Documente Academic

Documente Profesional

Documente Cultură

Bronze Suction Shell Corrosion Study PDF

Încărcat de

GTpianomanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bronze Suction Shell Corrosion Study PDF

Încărcat de

GTpianomanDrepturi de autor:

Formate disponibile

CORROSION MONITORING IN PAPER MACHINE

WHITE WATERS

Angela Wensley & Harry Dykstra

Bacon Donaldson Consulting Engineers

12271 Horseshoe Way

Richmond, BC, Canada

V7A 4V4

Alicja Augustyn

Avenor Inc.

2001 Neebing Avenue

Thunder Bay, ON, Canada

P7E 6S3

ABSTRACT

A year-long program of white water corrosion monitoring was

initiated at the Avenor Thunder Bay mill after rapid corrosion of

bronze couch rolls was observed. The program consisted of

weekly chemical analysis of white waters from three paper

machines, in conjunction with suction roll bronze (85Cu-5Pb5Sn-5Zn) corrosion rate monitoring by the linear polarization

resistance (LPR) method. using corrosion probes installed in

white water piping. White water corrosivity was found to be

related to the thiosulfate concentration. As the thiosulfate

concentration often exceeded 20 ppm, it was necessary to

employ corrosion inhibitors to protect the bronze rolls.

Keywords:

corrosion testing, paper machines. suction

rolls. white water

INTRODUCTION

The newsprint machines in the Avenor mill in Thunder Bay,

Ontario, have a number of suction rolls made from centrifugally

cast 1N bronze alloy (nominally 85% Cu, 5% Pb, 5% Sn, 5%

Zn), an alloy more noteworthy for its good casting properties

than for its corrosion resistance1-7.

The suction roll shells at the Thunder Bay mill are experiencing

corrosion of both the outside and inside surfaces (manifested by

the appearance of black streaks on the surfaces), and

enlargement of the suction hole bores. It has been necessary to

apply a corrosion inhibitor to showers on both the inside and

outside of the bronze suction shells, although this is an

expensive process and the need for continual application has

been questioned.

water corrosion monitoring program was initiated for three

paper machine white water systems at the Thunder Bay mill.

The program duration was one year. In that time period:

1.

White waters were sampled on a weekly basis for chemical

analysis of inorganic species, including thiosulfate and

chlorides.

2.

Six corrosion probes were installed in white water systems

for instantaneous corrosion rate monitoring of 85-5-5-5

bronze by the linear polarization resistance (LPR) method.

3.

The LPR results were verified by weight loss

measurements on the bronze electrodes, which were

removed and replaced every 3-6 months.

4.

The bronze electrodes were also examined by scanning

electron microscopy ( S E M ) a n d X - r a y e n e r g y

spectroscopy (XES) after exposure in white water systems.

EXPERIMENTAL

The white water corrosion monitoring program involved both

mill personnel and consultants. White water analysis, corrosion

probe installation, and LPR corrosion rate monitoring were

performed by Avenor personnel; data analysis, and microscopy

were performed at the Bacon Donaldson laboratory.

Monitoring Locations

Two locations on three paper machines (PMs 3,4. and 5) were

selected for corrosion monitoring by simultaneous white water

sampling and LPR corrosion rate measurements. The locations

were selected for accessibility for installation of the corrosion

probes and of nearby valves for white water sampling. The

locations selected also had high flow velocities (mostly in pipes

ahead of pumps), which prevented buildup of slimy deposits

around the probe electrodes.

The six monitoring locations were:

1.

PM3 inlet of pump from wire pit overflow to saveall.

2.

PM3 white water silo.

3.

PM4 inlet of pump from wire pit overflow to saveall.

4.

PM4 inlet of seal pit pump.

5.

PM5 white water silo.

6.

Inlet to rich white water chest.

To obtain a better understanding of the causes and control of

corrosion of bronze suction roll shells, a comprehensive white

1997 Engineering & Papermakers Conference /489

S-ar putea să vă placă și

- Thread CalculationsDocument2 paginiThread CalculationsilyaskureshiÎncă nu există evaluări

- 2020-07-13 A.R CdeDocument1 pagină2020-07-13 A.R CdeGTpianomanÎncă nu există evaluări

- Q4 SF and Q4SF OR Manual PDFDocument44 paginiQ4 SF and Q4SF OR Manual PDFGTpianomanÎncă nu există evaluări

- ASME Conformity AssessmentDocument31 paginiASME Conformity AssessmentGTpianomanÎncă nu există evaluări

- NAVSEA T9074 As GIB 010 271 Requirements For Nondestructive Testing MethodsDocument118 paginiNAVSEA T9074 As GIB 010 271 Requirements For Nondestructive Testing MethodsAle FatalaÎncă nu există evaluări

- ASNT L3 - Renewal Qualifications PDFDocument3 paginiASNT L3 - Renewal Qualifications PDFKeithÎncă nu există evaluări

- The Corrugated Process - Rick Duke Presentation 4-8-20Document29 paginiThe Corrugated Process - Rick Duke Presentation 4-8-20GTpianomanÎncă nu există evaluări

- LTA and Dryer Cylinders - Applying Mandatory Appendix 32Document2 paginiLTA and Dryer Cylinders - Applying Mandatory Appendix 32GTpianomanÎncă nu există evaluări

- Steam TablesDocument6 paginiSteam TablesRichard Olawoyin100% (1)

- UTG 38 DL +user ManualDocument318 paginiUTG 38 DL +user ManualShahbaz KhanÎncă nu există evaluări

- PCA Dryer Can Inspection Requirements (Rev 5)Document7 paginiPCA Dryer Can Inspection Requirements (Rev 5)GTpianomanÎncă nu există evaluări

- Steam TrapDocument60 paginiSteam Trap~E~67% (3)

- US-ANDROID DatasheetDocument10 paginiUS-ANDROID DatasheetGTpianomanÎncă nu există evaluări

- Thread CalculationsDocument2 paginiThread CalculationsilyaskureshiÎncă nu există evaluări

- Examination of Paper Machine Rolls Using Acoustic Emission From Crack Face RubbingDocument7 paginiExamination of Paper Machine Rolls Using Acoustic Emission From Crack Face RubbingGTpianoman100% (1)

- Tensile Strength Vs HRBDocument1 paginăTensile Strength Vs HRBGTpianomanÎncă nu există evaluări

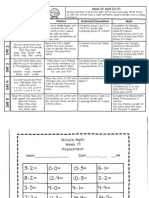

- 1st Grade April 20 24 PDFDocument9 pagini1st Grade April 20 24 PDFGTpianomanÎncă nu există evaluări

- 1st Grade April 20 24 PDFDocument9 pagini1st Grade April 20 24 PDFGTpianomanÎncă nu există evaluări

- CPI Steam Heated BoilerDocument4 paginiCPI Steam Heated BoilerGTpianomanÎncă nu există evaluări

- ASNT L3 - Renewal Qualifications PDFDocument3 paginiASNT L3 - Renewal Qualifications PDFKeithÎncă nu există evaluări

- ASIO4ALL v2 Instruction ManualDocument11 paginiASIO4ALL v2 Instruction ManualDanny_Grafix_1728Încă nu există evaluări

- Acoustic Emission Monitoring of Structures During Controlled StimulationDocument5 paginiAcoustic Emission Monitoring of Structures During Controlled StimulationGTpianomanÎncă nu există evaluări

- Corroded Steel Caused 'Catastrophic Failure' Leading To Tank Explosion That Killed 4 Near Soulard - MetroDocument8 paginiCorroded Steel Caused 'Catastrophic Failure' Leading To Tank Explosion That Killed 4 Near Soulard - MetroGTpianomanÎncă nu există evaluări

- Updated Al AzharEngineeringConference 2017FFSPresentationDocument79 paginiUpdated Al AzharEngineeringConference 2017FFSPresentationGTpianomanÎncă nu există evaluări

- Steam Systems, Inc.: WFMT Indication On D/S Head Attachment On Dryer No. 40Document1 paginăSteam Systems, Inc.: WFMT Indication On D/S Head Attachment On Dryer No. 40GTpianomanÎncă nu există evaluări

- The Constitution of The United StatesDocument21 paginiThe Constitution of The United StatesJeff PrattÎncă nu există evaluări

- UT Technotes 2011.enDocument11 paginiUT Technotes 2011.enAlexandru StefanÎncă nu există evaluări

- Olympus UT Catalog PDFDocument52 paginiOlympus UT Catalog PDFGTpianomanÎncă nu există evaluări

- The Constitution of The United StatesDocument21 paginiThe Constitution of The United StatesJeff PrattÎncă nu există evaluări

- NASA Fastener Design ManualDocument100 paginiNASA Fastener Design ManualAaron D. MillerÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Tandem Island Manual - Rev BDocument20 paginiTandem Island Manual - Rev BJesus OrtizÎncă nu există evaluări

- 1E Star Trek Customizable Card Game - 9 Deep Space 9 RulebookDocument16 pagini1E Star Trek Customizable Card Game - 9 Deep Space 9 RulebookmrtibblesÎncă nu există evaluări

- Development of A Mobile Airline Reservation Application: January 2012Document10 paginiDevelopment of A Mobile Airline Reservation Application: January 2012JakezWeruÎncă nu există evaluări

- Answers UNIT 2Document5 paginiAnswers UNIT 2c00113194Încă nu există evaluări

- The Cheerful Cricket and Others by Marks, Jeannette Augustus, 1875-1964Document26 paginiThe Cheerful Cricket and Others by Marks, Jeannette Augustus, 1875-1964Gutenberg.orgÎncă nu există evaluări

- ArtemisDocument3 paginiArtemisAxeliaÎncă nu există evaluări

- Re - 1984-10Document146 paginiRe - 1984-10Anonymous kdqf49qb100% (3)

- CQ Amateur Radio July 2023Document116 paginiCQ Amateur Radio July 2023AlexÎncă nu există evaluări

- 9-Chinese Zodiac - MonkeyDocument5 pagini9-Chinese Zodiac - MonkeyTere ChongÎncă nu există evaluări

- Block Diagram (SBD) - Network Projector Front End - TIDocument3 paginiBlock Diagram (SBD) - Network Projector Front End - TIvkarthikeyanvÎncă nu există evaluări

- Danse Bacchanale.Document17 paginiDanse Bacchanale.César CunhaÎncă nu există evaluări

- KDLV32XBR1Document174 paginiKDLV32XBR1videosonÎncă nu există evaluări

- LBS Drawings ALLDocument41 paginiLBS Drawings ALLGus DurÎncă nu există evaluări

- Video ConferencingDocument2 paginiVideo ConferencingJeoÎncă nu există evaluări

- Week 2 Welcome To The Lord's TableDocument10 paginiWeek 2 Welcome To The Lord's TableShower of RosesÎncă nu există evaluări

- Tour Guiding-2d&1n 1Document4 paginiTour Guiding-2d&1n 1Lorielyn Arnaiz CaringalÎncă nu există evaluări

- Cisco 4000 Family Integrated Services Router Data Sheet - CiscoDocument30 paginiCisco 4000 Family Integrated Services Router Data Sheet - Ciscoakarki77Încă nu există evaluări

- Heritage 1000 BrochureDocument13 paginiHeritage 1000 BrochureBrandy ThomasÎncă nu există evaluări

- 6310 Installation Manual (ENG) PDFDocument1 pagină6310 Installation Manual (ENG) PDFipas191266Încă nu există evaluări

- Tata - Eureka Park - New Plan 420x297-03122021 FINALDocument14 paginiTata - Eureka Park - New Plan 420x297-03122021 FINALEstate NCRÎncă nu există evaluări

- Badminton SafetyDocument4 paginiBadminton SafetyGrace Suzette ChiPandaÎncă nu există evaluări

- Amal Piccolo Class 9 - 30Document2 paginiAmal Piccolo Class 9 - 30bartsten333Încă nu există evaluări

- Deutsche HospitalityDocument16 paginiDeutsche Hospitalityd7oombautista1126Încă nu există evaluări

- Manual Hmi Pws6300sDocument10 paginiManual Hmi Pws6300skiedinhoÎncă nu există evaluări

- Winter Dubai Turki 2-11 Maret 2023Document4 paginiWinter Dubai Turki 2-11 Maret 2023Hukma ShabiyyahÎncă nu există evaluări

- Photos With ImpactDocument208 paginiPhotos With ImpactUğurTufanEmeksiz100% (1)

- English Formative Test 1Document2 paginiEnglish Formative Test 1ima rohimaÎncă nu există evaluări

- BELLA CIAO CHORDS (Ver 2) by Misc Traditional @Document3 paginiBELLA CIAO CHORDS (Ver 2) by Misc Traditional @Miss_AccountantÎncă nu există evaluări

- Chicken Curry: IngredientsDocument6 paginiChicken Curry: IngredientsMary Ann PateñoÎncă nu există evaluări

- Steps For NBI Clearance Renewal & New ApplicantDocument5 paginiSteps For NBI Clearance Renewal & New ApplicantneilÎncă nu există evaluări