Documente Academic

Documente Profesional

Documente Cultură

TII-HZI-50021252 - 1.0 - TII 16.20 Requirements For Contractors Technical Documents

Încărcat de

Born ToSinTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TII-HZI-50021252 - 1.0 - TII 16.20 Requirements For Contractors Technical Documents

Încărcat de

Born ToSinDrepturi de autor:

Formate disponibile

Severnside Energy Recovery Centre

Severn Road

Severnside

South Gloucestershire

BS10 7SP

Project Manager: SITA UK Ltd

Employer: SITA West London Ltd

Address

SITA House

Grenfell Road

Maidenhead

Berkshire SL6 1ES.

5.0

4.0

3.0

2.0

1.0

0.0

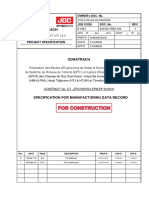

Rev

Stl

27.09.2013

Stl

12.08.2013

Author

A31

27.09.2013

A31

12.08.2013

Reviewer

Vofa

27.09.2013

Vofa

12.08.2013

Approver

Hat

27.09.2013

Hat

12.08.2013

Reviewer 2

(Initials Date, Visa)

(Initials Date, Visa)

(Initials Date, Visa)

(Initials Date, Visa)

Chapter 3.3 Adapted

First Issue

Short description of change

TII 16.20 Requirements for contractors technical documents

Project Nr

P-3231

Project Name

AIC

DocType

Supplier

SERC

000000

TII

HZI

HZI Document Nr - Rev_

50021252 -1.0

Issued by

Hitachi Zosen Inova AG

Hardturmstrasse 127

P.O. Box 680

8037 Zurich, Switzerland

Template DocNo Rev: 50020951-1.0

www.hz-inova.com

Tel. +41 (0)44 277 11 11

Fax +41 (0)44 277 13 13

All rights reserved according to ISO 16016

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

Document Nr-Rev:

50021252 - 1.0

Hitachi Zosen Inova AG

Table of contents

1

Introduction ............................................................................................................ 4

1.1

1.2

1.3

Objective .................................................................................................................. 4

Scope ....................................................................................................................... 4

Definitions and Abbreviations ................................................................................... 4

Delivery of Documents and Data .......................................................................... 5

2.1

Naming of Documents .............................................................................................. 5

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

Document Type ............................................................................................................................... 5

Supplier............................................................................................................................................ 7

Document number (8 digits) ............................................................................................................ 7

Revison No ...................................................................................................................................... 7

Document title .................................................................................................................................. 7

2.2

2.3

Cover page of Word and Excel Documents ............................................................. 7

Header for Drawings ................................................................................................ 7

Software requirements .......................................................................................... 8

3.1

3.2

3.3

Microsoft Office 2010 ............................................................................................... 8

Drawings: ................................................................................................................. 8

3D-based Tools ........................................................................................................ 8

3.3.1

3.3.2

3.3.3

3.3.4

Aveva PDMS 12.1 ........................................................................................................................... 8

Inventor ............................................................................................................................................ 8

Autodesk Navisworks 2012, NWD- Files (3d-Viewer) ..................................................................... 8

Interfaces: ........................................................................................................................................ 8

3.4

3.5

Time schedules: ....................................................................................................... 9

Other formats: .......................................................................................................... 9

Quality/ accuracy of exchanged Documents/ Information ............................... 10

4.1

4.2

Process Engineering .............................................................................................. 10

P&ID (Piping and Instrumentation Diagram) .......................................................... 10

4.2.1

4.3

4.3.1

4.3.1.1

4.3.1.2

4.3.1.3

4.3.2

4.3.2.1

4.3.2.2

4.3.2.3

4.4

4.4.1

4.4.2

4.5

4.6

4.7

4.7.1

Check of P&ID ............................................................................................................................... 10

Electrical Data (ED): Consumer, Instrument and Signal Exchange List ................. 10

Electrical Data ED2 ....................................................................................................................... 10

Degree of precision for the electrical consumers: ......................................................................... 10

Degree of precision for the instruments list: .................................................................................. 10

Degree of precision for the signal list (I/O list):.............................................................................. 11

Electrical Data ED3 ....................................................................................................................... 11

Degree of precision for the electrical consumers: ......................................................................... 11

Degree of precision for the instruments list: .................................................................................. 11

Degree of precision for the signal list (I/O list):.............................................................................. 11

Automation Data (AD): Interface from PUs / System Contractors to DCS ............ 11

Automation Data AD1 .................................................................................................................... 11

Automation Data AD2 .................................................................................................................... 11

Interface List ........................................................................................................... 12

Working with templates for lists / final engineering data ......................................... 12

Arrangement Drawings (Applicable for System Contractors, e.g. Turbine) ........... 12

Content for Building Data BD2: ..................................................................................................... 12

Print date 27.09.13 12:04

Last saved 27.09.13

Page 2 of 14

Project Name: SERC

Title:

AIC:

4.7.2

4.8

000000

TII 16.20 Requirements for contractors

technical documents

Document Nr-Rev:

50021252 - 1.0

Hitachi Zosen Inova AG

Additional Information for Building Data BD3: ............................................................................... 12

Equipment Outline Drawing / Building Data (BD) / Load table ............................... 13

4.8.1

4.8.2

Content for Building Data BD2: ..................................................................................................... 13

Additional Information for Building Data BD3 ................................................................................ 13

4.9

4.10

Functional Design specification (FDS) ................................................................... 13

Erection and Installation Instructions ...................................................................... 14

Print date 27.09.13 12:04

Last saved 27.09.13

Page 3 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Introduction

1.1

Objective

Hitachi Zosen Inova AG

This document defines the data content of various documents (listed in attachment 2, incl.

delivery date) that have to be handed over to HZI at different stages during the project. The

following binding definitions will help the contractor to supply the necessary data and

information in the needed accuracy. Binding data, which are already stated in the contract,

cannot be changed without permission of HZI (i.e. motor size, sound pressure level).

1.2

Scope

This instruction applies to all procurement lots. It has to be considered that not all the

documents described in this document have to be delivered by every Contractor. Only the

documents stated in the TSD attachment 2 Documents from Contractor have to be

delivered.

1.3

Definitions and Abbreviations

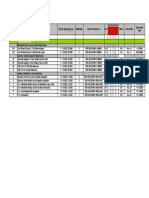

Table 1: Definitions and abbreviations

Abbreviation

Definition

HZI

Hitachi Zosen Invova AG, Purchaser

Contractor

HZIs sub-contractor, HZIs Supplier

TII

HZI Technical Implementation Instruction

P&ID

Piping & Instrumentation Diagram

PU

Package units

ED

Electrical Data

BD

Building Data

AD

Automation Data

TSD

Technical Specification Document, technical part of the inquiry/ order

Print date 27.09.13 12:04

Last saved 27.09.13

Page 4 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Delivery of Documents and Data

2.1

Naming of Documents

Hitachi Zosen Inova AG

Each document must have its own unique name. The name of each document shall be

marked as in the following example:

Doc Type - Supplier - Doc No._Rev.No_Document title

Example:

TGE HZI 50050505 _ 0.0 _ Noise information

1

2.1.1

Document Type

This code categorizes the document. The codes are divided into different main categories,

Make sure to choose one of the codes of the following table:

Table 2: Document Types

AGE = ANGEBOTE GENERAL

MGE = MINUTES OF MEETING GENERAL

ACA = Calculation

MCI = MoM Civil

AGP = GP410 document

MCO = MoM Customer

ALO = LOA document

MCS = MoM Consultant

AOF = Offer of HZI

MIN = MoM Internal (CSP; FGT)

MPM = MoM Project Meeting HZI

CCE = CONSTRUCTION SITE GENERAL

MSU = MoM Supplier

CBM = Bill of Material

MTP = MoM Third Party

CFO = Form

CLE = Leaflet

OGE = OPERATING MANUAL GENERAL

CMR = Method statement / Risk Assessment

CTR = Training

PGE = (Process) DIAGRAMS GENERAL

PFD = Process Flow Diagram

DGE = DRAWINGS GENERAL

PID = Piping and Instrumentation Diagram

DAC = Architectal Drawings

FDS = Functional Design Specification

DAR = Arrangement Drawing System

DCI = Civil Indications

QGE = Q-DOCUMENTS GENERAL

DDT = Detail Drawing

QPS = I&T Plan Site

DEI = EIC Drawing

QPW = I&T Plan Workshop

DLA = Layout Drawing

QRE = Q-Records

DLA = Load Drawing

DPI = Piping Drawing

RGE = PROCUREMENT GENERAL

Print date 27.09.13 12:04

Last saved 27.09.13

Page 5 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Hitachi Zosen Inova AG

Table 2: Document Types

DPL = Platform Drawing

RCO = Contract Supplier

DSO = Site Overview

RDC = Delivery Certificate

DSY = Safety Drawing

RIN = Inquiry

RPO = Purchase Order

JGE = PROJECT MANAGEMENT GENERAL

RPS = Progress Report Supplier

JCO = Concept (Em Pow. Etc)

RRQ = Request for Quotation

JCC = Contract Consortium

RSC = Supplier Claim

JCT = Contract Client

RTC = Technical and Commercial Comparison

JEV = Events (DCR; NCR; DNR; AR)

RTE = Tender

JFO = Form

RVO = Variation Order

JGC = General Commercial

JGI = Guideline / Instruction

SGE = TIME SCHEDULES GENERAL

JPR = Progress Report (int.ext)

SCC = CPC Client Progress Curves

JQG = Quality Gate Review

SCT = CPT Client Progress Tables

JRE = Report General

SIC = IPC Internal Progress Curves

JRV = Project Review

SIT = IPT Internal Progress Tables

JTE = Template

SMA = MTS Master Time Schedule

JWI = Work Instruction (AA)

SMP = Monthly Progress Report

SSU = Supplier Time Schedule

LGE = LISTS GENERAL

SSY = STS System Time Schedule

LCA = Cable List

STE = TTS Tender Time Schedule

LCO = Comos Overall

LDO = Document List

TGE = TECHNICAL DOCUMENT GENERAL

LDR = Drawing List

TD2 = TSD Attachment 2

LEC = E-Consumer List

TD3 = TSD Attachment 3

LEQ = Equipment List

TDA = TSD Attachment 1a

LEX = Supplier Exchange List

TDB = TSD Attachment 1b

LIF = Interface List

TDE = Design Document

LIN = Instrumentation List

TII = Technical Implementation Instruction

LOP = List of open points

TSD = Technical Specification Document

LPE = PED List

LPI = Piping List

LSI = Signal List

LTA = Tank Lists

LVA = Valve List

Print date 27.09.13 12:04

Last saved 27.09.13

Page 6 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Hitachi Zosen Inova AG

TGE HZI 50050505 _ 0.0 _ Noise information

1

2.1.2

Supplier

In order to identify the supplier, a 3 digit code is required which will be defined by HZI.

2.1.3

Document number (8 digits)

Our filing system requires a 8-digit number. Please generate the 8-digit document number

by your numbering system. The number must be unique.

2.1.4

Revison No

The revison number of the document has to be zero after the point. For example:

0.0; 1.0; 2.0

For internal (supplier) revisions, the digit behind the point shall be used. For example:

0.1, 0.2, 0.5

2.1.5

Document title

The name of the document can be defined by the supplier. A compelling, short description

is required.

2.2

Cover page of Word and Excel Documents

Each Word and Excel document must have a cover page, according to the templates that

will be delivered by HZI.

2.3

Header for Drawings

A standard document header will be handed over to the supplier. It has to be used for all

CAD-drawings. The contractor and their Sub-contractors have to prepare all documents

with this header. It is not allowed to use other headers in the documents. The contractor

can place the own header and his company logo on the document e.g. above the

standardised document header.

The contractor has to make sure that not more than 2 headers are shown on drawings,

including the HZI Header.

Print date 27.09.13 12:04

Last saved 27.09.13

Page 7 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Hitachi Zosen Inova AG

Software requirements

In order to assure simplified data transfer, the following systems and/or software shall be

used. If the contractor wants to use a different software (version) than stated below, he has

to inform HZI, and, on written approval, might do so.

Notice: If different software versions cause any conflicts, the contractor shall rectify this at

his own costs.

3.1

Microsoft Office 2010

3.2

Word, Style Arial, Font size 11, justified

Excel, Style Arial, Font size 10

Drawings:

Autocad 2012 Mechanical, dwg (dxf) - Files,

In case of using other CAD-Systems, files have to be prepared in dwg (dxf) format, that

they can be imported to Autocad 2005 Mechanical without using special converting

tools/programs. The parameters have to be done according HZI- Guidelines TVENG 005

and will be handed over if required.

3.3

3D-based Tools

3.3.1

Aveva PDMS 12.1

Parameters according to the following HZI-Guidelines:

3.3.2

AA42522 PDMS Naming Convention

AA42528 PDMS Data Exchange

AA42529 PDMS Project execution Requirements

Inventor

The data structure must be in agreement with HZI

3.3.3

Autodesk Navisworks 2012, NWD- Files (3d-Viewer)

This program will be used to only view 3D files

3.3.4

Interfaces:

SDNF - Interface

Preferred Interface, if no other requirements are specified, mainly for 3D data transfer of

steel constructions.

The data structure and file size must be in agreement with HZI

DGN - Interface

Data transfer between 3D-civil constructions if data transfer with SDNF is impossible, data

transfer in that configuration and structure needs to be approved by HZI in advance

STEP

Interface used for components. Data structure and file size needs to be agreed with HZI.

The detail of the component must be reduced in accordance with HZI.

Print date 27.09.13 12:04

Last saved 27.09.13

Page 8 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

Document Nr-Rev:

50021252 - 1.0

Hitachi Zosen Inova AG

Data transfer between different 3D-components, plant systems and process sections data

transfer in that configuration needs to be approved by HZI in advance.

Before the first CAD-files will be exchanged, a test run of the dxf / dwg-configuration must

be carried out. This will ensure the correct use of layer, layer style, type of lines, drawing

frame etc.

The final definition will be done by the purchaser after a satisfied test run.

The standardized header will be sent to the contractor after request.

3.4

Time schedules:

Civil Contractor: Check special requirements that will be handed over by HZI.

Other suppliers: No special software requirements, since there will be no direct exchange

between the systems.

3.5

Other formats:

ADOBE Acrobat 8.0

Documents have to be handed over in original format as well as in PDF. As for drawings

and P&IDs, the pdf - format has to be print size A3.

Print date 27.09.13 12:04

Last saved 27.09.13

Page 9 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Hitachi Zosen Inova AG

Quality/ accuracy of exchanged Documents/ Information

4.1

Process Engineering

4.2

Final data of heat loads (kW) for components at nominal and maximal ambient

temperature

Final data of surface sound pressure level including octave band for components

according to ISO 3746

P&ID (Piping and Instrumentation Diagram)

If HZI provides the P&IDs, the contractor has to check and confirm the content of the

document and to deliver the additional information for the P&IDs and the engineering data.

If the contractor provides its own P&ID, the rules stated in chapter 4.2.1 have to be

observed as well.

All data have to be filled out according to the template lists.

4.2.1

Check of P&ID

All items (actuators, motors, instruments, valves, etc.) shall be placed in the correct

position on the P&IDs, including already known drainage and venting of pipes.

All components shall be identifiable by a KKS-number. Basically, there has to be

ONE KKS-number for every component or system that has its own documentation

(manual, data sheet)/ordering number. E.g. a compressor has just one KKSNumber.

All E&IC-package units (autonomous items like cabinets etc.) shall be shown on

P&ID and shall be identifiable with KKS-numbers.

All limits of supply have to be marked on the P&ID. The symbol always causes a

change of the KKS-number.

All cross reference boxes to connecting P&IDs/systems (e.g. for compressed air,

water etc) shall be shown on the P&ID.

4.3

Electrical Data (ED): Consumer, Instrument and Signal Exchange

List

4.3.1

Electrical Data ED2

When handing over the ED2-Data, the degree of precision for the electrical consumers has

to be as follows:

4.3.1.1 Degree of precision for the electrical consumers:

Listing of all consumers, precision 10% (number of consumers)

All consumers >= 22 kW and all drives with frequency converter (power & type)

final data including motor data sheets

All consumers < 22 kW in a range of 20% precision

4.3.1.2 Degree of precision for the instruments list:

Listing of all instruments, precision 10% (number of instruments)

Type of instrument (temperature, pressure, flow, etc.), signal and power supply

definition (output signal, auxiliary voltage)

Print date 27.09.13 12:04

Last saved 27.09.13

Page 10 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Hitachi Zosen Inova AG

4.3.1.3 Degree of precision for the signal list (I/O list):

4.3.2

All electrical equipment signals shown on the latest version of the P&IDs shall be

included in the signal list.

Electrical Data ED3

When handing over the ED3-Data, the degree of precision for the electrical consumers has

to be as follows:

4.3.2.1 Degree of precision for the electrical consumers:

Listing of all consumers, final

All final information for all consumers, according to template list, including motor

data sheets

4.3.2.2 Degree of precision for the instruments list:

Listing of all instruments, final

Instrument range (max. /min. conditions), type of instrument, information about the

system/piping such as: DN, Medium, max. allowable pressure and temperature

Measurement principle

Hook-up definition

4.3.2.3 Degree of precision for the signal list (I/O list):

4.4

Final data

Automation Data (AD): Interface from PUs / System Contractors

to DCS

If the contractor supplies data for the DCS, the accuracy has to be as follows

4.4.1

Automation Data AD1

DCS Interface definition:

Signal exchange list of all signals from/to DCS, accuracy min. 90% (number of

signals)

Type of signals transmitted (binary, analogue. range) accuracy min. 90%

Kind of interface (HW, bus, type of protocol, baud rates, definition of first/last bit)

Graphic displays to be shown on Master - DCS:

4.4.2

Total amount of graphic displays 100%

Total variables on each graphic display, accuracy min. 90%

Draft operator screens to be shown on DCS

Draft functional description of control of PU

Automation Data AD2

DCS Interface definition:

Signal exchange list of all signals from/to DCS 100%

Type of signals transmitted (binary, analogue. range) 100%

Type of GSD files for Profibus

Bus protocols

Graphic displays to be shown on Master - DCS:

Print date 27.09.13 12:04

Last saved 27.09.13

Page 11 of 14

Project Name: SERC

Title:

AIC:

000000

Document Nr-Rev:

4.5

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Hitachi Zosen Inova AG

Total variables on each graphic display, 100%

Final operator screens to be shown on DCS

Final functional description of control of PU

Final logic diagrams to be programmed in DCS

Interface List

Purpose: The interface list serves as an information basis to ensure that all connections can

be engineered.

Each interface is defined with a number. The interface is always placed between two

different KKS-Numbers (number changing at minimum on equipment code level: e.g.

1HAD10 BR100 to 1HAD10 BR200).

4.6

Final dimensions (DN/PN)

Definition of the conditions at the interface

Definition of material

Definition of location

Connection details (welded, flanged, screwed)

Working with templates for lists / final engineering data

In order to exchange all the necessary information (e.g. for replacement) about each item, a

template Excel-list will be provided by HZI. The contractor has to fill in the Excel-lists

according to the instructions (e.g. valve list, piping list, consumer list, instrument list, signal

list, interface list, compressed air consumer list, etc.).

4.7

Arrangement Drawings (Applicable for System Contractors, e.g.

Turbine)

4.7.1

Content for Building Data BD2:

4.7.2

Building structures: Plan of each floor level, as well as longitudinal/cross-sections

Floor and walls openings bigger than 0.5 m2

Locations and dimensions of the main components with an accuracy of 0.5 m

General piping layout (main dimensions, design)

Lifting capacity and locations of the main lifting gear / cranes

Connection points for cleaning water hoses and vacuum cleaning system, if

applicable

Location of emergency shut offs

Interface drawing indicating the interfaces with third parties

Additional Information for Building Data BD3:

KKS designations

All floor and walls openings

Final locations and dimensions of the main components 0.0m

Final version for civil work related information

Location of power connections

Location of junction boxes

Required space for inspection and maintenance

Required space for dismantling and removal

Noise protection enclosures (if applicable)

Print date 27.09.13 12:04

Last saved 27.09.13

Page 12 of 14

Project Name: SERC

Title:

AIC:

4.8

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Hitachi Zosen Inova AG

Equipment Outline Drawing / Building Data (BD) / Load table

Purpose: The BD2-Issue of the "Equipment outline drawings" (EOD) serves as information

source for preparing the General Arrangement and for determining the layout. The EOD

also contains the information for the civil indication drawing and the load tables.

4.8.1

Content for Building Data BD2:

4.8.2

Final data of main dimensions and maximum operating weights of assembled units

(incl. max. weights for test purposes)

Final data of system relevant height requirements

Location and dimensions of connections for all media and location of all terminal

boxes

Space for admission/revisions/maintenance, requirements for erection and

commissioning

Requirements for accessibility to manholes, instrumentation and inspection

openings

Equipment supports, admissible forces and moments on connections. The

accuracy of forces and moments must lie within 0 to minus 10 %. E.g. a force is

indicated with 1000N. The final value must be between 900N and 1000N

Additional Information for Building Data BD3

Detailed load information (dead or live) with supports and anchorage details, design

of foundations, base frame for skids incl. anchor details with minimum spacing

between frame and pedestal/floor

Any auxiliary devices required for component erection/commissioning or

maintenance or repairs, e.g. disassembly devices, etc.

Location and designation of electrical and control system connections.

Degree of precision: All information shall be final.

4.9

Functional Design specification (FDS)

Purpose: This document shall show all logical functions for protection and operation of the

systems, subsystems and each component, implemented in the DCS.

If HZI submits the FDS, the contractor has to check or to comment the FDS.

If the contractor provides its own FDS, an example will be handed out and the rules stated

below have to be observed.

The following aspects shall be covered as a minimum:

Allowable modes of operation and restrictions of operation

Start-up, shut-down procedures and all other operating sequences

Open loop and closed loop control functions

Measurement and signal conditioning

Interlocks, alarms, trips (including the according protective actions, which have to

be initiated)

Set points

Functional description

Signal exchange list with the DCS

The contractor shall provide a clear and comprehensive documentation in form of text,

block diagrams, or sequence diagrams.

Print date 27.09.13 12:04

Last saved 27.09.13

Page 13 of 14

Project Name: SERC

Title:

AIC:

000000

TII 16.20 Requirements for contractors

technical documents

50021252 - 1.0

Document Nr-Rev:

Hitachi Zosen Inova AG

The FDS as built contains all the necessary changes applied during erection/

commissioning phase, marked as red correction.

4.10

Erection and Installation Instructions

Notice: in case of contradiction, the General Terms and Conditions have to be considered.

The erection instructions contain information required for the following:

Indication of all necessary erection activities (see minimum content)

Execution instructions for the erection of the specified equipment

All equipment is considered to be a black box. Its content is of no interest for erection

purposes, therefore papers for advertising purposes, drawings issued for design, fabrication

and shop assembly and sales documents are not acceptable because they are unsuitable

for planing the erection activities.

Content: The erection instructions should have at least the following content:

Simple and clear description of each equipment (black box) including overall

dimensions and weights (weights of every single equipment to install, crane load)

Requirements for erection on site

Guidelines for conservation and temporary storage on site

Special precaution measures for transportation and handling on site

Handling points for suspension (cables) or jacks

List and description of necessary tools, hoists and cranes, etc. for transportation

and handling on site

Complete erection instructions including descriptions of all procedures, safety

measures, part lists, material data, piping, valve, cable and instrument lists, wiring

diagrams, etc.

Erection time schedule including the following milestones: start on-site,

commissioning, clear site, full compliance/turn over, etc.

Manpower chart

Print date 27.09.13 12:04

Last saved 27.09.13

Page 14 of 14

S-ar putea să vă placă și

- B0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WDocument1 paginăB0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WNanang Cesc UttaÎncă nu există evaluări

- Requisition For Civil WorkDocument6 paginiRequisition For Civil WorkAMINÎncă nu există evaluări

- Vendor Evaluation Framework For EPC ContractorDocument10 paginiVendor Evaluation Framework For EPC ContractorRashmi Ranjan SamalÎncă nu există evaluări

- Pump TemplateDocument2 paginiPump TemplateamitkrayÎncă nu există evaluări

- 77.tec-Saukem-Loi003-E01-092 V1 R2Document13 pagini77.tec-Saukem-Loi003-E01-092 V1 R2Purushothaman SeenuÎncă nu există evaluări

- Project Standards and Specifications Fan and Blower Systems Rev01Document12 paginiProject Standards and Specifications Fan and Blower Systems Rev01vominhthaiÎncă nu există evaluări

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pagini1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67Încă nu există evaluări

- 20100PE-DW02-0005 Rev0 11-SD-2121-4Document1 pagină20100PE-DW02-0005 Rev0 11-SD-2121-4Jovit BeaÎncă nu există evaluări

- Drawing List Submitted To MECON 01Document1 paginăDrawing List Submitted To MECON 01Christopher LewisÎncă nu există evaluări

- Technical FF PRT C 20181016 171523 PDFDocument851 paginiTechnical FF PRT C 20181016 171523 PDFAayeshaÎncă nu există evaluări

- NAWCPF-MSBI-NCPF-000-CV-RFQ-31072 - 001 - CPF-Civil Works-SOWDocument45 paginiNAWCPF-MSBI-NCPF-000-CV-RFQ-31072 - 001 - CPF-Civil Works-SOWMouhebÎncă nu există evaluări

- 20100PE-DW02-0002 Rev0 11-SD-2121-1Document1 pagină20100PE-DW02-0002 Rev0 11-SD-2121-1Jovit BeaÎncă nu există evaluări

- Material Requisition xxxx-MR01/: SRU Thermal Reactor PACKAGE (4137.05-PK-311/321)Document28 paginiMaterial Requisition xxxx-MR01/: SRU Thermal Reactor PACKAGE (4137.05-PK-311/321)saptarshi jashÎncă nu există evaluări

- SPCL Offer 9 (New) - 03.12.09Document55 paginiSPCL Offer 9 (New) - 03.12.09ptn999Încă nu există evaluări

- 1574 - 03 Vol 2B - DS Package PDFDocument69 pagini1574 - 03 Vol 2B - DS Package PDFanjnaÎncă nu există evaluări

- Tyical Weight For Gate and Globe ValvesDocument1 paginăTyical Weight For Gate and Globe ValvesguhlÎncă nu există evaluări

- Ds BoilerDocument7 paginiDs Boilerwado11Încă nu există evaluări

- Document Deliverable List - CBFSF 2x450 TPD - R1 (Submitted 22102019)Document6 paginiDocument Deliverable List - CBFSF 2x450 TPD - R1 (Submitted 22102019)Berkat HarefaÎncă nu există evaluări

- Eil Job No.: A545: Owner:-Dangote Oil Refining CompanyDocument19 paginiEil Job No.: A545: Owner:-Dangote Oil Refining CompanySandip Sur100% (1)

- Piping Design Requirements For Turbine SystemsDocument12 paginiPiping Design Requirements For Turbine SystemsbikendiaguirreÎncă nu există evaluări

- TII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsDocument11 paginiTII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsBorn ToSinÎncă nu există evaluări

- JTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersDocument23 paginiJTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersBorn ToSinÎncă nu există evaluări

- 1KHF334933 - AHS-PS32-1402-B - SAS Functional Description For CCR Rev1Document34 pagini1KHF334933 - AHS-PS32-1402-B - SAS Functional Description For CCR Rev1kytong100% (1)

- N - Technical Spec. 110 Rev. E (IFP) - 110-2009-19Document273 paginiN - Technical Spec. 110 Rev. E (IFP) - 110-2009-19bbhattÎncă nu există evaluări

- HC AP ODU and Accessories Order Codes ReferenceDocument13 paginiHC AP ODU and Accessories Order Codes ReferenceSatish Chand JainÎncă nu există evaluări

- ENG... Electrical & Instrumentation Cables - (ENG-GS6-007)Document15 paginiENG... Electrical & Instrumentation Cables - (ENG-GS6-007)翟庆祥Încă nu există evaluări

- Review Template OM ManualDocument18 paginiReview Template OM ManualHenok DireÎncă nu există evaluări

- S 0100 1520 201 - 1 PDFDocument15 paginiS 0100 1520 201 - 1 PDFAliZenati100% (1)

- DRP001 Ouf Pro U 000 001 B4Document58 paginiDRP001 Ouf Pro U 000 001 B4ss50% (2)

- Communication Procedure (REL-N)Document18 paginiCommunication Procedure (REL-N)Handri PuriÎncă nu există evaluări

- Sample ITP Document PDFDocument111 paginiSample ITP Document PDFAudi GustiandiÎncă nu există evaluări

- Manufacturers Data Report (MDR) - Plant Projects EP-08-030-37Document17 paginiManufacturers Data Report (MDR) - Plant Projects EP-08-030-37MekhmanÎncă nu există evaluări

- 5 - Relatório de Teste de Conformidade A IEC 62109 Bureau Veritas - Inversor SolarEdge SE20.1KDocument131 pagini5 - Relatório de Teste de Conformidade A IEC 62109 Bureau Veritas - Inversor SolarEdge SE20.1KCesar Biasi de MouraÎncă nu există evaluări

- Isdn Informations enDocument96 paginiIsdn Informations ensmak85pkÎncă nu există evaluări

- MDR Manufacturers Data Report InfoDocument13 paginiMDR Manufacturers Data Report InfoSaut Maruli Tua Samosir100% (4)

- A307 T-1057 1001 TN Rev0Document2.089 paginiA307 T-1057 1001 TN Rev0VenkatRaghavendar100% (1)

- 3-98-00 Spec. For Steam Inerting Valve StationDocument11 pagini3-98-00 Spec. For Steam Inerting Valve StationlightsonsÎncă nu există evaluări

- 10080-1-ENGG-DBD-CI-001 - 0 - Control and Instrumentaion Design BasisDocument78 pagini10080-1-ENGG-DBD-CI-001 - 0 - Control and Instrumentaion Design BasisDinesh Boopalan50% (2)

- Anexo Sem Título 00041Document23 paginiAnexo Sem Título 00041AdrianoÎncă nu există evaluări

- 71.0402 General Construction - Substructures - AssemblyDocument201 pagini71.0402 General Construction - Substructures - Assemblythanhphucbr87Încă nu există evaluări

- D0246 Concept of Earthing Bonding PS-PRD-ALL-EnB-GEN-03001-D - Annex 1Document27 paginiD0246 Concept of Earthing Bonding PS-PRD-ALL-EnB-GEN-03001-D - Annex 1Satish Kumar100% (2)

- SURPASS HiT 7020 Technical Description Iss 01Document48 paginiSURPASS HiT 7020 Technical Description Iss 01Claudio Saez0% (1)

- TII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptDocument18 paginiTII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptBorn ToSinÎncă nu există evaluări

- Technical Description - Heating Water MHWDocument10 paginiTechnical Description - Heating Water MHWBorislav VulicÎncă nu există evaluări

- Pepperl+Fuchs 3094848-0.2Document13 paginiPepperl+Fuchs 3094848-0.2Mukund IndianÎncă nu există evaluări

- Hardware Module Description: Kongsberg Maritime Part No.330924Document42 paginiHardware Module Description: Kongsberg Maritime Part No.330924edi2805Încă nu există evaluări

- S-0100-1520-104 - 1 - Manuf Data Record PDFDocument13 paginiS-0100-1520-104 - 1 - Manuf Data Record PDFAliZenati100% (1)

- Dnp3 Device Profile Document For Reliatronics Inc. Model: RTU3200Document53 paginiDnp3 Device Profile Document For Reliatronics Inc. Model: RTU3200Alfredo RisueñoÎncă nu există evaluări

- Ecopetrol Coatings Specification - Rev 8Document28 paginiEcopetrol Coatings Specification - Rev 8Anderson Cogollo FigueroaÎncă nu există evaluări

- For Construction: SonatrachDocument69 paginiFor Construction: Sonatrachm.kÎncă nu există evaluări

- Technical Description - Cooling Water MKWH, HLK, MKWP, MKWEDocument17 paginiTechnical Description - Cooling Water MKWH, HLK, MKWP, MKWEBorislav VulicÎncă nu există evaluări

- BZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureDocument25 paginiBZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureManik KÎncă nu există evaluări

- 03-730003-4800000507-CH2-MEC-DBR-000003 - A v11Document30 pagini03-730003-4800000507-CH2-MEC-DBR-000003 - A v11WuillÎncă nu există evaluări

- JAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0Document13 paginiJAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0MedrouaÎncă nu există evaluări

- SR DSTE JHS Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No JHS-N-W-23-21 ClosingDocument11 paginiSR DSTE JHS Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No JHS-N-W-23-21 ClosingMadhav PrasadÎncă nu există evaluări

- MPS For Transmission LineDocument273 paginiMPS For Transmission Linepradeep.selvarajan100% (2)

- Tower Design ReportDocument91 paginiTower Design Reportkbkshanaka86% (7)

- Abb - Reference Designations For Equipment and Functions in SubstationsDocument38 paginiAbb - Reference Designations For Equipment and Functions in SubstationsjebicoreÎncă nu există evaluări

- MDR InfoDocument13 paginiMDR InfoRoger McGuire100% (1)

- Specification For High Voltage Switchgear: Owner Kandhkot Field Gas Compression Station (KFGCS) Project ContractorDocument19 paginiSpecification For High Voltage Switchgear: Owner Kandhkot Field Gas Compression Station (KFGCS) Project ContractorHassen LazharÎncă nu există evaluări

- TII-HZI-50021973 - 0.0 - TII 16.05 Thermal and Sound InsulationDocument19 paginiTII-HZI-50021973 - 0.0 - TII 16.05 Thermal and Sound InsulationBorn ToSinÎncă nu există evaluări

- TII-HZI-50021179 - 0 0 - TII 15 02 06 Cabinet Systems and EnclosuresDocument20 paginiTII-HZI-50021179 - 0 0 - TII 15 02 06 Cabinet Systems and EnclosuresBorn ToSinÎncă nu există evaluări

- TII-HZI-50021298 - 0.0 - TII 15.05.02 Instrumentation Master CatalogueDocument202 paginiTII-HZI-50021298 - 0.0 - TII 15.05.02 Instrumentation Master CatalogueBorn ToSinÎncă nu există evaluări

- TII-HZI-50021280 - 2.2 - TII 16.03 Steel Structures, Platforms, Stairs, RailingsDocument24 paginiTII-HZI-50021280 - 2.2 - TII 16.03 Steel Structures, Platforms, Stairs, RailingsBorn ToSinÎncă nu există evaluări

- TII-HZI-50021972 - 1.0 - TII 16.04 Corrosion ProtectionDocument40 paginiTII-HZI-50021972 - 1.0 - TII 16.04 Corrosion ProtectionBorn ToSinÎncă nu există evaluări

- TII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsDocument11 paginiTII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsBorn ToSinÎncă nu există evaluări

- Welding Consumables Handbook 0609Document647 paginiWelding Consumables Handbook 0609Born ToSin100% (1)

- TII-HZI-50022349 - 0.0 - TII 16.08 DuctsDocument13 paginiTII-HZI-50022349 - 0.0 - TII 16.08 DuctsBorn ToSinÎncă nu există evaluări

- TII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptDocument18 paginiTII-HZI-50021981 - 1.0 - TII 16.10 Colour ConceptBorn ToSinÎncă nu există evaluări

- JTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersDocument23 paginiJTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersBorn ToSinÎncă nu există evaluări

- TGE-HZI-50021204 0.0 EIC Standards and RegulationsDocument15 paginiTGE-HZI-50021204 0.0 EIC Standards and RegulationsBorn ToSinÎncă nu există evaluări

- RT AsmeDocument2 paginiRT AsmeBorn ToSinÎncă nu există evaluări

- TII-HZI-50022348 - 0.0 - TII 16.09 Welding, Steel Structure, Metal ConstructionDocument11 paginiTII-HZI-50022348 - 0.0 - TII 16.09 Welding, Steel Structure, Metal ConstructionBorn ToSinÎncă nu există evaluări

- JTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersDocument23 paginiJTE - HZI - 50021543 - 0.0 - Work Instruction OM For System SuppliersBorn ToSinÎncă nu există evaluări

- Follow Up Log Sheet That Done by Chimec Rep. For (CH1038 & CH1052 & CH1030) at Wells On 2010Document16 paginiFollow Up Log Sheet That Done by Chimec Rep. For (CH1038 & CH1052 & CH1030) at Wells On 2010Born ToSinÎncă nu există evaluări

- Rotator TNA 40 (40 TM) : EuropeDocument1 paginăRotator TNA 40 (40 TM) : EuropeBorn ToSinÎncă nu există evaluări

- Rotator TNA 40 (40 TM) : EuropeDocument1 paginăRotator TNA 40 (40 TM) : EuropeBorn ToSinÎncă nu există evaluări

- Cobalt Alloy 188 Data Sheet - Sept - PDFDocument1 paginăCobalt Alloy 188 Data Sheet - Sept - PDFBorn ToSinÎncă nu există evaluări

- Iso 14 1982 PDFDocument14 paginiIso 14 1982 PDFBorn ToSin67% (3)

- Zavar Precaik Dodataog Materijala Struja Napon - Brzina Dodavanja Zice Unos TopioteDocument1 paginăZavar Precaik Dodataog Materijala Struja Napon - Brzina Dodavanja Zice Unos TopioteBorn ToSinÎncă nu există evaluări

- Pipeline Maintenance Procedure C 70 C G 007 00 A1Document138 paginiPipeline Maintenance Procedure C 70 C G 007 00 A1Born ToSin100% (1)

- ASME Stamp 2Document1 paginăASME Stamp 2Born ToSinÎncă nu există evaluări

- Cobalt Alloy 188 Data Sheet - SeptDocument1 paginăCobalt Alloy 188 Data Sheet - SeptBorn ToSinÎncă nu există evaluări

- Welding Handbook ESABDocument529 paginiWelding Handbook ESABErdinc_Bal_1026100% (8)

- Uporedna Tabela ESAB To BOEHLERDocument5 paginiUporedna Tabela ESAB To BOEHLERBorn ToSin100% (1)

- Pressure Proced TestDocument6 paginiPressure Proced Testjamaljamal20Încă nu există evaluări

- PP 2006 03Document4 paginiPP 2006 03Born ToSinÎncă nu există evaluări

- BS en 1044-1999 - Brazing Filler MetalsDocument26 paginiBS en 1044-1999 - Brazing Filler MetalsBorn ToSinÎncă nu există evaluări

- p91 WeldingDocument5 paginip91 Weldingsaji_t1984100% (1)

- HDT334 Specs ENDocument1 paginăHDT334 Specs ENeynna79Încă nu există evaluări

- Text EditorDocument2 paginiText EditorVarunÎncă nu există evaluări

- IT111 Mod3CDocument48 paginiIT111 Mod3CAlthea Lei Delos ReyesÎncă nu există evaluări

- Lesson 17-Optimization Problems (Maxima and Minima Problems)Document18 paginiLesson 17-Optimization Problems (Maxima and Minima Problems)Jhonnel CapuleÎncă nu există evaluări

- Aoc TV LCDDocument68 paginiAoc TV LCDbambamtdoyÎncă nu există evaluări

- Sat 2004 Maths QuestionsDocument3 paginiSat 2004 Maths QuestionsSai Sumanth PÎncă nu există evaluări

- FFmpeg Compilation in Windows 10Document4 paginiFFmpeg Compilation in Windows 10Columbus CountyÎncă nu există evaluări

- Thar MN04-20CE - ABPR-20 Operator Manual PDFDocument53 paginiThar MN04-20CE - ABPR-20 Operator Manual PDFSerge LapointeÎncă nu există evaluări

- Managing Hotspot Clients With RadiusDocument34 paginiManaging Hotspot Clients With Radiusiosmaris2331Încă nu există evaluări

- IoT Based Solar Energy Monitoring SystemDocument5 paginiIoT Based Solar Energy Monitoring SystemhatomiÎncă nu există evaluări

- Haryana With CommentsDocument148 paginiHaryana With Commentsmanojkumartomar7513Încă nu există evaluări

- MPPT - Maximum Power Point TrackingDocument9 paginiMPPT - Maximum Power Point TrackingSanjeev ReddyÎncă nu există evaluări

- Csol 570 Network Visualization and Vulnerability Detection - Module 1 - Engineering Notes 1Document18 paginiCsol 570 Network Visualization and Vulnerability Detection - Module 1 - Engineering Notes 1api-694098467Încă nu există evaluări

- IT Roadmap For GRC SKDocument1 paginăIT Roadmap For GRC SKaakashÎncă nu există evaluări

- User Manual: Integrated Stall Rental E-Government Management System (ISRMS)Document20 paginiUser Manual: Integrated Stall Rental E-Government Management System (ISRMS)Celesamae Tangub VicenteÎncă nu există evaluări

- VRV Xpress Manual V612 Tcm135-168625Document82 paginiVRV Xpress Manual V612 Tcm135-168625Cărunta-Crista Sergiu80% (5)

- Maxicare Maintenance FormDocument1 paginăMaxicare Maintenance FormEdd Nysha ManguilimotanÎncă nu există evaluări

- Data Analyst Job DescriptionDocument16 paginiData Analyst Job DescriptionjannatbluebirdÎncă nu există evaluări

- HUAWEI - SD-WAN SolutionDocument235 paginiHUAWEI - SD-WAN Solutionbuafac10Încă nu există evaluări

- 4 ResalehDocument424 pagini4 ResalehArmin NiknamÎncă nu există evaluări

- Test 4Document32 paginiTest 4Santosh JagtapÎncă nu există evaluări

- Order Form For Littelfuse Door Lock2Document6 paginiOrder Form For Littelfuse Door Lock2Lester MuscaÎncă nu există evaluări

- PROJECTDocument34 paginiPROJECTBiswajit PaulÎncă nu există evaluări

- Programming Fundamentals in C 1.1Document193 paginiProgramming Fundamentals in C 1.1Sharaz HaiderÎncă nu există evaluări

- Computer Chapter 13Document45 paginiComputer Chapter 13Md. Sakib HossainÎncă nu există evaluări

- Data Checking PDFDocument9 paginiData Checking PDFdenzelfawnÎncă nu există evaluări

- 1581 Service Manual 314982-01 (1987 Jun) PDFDocument22 pagini1581 Service Manual 314982-01 (1987 Jun) PDFNatasyaÎncă nu există evaluări

- Tablesmith 4.5: RPG Generation ToolDocument36 paginiTablesmith 4.5: RPG Generation ToolBigBadKeithÎncă nu există evaluări

- As400 Subfile Programming Part II Basic CodingDocument13 paginiAs400 Subfile Programming Part II Basic Codingmaka123Încă nu există evaluări

- Unit 5 Dive Tables and Dive ComputersDocument29 paginiUnit 5 Dive Tables and Dive ComputersnoÎncă nu există evaluări