Documente Academic

Documente Profesional

Documente Cultură

Canada Takes A Lead in Benchmarking Pump Energy Efficiency

Încărcat de

GERMAN1979Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Canada Takes A Lead in Benchmarking Pump Energy Efficiency

Încărcat de

GERMAN1979Drepturi de autor:

Formate disponibile

PUMPS

Canada takes a lead in

benchmarking pump

energy efciency

A large-scale pump performance testing programme

looking at over 150 pumps in Canada covered energy

efciency as well as the accuracy of both thermodynamic

and conventional pump testing methods. FABIAN PAPA and

DJORDJE RADULJ summarise the main ndings from the

programme with regards to improving pump efciency

and the potential for benchmarking.

n May 2013, the results of a

large-scale pump performance

and energy efciency testing

programme conducted in Canada

were released.This programme

involved testing of more than

150 water pumps across eight

utilities in Ontario, Canadas

most populous province, for the

purposes of characterizing the

actual in situ performance of

these devices in order to help

drive awareness and motivate

energy conservation initiatives.

The result is a well-documented

reference that can be used by

practitioners worldwide for

comparative purposes, such

as benchmarking, as well as

to help improve general

practices in this eld.

Motivation

The linkages between water and

energy are gaining increasing attention

globally and, as both nancial pressures

and concerns over energy security

increase, so does the need to thoroughly assess the use of energy and the cost

associated with it.With this context in

mind, the Ontario Power Authority

(OPA), through its Conservation

Fund, provided the primary nancial

support of the above-mentioned

programme. OPA is an independent,

government-owned corporation

responsible for, among other things,

assessment of the long-term adequacy

of electrical resources in the province,

forecasting future demand and the

potential for conservation.This nancial support encouraged the participa30

WATER 21 DECEMBER 2013

and / or replacement, as well as pump

operation.The technologies available

for accurate and reliable testing exist

and are affordable to implement.

However, the real benets are derived

from the information obtained and the

savings that can often be realized.

tion of several water utilities in a

display of mutually benecial crosssectoral collaboration, the results of

which are having long-lasting transformative effects on the provinces water

sector in addition to spillover benets

beyond the boundaries of the participating utilities and the province.

Traditional practices

Although it is both intuitive and

understood that pumps deteriorate

with time and usage, their performance

is generally not measured or monitored. Operation and maintenance

practices are often based on rules-ofthumb and qualitative eld observations. Hydraulic models are frequently

used to design new pumping systems,

assess the operation of existing water

systems, develop energy optimization

strategies, etc. However, such models

generally use original manufacturer

specications for hydraulic performance and energy consumption of

pumps without proper consideration

of their actual behaviour.As a result,

many decisions are made without

complete or accurate information and,

accordingly, such decisions would be

expected to be inferior to those that

would be made with the best attainable

information in hand.

This testing programme goes a long

way towards lifting the veil of uncertainty surrounding the actual performance of water pumps as they operate

in our current systems, and allows for

the assessment of benets and costs so

that nancially sound business cases

can be made in relation to pump

maintenance, including rehabilitation

Figure 1: The

thermodynamic

testing method

The programme

Over the course of 2011 and 2012,

eld tests of more than 150 pumps

were conducted, using either or both

of the thermodynamic and conventional pump testing methods.While

both methods are capable of producing

reliable results when favourable site

conditions permit, it was found that

the thermodynamic method which

determines a pumps efciency by

measuring the unproductive thermal

energy gain in the pumped uid

(water) is generally more applicable,

accurate and reliable than the conventional method when it comes to most

eld tests.The thermodynamic

method involves the insertion of

temperature probes and pressure

gauges on both the upstream and

downstream sides of the pump (Figure

1), as well as the measurement of

power input to the pumps motor.

The pumps ranged in age from less

than one year old to 61 years old, and

their motor sizes ranged from 22kW

(30 hp) to 3000kW (4000 hp).

Approximately 15% of all pumps

tested were controlled using variable

frequency drives (VFDs).As part of the

programme, training workshops were

held with each of the participating

utilities to discuss the technology,

the testing methods and the ndings,

which in addition to providing

technical results also implemented

nancial assessments to demonstrate

the potential savings for each of

the pumps.

The results

Any given pump has a point of

operation where its energy efciency

is highest, known as its best efciency

point (BEP), and the efciency falls

away from this peak as ow either

increases or decreases away from this

point.There are two general ways in

which a pump can lose efciency:

largely physical reasons associated

with wear and tear, corrosion, uid

turbulence or cavitation, etc.; and for

reasons of sub-optimal operation,

where the pump operates away from its

BEP. For purposes of this programme,

the following denitions were applied

and results obtained.

Efciency loss

Efciency loss is the difference

between the manufacturers

BEP and the tested BEP.This

is a measure of how the pumps

efciency has deteriorated since its

original manufacture.Any degradation

using this measure can typically be

recovered, at least partially, through

pump refurbishment.The average

efciency loss for all the pumps

tested was 9.3%.

Overall efciency gap

The overall efciency gap is the

difference between the manufacturers

BEP and the efciency at the current

typical operating point of the pump.

In addition to the efciency loss, this

measure also includes any inefciency

associated with the operation of the

pump outside of its peak range.This

measure provides an indication of the

degree to which both pump refurbishment (as above) as well as improved

operational strategies may improve

overall pump efciency.The average

overall efciency gap for all the pumps

tested was 12.7%.

The average efciency for all the

pumps tested was found to be 73.7%

(not including any inefciencies

imposed by pump motors or drives),

compared with the average taken from

the manufacturers specications at the

pumps BEPs, which was 86.4%.This is

a sizable departure, however, what is

perhaps more interesting is that the

average wire-to-water efciency

(which includes motor and drive

efciencies) for all the pumps tested

was 69.4%, meaning that more than

30% of the electrical energy input to

Utilization Rate (Fraction of Time Operated Annually)

PUMPS

Pump motor size (hp)

Figure 2: Graphical

testing frequency

guideline

the pumping units was essentially lost

or wasted.

These results provide a rather clear

indication that there is opportunity

for improvement and that industry

practices ought to consider actual

pump efciencies in a serious manner.

In fact, refurbishments conducted on

two pumps during the programme

resulted in the recovery of 65% and

71% of their respective efciency

losses.

Benchmarking

One of the most important contributions of this programme is the benchmarking information that the more

than 150 tested pumps provides.

Both the newly developed Pump

Energy Indicator (PEI) and the

IWA Standardised Energy

Consumption Performance

Indicator (Ph5) were shown to

be superior to any other metric

or performance indicator available

in the industry.These two metrics

are quite similar and relate energy

consumption to both the ow and

the head produced by the pump.

The subtle difference between these

metrics is that the PEI is an instantaneous measure while Ph5 is a longterm average (typically one year).

The averages of these performance

indicators for the pumps tested were

found to be: PEI 3980 kWh/Mm3/m

water; and Ph5 0.398 kWh/m3/

100m water (assuming direct

extrapolation to an annual basis).

It is noted that these results are

18.8% higher than the original

manufacturers specications,

more accurately reecting the

gap in current versus potential

performance levels.

Testing frequency

The programme developed several

nancial models to support decisions

regarding potential interventions such

as pump refurbishments or modications to operating practices. One of

the more useful outcomes of such

modelling was the development of a

graphical testing frequency guideline

(see Figure 2), which relates the

nancial importance of pumps to

their (motor) size and utilization rate.

This particular guideline as shown

is based on cost assumptions that are

relevant to the Canadian context

and may not be directly applicable

elsewhere. However, the concept

remains and the graph can be adjusted

for different geographies as well as over

time as conditions change within each.

Closing thoughts

Pumping is central to water supply,

transmission, and distribution systems,

and often represents one of the largest

cost items for a utility. Measuring and

monitoring the energy efciency of

pumps during their productive life

can yield many positive results,

nancial and otherwise, and thereby

achieve multiple goals of nancial and

environmental sustainability.

For more information on this pump

performance and energy efciency testing

program, or to request a copy of the nal

report, visit: www.hydratek.com/opa

About the authors

Fabian Papa is a Director at HydraTek &

Associates Inc., Ontario, Canada.

Djordje Radulj is Managing Director at

HydraTek & Associates Inc., Ontario,

Canada.

WATER 21 DECEMBER 2013

33

S-ar putea să vă placă și

- Energy Efficiency: Concepts and CalculationsDe la EverandEnergy Efficiency: Concepts and CalculationsEvaluare: 4.5 din 5 stele4.5/5 (3)

- International Divider WallsDocument20 paginiInternational Divider Wallshaliza amirah100% (2)

- 2019 Caterpillar Mining Equipment Management Metrics Document - Version 4Document78 pagini2019 Caterpillar Mining Equipment Management Metrics Document - Version 4mauricio100% (4)

- Peerless Pump Tech BulletinsDocument176 paginiPeerless Pump Tech BulletinsWilhelm ThorleyÎncă nu există evaluări

- Energy Efficiency of Pumps StudyDocument69 paginiEnergy Efficiency of Pumps StudyberkiÎncă nu există evaluări

- RT600E Product Guide Imperial PDFDocument16 paginiRT600E Product Guide Imperial PDFjesus3hernandez_4Încă nu există evaluări

- The Coating Inspectors HandbookR3.1Document64 paginiThe Coating Inspectors HandbookR3.1Akhter Khan100% (11)

- RT600E Product Guide Imperial PDFDocument16 paginiRT600E Product Guide Imperial PDFjesus3hernandez_4Încă nu există evaluări

- Departmental Action Plan AnnotatedDocument8 paginiDepartmental Action Plan Annotatedapi-412208005Încă nu există evaluări

- Energy Management Self AssessmentDocument10 paginiEnergy Management Self AssessmentHans De KeulenaerÎncă nu există evaluări

- Refurbishment Is Vital To Efficiency (World Pumps June 2014) With CoverDocument3 paginiRefurbishment Is Vital To Efficiency (World Pumps June 2014) With CoverGerman FavelaÎncă nu există evaluări

- Pump Life Cycle CostDocument19 paginiPump Life Cycle CostSAMEER100% (3)

- Energy Efficiency Planning, Funding and Improvements For New Hampshire's Drinking Water and Wastewater SystemsDocument24 paginiEnergy Efficiency Planning, Funding and Improvements For New Hampshire's Drinking Water and Wastewater Systemsmmihai_popa2006Încă nu există evaluări

- Selecting A Centrifugal Pumps by System Analysis PDFDocument27 paginiSelecting A Centrifugal Pumps by System Analysis PDFmishraenggÎncă nu există evaluări

- Pump EE by ThermodynamicsDocument21 paginiPump EE by Thermodynamicsrazali131266Încă nu există evaluări

- LCC Guide For Pumps PDFDocument19 paginiLCC Guide For Pumps PDFAshish ThapliyalÎncă nu există evaluări

- LCC Executive SummaryDocument23 paginiLCC Executive SummarySuhartomtÎncă nu există evaluări

- Energy & EnvironmentDocument227 paginiEnergy & EnvironmentBalasundaramSrinivasaRajkumar0% (1)

- IWA - Water 21 - Feb 2014Document1 paginăIWA - Water 21 - Feb 2014jeddptÎncă nu există evaluări

- Analysis and Investigation of The Cause of Increased Energy Consumption in A Centrifugal Dewatering PlantDocument5 paginiAnalysis and Investigation of The Cause of Increased Energy Consumption in A Centrifugal Dewatering PlantResearch ParkÎncă nu există evaluări

- Selecting A Centrifugal Pump by SystemDocument27 paginiSelecting A Centrifugal Pump by SystemBogdan ChivulescuÎncă nu există evaluări

- LBNL 51042 PDFDocument9 paginiLBNL 51042 PDFraguÎncă nu există evaluări

- UOP Energy Management Solutions PaperDocument5 paginiUOP Energy Management Solutions PaperDeni Yudha PermanaÎncă nu există evaluări

- Select Hydraulic Institute Standards-Pump Operations, Efficiency, Testing & SystemsDocument4 paginiSelect Hydraulic Institute Standards-Pump Operations, Efficiency, Testing & SystemsHongwei GuanÎncă nu există evaluări

- Guidelines Flare Vent MeasurementDocument36 paginiGuidelines Flare Vent MeasurementAngie Paola Sanabria MartinezÎncă nu există evaluări

- Pump Systems Energy Efficiency Reference ManualDocument0 paginiPump Systems Energy Efficiency Reference ManualAlda England100% (1)

- Best Practice Guide PumpDocument39 paginiBest Practice Guide PumpjavgeekÎncă nu există evaluări

- Pumping 6Document2 paginiPumping 6Foulen FouleniÎncă nu există evaluări

- Energy Reductions in The Pulp-And-Paper Industry by Upgrading Conventional Pumping Systems Through The Installation of Vfds - A Case StudyDocument6 paginiEnergy Reductions in The Pulp-And-Paper Industry by Upgrading Conventional Pumping Systems Through The Installation of Vfds - A Case StudytorinomgÎncă nu există evaluări

- Variable Speed Pumping in Thermal and Nuclear Power Plants: Frequency Converter Versus Hydrodynamic CouplingDocument7 paginiVariable Speed Pumping in Thermal and Nuclear Power Plants: Frequency Converter Versus Hydrodynamic CouplingNath BoyapatiÎncă nu există evaluări

- Guidelines Flare Vent Measurement PDFDocument36 paginiGuidelines Flare Vent Measurement PDFVivek JoshiÎncă nu există evaluări

- A Study of Energy Optimisation of Urban Water Distribution Systems Using Potential ElementsDocument19 paginiA Study of Energy Optimisation of Urban Water Distribution Systems Using Potential ElementsMaraah IssaÎncă nu există evaluări

- Application of Genetic Algorithms Pump Scheduling For Water SupplyDocument6 paginiApplication of Genetic Algorithms Pump Scheduling For Water SupplySam ArÎncă nu există evaluări

- E E Gya It in Ses Dy F Centr: N R Ud Ca Tu ODocument5 paginiE E Gya It in Ses Dy F Centr: N R Ud Ca Tu ORamyLloydLotillaÎncă nu există evaluări

- Water: Hydropower Generation Through Pump As Turbine: Experimental Study and Potential Application To Small-Scale WDNDocument19 paginiWater: Hydropower Generation Through Pump As Turbine: Experimental Study and Potential Application To Small-Scale WDNJuuzou Tooru Karma TobioÎncă nu există evaluări

- Small-scale pumped irrigation - energy and cost optimizationDocument90 paginiSmall-scale pumped irrigation - energy and cost optimizationP.Sang-GeoÎncă nu există evaluări

- Variable Speed Pumping, A Guide To Successful ApplicationDocument6 paginiVariable Speed Pumping, A Guide To Successful Applicationongjoel0% (1)

- Energy Management Action PlanDocument8 paginiEnergy Management Action Plan3319826100% (1)

- Field Study Verification AdvancesDocument10 paginiField Study Verification Advancesdaburto2Încă nu există evaluări

- RefMaterial - Article - SpecificSpeed-basedPumpFlowRat PDFDocument13 paginiRefMaterial - Article - SpecificSpeed-basedPumpFlowRat PDFrayasam08Încă nu există evaluări

- A2A Training Modules 1 To 3Document54 paginiA2A Training Modules 1 To 3Jose DenizÎncă nu există evaluări

- Power Consumption Optimization For Multiple Parallel Centrifugal PumpsDocument6 paginiPower Consumption Optimization For Multiple Parallel Centrifugal PumpshachanÎncă nu există evaluări

- Achieving Sustainable Energy Reduction in An Industrial SettingDocument2 paginiAchieving Sustainable Energy Reduction in An Industrial SettingKit OungÎncă nu există evaluări

- Spe 99446Document8 paginiSpe 99446Nana Silvana AgustiniÎncă nu există evaluări

- High-Efficiency Single-Phase Air Conditioner: Energy Innovations Small Grant Program Building End Use Energy EfficiencyDocument57 paginiHigh-Efficiency Single-Phase Air Conditioner: Energy Innovations Small Grant Program Building End Use Energy EfficiencyNius Pahala NainggolanÎncă nu există evaluări

- An Energy Management Guidebook For Wastewater and Water UtilitiesDocument113 paginiAn Energy Management Guidebook For Wastewater and Water UtilitiesIbrahim Al-MutazÎncă nu există evaluări

- Water: Optimization of The Design of Water Distribution Systems For Variable Pumping Flow RatesDocument20 paginiWater: Optimization of The Design of Water Distribution Systems For Variable Pumping Flow Ratespujan kattelÎncă nu există evaluări

- The Water - Energy Nexus: Integrated Management and Adap9ve GovernanceDocument17 paginiThe Water - Energy Nexus: Integrated Management and Adap9ve Governanceapi-145663568Încă nu există evaluări

- Energy Tips - Pumping Systems: Select An Energy-Efficient Centrifugal PumpDocument2 paginiEnergy Tips - Pumping Systems: Select An Energy-Efficient Centrifugal PumpBang RegarÎncă nu există evaluări

- Esl Ie 05 05 05Document11 paginiEsl Ie 05 05 05blindjaxxÎncă nu există evaluări

- Calibrating Custody Transfer Gas Meter PDFDocument18 paginiCalibrating Custody Transfer Gas Meter PDFzohaibjamilÎncă nu există evaluări

- Wastewater Treatment Plant Operation: Simple Control Schemes with a Holistic PerspectiveDocument28 paginiWastewater Treatment Plant Operation: Simple Control Schemes with a Holistic PerspectiveAhmed AmediÎncă nu există evaluări

- Cost For Headwater Benefits Assessment: A NewDocument12 paginiCost For Headwater Benefits Assessment: A NewMinisoft2002Încă nu există evaluări

- Variables PpedDocument24 paginiVariables PpedLuis LopezÎncă nu există evaluări

- SPE 185472 New Trends in Waterflooding Project OptimizationDocument29 paginiSPE 185472 New Trends in Waterflooding Project Optimizationk.leya424Încă nu există evaluări

- Pump EffDocument15 paginiPump Effawhk2006Încă nu există evaluări

- Maximising Refinery Margin With Minimal CapexDocument12 paginiMaximising Refinery Margin With Minimal CapexWon JangÎncă nu există evaluări

- Energies 12 04136Document14 paginiEnergies 12 04136Rania YaseenÎncă nu există evaluări

- Anglogold Ashanti Compressor Optimization Project - The Potential of System CFD Codes in The Mining IndustryDocument5 paginiAnglogold Ashanti Compressor Optimization Project - The Potential of System CFD Codes in The Mining IndustryAndre NelÎncă nu există evaluări

- Article 5Document38 paginiArticle 5mouadÎncă nu există evaluări

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceDe la EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceÎncă nu există evaluări

- Power-to-Gas: Bridging the Electricity and Gas NetworksDe la EverandPower-to-Gas: Bridging the Electricity and Gas NetworksÎncă nu există evaluări

- Energy Management Principles: Applications, Benefits, SavingsDe la EverandEnergy Management Principles: Applications, Benefits, SavingsEvaluare: 4.5 din 5 stele4.5/5 (3)

- Comparative Study on Policies for Products’ Energy Efficiency in EU and China: Joint Statement Report Series, #6De la EverandComparative Study on Policies for Products’ Energy Efficiency in EU and China: Joint Statement Report Series, #6Încă nu există evaluări

- Process System Value and Exergoeconomic Performance of Captive Power PlantsDe la EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsÎncă nu există evaluări

- Energy Management and Efficiency for the Process IndustriesDe la EverandEnergy Management and Efficiency for the Process IndustriesÎncă nu există evaluări

- EPP 2044 0116 - CTsDocument32 paginiEPP 2044 0116 - CTsGERMAN1979Încă nu există evaluări

- INFORMACION TECNICA Del Libro Electric Power Distribution de T.A. SHORT PDFDocument3 paginiINFORMACION TECNICA Del Libro Electric Power Distribution de T.A. SHORT PDFGERMAN1979Încă nu există evaluări

- Catalogue CFL00897 (1) Solenoides PDFDocument148 paginiCatalogue CFL00897 (1) Solenoides PDFGERMAN1979Încă nu există evaluări

- Application Note 1:: Submersible PumpDocument2 paginiApplication Note 1:: Submersible PumpGERMAN1979Încă nu există evaluări

- Electrical Submersible Drainage Pump: Pump Types Shaft SealsDocument1 paginăElectrical Submersible Drainage Pump: Pump Types Shaft SealsGERMAN1979Încă nu există evaluări

- Logo Verification ReportDocument1 paginăLogo Verification ReportAdrian AmzarÎncă nu există evaluări

- Features: 55 Series - General Purpose Relays 7 - 10 ADocument14 paginiFeatures: 55 Series - General Purpose Relays 7 - 10 AGERMAN1979Încă nu există evaluări

- AN-01 Submersible PDFDocument2 paginiAN-01 Submersible PDFGERMAN1979Încă nu există evaluări

- sf6 Leakage 1998 560 0008 1Document20 paginisf6 Leakage 1998 560 0008 1xuxiangguo4582Încă nu există evaluări

- PL2303 Windows Driver User Manual v1.10.0Document21 paginiPL2303 Windows Driver User Manual v1.10.0Adam Iglesia ÜÎncă nu există evaluări

- Cathodic ProtectionDocument22 paginiCathodic ProtectionFakhr-e-Alam100% (1)

- Flyer E10 HP PDFDocument4 paginiFlyer E10 HP PDFGERMAN1979Încă nu există evaluări

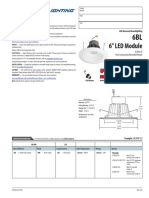

- 6bl LedDocument2 pagini6bl LedGERMAN1979Încă nu există evaluări

- Supresor Transitorios FamosaDocument14 paginiSupresor Transitorios FamosaGERMAN1979Încă nu există evaluări

- Features: 55 Series - General Purpose Relays 7 - 10 ADocument14 paginiFeatures: 55 Series - General Purpose Relays 7 - 10 AGERMAN1979Încă nu există evaluări

- Catalogue CFL00897 (1) SolenoidesDocument148 paginiCatalogue CFL00897 (1) SolenoidesGERMAN1979Încă nu există evaluări

- Link Belt RTC8040Document20 paginiLink Belt RTC8040German FavelaÎncă nu există evaluări

- Excalibur 9018-B3 MR: Typical Applications Key FeaturesDocument2 paginiExcalibur 9018-B3 MR: Typical Applications Key FeaturesGERMAN1979Încă nu există evaluări

- An Introduction To Cathodic Protection PDFDocument5 paginiAn Introduction To Cathodic Protection PDFGERMAN1979Încă nu există evaluări

- CG Spd240wDocument3 paginiCG Spd240wGERMAN1979Încă nu există evaluări

- Features: 55 Series - General Purpose Relays 7 - 10 ADocument14 paginiFeatures: 55 Series - General Purpose Relays 7 - 10 AGERMAN1979Încă nu există evaluări

- Electrical Submersible Drainage Pump: Pump Types Shaft SealsDocument1 paginăElectrical Submersible Drainage Pump: Pump Types Shaft SealsGERMAN1979Încă nu există evaluări

- RT875CDocument12 paginiRT875CMahmud MaherÎncă nu există evaluări

- Article - Benchmarking IntroDocument5 paginiArticle - Benchmarking Introkary290790Încă nu există evaluări

- WM PDFDocument51 paginiWM PDFKhaled KamelÎncă nu există evaluări

- B2B SaaS Metrics Benchmark 2023 REPORTDocument51 paginiB2B SaaS Metrics Benchmark 2023 REPORTstartupcommunity.top100% (1)

- LA Notes 1Document27 paginiLA Notes 1soksokanaÎncă nu există evaluări

- Plunkett Analytics Financial Benchmarks Report SampleDocument64 paginiPlunkett Analytics Financial Benchmarks Report SampleYeshwanth BabuÎncă nu există evaluări

- Human Capital Reporting - CIPD Sesson 7Document75 paginiHuman Capital Reporting - CIPD Sesson 7Swashq100% (1)

- Benchmarking Key to SuccessDocument2 paginiBenchmarking Key to SuccessSmile HouseÎncă nu există evaluări

- Improving Drilling Performance Through Systematic Analysis of Historical Data Case Study of A Canadian Field - SPE-87177-MSDocument8 paginiImproving Drilling Performance Through Systematic Analysis of Historical Data Case Study of A Canadian Field - SPE-87177-MSMohabÎncă nu există evaluări

- IVW Category Sourcing Strategy Guide For LGR V1 2 270109TAGDocument39 paginiIVW Category Sourcing Strategy Guide For LGR V1 2 270109TAGdani2611Încă nu există evaluări

- Warehouse Cost CalculationDocument4 paginiWarehouse Cost CalculationariningtyaskÎncă nu există evaluări

- Quality Function Deployment Article Ronald G. BayDocument16 paginiQuality Function Deployment Article Ronald G. BayKhubaib IftikharÎncă nu există evaluări

- LO3 Conduct Walk Through and Compare or Contrast Expected PerformanceDocument6 paginiLO3 Conduct Walk Through and Compare or Contrast Expected Performanceasnake bogaleÎncă nu există evaluări

- (Management and Industrial Engineering) J. Paulo Davim (Eds.) - Progress in Lean Manufacturing-Springer International Publishing (2018)Document134 pagini(Management and Industrial Engineering) J. Paulo Davim (Eds.) - Progress in Lean Manufacturing-Springer International Publishing (2018)Ismael Suarez100% (1)

- Spe 109555 PaDocument8 paginiSpe 109555 PaCarlos David ObandoÎncă nu există evaluări

- Handbook Asset ManagementDocument232 paginiHandbook Asset ManagementGilmer PatricioÎncă nu există evaluări

- Knowing When To Sell - Critical ReviewDocument3 paginiKnowing When To Sell - Critical ReviewRashmi RaniÎncă nu există evaluări

- CBSE School Quality Assessment and AssuranceDocument9 paginiCBSE School Quality Assessment and AssuranceMaxtron MoonÎncă nu există evaluări

- Benchmarking of Data For Power Quality EvaluationDocument7 paginiBenchmarking of Data For Power Quality EvaluationErickson AbiolÎncă nu există evaluări

- Office TPM ConceptsDocument9 paginiOffice TPM ConceptsNivedh Vijayakrishnan100% (1)

- Flexible Budgets, Direct-Cost Variances, and Management ControlDocument21 paginiFlexible Budgets, Direct-Cost Variances, and Management ControlUmar FarooqÎncă nu există evaluări

- McKinsey 2020 Asia Asset Management Survey - Brochure - 2020!10!15Document22 paginiMcKinsey 2020 Asia Asset Management Survey - Brochure - 2020!10!15New DiensÎncă nu există evaluări

- Lakshmi MittalDocument14 paginiLakshmi MittalArslan100% (1)

- Case Study On Product DissectionDocument6 paginiCase Study On Product Dissectionkary290790Încă nu există evaluări

- MGMT3057 04122018Document7 paginiMGMT3057 04122018Xhano M. WilliamsÎncă nu există evaluări

- Amit Kumar: Education: SummaryDocument2 paginiAmit Kumar: Education: SummarysugandhtÎncă nu există evaluări

- Sales Enablement Benchmark ReportDocument11 paginiSales Enablement Benchmark ReportDemand MetricÎncă nu există evaluări