Documente Academic

Documente Profesional

Documente Cultură

Bucket Elevator Datasheet en

Încărcat de

peymanemanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bucket Elevator Datasheet en

Încărcat de

peymanemanDrepturi de autor:

Formate disponibile

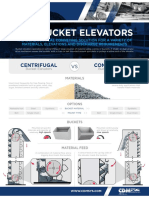

Bucket Elevator

Selection Guide

Bucket Elevator Selection Guide

Bucket Elevator

Selection Guide

Bucket Elevators are ideal for elevating a

variety of bulk materials economically,

efficiently and reliably. The two main

type of Bucket Elevators are Centrifugal

type and Continuous type.

Centrifugal Bucket Elevators are extremely suitable for handling fine, free flowing

materials. They have Lower feed point,

simpler loading and lesser no. of buckets

compared to continuous type. Buckets

are on chain or belt and travel at high

speeds to effect discharge by centrifugal

forces as they pass around the head pulley. The buckets are mounted at intervals

on a chain belt.

The buckets are mounted continuously on

the normally friction surface belts. Continuous type steel buckets are used leaving minimum clearance between the

buckets. Drive is through shaft mounted

gear reducer with built in back stop or

through geared motor with chain drive.

The most suitable bucket elevators for

your application can be find by using

material selection table.

Continuous Bucket elevators have buckets mounted continuously on chain or

belt. These elevators are suitable for sluggish, aerated and friable material or material with larger % of lumps. Loading of

the buckets is through loading leg and

discharged over the face of the preceding

bucket while passing around the head

wheel.

Bucket Elevator Selection Guide

Material

Alfalfa Meal

Almonds, broken

Almonds, whole

Alum, ne

Alum, lumpy

Alumina

Aluminum chips

Aluminum hydrate

Aluminum ore, crushed (3" minus)

Aluminum oxide

Aluminum silicate

Aluminum sulphate

Ammonium chloride, crystalline

Ammonium nitrate

Ammonium sulphate, granular

Ashes (dry coal 3" minus)

Asphalt, crushed (1/2" minus)

Bakelite, powdered (similar products)

Baking powder

Barite

Barley

Bauxite, crushed (3" minus)

Beans, dry navy

Beans, whole castor

Bentonite (100 mesh minus)

Bentonite, crude

Bone meal

Bones, crushed (1/2" minus)

Bones, granulated or ground (1/8" miBorax, ne

Borax, screenings (1/2" minus)

Bran

Brewers grain, spent dry

Brewers grain, spent wet

Calcium oxide

Carbon black powder, channel

Carbon black powder, furnace

Carbon black, pelletized

Carborundum (3" minus)

Cast iron borings

Density (kg/lit)

Min

Max

0 27

0 45

0 45

0 72

08

08

0 11

0 29

12

1 12

0 78

0 86

0 72

0 72

0 72

0 56

0 72

0 56

0 64

2 88

0 61

12

0 58

0 77

0 56

08

0 54

08

0 88

0 72

0 88

0 26

0 88

04

0 96

0 32

0 06

0 06

16

2 08

0 27

0 48

0 48

08

0 96

1 04

0 24

0 29

1 36

1 92

0 78

0 86

0 83

0 72

0 93

0 64

0 72

0 72

0 88

2 88

0 61

1 36

0 58

0 77

0 64

0 96

0 64

08

0 96

0 88

0 96

0 32

0 96

0 48

1 04

04

0 11

0 11

16

32

Centrifugal

Continuous Discharge

Consult

100 200 1400 700 800 1000 1100 1400 PAXAA

Bucket Elevator Selection Guide

Material

Cement clinker

Cement, portland

Cement, portland aerated

Chalk, lumpy

Chalk, pulverized (100 mesh minus)

Charcoal

Cinders, blast furnace

Cinders, coal

Clover seed

Coal, anthracite sized

Coal, anthracite, river coal & culm

Coal, bituminous, mined 50 mesh minus

Coal, bituminous, mined, run of mine

Coal, bituminous, mined, sized, over 1/2"

Coal, bituminous, mined, slack, 1/2" minus

Coal, bituminous, mined, stripping, unCocoa beans

Coee, green bean

Coee, roasted bean

Coke breeze, 1/4" minus

Coke, loose

Coke, petroleum, calcined

Copra

Copra Cake, groud

Copra Cake, lumpy

Copra meal

Cork, ne ground

Cork, granulated

Corn germs

Corn grits

Corn sugar

Corn, cracked

Corn, seed

Corn, shelled

Cornmeal

Cottonseed hulls

Cottonseed meal

Cottonseed meats

Cottonseed, cake, lumpy

Cottonseed, dry delinted

Density (kg/lit)

Min

Max

1 51

0 96

12

12

1 04

0 29

0 64

0 91

0 77

0 88

0 88

08

0 69

0 72

0 72

08

0 48

0 51

0 35

0 37

0 56

04

0 35

04

0 64

0 64

0 19

0 19

0 72

0 72

0 72

0 34

0 64

05

0 61

0 56

0 29

0 64

0 19

0 56

1 51

12

1 52

1 36

12

04

0 64

0 91

0 77

0 96

0 96

0 86

08

0 88

0 88

0 96

0 64

0 51

0 42

0 56

0 72

0 56

0 35

0 48

0 72

0 72

0 24

0 24

08

0 72

0 72

0 34

0 72

05

0 64

0 56

04

0 72

0 19

0 64

Continuous Discharge Consult

100 200 1400 700 800 1000 1100 PAXAA

Centrifugal

B

B

B

B

B

Bucket Elevator Selection Guide

Material

Cottonseed, dry with lint

Cracklings, crushed, 3" minus

Cullet

Dolomite, lumpy

Ebonite, crushed 1/2" minus

Feldspar, ground 1/2" minus

Feldspar, powdered 200 mesh

Flaxseed cake, expeller

Flaxseed meal

Flour, wheat

Flourspar, 1/2" screenings

Flue dust, boiler house, dry

Fuller's Earth, burnt, oil lter

Fuller's Earth, dry

Fuller's Earth, oily

Fuller's Earth, raw, oil lter

Glass batch

Glue, ground, 1/8" minus

Glue, pearl

Grains, distillery, spent dry

Granite, 1/2" screenings

Grass seed

Gravel, screened

Gypsum 1/2" screeninqs

Gypsum, 1 1/2" to 3" lumps

Gypsum, dust, aerated

Gypsum, dust, non-aerated

Hops, spent, dry

Hops, spent, wet

Ice, crushed

Ilmenite ore

Lignite, air dried

Lime, ground, 1/8" minus

Lime, hydrated, 1/8" minus

Lime, hydrated, pulverized

Lime, pebble

Limestone, agricultural, 1/8" minus

Limestone, crushed

Limestone, dust

Linseed meal

Density (kg/lit)

Min

Max

0 64

1 28

0 64

1 44

1 04

1 12

16

0 77

04

0 56

0 56

1 36

0 48

0 96

0 64

0 56

1 28

0 64

0 64

0 48

1 28

0 16

1 44

1 49

0 96

1 12

1 12

0 56

08

0 56

2 24

0 72

0 96

0 64

0 85

0 51

1 09

1 36

1 28

04

0 64

1 92

08

16

1 12

1 36

16

08

04

0 64

0 64

1 68

0 56

1 04

0 64

0 64

16

0 64

0 64

0 48

1 44

0 19

16

1 49

1 12

1 28

1 28

0 56

0 88

0 72

2 56

0 88

1 04

0 64

09

0 64

1 09

1 44

1 36

04

Centrifugal

Continuous Discharge Consult

100 200 1400 700 800 1000 1100 PAXAA

B

B

x2

x2

B

B

B

B

B

Bucket Elevator Selection Guide

Material

Malt meal

Malt, dry ground, 1/8" minus

Malt, dry, whole

Malt, wet or green

Marble, crushed, 1/2" minus

Meat Scrap

Muriate of potash

Mustard seed

Oats, rolled

Oxalic acid crystals

Peanuts, shelled

Peas, dried

Phosphate rock, broken, dry

Phosphate rock, pulverized

Phosphate, acid fertilizer

Phosphate, triple super

Pumice, ground, 1/8" minus

Rice bran

Rice grits

Roo nq granules

Rubber, ground

Salt, cake, dry, coarse

Salt, cake, dry, pulverized

Salt, dry, coarse

Salt, dry, ne

Sand, damp bank

Sand, dry bank

Sand, dry silica**

Sand, foundry, prepared

Sand, foundry, shakeout

Sawdust

Shale, crushed

Slag, blast furnace, crushed

Slag, blast furnace, granulated, dry

Slag, blast furnace, granulated, wet

Slate, crushed, 1/2" minus

Slate, dust

Soap beads or granules

Soap akes

Soda ash, heavy

Density (kg/lit)

Min

Max

0 35

0 43

0 96

0 58

0 54

08

1 23

0 72

03

0 96

0 72

0 56

12

0 96

08

0 96

0 64

0 26

0 67

1 36

1 04

1 12

0 64

1 36

0 96

1 76

1 44

1 44

1 12

1 44

0 16

1 36

1 28

0 96

1 44

1 28

1 12

0 24

0 08

0 32

0 35

0 48

1 04

0 64

0 64

0 88

1 23

0 72

03

0 96

08

0 72

1 36

0 96

0 88

0 96

0 72

0 32

0 72

1 52

1 12

1 28

0 88

1 36

1 36

2 08

1 76

16

1 44

16

0 21

1 44

1 44

1 04

16

1 44

1 28

04

0 24

0 56

Centrifugal

Continuous Discharge Consult

100 200 1400 700 800 1000 1100 PAXAA

B

B

B

B

B

B

B

B

Bucket Elevator Selection Guide

Material

Soda ash, light

Soybean cake, over 1/2"

Soybean akes, raw

Soybean meal, cold

Soybean meal, hot

Soybeans, cracked

Steel chips, crushed

Stone, crushed

Sugar beet, pulp, dry

Sugar beet, pulp, wet

Sugar, granulated

Sugar, powdered

Sugar, raw, cane

Tanbark, ground

Timothy seed

Wheat germ

Wheat, cracked

Wood chips

Wood shavings

Zinc concentrate

Zinc dust

Zinc ore, crushed

Zinc ore, roasted

Zinc oxide, heavy

Zinc oxide, light

B

LA

X2

Density (kg/lit)

Centrifugal

Continuous Discharge Consult

Min

Max 100 200 1400 700 800 1000 1100 PAXAA

0.88

1.04

0.48

0.64

0.64

0.69

0.32

0.42

0.64

0.64

0.64

0.64

1.6

2.4

1.44

1.6

LA

0.8

0.96

LA

0.8

0.88

0.19

0.24

0.88

1.04

0.88

1.04

0.88

0.88

0.58

0.58

0.64

0.72

0.45

0.45

B

0.16

0.48

B

0.13

0.24

3.2

3.2

1.2

1.28

2.56

2.56

1.76

1.76

0.48

0.56

0.16

0.24

Belt Type Elevator

Loading leg

Select elevator with double the required capacity

S-ar putea să vă placă și

- Corbel Design Using Strut and Tie Method and According To AS3600Document3 paginiCorbel Design Using Strut and Tie Method and According To AS3600Jay Ryan SantosÎncă nu există evaluări

- Dozer User GuideDocument123 paginiDozer User GuideJileni BouguimaÎncă nu există evaluări

- Bucket Elevator CatalogDocument20 paginiBucket Elevator CatalogLeonardo De la CruzÎncă nu există evaluări

- SC-2103681-ME1a - Manual 660.YTC. (1x6.5kW) .6 M1546-51G K460-4522-12FO-FC-R M9PG-OT-WP-LCBT + DG90-DB120 + 2xDG45 4xM1Document61 paginiSC-2103681-ME1a - Manual 660.YTC. (1x6.5kW) .6 M1546-51G K460-4522-12FO-FC-R M9PG-OT-WP-LCBT + DG90-DB120 + 2xDG45 4xM1kiên phạm trungÎncă nu există evaluări

- 638050Document3 pagini638050Alex CentenoÎncă nu există evaluări

- Huber - Folleto - Deshidratador - RoS 3QDocument4 paginiHuber - Folleto - Deshidratador - RoS 3Qenzo_kcrs2787109Încă nu există evaluări

- HEMM Maintenance - ConceptDocument12 paginiHEMM Maintenance - ConceptDinesh Kumar MaliÎncă nu există evaluări

- Standard Paint Specification Rev 1-2-24!09!14Document3 paginiStandard Paint Specification Rev 1-2-24!09!14Puji RahmawatiÎncă nu există evaluări

- FLS Apron Feeder BrochureDocument4 paginiFLS Apron Feeder BrochureMilan SjausÎncă nu există evaluări

- PROK Product CatalogueDocument32 paginiPROK Product CatalogueDiego AndradeÎncă nu există evaluări

- 2009 IPCC Morrison and LourelDocument13 pagini2009 IPCC Morrison and LourelArnold Chavez AtalayaÎncă nu există evaluări

- CDM Bucket Elevators: Centrifugal ContinuousDocument2 paginiCDM Bucket Elevators: Centrifugal ContinuousOcta IrawanÎncă nu există evaluări

- Bucket Elevators 150520Document16 paginiBucket Elevators 150520RICARDOALEXBORGESÎncă nu există evaluări

- Sis 2.0 PDFDocument4 paginiSis 2.0 PDFDahi Med100% (1)

- AUMUND Apron FeedersDocument12 paginiAUMUND Apron Feederschannakeshava pandurangaÎncă nu există evaluări

- Synergy Shuttle ConveyorDocument5 paginiSynergy Shuttle ConveyorTamal Tanu RoyÎncă nu există evaluări

- Siwertell Ship Unloaders - Original - 33001 PDFDocument6 paginiSiwertell Ship Unloaders - Original - 33001 PDFHarish KumarÎncă nu există evaluări

- Spiral Classifier English VersioinDocument5 paginiSpiral Classifier English VersioinRogelio Israel LedesmaÎncă nu există evaluări

- Root Cause Analysis Presentation (RCA)Document21 paginiRoot Cause Analysis Presentation (RCA)beriÎncă nu există evaluări

- Operation and Maintenance Manual: Belt DiverterDocument38 paginiOperation and Maintenance Manual: Belt DiverterTinTunNaingÎncă nu există evaluări

- Bucket ElevatorDocument9 paginiBucket Elevatorkoripella_prasadÎncă nu există evaluări

- Van Aarsen Mix Datasheet MultiMix Twin Shaft Paddle Mixer V001Document2 paginiVan Aarsen Mix Datasheet MultiMix Twin Shaft Paddle Mixer V001TienQuan DoÎncă nu există evaluări

- Iso 3684 1990Document8 paginiIso 3684 1990joaquin fuentealba moralesÎncă nu există evaluări

- HFB Feeder Breaker - HAZEMAG MiningDocument4 paginiHFB Feeder Breaker - HAZEMAG MiningAndi Muhammad AkmalÎncă nu există evaluări

- ENG - Electric Motor Series of HGFDocument66 paginiENG - Electric Motor Series of HGFsaga2000cnÎncă nu există evaluări

- Ido Tank CilDocument40 paginiIdo Tank CilSafrin SangiaÎncă nu există evaluări

- Drum ChipperDocument28 paginiDrum ChipperchienhamthepÎncă nu există evaluări

- Conveyor Chain Installation, Maintenance, & Best Practices - 001Document19 paginiConveyor Chain Installation, Maintenance, & Best Practices - 001num fistismÎncă nu există evaluări

- R SeriesComperision PDFDocument1 paginăR SeriesComperision PDFSarojini VeeraraghavanÎncă nu există evaluări

- Catalogo Control ContaminantesDocument132 paginiCatalogo Control ContaminantesJose Jaramillo50% (2)

- Brochure PV-311 High Res A4 Tcm835-3508041Document4 paginiBrochure PV-311 High Res A4 Tcm835-3508041David SantoÎncă nu există evaluări

- Bucket Elevator: Owner/Operator's Manual and Installation/Maintenance GuideDocument130 paginiBucket Elevator: Owner/Operator's Manual and Installation/Maintenance Guideimvp5640Încă nu există evaluări

- 02 SCREENS Syntron Vibrating Screens PDFDocument36 pagini02 SCREENS Syntron Vibrating Screens PDFPhanHatham100% (1)

- Ball MillDocument10 paginiBall MillLuthfanÎncă nu există evaluări

- Load and Haul Fleet Selection Based On Fixed Plant ProductionDocument25 paginiLoad and Haul Fleet Selection Based On Fixed Plant Productionchalsea100% (1)

- Allmineral SIMADocument39 paginiAllmineral SIMAkselvan_1Încă nu există evaluări

- Repor T JobDocument2 paginiRepor T JobLiebherr67% (3)

- Apron Feeder DScrusherDocument7 paginiApron Feeder DScrusherRyan R CunninghamÎncă nu există evaluări

- Continuous Mining Systems: Industrial SolutionsDocument3 paginiContinuous Mining Systems: Industrial SolutionsPero PericÎncă nu există evaluări

- Flyer Sewage Sludge DryingDocument6 paginiFlyer Sewage Sludge Dryingkosmc123Încă nu există evaluări

- 11 - Transport Cross-Beam For Roll UnitsDocument43 pagini11 - Transport Cross-Beam For Roll UnitsCHRISTIAN ROJAS VALENZUELAÎncă nu există evaluări

- Feed Material Guide For POLYCOM: Machine Manual en-PM - MFU.001.BDocument39 paginiFeed Material Guide For POLYCOM: Machine Manual en-PM - MFU.001.BYinder Vega OsorioÎncă nu există evaluări

- Multitrans UkDocument4 paginiMultitrans UknmaafonsoÎncă nu există evaluări

- Predicting The Future - Trends For Predictive Maintenance: Dr. Dirk WoldtDocument24 paginiPredicting The Future - Trends For Predictive Maintenance: Dr. Dirk WoldtBülent BulutÎncă nu există evaluări

- GSI Bucket Elevator AssemblyDocument38 paginiGSI Bucket Elevator AssemblyElias ArizaÎncă nu există evaluări

- IPCC ConceptDocument24 paginiIPCC ConceptTapadev DasÎncă nu există evaluări

- IB10000 F GBCM1214700026 ENGBrochure BWFAWFmailDocument26 paginiIB10000 F GBCM1214700026 ENGBrochure BWFAWFmailkilowatito2004Încă nu există evaluări

- Blasthole Drill Technical Training CatalogDocument30 paginiBlasthole Drill Technical Training CatalogCAT MINING SHOVEL100% (1)

- Catallogo Pala Cable 7495 HFDocument4 paginiCatallogo Pala Cable 7495 HFmarceloÎncă nu există evaluări

- Beumer Central Chain Bucket ElevatorDocument8 paginiBeumer Central Chain Bucket ElevatorIrshad HussainÎncă nu există evaluări

- DIN 22.102 - Gumene Transportne TrakeDocument4 paginiDIN 22.102 - Gumene Transportne TrakeThomas WilliamsÎncă nu există evaluări

- Failure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFDocument9 paginiFailure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFCezar PajaresÎncă nu există evaluări

- MCS-Modular Conveyor System PDFDocument87 paginiMCS-Modular Conveyor System PDFJuan Manuel LaraÎncă nu există evaluări

- Cascade Air Separator KVT enDocument6 paginiCascade Air Separator KVT enkamjulajayÎncă nu există evaluări

- 22-23 - 103727 - Operating ManualDocument246 pagini22-23 - 103727 - Operating Manualtc_sundarÎncă nu există evaluări

- Why Skewing Is Not Beneficial For Your HPGRDocument8 paginiWhy Skewing Is Not Beneficial For Your HPGRAbe ArdiÎncă nu există evaluări

- Compact Bucket Wheel ExcavatorsDocument8 paginiCompact Bucket Wheel ExcavatorsSyed TauqeerÎncă nu există evaluări

- Bulk Density TableDocument6 paginiBulk Density Tabletinz_3Încă nu există evaluări

- Tapco Catalog 09 p88-94 PDFDocument7 paginiTapco Catalog 09 p88-94 PDFJyotibaraje JadhavÎncă nu există evaluări

- Mass, Weight, Density or Specific Gravity of Bulk Materials PDFDocument8 paginiMass, Weight, Density or Specific Gravity of Bulk Materials PDFImam MaulanaÎncă nu există evaluări

- FST CatDocument49 paginiFST CatDaniel NealÎncă nu există evaluări

- Chapter 16 Rice MillingDocument85 paginiChapter 16 Rice MillingRyza MartizanoÎncă nu există evaluări

- TL-SG1008D V6 QigDocument2 paginiTL-SG1008D V6 QigpeymanemanÎncă nu există evaluări

- Errata Listing - 28th-Edition 42115Document5 paginiErrata Listing - 28th-Edition 42115Gabo FernándezÎncă nu există evaluări

- PAXAA Cyclone Product Catalog enDocument6 paginiPAXAA Cyclone Product Catalog enpeymanemanÎncă nu există evaluări

- Bulletin A 610Document1 paginăBulletin A 610peymanemanÎncă nu există evaluări

- PAXAA-Catalog-Centrifugal Elevator-En PDFDocument10 paginiPAXAA-Catalog-Centrifugal Elevator-En PDFpeymanemanÎncă nu există evaluări

- Centrifugal Elevator Catalog enDocument10 paginiCentrifugal Elevator Catalog enpeymanemanÎncă nu există evaluări

- Bucket Elevator Datasheet FaDocument8 paginiBucket Elevator Datasheet FapeymanemanÎncă nu există evaluări

- Speciminum DataDocument1.496 paginiSpeciminum DataMu SherifÎncă nu există evaluări

- Topic 1 - Fluid PropertiesDocument41 paginiTopic 1 - Fluid PropertiesFattihiEkhmalÎncă nu există evaluări

- Metals and NonMetals Class 10 Notes Science ChemistryDocument4 paginiMetals and NonMetals Class 10 Notes Science ChemistrygooodeÎncă nu există evaluări

- Jis G3101-2010 en PDFDocument14 paginiJis G3101-2010 en PDFabdulloh_99Încă nu există evaluări

- Instruction Manual (METAREFRE-O)Document4 paginiInstruction Manual (METAREFRE-O)dhanamvijayakumarÎncă nu există evaluări

- Form-I: "This Is Computer Generated Document From OCMMS by HPSPCB"Document5 paginiForm-I: "This Is Computer Generated Document From OCMMS by HPSPCB"GREEN LEAFÎncă nu există evaluări

- Interaction DiagramDocument27 paginiInteraction DiagramAlfie Angelo ReyesÎncă nu există evaluări

- Gujarat Technological UniversityDocument3 paginiGujarat Technological UniversityApurv GuptaÎncă nu există evaluări

- The Thermal Conductivity of Alumina Nanoparticles Dispersed in Ethylene GlycolDocument4 paginiThe Thermal Conductivity of Alumina Nanoparticles Dispersed in Ethylene GlycolShourya JainÎncă nu există evaluări

- Hempafloor Self-Level 200Document2 paginiHempafloor Self-Level 200Fadi MagdyÎncă nu există evaluări

- Adnan AlamDocument54 paginiAdnan AlamarshadscmeÎncă nu există evaluări

- The Influence of The Addition of Fibers On Properties of Self-Compacting Concrete Produced With Recycled Coarse AggregateDocument7 paginiThe Influence of The Addition of Fibers On Properties of Self-Compacting Concrete Produced With Recycled Coarse AggregateSIDDU HUSSAINÎncă nu există evaluări

- Cristal de CalcantitaDocument21 paginiCristal de Calcantitaisabelle_torre_1Încă nu există evaluări

- Soil Behavior: Spring 2005Document3 paginiSoil Behavior: Spring 2005HafiyÎncă nu există evaluări

- Journal of Science: Advanced Materials and Devices: Original ArticleDocument8 paginiJournal of Science: Advanced Materials and Devices: Original ArticleSamah SamahÎncă nu există evaluări

- Pasco CatalogDocument7 paginiPasco CatalogItx MinhasÎncă nu există evaluări

- Young's Modulus of Glass and PVBDocument13 paginiYoung's Modulus of Glass and PVBsongyanxinÎncă nu există evaluări

- Pressure Testing Methods DVGW G 469Document14 paginiPressure Testing Methods DVGW G 469koulis1386% (7)

- A304-11 Standard Specification For Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsDocument48 paginiA304-11 Standard Specification For Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsUTTAM JAINÎncă nu există evaluări

- Introduction To EOR ProcessesDocument23 paginiIntroduction To EOR Processesحسين رامي كريم A 12Încă nu există evaluări

- Stabilization ShellacDocument9 paginiStabilization ShellacbaoÎncă nu există evaluări

- Etching and Lithography in MicrofabricationDocument8 paginiEtching and Lithography in MicrofabricationWhizzWrÎncă nu există evaluări

- Avk Gate Valve, Flanged, Pn10/16 06/30-0035: EN 558-2 S.14/DIN F4, DN40-600Document3 paginiAvk Gate Valve, Flanged, Pn10/16 06/30-0035: EN 558-2 S.14/DIN F4, DN40-600Ali AafaaqÎncă nu există evaluări

- Shear Tab - Double Col - AISC 13th Ed - Ver1Document178 paginiShear Tab - Double Col - AISC 13th Ed - Ver1pelaoguenoÎncă nu există evaluări

- Bamboo Reinforcement Concrete - Ghavami - 2004Document13 paginiBamboo Reinforcement Concrete - Ghavami - 2004immortalsky100% (2)

- Koolfoam InsulationDocument5 paginiKoolfoam InsulationsepasepasepaÎncă nu există evaluări

- Org ChemDocument22 paginiOrg ChemRay-ann Dela FuenteÎncă nu există evaluări