Documente Academic

Documente Profesional

Documente Cultură

2011 01 PDF

Încărcat de

Lawrence MilfordTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2011 01 PDF

Încărcat de

Lawrence MilfordDrepturi de autor:

Formate disponibile

Performance of Soil Nailed Wall and Ground Anchor as Retaining Structure

for a Drill & Blast Tunnel Portal

Peir-Tien LEE, Kuan-Seng KOO & Yean-Chin TAN

G&P Geotechnics Sdn Bhd, Malaysia

gnp-geo@gnpgroup.com.my

Andrew YEOW

Gamuda Engineering Sdn Bhd, Malaysia

andrew@gamuda.com.my

Abstract: Embedded retaining walls such as contiguous bored pile (CBP) wall, diaphragm wall or micropile wall with temporary anchorage or strutting system are commonly adopted as retaining structure for tunnel portal. Disadvantages of the abovementioned retaining wall system for drill and blast tunnel is that the contractor needs to cut the retaining wall reinforcements, which is time consuming

and costly, in order to facilitate installation of the tunnel crown supporting system such as umbrella arch. In this paper, a cost effective

and ease of construction design approach of soil nailed wall with gradient of 4v:1h as an alternative to the conventional embedded retaining wall will be presented. Combination of 12m long soil nails and 150mm thick reinforced shotcrete are adopted to resist the lateral earth pressure and facilitate the construction of umbrella arch. The performance of the soil nailed wall during excavation and tunneling works is presented in this paper to demonstrate its effectiveness. Micropile wall with temporary ground anchors are also adopted as

temporary retaining system for the cut and cover tunnel. This paper will also present the instrumentation results such as inclinometers

and load cell on the temporary ground anchors. Back analyses using Finite Element Modeling (FEM) was performed to evaluate the

performance of the temporary retaining wall.

INTRODUCTION

The electrified double tracks project for northern part of Peninsular Malaysia is currently under construction with the purpose to

improve the interstate transportation system. As part of the

double tracks transverse through hilly terrain, a 2.9km length

twin tunnels were proposed at Bukit Berapit, Perak. The twin

tunnels will be constructed partly by cut and cover construction

technique (shallow overburden condition) and partly as a conventional tunnel by drill and blast method (deep overburden condition). In view of its close proximity to North-South Expressway

(PLUS), the most importance highway in Malaysia, micropile

wall with temporary ground anchors are adopted as the retaining

structure for the temporary tunnel portal excavation.

However, the contractor need to cut the reinforcement of the

micropile wall, which is time consuming, in order to facilitate installation of the tunnel crown supporting system such as umbrella

arch. Therefore, soil nailed wall was then proposed as an alternative retaining wall at the tunnel face area in order to overcome the

time constraint issue. Whilst, micropile wall with temporary

ground anchors are still adopted at other area as shown in Figure

1.

This paper presents the performance of the soil nailed wall in

terms of deformation behavior during excavation and tunneling

works. The finite element method (FEM) using PLAXIS computer software was used to predict wall lateral displacement and

ground anchor forces. The difference between the predicted lateral wall displacement and ground anchor forces obtained from

Fig. 1. Boreholes and instrumentation layout.

back-analyses and actual field measurements are presented and

discussed.

2 GENERAL GEOLOGY AND SUBSOIL CONDITIONS

2.1 General Geology

General geological map of Perak, Malaysia indicates that the site

is underlain by Granite Formation. The presence of Granite bedrock has been detected and confirmed during the subsurface investigation (S.I.) works.

2.2 Subsoil Condition

The subsoil strata generally consist of a layer of weathered residual soil material overlying the granitic bedrocks. The overburden subsoil mainly consists of sandy SILT according to British

Soil Classification (BSCS). The interpreted borehole profiles

showing the SPT-N values, major/minor components of soil and

Rock Quality Designation (RQD) for rock are presented in Figure

2.

a) Cutting of retaining wall reinforcements, which is time

consuming, is not required during the installation of the

tunnel crown supporting system such as umbrella arch

b) More cost effective as conventional embedded retaining

wall need to design for different wall behaviors namely

before and after cutting of the wall reinforcements

4 DESIGN AND PERFORMANCE OF SOIL NAILED WALL

4.1 Design

The design of soil nailed wall was carried out with reference to

Manual for Design and Construction Monitoring of Soil Nail

Walls by the Federal Highway Administration, U.S. Department

of Transportation (FHWA) to prevent three (3) potential failure

modes namely nail tendon failure, nail pull out failure and face

failure. Whilst, the overall stability of soil nailed wall was assessed using limit equilibrium method in accordance to Hong

Kong Geotechnical Manual of Slope (GCO 1984).

Fig. 2. Borehole profiles.

4.2 Performance

3 RETAINING WALL SCHEME AND CONSTRUCTION

The layout of the micropile wall and soil nailed wall is as shown

in Figure 1. 300mm diameter micropiles were constructed at

500mm spacing to form the retaining wall. Micropile wall is

adopted in view of its mobility as the project site is at hilly terrain

which makes it not suitable for heavy machineries. The depth of

micropile wall is generally about 12m to 16m into soil. However,

if Granite bedrock was encountered at shallow depth below the

final excavation level, 1m rock socket was found sufficient. 3

layers of temporary ground anchors were installed to support the

15.5m deep excavation as shown in Figure 3.

Whilst, for the tunnel face, 10m high soil nailed wall with gradient of 4v:1h and combination of 12m long soil nails and

150mm thick reinforced shotcrete as shown in Figure 4 was

adopted as an alternative to conventional embedded retaining

wall. The advantages of soil nailed wall compared to conventional embedded retaining wall are as follows:

One (1) inclinometer, INC3, was installed at the back of the soil

nailed wall as shown in Figure 1 to monitor the wall displacement. Figure 5 shows the measured wall displacement during various stages of excavation and installation of tunnel crown supporting system. The soil nailed wall has moved laterally about

16mm at the final excavation with relatively fixed toe embedment. Whilst, during the installation of first course of the tunnel

crown supporting system, the recorded wall lateral displacement

is only 13mm.

Fig. 3. 15.5m deep excavation with 3 levels of temporary

ground anchors

5.2 Results and Discussion

Fig. 4. Soil nailed wall for tunnel face

Ground Level at RL70m

0

Excavation side

1

2

3

4

Depth (m)

5

6

7

8

9

10

11

Legend

29-01-2010

05-02-2010_Exc to RL67m

13-02-2010_Exc to RL65m

03-03-2010_Exc to RL62m

26-03-2010_Exc to RL62m

09-04-2010_Exc to RL57m

20-05-2010_Exc to RL57m

17-06-2010_Exc to RL57m

29-07-2010_Exc to RL57m

12

-50 -40 -30 -20 -10 0

10 20

Lateral Displacement (mm)

30

40

50

Fig. 5 Lateral displacement of soil nailed wall

5 BACK ANALYSES

5.1 Introduction

The simulation of the excavation processes was carried out using

finite element modeling (FEM) software, PLAXIS. Figure 6

shows the FEM model of micropile wall with temporary ground

anchors at the final stage utilizing 15-node element under 2-D

plane strain conditions. Effective stress parameters using Hardening Soil Model is adopted to model the soil behavior in the retaining wall analyses. The soil material is assigned with undrained behavior and coupled with consolidation analyses to

simulate the actual soil behavior from undrained to drained condition due to dissipation of pore water pressure. The undrained

soil model coupled with consolidation analyses is able to predict

a more representative wall displacement and wall bending moment relative to the construction sequence as compared to conventional drained analyses.

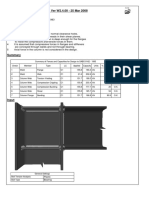

The original subsoil parameters adopted in the back analyses

are tabulated in Table 1.

The back analyses results presented in this paper include relative

wall lateral displacement, ground movement and ground anchor

loads. The wall lateral displacement profiles from both actual

measurement and back analyses are shown in Figure 7. Generally, there is good and reasonably match between the measured and

back analyzed wall lateral displacement profiles. Hence, it is evident that the behavior of residual soil can be modeled using

Hardening Soil Model for excavation analyses.

It is observed that the wall top displacement (the first 8m) for

all stages obtained from back analyses overestimated the wall

displacement. Whilst, the back analyses results were quite tallied

with the measured lateral displacement for the subsequent depth

(from 8m and below). This may due to the suction behavior of

the partially saturated subsoil as the groundwater table is at

RL65.5, which is about 8m below top of wall level. The less lateral displacement measured by inclinometer as compare to FEM

back analyses for the top 8m is probably cause by the suction effect of the partially saturated material which may not be considered in the FEM analysis in view of software limitation.

Figure 8 showing the groundwater level profile recorded by

standpipe installed at about 8m from soil side of wall. The initial

recorded groundwater level is about RL65m (8m below the wall

top level) and draws down to about RL61m during the excavation

process. As compared to the monitored results, the groundwater

level in the back analyses is similar with the trend of monitored

groundwater level with differential of 1m.

Figure 9 shows the comparison between measured and computed ground anchor loads from installation stage to final excavation. The ground anchor loads were measured by vibrating wire

load cell installed at every layers of ground anchors. It is observed that the back analyses results overestimated the ground

anchor loads by 6% to 23% at the final stage for all levels of

ground anchors. No significant increase in load for the first level

of ground anchor is recorded and this tallied with no significant

lateral wall displacement for the first 8m as shown by the inclinometer reading. In addition, some ground anchors have shown

reduction of prestressed load (about 4% to 6% of the prestressed

load) during ground anchor installation and excavation process.

This reduction was probably due to prestress of surrounding

ground anchor after the instrumented ground anchor was locked

to designed prestressed load.

6 CONCLUSIONS

Based on the discussions in earlier sections, the following conclusions can be made:

a) Soil nailed wall was adopted successfully as an alternative to conventional embedded retaining for tunnel face

in view of its construction practicality and cost effectiveness.

b) Back analyses by FEM produce reasonable prediction of

wall lateral displacement and ground anchor loads expect

for partially saturated material (above groundwater table)

as the suction behavior might have further enhanced the

stiffness of the subsoil.

c) The effective Youngs Modulus (E) and the effective unloading/reloading Youngs Modulus (Eur) which are correlated based on 3000xSPT-N and 9000xSPT-N respectively are suitable to be adopted for Granite Formation

residual soil in FEM modeling of excavation analyses.

Table 1. Subsoil parameters

Reduce

levels (RLm)

Soil type

77 - 73

73 - 69

69 - 66

66 - 63

63 - 60

60 - 57

57 - 40

sandy CLAY

gravely SILT

gravely SILT

gravely SILT

gravely SILT

fracture granite

granite

SPTN/

RQD

Unit weight

(kN/m3)

Permeability

(m/s)

c'

phi'

E50

Eoed

Eur

N=5

N=13

N=24

N=32

N=100

RQD=0

RQD=20

18

18

18

19

20

22

22

1.00E-07

1.00E-07

1.00E-07

1.00E-08

1.00E-09

1.00E-07

1.00E-07

5

10

15

15

20

30

100

28

31

33

34

35

42

45

15000

39000

72000

96000

300000

15000

39000

72000

96000

300000

E = 1000000

E = 2000000

45000

117000

216000

288000

900000

600

500

400

300

200

Level 1 ground anchor (top)

0

100

600

0

Load (kN)

500

300

200

66

100

65

600

0

64

500

Level 2 ground anchor

400

63

300

62

200

61

Level 3 ground anchor (bottom)

100

60

0

0

59

0

50

100

150

200

10

20

30

40

50

60

70

80

Graph 1

Calculated

250

Time (days)

Calculated

Measured (STD2)

90

100 110 120 130 140 150 160 170

Time (days)

180 190 200 210 220

Graph 1

Measured

Fig. 9 Ground anchor loads profiles

Fig. 8 Groundwater level profile

Lateral Displacement (mm)

-8

16

24

-8

16

24

-8

16

24

-8

16

24

-8

16

24

-2

-2

-4

-4

-6

-6

-8

-8

-10

-10

-12

-12

-14

-14

-16

-16

-18

-18

-20

-20

Excavation to RL70m (3m bgl)

Excavate to RL66m (7m bgl)

Excavation to RL62m (11m bgl)

Measured

Excavation to RL60m (13m bgl)

Calculated

Fig. 7 Wall lateral displacement profiles

Excavation to RL57.5m (15.5m bgl)

Depth (m)

Depth (m)

Groundwater table (RLm)

Fig. 6 Finite element modeling of excavation

400

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Pinned Connection Joint ReactionsDocument11 paginiPinned Connection Joint ReactionsPrakash Singh RawalÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Snap Fit DesignDocument22 paginiSnap Fit Designsachinrawool100% (1)

- Mat Reinforcement Calculations For SlabDocument6 paginiMat Reinforcement Calculations For SlabnsureshbabuÎncă nu există evaluări

- SIDRA Intersection Guideline ADOPTEDDocument18 paginiSIDRA Intersection Guideline ADOPTEDmrdvirusÎncă nu există evaluări

- Drill String FatigueDocument14 paginiDrill String FatigueHunterÎncă nu există evaluări

- FE-Fatigue TheoryDocument107 paginiFE-Fatigue Theoryer_paramjeetgill100% (3)

- Caltrans-Bridge Design Practice Feb 2015Document54 paginiCaltrans-Bridge Design Practice Feb 2015Zain Saeed100% (1)

- Revised: Author:: Nonferrous AlloysDocument46 paginiRevised: Author:: Nonferrous Alloys孙俊磊Încă nu există evaluări

- Design of Rectangular Reinforced Concrete BeamDocument7 paginiDesign of Rectangular Reinforced Concrete BeamsaadÎncă nu există evaluări

- POV Action Video Cameras Sunglasses - ManualDocument5 paginiPOV Action Video Cameras Sunglasses - ManualLawrence Milford0% (1)

- Joints in Steel Structures Based On Eurocode 3Document17 paginiJoints in Steel Structures Based On Eurocode 3uhu_plus6482Încă nu există evaluări

- Flat Slab ExampleDocument103 paginiFlat Slab ExampleShishir Kumar Nayak100% (3)

- Shear Reinforcement Design of Beam Column JointsDocument35 paginiShear Reinforcement Design of Beam Column JointsAnggi Novi AndriÎncă nu există evaluări

- RMN of I Ic, ML I: Economic Growth by State, 2013Document4 paginiRMN of I Ic, ML I: Economic Growth by State, 2013Lawrence MilfordÎncă nu există evaluări

- Torsional-Distortional Performance of Multi-Cell Trapezoidal Box Girder With All Inclined Web MembersDocument7 paginiTorsional-Distortional Performance of Multi-Cell Trapezoidal Box Girder With All Inclined Web MembersLawrence MilfordÎncă nu există evaluări

- Hayati FPTPK (Pkgas)Document19 paginiHayati FPTPK (Pkgas)Lawrence MilfordÎncă nu există evaluări

- Bon PerlaksanaanDocument3 paginiBon PerlaksanaanFarhanÎncă nu există evaluări

- Hardy Cross 1 Soln PDFDocument2 paginiHardy Cross 1 Soln PDFLawrence MilfordÎncă nu există evaluări

- Sajak Karya LouisDocument2 paginiSajak Karya LouisLawrence MilfordÎncă nu există evaluări

- 5english Language Year 1 PDFDocument9 pagini5english Language Year 1 PDFLawrence MilfordÎncă nu există evaluări

- Mahathir Mohamad: Malaysia's Longest-Serving Prime MinisterDocument50 paginiMahathir Mohamad: Malaysia's Longest-Serving Prime MinisterLawrence MilfordÎncă nu există evaluări

- (6-10) Proposal of Development Noh KwanSubDocument1 pagină(6-10) Proposal of Development Noh KwanSubLawrence MilfordÎncă nu există evaluări

- Hardy Cross 1 SolnDocument4 paginiHardy Cross 1 SolnLawrence MilfordÎncă nu există evaluări

- NotesDocument4 paginiNotesLawrence MilfordÎncă nu există evaluări

- Port of Tanjung Pelepas Performance StandardDocument1 paginăPort of Tanjung Pelepas Performance StandardLawrence MilfordÎncă nu există evaluări

- Khazanah Nasional Berhad ("Khazanah" or "Company") : Term Sheet For The BondsDocument5 paginiKhazanah Nasional Berhad ("Khazanah" or "Company") : Term Sheet For The BondsFarhanÎncă nu există evaluări

- (6-10) Proposal of Development Noh KwanSubDocument10 pagini(6-10) Proposal of Development Noh KwanSubLawrence MilfordÎncă nu există evaluări

- Flats Lab ExampleDocument69 paginiFlats Lab ExampleLawrence MilfordÎncă nu există evaluări

- MRT Line 2 EIA IntroductionDocument6 paginiMRT Line 2 EIA IntroductionLawrence MilfordÎncă nu există evaluări

- NotesDocument1 paginăNotesLawrence MilfordÎncă nu există evaluări

- 11 Section9Document5 pagini11 Section9Lawrence MilfordÎncă nu există evaluări

- KVMRT PDP SBK Pkg4 Via ST BR PP 1133 t01Document1 paginăKVMRT PDP SBK Pkg4 Via ST BR PP 1133 t01Lawrence MilfordÎncă nu există evaluări

- 2015 CITY OF EUGENE STANDARD DRAWINGS INDEXDocument8 pagini2015 CITY OF EUGENE STANDARD DRAWINGS INDEXLawrence MilfordÎncă nu există evaluări

- (6-10) Proposal of Development Noh KwanSubDocument10 pagini(6-10) Proposal of Development Noh KwanSubLawrence MilfordÎncă nu există evaluări

- Marine Traffic Risk Assessment For Hong Kong Waters (Mara Study)Document25 paginiMarine Traffic Risk Assessment For Hong Kong Waters (Mara Study)Lawrence MilfordÎncă nu există evaluări

- Introduction to Settlement Calculations and Soil Consolidation TheoriesDocument3 paginiIntroduction to Settlement Calculations and Soil Consolidation TheoriesLawrence MilfordÎncă nu există evaluări

- Waiting Line and Queuing Theory: Kusdhianto Setiawan Gadjah Mada UniversityDocument17 paginiWaiting Line and Queuing Theory: Kusdhianto Setiawan Gadjah Mada UniversityLawrence MilfordÎncă nu există evaluări

- Pushover PP TDocument58 paginiPushover PP TJuan José Ricaldi MirandaÎncă nu există evaluări

- Waiting Line and Queuing Theory: Kusdhianto Setiawan Gadjah Mada UniversityDocument17 paginiWaiting Line and Queuing Theory: Kusdhianto Setiawan Gadjah Mada UniversityLawrence MilfordÎncă nu există evaluări

- Direct Displacement Based Seismic Design of Concrete StructuresDocument25 paginiDirect Displacement Based Seismic Design of Concrete StructuresGerardo MendozaÎncă nu există evaluări

- Chapter 11Document40 paginiChapter 11Casao JonroeÎncă nu există evaluări

- Assessment of Seismic Forces by Equivalent Static Force Analysis As Per IS 1893 (Part I) : 2002Document11 paginiAssessment of Seismic Forces by Equivalent Static Force Analysis As Per IS 1893 (Part I) : 2002Rajesh JadhavÎncă nu există evaluări

- Mechanical Behavior of Materials - Lecture Slides - Chapter 9Document73 paginiMechanical Behavior of Materials - Lecture Slides - Chapter 9Jun-Dong LeeÎncă nu există evaluări

- Som Syllabus (Ce2252)Document1 paginăSom Syllabus (Ce2252)rajapratyÎncă nu există evaluări

- 20-30% Explosive Energy Used for Rock Breaking, Rest Wasted as Ground VibrationsDocument21 pagini20-30% Explosive Energy Used for Rock Breaking, Rest Wasted as Ground Vibrationstridev kant tripathiÎncă nu există evaluări

- Design Footing Area With Biaxial Bending: Appendix Ii.™NotationDocument5 paginiDesign Footing Area With Biaxial Bending: Appendix Ii.™NotationFarhan AhmadÎncă nu există evaluări

- Interaction Diagram 6Document35 paginiInteraction Diagram 6Petalio RowenaÎncă nu există evaluări

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Document1 paginăA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Vivek MishraÎncă nu există evaluări

- Beam - Column Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsDocument2 paginiBeam - Column Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsNyu123456Încă nu există evaluări

- Prestressed Concrete Structures 500 OqaDocument90 paginiPrestressed Concrete Structures 500 OqasanthiamuthaÎncă nu există evaluări

- RC18 Column02Document8 paginiRC18 Column02assaad006Încă nu există evaluări

- UntitledDocument187 paginiUntitledudomÎncă nu există evaluări

- Cold-Formed Steel Flexural Member With Edge Stiffened Holes Behavior, Optimization, and DesignDocument9 paginiCold-Formed Steel Flexural Member With Edge Stiffened Holes Behavior, Optimization, and Designchristos032Încă nu există evaluări

- Fract Mechanics - de ZG514Document13 paginiFract Mechanics - de ZG514Umesh BhadaleÎncă nu există evaluări

- Multi-Storey Building Analysis and DesignDocument5 paginiMulti-Storey Building Analysis and DesignSyed Azeem0% (1)

- Stress Analysis and ApplicationsDocument86 paginiStress Analysis and ApplicationsJAMES TRIXIAN PARAJASÎncă nu există evaluări

- Definition of High Strength ConcreteDocument77 paginiDefinition of High Strength ConcreteБисера СпасовскиÎncă nu există evaluări

- Seismic Performance of Re-Entrant Corner BuildingsDocument5 paginiSeismic Performance of Re-Entrant Corner BuildingsRezviÎncă nu există evaluări