdeybi resarteÎncă nu există evaluări

- BS en Iso 08624-2011Document18 paginiBS en Iso 08624-2011Guillermo VegaÎncă nu există evaluări

- Test Methods For Lead-Free Solders-Methods Testing Mec Hanical C Haracteristics-Tensi LeDocument9 paginiTest Methods For Lead-Free Solders-Methods Testing Mec Hanical C Haracteristics-Tensi LeWawan Nur CahyoÎncă nu există evaluări

- ASTM D 2851-98 - Liquid Optical AdhesiveDocument3 paginiASTM D 2851-98 - Liquid Optical AdhesiveBatÎncă nu există evaluări

- Unspecified Tolerances Plastic Parts: 1. ObjectDocument7 paginiUnspecified Tolerances Plastic Parts: 1. ObjectDiegoÎncă nu există evaluări

- Is 10951 (Polyproplyne)Document17 paginiIs 10951 (Polyproplyne)rohitjhangraindiaÎncă nu există evaluări

- Polypropylene Injection and Extrusion Materials Using ISO Protocol and MethodologyDocument20 paginiPolypropylene Injection and Extrusion Materials Using ISO Protocol and MethodologyProvocateur SamaraÎncă nu există evaluări

- Trends in Maternal Mortality: Executive SummaryDocument16 paginiTrends in Maternal Mortality: Executive SummarykansaÎncă nu există evaluări

- Chemistry SyllabusDocument9 paginiChemistry Syllabusblessedwithboys0% (1)

- SMD - Metal-Sheet Decking DesignDocument10 paginiSMD - Metal-Sheet Decking DesignAchilles YipÎncă nu există evaluări

- 19bcd7246 Assignment2 L27+L28+L31+L32Document7 pagini19bcd7246 Assignment2 L27+L28+L31+L32Sriharshitha DeepalaÎncă nu există evaluări

- Nfrc100a 2010Document49 paginiNfrc100a 2010Amy ShepardÎncă nu există evaluări

- Pics Dany and Camy Preteen Models Checked PDFDocument3 paginiPics Dany and Camy Preteen Models Checked PDFChris0% (2)

- Superheterodyne ReceiverDocument22 paginiSuperheterodyne ReceiverdeepanilsaxenaÎncă nu există evaluări

- Manual Completo Sinovo SD600Document221 paginiManual Completo Sinovo SD600Felipe de PaulaÎncă nu există evaluări

- CorrectDocument45 paginiCorrectaskerman 3Încă nu există evaluări

- The Future of Luxury Fashion ReportDocument70 paginiThe Future of Luxury Fashion Reportsalma andjaniÎncă nu există evaluări

- Troubleshooting Edge Quality: Mild SteelDocument14 paginiTroubleshooting Edge Quality: Mild SteelAnonymous U6yVe8YYCÎncă nu există evaluări

- Agile Assignment 2Document2 paginiAgile Assignment 2Sameen ShakeelÎncă nu există evaluări

- Risktec Drilling Soc 0.3 PDFDocument16 paginiRisktec Drilling Soc 0.3 PDF1sÎncă nu există evaluări

- DNSDocument23 paginiDNSkalugareniÎncă nu există evaluări

- Crane Company Within SingaporeDocument4 paginiCrane Company Within SingaporeRash AcidÎncă nu există evaluări

- hts336555 Philips Manual PDFDocument35 paginihts336555 Philips Manual PDFSalomão SouzaÎncă nu există evaluări

- 2.5 PsedoCodeErrorsDocument35 pagini2.5 PsedoCodeErrorsAli RazaÎncă nu există evaluări

- Microsoft MB-210 Exam Dumps With Latest MB-210 PDFDocument10 paginiMicrosoft MB-210 Exam Dumps With Latest MB-210 PDFJamesMartinÎncă nu există evaluări

- Smart CityDocument4 paginiSmart CityRendi NafiahÎncă nu există evaluări

- Advanced Software Upgrade GuideDocument5 paginiAdvanced Software Upgrade GuideMiguel RibeiroÎncă nu există evaluări

- Articol S.brînza, V.stati Pag.96Document154 paginiArticol S.brînza, V.stati Pag.96crina1996Încă nu există evaluări

- Container Generator Qac Qec Leaflet EnglishDocument8 paginiContainer Generator Qac Qec Leaflet EnglishGem RÎncă nu există evaluări

- Cars and Trucks With Mitsubishi TD04 TurbochargerDocument17 paginiCars and Trucks With Mitsubishi TD04 TurbochargersampapaÎncă nu există evaluări

- Tohatsu 2 Stroke Service Manual 1992 2000Document329 paginiTohatsu 2 Stroke Service Manual 1992 2000Adi Peterfi97% (38)

- Britain, Germany and Colonial Violence in South-West Africa, 1884-1919Document238 paginiBritain, Germany and Colonial Violence in South-West Africa, 1884-1919Саша ШестаковаÎncă nu există evaluări

- Bridge Superstructure DesignDocument276 paginiBridge Superstructure Designrenzo wilber bernedo beltranÎncă nu există evaluări

- Physical-Science11 Q1 MODULE-1 08082020Document27 paginiPhysical-Science11 Q1 MODULE-1 08082020Cristilyn Briones67% (3)

- Class Note 2 - Rain GaugesDocument6 paginiClass Note 2 - Rain GaugesPrakash PatelÎncă nu există evaluări

- Building Materials Purchase ListDocument123 paginiBuilding Materials Purchase ListRizki AmrullahÎncă nu există evaluări

- Domestic Water-Supply - TheoryDocument19 paginiDomestic Water-Supply - Theoryyarzar17Încă nu există evaluări