Documente Academic

Documente Profesional

Documente Cultură

14 - Job Safety Analysis-loading and Offloading Materials装卸料

Încărcat de

Jayvee Baradas ValdezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

14 - Job Safety Analysis-loading and Offloading Materials装卸料

Încărcat de

Jayvee Baradas ValdezDrepturi de autor:

Formate disponibile

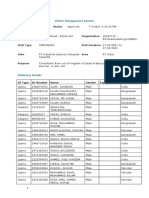

JOB SAFETY ANALYSIS

Task Order/Contract No.

:

Project No :U&I Multi discipline

Date :10-02-2015

Prepared By Wang Haitao

Company Name:

SEG

Area : U&I Multi discipline Contract Lay-down And

Building :N/A

Job-site.

Error: Reference source not foundWork Scope/Description /:

Primary

loading and offloading materials

Project HSE

Emergency Contact Person(s):

Emergency Radio/Phone No .:

Error: Reference source not foundSpecific Work Location(s):

Pre-Task Walkthrough Conducted

:

Yes

No

HSE Program Reference

(***):

Corporate

/000

Project-Specific

Before issuing a Permit to Work, the Issuer must review the job and consider the following

:

1. Do you know EXACTLY what the intended job entails ?

2. Do you need to personally visit the work area ?

3. Does the employee about to do the job also know EXACTLY what the job entails

?

4. Does the Permit to Work fall within your level

HAVE YOU CONSIDERED ?

Accessibility

Area Classification

Portable Electrical Equipment

Pressure

Cramped Work Area

Process and Other Liquids

Dust, Powders, Solids

Electric Power

Fumes, Odors

Radioactive Emissions

Residual Process Materials

Restricted Field of Vision

Gases, Flashing Liquids

Services Steam, Water, Air

Ignition of Surrounding Material

Temperatures

Motive Power

Traffic Ways

Noise

Vapor

Obstructions, Falling Objects

Weather Conditions

Other People

Other Sections

Atmosphere Testing Frequency

Welding Flash

Working at Height

Hearing Protection

Auxiliary Lighting

Ladder, Scaffolding

Breathing Protection

Safety Spectacles

Emergency Exit Route

Standby Person(s) How many?

Environmental Safeguards

Standby Persons Briefing

Footwear

Standby Persons Protection

Gloves

Goggles

Head Protection

Ventilation

Written Procedure

Superintendent Appointed

Site Statutory Induction Completed

1

Health, Safety, and Environmental

JOB SAFETY ANALYSIS

Project No :U&I Multi discipline

Task Order/Contract No.

:

Date :10-02-2015

Dress Standards/Protective Clothing

Names on Plant Access Board

PPE Checked

ID Badging, where appropriate

Test Date of Equipment Checked

Contractor Licenses Checked

Contractor Insurance Checked

HSE Training Completed

Plant Standards Communicated

Skill Training and Accreditation

Contractor Briefing Completed

Checklist Completed

Walkdowns

Walkdowns are completed in advance of the work .

Ideally, this review includes walkdown by the employees who will actually perform the task .

During the walkdown, the work scope is validated and verified, including materials and special tools needed to complete the task.

The walkdown should consider environmental and workplace factors that may impact critical steps of the task

.

The consistency and thoroughness of walkdowns are improved with the aid of a checklist.

Use the walkdown as an opportunity to observe physical limitations that may exacerbate performance, especially at the critical steps, or

hinder execution.

The results of the walkdowns are incorporated into work packages or documentation preparation.

Safety Task Assignment

Qualification for the task is first and foremost, but not the only, consideration .

Assigning the right employee to the task is an opportunity for the supervisor to evaluate the risk, complexity, and frequency of

performance of the task .

Experience, proficiency, personal readiness, and previous risk-taking behavior should be considered in light of the risk and complexity

of the task, as well as how often task has been performed

.

Factors related to an employees mental, physical, and emotional readiness to work should be considered such as fatigue, illness,

emotional stress, and physical disabilities relevant to the task.

Pre-Task Briefings

Employees should be given the opportunity to talk about what is to be accomplished and what should be avoided

.

Possible negative consequences should be discussed to identify additional controls or barriers needed

The supervisor and the employee can develop contingencies for the most likely and worst-case outcomes

.

Health, Safety, and Environmental

JOB SAFETY ANALYSIS

Project No :U&I Multi discipline

Task Order/Contract No.

:

Date :10-02-2015

Such thinking enhances situational awareness and improves application of error-prevention tools at critical points in a task

.

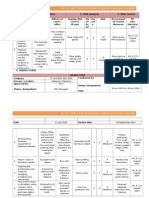

Work Activity

Hazards Present

Required Safety Measures/PPE

/

Work Activity

Hazards Present

Required Safety Measures/PPE

1- Over speeding

2- Collision with existing facilities

.

1.Transportation

materials/equipments

/containers

3- Uneven ground conditions

4- Failure of transportation vehicles

2-Manual handling of materials, tools and

equipments

1- Improper manual handling such

as, improper posture, twisting,

awkward positioning

2- Pinch points / trap points

3-Loading, Offloading and Lifting of

materials/equipments/containers by crane

1- Falling of load.

2- Improper /damage lifting gears

/

1- Follow Maaden speed limit and traffic

management system.

MAADEN

2- Ensure tr Identify existing facilities.

3- ansportation vehicle is driving on the

regular route on firm and level

surface, and ground condition to be

suitable for the load

4- Inspect the equipments before

operation and only competent person

can operate.

1- Avoid twisting, awkward positioning

while manual handling objects.

2- Use proper hand gloves. And do not

keep hands and finger in trap points.

1- Properly tie-off the load

2- Check the lifting gears before use

and Use slings and lifting gear with

correct SWL rating

,

Health, Safety, and Environmental

JOB SAFETY ANALYSIS

Project No :U&I Multi discipline

Task Order/Contract No.

:

3- Improper Lifting and rigging of

materials.

4- Poor Visual Communication

5- Uneven Ground

Date :10-02-2015

3- Only certified competent person can

operate the equipment and give the

lifting signals.

4- Suspend lifting when the visual

communication is poor, such as

sandstorm weather.

5- Check ground condition before start

work, and the outriggers of crane

shall be put on level and strong

ground and supported by proper pats.

6- When the wind speed is more

than32KPH, lifting shall be stopped

immediately

32 /

6- High wind

7- Sw Unauthorized people inside

the lifting area

8- Overload of the crane

7- Barricade the lifting area and put

warning sign around the lifting area

8- Lifting according to the load chart of

the crane

9- Swing of the load may hit the

people or existing facilities

9- Properly use of tag line to control the

load.

10- Fall from Height

10- Stay away at the edge of the trailer /

squat down while slinging / 3 point

contact must be done while climbing

a ladder.

11- Horse playing

11- Give instruction at the toolbox

meeting to the workers that

Horseplaying is prohibited. / 100%

supervision is a must.

1- scattered/loose materials

1- Remove left out materials. Remove

trash and debris and disposes it

properly.

Health, Safety, and Environmental

JOB SAFETY ANALYSIS

Project No :U&I Multi discipline

Task Order/Contract No.

:

Date :10-02-2015

4-job finished

2- unattended tools/equipments

2- clean and remove the tools/

equipments to the storage area

,

Note: This form is referenced in numerous practices.

Health, Safety, and Environmental

S-ar putea să vă placă și

- JSO Cable Drum (02 Sept.'07)Document2 paginiJSO Cable Drum (02 Sept.'07)Francis Enriquez TanÎncă nu există evaluări

- Hot Work PermitDocument1 paginăHot Work PermitAndy SaycoÎncă nu există evaluări

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 paginăJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaÎncă nu există evaluări

- Spencer Stormcote Smooth Textured Masonry Paint (01.08.2007)Document4 paginiSpencer Stormcote Smooth Textured Masonry Paint (01.08.2007)Ikram SyedÎncă nu există evaluări

- Angle Grinder PDFDocument2 paginiAngle Grinder PDFcityofdarwingisÎncă nu există evaluări

- Aug Toolbox Talks Confined Spaces 0517Document2 paginiAug Toolbox Talks Confined Spaces 0517WaSim AKramÎncă nu există evaluări

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 paginiPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834Încă nu există evaluări

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocument8 paginiSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajÎncă nu există evaluări

- Hot Work Permit FormDocument2 paginiHot Work Permit FormN.JÎncă nu există evaluări

- JSA Mechanical Activity Risk AssessmentDocument1 paginăJSA Mechanical Activity Risk Assessmentjithin shankarÎncă nu există evaluări

- Jsa Grinding W Angle GrinderDocument2 paginiJsa Grinding W Angle GrinderMichael Angelo SanteÎncă nu există evaluări

- EVT471Document3 paginiEVT471Nurul AqielaÎncă nu există evaluări

- Employee Incident Report Form 1 1Document3 paginiEmployee Incident Report Form 1 1api-459048769100% (1)

- Safety Violation Notice General Information: ST ND RDDocument2 paginiSafety Violation Notice General Information: ST ND RDAsif Hussain100% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 paginiKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelÎncă nu există evaluări

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 paginiR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalÎncă nu există evaluări

- HSE guidance on safety devices for rapid roller doorsDocument11 paginiHSE guidance on safety devices for rapid roller doorsmsc920138Încă nu există evaluări

- Working at Height PermitDocument2 paginiWorking at Height PermitFadliansyah Arisetree83% (6)

- 7 Hand Held Power ToolsDocument4 pagini7 Hand Held Power ToolsGilmar MonteiroÎncă nu există evaluări

- Air Compressor Operation SafetyDocument10 paginiAir Compressor Operation SafetyKelvin TanÎncă nu există evaluări

- JSA ScaffoldingDocument2 paginiJSA ScaffoldingHrishikesh UnnikrishnanÎncă nu există evaluări

- Excavation PermitDocument2 paginiExcavation PermitRajesh Kumar SinghÎncă nu există evaluări

- JSA Ladders Working at Heights 001Document2 paginiJSA Ladders Working at Heights 001Anonymous voA5Tb0Încă nu există evaluări

- JSA ScaffoldingDocument2 paginiJSA Scaffoldingmyco samÎncă nu există evaluări

- Akk Jha Installation of Diesel TankDocument3 paginiAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Jsa-Jha For Using of Hand ToolsDocument2 paginiJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- HIRA 008 Height Work.Document4 paginiHIRA 008 Height Work.srinibas mohapatraÎncă nu există evaluări

- Wael GC3 Observation SheetDocument11 paginiWael GC3 Observation SheetSivaÎncă nu există evaluări

- JSA Hot WorkDocument2 paginiJSA Hot Workchhotelal kumar100% (1)

- Jsa PaintDocument2 paginiJsa PaintKhalid NaseemÎncă nu există evaluări

- Job Safety Analysis - Clinker StorageDocument4 paginiJob Safety Analysis - Clinker StorageMohammed MinhajÎncă nu există evaluări

- JSA Loading UnloadingDocument2 paginiJSA Loading UnloadingXtra Babe100% (2)

- Job HAzard Analysis Welding Operations MiftahDocument3 paginiJob HAzard Analysis Welding Operations MiftahLukmanElekAe100% (2)

- 04 Jsa For Camp Constn & Associated FacilitysDocument5 pagini04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- Electric Hand Drill Risk AssessmentDocument4 paginiElectric Hand Drill Risk AssessmentTariq AkhtarÎncă nu există evaluări

- 7-SOP06 - Working at Height Vers 1.1Document10 pagini7-SOP06 - Working at Height Vers 1.1Reaz UddinÎncă nu există evaluări

- Pha ExcavationDocument13 paginiPha ExcavationirshadÎncă nu există evaluări

- Hot Work Permit ChecklistDocument3 paginiHot Work Permit ChecklistUmair KhanÎncă nu există evaluări

- Alkifah Holding Company: Alkifah Contracting Company (KCC) Near Miss/Potential Hazard FormDocument2 paginiAlkifah Holding Company: Alkifah Contracting Company (KCC) Near Miss/Potential Hazard FormArshad MahmoodÎncă nu există evaluări

- Qatar Liquefied Gas Company Limited JSA for Cutting, Grinding and WeldingDocument5 paginiQatar Liquefied Gas Company Limited JSA for Cutting, Grinding and WeldingMohammad Fazal KhanÎncă nu există evaluări

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 paginiJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoÎncă nu există evaluări

- Job Hazard Analysis for Confined Space EntryDocument6 paginiJob Hazard Analysis for Confined Space EntryArun ArunbolluÎncă nu există evaluări

- Injury Prevention for Bathroom CleaningDocument1 paginăInjury Prevention for Bathroom CleaningSajid HussainÎncă nu există evaluări

- Tie in Hot Work JHADocument4 paginiTie in Hot Work JHAmalik jahan100% (2)

- Permit To Work EOH-SP-FORM 531.01Document2 paginiPermit To Work EOH-SP-FORM 531.01Brad EubankÎncă nu există evaluări

- Work at Height Safety AnalysisDocument2 paginiWork at Height Safety AnalysiszebmechÎncă nu există evaluări

- Part 3 ObservationsDocument7 paginiPart 3 ObservationsAmjadÎncă nu există evaluări

- 052 Sand BlastingDocument2 pagini052 Sand Blastingwilson mantilla100% (1)

- Pre-Job Safety Assessment ChecklistDocument2 paginiPre-Job Safety Assessment Checklistgueettaf faresÎncă nu există evaluări

- Hot Work Permit: This Permit Is Not Valid Unless All Appropriate Fields Are CompletedDocument2 paginiHot Work Permit: This Permit Is Not Valid Unless All Appropriate Fields Are CompletedEl Saleh newcapital100% (1)

- JHA Stacks EDG Substation r0 14 August 2017 EdittedDocument5 paginiJHA Stacks EDG Substation r0 14 August 2017 EdittedJeniffer Ong100% (1)

- JOB SAFETY ANALYSIS FOR HEAT TRACING REPAIRDocument12 paginiJOB SAFETY ANALYSIS FOR HEAT TRACING REPAIRChung Trịnh100% (2)

- Job Safety Analysis: Night Work at SiteDocument2 paginiJob Safety Analysis: Night Work at SiteSaiyad RiyazaliÎncă nu există evaluări

- VR-ForM-F06.10 (Hot Work Permit Request Form)Document1 paginăVR-ForM-F06.10 (Hot Work Permit Request Form)imtz2013Încă nu există evaluări

- JSA 08 Gas WeldingDocument1 paginăJSA 08 Gas Weldingmuthuswamy77Încă nu există evaluări

- Workplace Vocabulary for Esl Students: With Exercises and TestsDe la EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsÎncă nu există evaluări

- StudentStudymet581161 4Document4 paginiStudentStudymet581161 4CM VendhenÎncă nu există evaluări

- 01 PTW For Work at Height (MEWP) - DailyDocument6 pagini01 PTW For Work at Height (MEWP) - DailyIgnatius TanÎncă nu există evaluări

- 06 PTW WAH (Day - Night) - DailyDocument6 pagini06 PTW WAH (Day - Night) - DailyIgnatius TanÎncă nu există evaluări

- Sinopec-Tr-Safety Training Attendance SheetsDocument2 paginiSinopec-Tr-Safety Training Attendance SheetsJayvee Baradas ValdezÎncă nu există evaluări

- Request# Status: Visitor Management SystemDocument3 paginiRequest# Status: Visitor Management SystemJayvee Baradas ValdezÎncă nu există evaluări

- SINOPEC - RTR SOC Attendance Sheet 24-08-2021Document3 paginiSINOPEC - RTR SOC Attendance Sheet 24-08-2021Jayvee Baradas ValdezÎncă nu există evaluări

- HSE VIOLATION NOTIFICATION SINOPEC 001 - Mass Toolbox MeetingDocument4 paginiHSE VIOLATION NOTIFICATION SINOPEC 001 - Mass Toolbox MeetingJayvee Baradas ValdezÎncă nu există evaluări

- Sinopec Status of Firstaid BoxDocument1 paginăSinopec Status of Firstaid BoxJayvee Baradas ValdezÎncă nu există evaluări

- SA ID Cancellation ReceiptDocument1 paginăSA ID Cancellation ReceiptJayvee Baradas ValdezÎncă nu există evaluări

- Smoke Detector Test and Inspection ReportDocument1 paginăSmoke Detector Test and Inspection ReportJayvee Baradas ValdezÎncă nu există evaluări

- SDM 023 Attendance SheetDocument1 paginăSDM 023 Attendance SheetJayvee Baradas ValdezÎncă nu există evaluări

- Sinopec: Company Work Locations Manpower Work Activities Supervisors Name & Contact No#Document2 paginiSinopec: Company Work Locations Manpower Work Activities Supervisors Name & Contact No#Jayvee Baradas ValdezÎncă nu există evaluări

- Job Safety Analysis Work SheetDocument10 paginiJob Safety Analysis Work SheetJayvee Baradas ValdezÎncă nu există evaluări

- 0002 Rev 00 Jsa TR Seg Piping ErectionDocument11 pagini0002 Rev 00 Jsa TR Seg Piping ErectionJayvee Baradas ValdezÎncă nu există evaluări

- T40 RattlerDocument3 paginiT40 RattlerDeo MananganÎncă nu există evaluări

- ADA-third Party NEWDocument1 paginăADA-third Party NEWJayvee Baradas ValdezÎncă nu există evaluări

- Drinking WaterDocument1 paginăDrinking WaterJayvee Baradas ValdezÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- RPB Astro Instruction ManualDocument20 paginiRPB Astro Instruction ManualJayvee Baradas ValdezÎncă nu există evaluări

- Sinopec Status of Firstaid BoxDocument1 paginăSinopec Status of Firstaid BoxJayvee Baradas ValdezÎncă nu există evaluări

- FGP SEG TR JSA 20 - Man Lift Operation Rev. 02Document15 paginiFGP SEG TR JSA 20 - Man Lift Operation Rev. 02Jayvee Baradas ValdezÎncă nu există evaluări

- Application Form OSH PractitionerDocument3 paginiApplication Form OSH PractitionerJayvee Baradas Valdez100% (4)

- Good Practices Guide To Dark Rooms OperationsDocument3 paginiGood Practices Guide To Dark Rooms OperationsJayvee Baradas Valdez0% (1)

- Guidelines DO16Document77 paginiGuidelines DO16Marlo ChicaÎncă nu există evaluări

- Visio Miguel ProjectDocument1 paginăVisio Miguel ProjectJayvee Baradas ValdezÎncă nu există evaluări

- Using the Ladder UnsafelyDocument14 paginiUsing the Ladder UnsafelyJayvee Baradas ValdezÎncă nu există evaluări

- Powerline Pre Board Ree Sept 2010 PDFDocument14 paginiPowerline Pre Board Ree Sept 2010 PDFJayvee Baradas ValdezÎncă nu există evaluări

- Saes T 555Document21 paginiSaes T 555Jayvee Baradas ValdezÎncă nu există evaluări

- Powder Actuated ToolsDocument1 paginăPowder Actuated ToolsJayvee Baradas ValdezÎncă nu există evaluări

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument8 paginiContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualJayvee Baradas ValdezÎncă nu există evaluări

- NEMA Enclosure Types 11-05-2Document9 paginiNEMA Enclosure Types 11-05-2Duron SaavedraÎncă nu există evaluări

- S2 Recruitment Guide - SuikosourceDocument4 paginiS2 Recruitment Guide - SuikosourceJayvee Baradas ValdezÎncă nu există evaluări

- JSA Template 2017-05-30 Powder Actuated ToolsDocument19 paginiJSA Template 2017-05-30 Powder Actuated ToolsJayvee Baradas Valdez100% (2)

- Format Question Bank RevisedDocument21 paginiFormat Question Bank RevisedkhananuÎncă nu există evaluări

- PCH (R-407C) SeriesDocument53 paginiPCH (R-407C) SeriesAyman MufarehÎncă nu există evaluări

- Four Ball EPDocument5 paginiFour Ball EPu4sachinÎncă nu există evaluări

- Zelenbabini Darovi Ivana N Esic - CompressDocument167 paginiZelenbabini Darovi Ivana N Esic - CompressСања Р.0% (1)

- Examining Oral Communication FunctionsDocument5 paginiExamining Oral Communication FunctionsJoshua Lander Soquita CadayonaÎncă nu există evaluări

- The Importance of Understanding A CommunityDocument23 paginiThe Importance of Understanding A Communityra sÎncă nu există evaluări

- i-PROTECTOR SPPR Catalogue 1.0Document2 paginii-PROTECTOR SPPR Catalogue 1.0Sureddi KumarÎncă nu există evaluări

- Bill of Quantity: Baner Lifespaces LLPDocument6 paginiBill of Quantity: Baner Lifespaces LLPSales AlufacadesÎncă nu există evaluări

- In The Shadow of The CathedralDocument342 paginiIn The Shadow of The CathedralJoy MenezesÎncă nu există evaluări

- CH 07Document40 paginiCH 07Ambreen31Încă nu există evaluări

- Noam Text ליגר טסקט םעֹנDocument20 paginiNoam Text ליגר טסקט םעֹנGemma gladeÎncă nu există evaluări

- Karl Marx AssignmentDocument1 paginăKarl Marx Assignmenthanunarabella1Încă nu există evaluări

- Aadhaar is proof of identity, not citizenshipDocument1 paginăAadhaar is proof of identity, not citizenshipPARTAPÎncă nu există evaluări

- PAPTAC-FW Quality ExcursionsDocument5 paginiPAPTAC-FW Quality ExcursionsGarth110Încă nu există evaluări

- Corporate Presentation Codex International Fev 2022Document9 paginiCorporate Presentation Codex International Fev 2022Stephane SeguierÎncă nu există evaluări

- 1.4 Solved ProblemsDocument2 pagini1.4 Solved ProblemsMohammad Hussain Raza ShaikÎncă nu există evaluări

- The 4th International Conference of the International Forum on Urbanism (IFoU) 2009 Amsterdam/Delft - FiberCity as a Paradigm Shift of Urban DesignDocument4 paginiThe 4th International Conference of the International Forum on Urbanism (IFoU) 2009 Amsterdam/Delft - FiberCity as a Paradigm Shift of Urban DesignChris de VriesÎncă nu există evaluări

- How To Set Up Simulator Ard MMDocument12 paginiHow To Set Up Simulator Ard MMJayakrishnaÎncă nu există evaluări

- Myers Et Al - Clear and Present ThinkingDocument214 paginiMyers Et Al - Clear and Present ThinkingAEÎncă nu există evaluări

- PGSuperDocument71 paginiPGSuperVietanh PhungÎncă nu există evaluări

- Katsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsDocument33 paginiKatsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsHamisu TafashiyaÎncă nu există evaluări

- Handout 4: Course Notes Were Prepared by Dr. R.M.A.P. Rajatheva and Revised by Dr. Poompat SaengudomlertDocument7 paginiHandout 4: Course Notes Were Prepared by Dr. R.M.A.P. Rajatheva and Revised by Dr. Poompat SaengudomlertBryan YaranonÎncă nu există evaluări

- Life Model For Rolling Contact, Applied To The Optimization of A Tripode Constant Velocity JointDocument244 paginiLife Model For Rolling Contact, Applied To The Optimization of A Tripode Constant Velocity Jointbee140676Încă nu există evaluări

- Generative NLP Robert DiltsDocument11 paginiGenerative NLP Robert DiltsTyler Durden100% (22)

- Rubrics (Introduction To Human Resource Management) (HRM533)Document5 paginiRubrics (Introduction To Human Resource Management) (HRM533)norshaheeraÎncă nu există evaluări

- Spe 143287 MS PDocument11 paginiSpe 143287 MS PbvkvijaiÎncă nu există evaluări

- Assignment 5: Building More Complex Tasks: 1 BackgroundDocument3 paginiAssignment 5: Building More Complex Tasks: 1 Backgroundt_hoffmannÎncă nu există evaluări

- Mechanical Vapor RecompressionDocument9 paginiMechanical Vapor Recompressionnarayana reddy0% (1)

- Desktop HDD, Processors, and Memory DocumentDocument13 paginiDesktop HDD, Processors, and Memory DocumentsonydearpalÎncă nu există evaluări

- Energies: Review of Flow-Control Devices For Wind-Turbine Performance EnhancementDocument35 paginiEnergies: Review of Flow-Control Devices For Wind-Turbine Performance Enhancementkarthikeyankv.mech DscetÎncă nu există evaluări