Documente Academic

Documente Profesional

Documente Cultură

Model Qap Cable Tray

Încărcat de

veerendraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Model Qap Cable Tray

Încărcat de

veerendraDrepturi de autor:

Formate disponibile

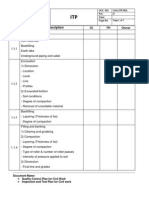

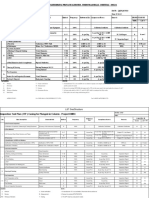

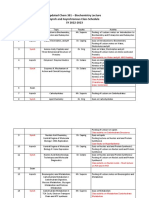

QUALITY ASSURANCE PLAN (MODEL)

PROJECT :

NAME OF

EQUIPMENT : Cable Tray

SR. NO. ITEM /COMPONENTS &

CHRACTERISTICS

A

Raw Material & Bought Out

Items.

1

(MS Sheet/Channel/Angle)

Chemical composition

a

Physical Properties

b

Surface Finish

c

Dimensions

d

2

Fasteners and Hardwares

Visual and Dimensional

a

CLIENT:

VENDOR :

NIT/P.O. REFERENCE :

NATURE OF

CHECKS

QUANTUM OF

CHECKS

REFERENCE

DOCUMENTS

ACCEPTANCE RECORD

NORMS

FORMAT

INSP. AGENCY

Perform Witness Verify

REMARKS

Chem.

Test

Visual

Measurement

Sampling Plan

-do-do-do-

Tech.Spec./ Appd.drg./IS:1079

-do-doTech.Spec./ Appd.drg./IS:1852

TC

TC

TC

TC

3/2

3/2

3/2

3/2

1

1

1

1

TC

TC

TC

TC

Visual &

Measurement

Measurement

-do-

Tech.Spec./ Appd.drg./IS:1367

TC

3/2

TC

-do-

-do-

TC

3/2

TC

Quantity of Zinc Deposit Over

Threaded Portion

B

1

Chem./Visual

Sampling plan

Tech.Spec./ Appd.drg./IS:2629

TC

3/2

TC

2

a)

b)

c)

In Process Inspection

Galvanishing

Galvanisation, Chemical

Composition of Zinc, Surface

Defects, Bath Temperature.

Galvanished Trays

Surface Defects

Uniformity of Zinc Coating

Thickness of Zinc Coating

Visual

Test

Measurement

Sampling Plan

-do-do-

-doTech.Spec./ Appd drg./IS:2633

Tech.Spec./ Appd drg.

TC

TC

TC

3/2

3/2

3/2

1

1

1

TC

TC

TC

d)

e)

Adhesion Test

Weight of Zinc Coating

Physical

Measurement

-do-do-

Tech.Spec./ Appd drg./IS:2629

Tech.Spec./ Appd drg./IS:6745

TC

TC

3/2

3/2

1

1

TC

TC

Visual

-doTech.Spec./ Appd drg.

TC

3/2

1

TC

3

Dicromating

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be filled. 1- will indicate CUSTOMER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

Signature

Signature & Seal

(VENDORS Q.C. DEPT. OR REPRESENTATIVE)

Page 154

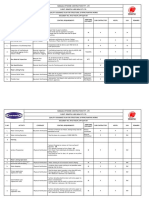

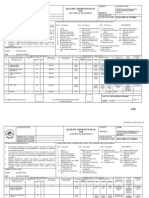

QUALITY ASSURANCE PLAN(MODEL)

PROJECT :

NAME OF

EQUIPMENT : Cable Tray

SR. NO. ITEM /COMPONENTS &

CHRACTERISTICS

C

1

2

3

4

5

6

7

8

Final Inspection

Dimension/ Finish of Trays &

Covers

Load Capacity

Surface defects / Black Spot

Uniformity of Zinc Coating

Weight of Zinc Coating

Check for Dicromating

Thickness of Zinc Coating

Adhesion Test

CLIENT:

VENDOR :

NIT/P.O. REFERENCE :

NATURE OF

CHECKS

Measurement

& Visual

Deflection Test

Visual

Test

Measurement

Visual

Measurement

Hammer Test

QUANTUM OF

CHECKS

REFERENCE

DOCUMENTS

ACCEPTANCE RECORD

NORMS

FORMAT

INSP. AGENCY

Perform Witness Verify

REMARKS

Sampling Plan

-do-

TC

3/2

TC

-do-do-do-do-do-do-do-

-do-doTech.Spec./ Appd drg./IS:2633

Tech.Spec./ Appd drg./IS:6745

Tech.Spec./ Appd drg./IS:2629

Tech.Spec./ Appd drg.

Tech.Spec./ Appd drg./IS:2629

TC

TC

TC

TC

TC

TC

TC

3/2

3/2

3/2

3/2

3/2

3/2

3/2

1

1

1

1

1

1

1

TC

TC

TC

TC

TC

TC

TC

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be filled. 1- will indicate CUSTOMER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

Signature

Signature & Seal

(VENDORS Q.C. DEPT. OR REPRESENTATIVE)

Page 155

S-ar putea să vă placă și

- Larsen & Toubro underground piping inspection planDocument4 paginiLarsen & Toubro underground piping inspection planBhavani PrasadÎncă nu există evaluări

- Itr Ew 01a - EngDocument2 paginiItr Ew 01a - Engwassim nasriÎncă nu există evaluări

- ITP For EarthingDocument18 paginiITP For EarthingBilibili weekly TOP 10 videos0% (1)

- Valve Actuator ChecklistDocument2 paginiValve Actuator Checklisthamoody_007Încă nu există evaluări

- Quality Assurance Plan for Structural FabricationDocument1 paginăQuality Assurance Plan for Structural FabricationproxywarÎncă nu există evaluări

- JX NIPPON Oil & Gas Low Voltage Cable ITRDocument2 paginiJX NIPPON Oil & Gas Low Voltage Cable ITRAmy100% (1)

- Painting Inspection ReportDocument1 paginăPainting Inspection Reportعبداللة العبداللةÎncă nu există evaluări

- L&T ECCD Inspection & Test Plan for Structural WorksDocument4 paginiL&T ECCD Inspection & Test Plan for Structural Worksmanu_gite100% (2)

- Rsae-Frm-227 Inspection Check List For Motor Solo RunDocument1 paginăRsae-Frm-227 Inspection Check List For Motor Solo RunkamilÎncă nu există evaluări

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 paginiRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksAjoy Prasad75% (4)

- Checklist For Cable Try Fabrication and EractionDocument2 paginiChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- Inspection Release Note for TD Power ProjectDocument1 paginăInspection Release Note for TD Power ProjectKarthik S67% (3)

- I&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Document16 paginiI&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Mohd Sami UddinÎncă nu există evaluări

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 paginăFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWÎncă nu există evaluări

- RAPID PROJECT REFINERY TANK FARM CABLE CHECKLISTDocument1 paginăRAPID PROJECT REFINERY TANK FARM CABLE CHECKLISTnayumÎncă nu există evaluări

- Advanced PharmacognosyDocument13 paginiAdvanced PharmacognosyLisa DamayantiÎncă nu există evaluări

- LV Panel ChecklistDocument1 paginăLV Panel ChecklistvaradharajanÎncă nu există evaluări

- Inspection and Test Plan For Battery Charger PDFDocument5 paginiInspection and Test Plan For Battery Charger PDFkrit_kasemÎncă nu există evaluări

- Stage Wise Inspection ReportDocument2 paginiStage Wise Inspection ReportKarthi Keyan100% (2)

- Plant Location Company Doc. No. NADocument8 paginiPlant Location Company Doc. No. NAsivaÎncă nu există evaluări

- ItpDocument7 paginiItpJose Sherin100% (1)

- QAP For Ducting V1 R0Document1 paginăQAP For Ducting V1 R0Hema NandhÎncă nu există evaluări

- E&I Quality PlanDocument9 paginiE&I Quality PlanJithuRajÎncă nu există evaluări

- Dayang Enterprise Sdn. BHD.: Inspection and Test Plan (Instrument)Document2 paginiDayang Enterprise Sdn. BHD.: Inspection and Test Plan (Instrument)AmyÎncă nu există evaluări

- ITP - Control PanelDocument2 paginiITP - Control PanelHoras Canman Sianipar100% (1)

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 paginiInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoÎncă nu există evaluări

- Quality Assurance Plan For ErectionDocument8 paginiQuality Assurance Plan For Erectionsushant_jhawerÎncă nu există evaluări

- Ripening of CheeseDocument18 paginiRipening of CheeseHASVRDÎncă nu există evaluări

- QAP - LT Panel PDFDocument8 paginiQAP - LT Panel PDFAkshay Ajay100% (2)

- Installation Checklist for Flow Meter ReportDocument1 paginăInstallation Checklist for Flow Meter ReportZulfequar R. Ali Khan100% (2)

- Visual Inspection Report FormDocument2 paginiVisual Inspection Report Formrosid_alhusna60% (5)

- Standard QAP - 4MWDocument2 paginiStandard QAP - 4MWSAEL SOLAR100% (2)

- Sludge Dewatering PDFDocument36 paginiSludge Dewatering PDFPaul Maposa100% (2)

- Sika Solutions For Concrete BridgesDocument17 paginiSika Solutions For Concrete BridgescaapromoÎncă nu există evaluări

- Daily Paint ReportDocument2 paginiDaily Paint Reportcarey stewart100% (3)

- Al Karamah School LV Panel ReplacementDocument35 paginiAl Karamah School LV Panel ReplacementAnandu AshokanÎncă nu există evaluări

- Checklist For Erection of USSDocument3 paginiChecklist For Erection of USSsasikumarÎncă nu există evaluări

- Revised IMIR ReportDocument2 paginiRevised IMIR ReportSimbu ArasanÎncă nu există evaluări

- 1.0 Cable Tray Technical Data SheetDocument2 pagini1.0 Cable Tray Technical Data SheetRahul100% (1)

- Item description and quality checks for 11kV VCB panelDocument5 paginiItem description and quality checks for 11kV VCB panelARUNKUMARANNANBHEDAÎncă nu există evaluări

- Itp For InsulationDocument14 paginiItp For InsulationHytham El-NoubyÎncă nu există evaluări

- Tes H 107 01 R1 Painting PDFDocument58 paginiTes H 107 01 R1 Painting PDFUtkucan KILIÇÎncă nu există evaluări

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 paginiDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MP100% (1)

- Pay Revision Circular of Executives W.E.F. 01.01.2017Document10 paginiPay Revision Circular of Executives W.E.F. 01.01.2017RJ Laxmikaant100% (1)

- Low Voltage Cable - Itr ADocument2 paginiLow Voltage Cable - Itr AHaider HassanÎncă nu există evaluări

- L&T GeoStructure casing inspection planDocument2 paginiL&T GeoStructure casing inspection plansanil50% (2)

- Welder Monitoring SheetDocument1 paginăWelder Monitoring SheetQC apollohx100% (1)

- KP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection (CP)Document7 paginiKP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection (CP)Utku Can Kılıç100% (2)

- Project On Fuel Cells: A Concise Look at Fuel Cell TechnologyDocument12 paginiProject On Fuel Cells: A Concise Look at Fuel Cell TechnologySagar RastogiÎncă nu există evaluări

- MDCC Format - PGCILDocument1 paginăMDCC Format - PGCILnamanagrawal2590100% (1)

- Membrane EngDocument5 paginiMembrane EngMeirbekÎncă nu există evaluări

- QAP For Painting WorksDocument3 paginiQAP For Painting WorksRanjan KumarÎncă nu există evaluări

- ITP Grounding SystemDocument2 paginiITP Grounding SystemGALIH WIBISONOÎncă nu există evaluări

- 0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)Document2 pagini0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)ResearcherÎncă nu există evaluări

- TABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedDocument3 paginiTABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedKennedy VasconezÎncă nu există evaluări

- Contents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) ProjectDocument3 paginiContents:: Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Projectpunitg_2Încă nu există evaluări

- CMTDocument284 paginiCMTAaron R. AllenÎncă nu există evaluări

- Section 2 QAP, Cable TrayDocument3 paginiSection 2 QAP, Cable TrayveerendraÎncă nu există evaluări

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 paginiFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- QAP Plan Elect.Document2 paginiQAP Plan Elect.insap_dineshÎncă nu există evaluări

- Steel Stack Mfg RecordDocument14 paginiSteel Stack Mfg RecordManuel LombarderoÎncă nu există evaluări

- Inspection & Test Plan for Chilled Water Expansion TanksDocument1 paginăInspection & Test Plan for Chilled Water Expansion TanksvictorÎncă nu există evaluări

- Cold Test Report 3Document1 paginăCold Test Report 3Venkitesh PG100% (1)

- 417-DS-IMA-6144B (Junction Box Data Sheet)Document2 pagini417-DS-IMA-6144B (Junction Box Data Sheet)mithunceaÎncă nu există evaluări

- Calibration Certificate For Digital MultimeterDocument12 paginiCalibration Certificate For Digital MultimeterVallik TadÎncă nu există evaluări

- ITP For Flow MeterDocument4 paginiITP For Flow MeterSayee KrishnanÎncă nu există evaluări

- TR001 Control Cable CFA901-Continuity TestDocument4 paginiTR001 Control Cable CFA901-Continuity TestCharlie MendozaÎncă nu există evaluări

- Saudi Aramco inspection plan for medium voltage cablesDocument3 paginiSaudi Aramco inspection plan for medium voltage cablesHatemS.MashaGbehÎncă nu există evaluări

- Winter Holiday Assignment 7th 2023-24Document1 paginăWinter Holiday Assignment 7th 2023-24veerendraÎncă nu există evaluări

- Biodata PallaviDocument2 paginiBiodata PallaviveerendraÎncă nu există evaluări

- 0 - Abhishek BiodataDocument3 pagini0 - Abhishek BiodataveerendraÎncă nu există evaluări

- Circular Reg. Sunday Working On 31.12.2023Document1 paginăCircular Reg. Sunday Working On 31.12.2023veerendraÎncă nu există evaluări

- Lead Sheathed Cable CatalogueDocument1 paginăLead Sheathed Cable CatalogueveerendraÎncă nu există evaluări

- Class Vii Revision Syllabus-1Document2 paginiClass Vii Revision Syllabus-1veerendraÎncă nu există evaluări

- Class 4 Winter BreakDocument4 paginiClass 4 Winter BreakveerendraÎncă nu există evaluări

- Interview Schedule GM To ED 2023 - 230726 - 154420-1Document5 paginiInterview Schedule GM To ED 2023 - 230726 - 154420-1veerendraÎncă nu există evaluări

- 1CX95 Ayy FRLSDocument6 pagini1CX95 Ayy FRLSveerendraÎncă nu există evaluări

- MOMPublishPdf20230725182144 - 230725 193209Document1 paginăMOMPublishPdf20230725182144 - 230725 193209veerendraÎncă nu există evaluări

- 1000A Cu Cert - IT 15.002Document32 pagini1000A Cu Cert - IT 15.002veerendraÎncă nu există evaluări

- BC 49399 Room Layout For 108 Yhp39 (2 Sets)Document1 paginăBC 49399 Room Layout For 108 Yhp39 (2 Sets)veerendraÎncă nu există evaluări

- fRONT SHEET OGADocument1 paginăfRONT SHEET OGAveerendraÎncă nu există evaluări

- Quality Assurance Plan Cable Tray & AccessoriesDocument1 paginăQuality Assurance Plan Cable Tray & AccessoriesveerendraÎncă nu există evaluări

- QAPDocument2 paginiQAPveerendraÎncă nu există evaluări

- Type Test Procedure-SignedDocument2 paginiType Test Procedure-SignedveerendraÎncă nu există evaluări

- BSNL Mobile Bill DetailsDocument1 paginăBSNL Mobile Bill DetailsveerendraÎncă nu există evaluări

- Data Sheet - Cable Tray & Support AccessoriesDocument3 paginiData Sheet - Cable Tray & Support AccessoriesveerendraÎncă nu există evaluări

- Yhp39 220Document1 paginăYhp39 220veerendraÎncă nu există evaluări

- COMPANY PROFILE AsianDocument2 paginiCOMPANY PROFILE AsianveerendraÎncă nu există evaluări

- Test Certificate: M/S Chemtech MarketingDocument2 paginiTest Certificate: M/S Chemtech MarketingveerendraÎncă nu există evaluări

- Print ReceiptDocument1 paginăPrint ReceiptAnonymous 0BYsFuVÎncă nu există evaluări

- Drawing Format - Silt Flushing BoardDocument1 paginăDrawing Format - Silt Flushing BoardveerendraÎncă nu există evaluări

- IFB Part-3-Arun-IiiDocument4 paginiIFB Part-3-Arun-IiiveerendraÎncă nu există evaluări

- Invitation For Bid (Ifb) : SJVN LTDDocument4 paginiInvitation For Bid (Ifb) : SJVN LTDveerendraÎncă nu există evaluări

- IFB Part-2-Arun-IiiDocument4 paginiIFB Part-2-Arun-IiiveerendraÎncă nu există evaluări

- Print ReceiptDocument1 paginăPrint ReceiptAnonymous 0BYsFuVÎncă nu există evaluări

- BSNL receipt for payment of bills and demand notesDocument1 paginăBSNL receipt for payment of bills and demand notesvishu_mmmecÎncă nu există evaluări

- Print ReceiptDocument1 paginăPrint ReceiptAnonymous 0BYsFuVÎncă nu există evaluări

- Springwire Xinhua 2006Document10 paginiSpringwire Xinhua 2006teban09Încă nu există evaluări

- Experiment 2: Brinell Hardness TestDocument5 paginiExperiment 2: Brinell Hardness TestseifÎncă nu există evaluări

- 2D Transient Heat Transfer of Steel IngotDocument15 pagini2D Transient Heat Transfer of Steel IngotAnonymous sUbNSWmQÎncă nu există evaluări

- GATE-Architecture Sample QuestionsDocument6 paginiGATE-Architecture Sample QuestionsCharan ReddyÎncă nu există evaluări

- Xanthan Gum-USPDocument2 paginiXanthan Gum-USPLaboratorium FarmasiÎncă nu există evaluări

- Heating Element ArticleDocument10 paginiHeating Element ArticleFrea Kent-Dazze D'DrughiÎncă nu există evaluări

- S1 2016 330961 BibliographyDocument6 paginiS1 2016 330961 BibliographyVelda KartikaswastiÎncă nu există evaluări

- Product Information Sheet: Alloy Cusn12Document1 paginăProduct Information Sheet: Alloy Cusn12Hawraa AlbahadlyÎncă nu există evaluări

- SY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchDocument3 paginiSY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchLYKA ANTONETTE ABREGANAÎncă nu există evaluări

- Imp Questions For Unit-1Document12 paginiImp Questions For Unit-1aravelli abhinavÎncă nu există evaluări

- Chemical Composition of A Fountain Pen InkDocument4 paginiChemical Composition of A Fountain Pen InkmynamecoolÎncă nu există evaluări

- Material TechnologyDocument46 paginiMaterial TechnologyVarunÎncă nu există evaluări

- ThermodynamicsDocument12 paginiThermodynamicsWasif RazzaqÎncă nu există evaluări

- Density Calculations Worksheet IDocument2 paginiDensity Calculations Worksheet Iapi-218999959Încă nu există evaluări

- Chemical Reaction Lab ReportDocument14 paginiChemical Reaction Lab ReportBùi Nhật MaiÎncă nu există evaluări

- Puresilk Salt ChlorinatorDocument10 paginiPuresilk Salt Chlorinatornike_y2kÎncă nu există evaluări

- Universitas Ahmad Dahlan - JellyDocument15 paginiUniversitas Ahmad Dahlan - JellyMaqfirotul LailyÎncă nu există evaluări

- Chapter 2-The Column in GCDocument92 paginiChapter 2-The Column in GCkhanhvan2105Încă nu există evaluări

- OVERVIEW (4 Points) : CH116 General and Organic Principles LabDocument4 paginiOVERVIEW (4 Points) : CH116 General and Organic Principles Labapi-557329548Încă nu există evaluări

- Test Report E-Liquid: 1 Sample InformationDocument10 paginiTest Report E-Liquid: 1 Sample InformationVangel PetrovÎncă nu există evaluări

- Backup Rings Respaldo de OringsDocument8 paginiBackup Rings Respaldo de OringsRPINILLA (EICO S.A.)Încă nu există evaluări

- Cambridge IGCSE (9-1) : PHYSICS 0972/41Document16 paginiCambridge IGCSE (9-1) : PHYSICS 0972/41dowanahamidÎncă nu există evaluări

- Food Process Engineering Lab 3. BOILER OPERATIONDocument22 paginiFood Process Engineering Lab 3. BOILER OPERATIONMuhyiddin Noor AfandiÎncă nu există evaluări