Documente Academic

Documente Profesional

Documente Cultură

E4340 Techspec

Încărcat de

Faquruddin AliTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

E4340 Techspec

Încărcat de

Faquruddin AliDrepturi de autor:

Formate disponibile

LANL Engineering Standards Manual STD-342-100

Section D10+E10 Equipment

Chapter 6, Mechanical

Rev. 4, 9/29/14

TABLE OF CONTENTS

D10+E10 EQUIPMENT

D10+E10 GENERAL ................................................................................................................................... 3

D10

CONVEYING ........................................................................................................................... 3

D1010

ELEVATORS AND LIFTS ...................................................................................................... 3

1.0

General ...................................................................................................................................... 3

D1090

OTHER CONVEYING SYSTEMS (programmatic & facility)................................................ 3

1.0

Cranes ........................................................................................................................................ 3

2.0

General ...................................................................................................................................... 3

3.0

Special Requirements for Nuclear Material Handling Equipment ............................................ 5

E10

EQUIPMENT ............................................................................................................................ 5

E1020

INSTITUTIONAL EQUIPMENT (programmatic and facility) ............................................... 5

1.0

General ...................................................................................................................................... 5

2.0

Gloveboxes ................................................................................................................................ 7

3.0

Special Requirements For Nuclear-Safety-Related Process Equipment .................................. 7

Page 1 of 8

LANL Engineering Standards Manual STD-342-100

Chapter 6, Mechanical

Section D10+E10 Equipment

Rev. 4, 9/29/14

RECORD OF REVISIONS

Rev

Date

5/22/02

Initial issue.

Tobin Oruch,

FWO-SEM

Kurt Beckman,

FWO-SEM

6/9/04

Charles DuPr,

FWO-DECS

Gurinder Grewal,

FWO-DO

10/27/06

Added elevator and crane material from Arch

chapter; made standards tables required;

other minor changes.

Administrative changes only. Organization

and contract reference updates from LANS

transition. IMP and ISD number changes

based on new Conduct of Engineering IMP

341. Master Spec number/title updates.

Other administrative changes.

Addressed tanks in rad service;

administrative changes.

Charles DuPr,

Kirk Christensen,

FM&E-DES

CENG

Charles DuPr,

Larry Goen,

ES-DE

ES-DO

DOE O 420.1C and G 420.1-1A update,

other admin and minor changes.

Michael Ladach,

Mel Burnett,

ES-EPD

CENG

3

4

9/29/09

9/29/14

Description

POC

OIC

CONTACT THE MECHANICAL STANDARDS POC AND COMMITTEE

for upkeep, interpretation, and variance issues

Ch. 6, D10+E10

Mechanical POC and Committee

This document is online at http://engstandards.lanl.gov/

Page 2 of 8

LANL Engineering Standards Manual STD-342-100

Section D10+E10 Equipment

Chapter 6, Mechanical

Rev. 4, 9/29/14

D10+E10 GENERAL

NOTE: See ESM Chapter 1 Section Z10 and Mechanical Chapter 6 Section D10-30GEN for

additional requirements and definitions.

D10

CONVEYING

D1010

ELEVATORS AND LIFTS

1.0

GENERAL

A. Refer to ESM Architectural Chapter (Section C-Interiors) for additional requirements for

elevators (potentially).

B. Elevator pit must have a sump, automatic pump, and piping per UPC directed to outside of

building (or, with POC permission, location that will not cause a safety issue).1

C. Refer to the following LANL Master Specifications:

1. Section 14 2423, Hydraulic Passenger Elevators.

2. Section 14 2413, Hydraulic Freight Elevators.

D1090

1.0

OTHER CONVEYING SYSTEMS (PROGRAMMATIC & FACILITY)

CRANES

A. Refer to the following LANL Master Specifications:

1. Section 41 2225, Hoists and Trolleys.

2. Section 41 2213.13, Bridge Cranes.

B. Guidance: Refer to P101-25, Cranes, Hoists, Lifting Devices, and Rigging Equipment,

especially Appendix A, Overhead and Gantry Cranes; Appendix B, Overhead Hoists; and

Appendix C, Mobile Cranes, Crawler, Locomotive, and Wheel-Mounted Cranes

C. For crane modifications, the LANL Crane Safety Program Owner in IHS should review

proposed modifications that are proposed by a qualified mechanical engineer

2.0

GENERAL

A. Follow the standards in Table D1090-1 below when designing/specifying conveying

equipment. They represent the minimum acceptable methods. 2

1

ASME A17.1 2.2.2.4 and 5; all LANL elevators have Firefighters Emergency Operation function; therefore, they are required

to have sumps/pumps. Clean Water Act allows discharge of untested/treated firefighting water (ref. FedReg Vol 65 No. 210

10/30/2000 sections 64759-60, 64763, and 64807.

2

Refer to ESM Chapter 1 Section Z10 on Code of Record for implementation schedule of 420.1C-driven requirements.

Page 3 of 8

LANL Engineering Standards Manual STD-342-100

Chapter 6, Mechanical

Section D10+E10 Equipment

Rev. 4, 9/29/14

TABLE D1090-1

Standards for Material Handling Equipment

Function/

Component

Design

Standards for

Cranes and

other

Material

Handling

Equipment

ML-3/4

General Service

CMAA 70, CMAA 74,

and/or the applicable

design standards

referenced in DOE-STD1090 (2011, Section 14)

for other equipment.

Operation,

Inspection,

Maintenance,

and testing

Standards

DOE-STD-1090

ML-2/

Safety Significant (SS) *

Applicable CMAA

Standards

ML-1/

Safety Class (SC) **

Applicable CMAA

Standards

ASME B30.2

ASME NOG-1 Type II or

ASME NUM-1 Type II

ASME B30.2; ASME NOG1 Type 1 or ASME NUM-1

Type 1

ANSI 14.6 for Special

Lifting Devices for

Shipping Containers

Weighing 10,000 Pounds

(4500 kg) or More.

DOE-STD-1090

ANSI 14.6 for Special

Lifting Devices for Shipping

Containers Weighing 10,000

Pounds (4500 kg) or More

DOE-STD-1090

Applicable CMAA

Standards.

Applicable CMAA Standards

ASME NOG-1, ASME

NUM-1, ASME B30.2

DOE-STD-1090

DOE-STD-1090 or ANSI

14.6 for Special Lifting

Devices for Shipping

Containers Weighing 10

000 Pounds (4500 kg) or

More

ASME NUM-1, B30.2;

DOE-STD-1090

DOE-STD-1090 or ANSI

14.6 for Special Lifting

Devices for Shipping

Containers Weighing 10 000

Pounds (4500 kg) or More

* ASME NOG-1 and NUM-1, Type II equipment is equipment that is not used to handle critical loads and is required

to withstand a seismic event. A unique design is required if this is not the safety significant function.

** ASME NOG-1 and NUM-1, Type I equipment is equipment that is used to handle critical loads and is required to

withstand a seismic event. A unique design is required if this is not the safety class function.

Titles for Table D1090-1

ANSI N14.6, Special Lifting Devices for Shipping Containers Weighing 10,000 Pounds (4500 kg) or More

ASME NOG-1, Rules for Construction of Overhead and Gantry Cranes (Top Running Bridge, Multiple Girder)

ASME NUM-1, Rules for Construction of Cranes, Monorails, and Hoists (with Bridge, Trolley or Hoist of the

Underhung Type)

CMAA Specification 70, Specifications for Top Running Bridge & Gantry Type Multiple Girder Electric Overhead

Traveling Cranes

CMAA Specification 74, Specifications for Top Running & Under Running Single Girder Electric Traveling Cranes

Utilizing Under Running Trolley Hoists

DOE-STD-1090, Hoisting and Rigging

Page 4 of 8

LANL Engineering Standards Manual STD-342-100

Section D10+E10 Equipment

Chapter 6, Mechanical

Rev. 4, 9/29/14

3.0

SPECIAL REQUIREMENTS FOR NUCLEAR MATERIAL HANDLING EQUIPMENT

3.1

General Guidance

A. Safety-significant and safety-class handling equipment (cranes, manipulators, etc.) are only

classified as such if their failure would create a radiological material release exceeding the

guidelines for either classification. The safety-significant classification, as a defense-indepth provision, is the more common classification for remote material handling equipment.

3.2

General Requirements

A. Failure modes for mechanical handling equipment used to move radioactive materials must

address mid-operational failures, and designs must include recovery methods for such

occurrences.

B. Designs must accommodate periodic maintenance and inspection.

E10

EQUIPMENT

E1020

INSTITUTIONAL EQUIPMENT (PROGRAMMATIC AND FACILITY)

1.0

GENERAL

A. Follow the standards in Table E1020-1 when designing/specifying equipment.

B. Follow DOE-STD-1132, Design Considerations, documenting any exceptions taken.

C. Also refer to Chapter 11, Hazardous Process and Chapter 12, Nuclear for additional

requirements for such equipment.

Page 5 of 8

LANL Engineering Standards Manual STD-342-100

Chapter 6, Mechanical

Section D10+E10 Equipment

Rev. 4, 9/29/14

TABLE E1020-1

Codes and Standards for Process Equipment

Function/

ML-3/4

ML-2/

ML-1/

Component

General Service

Safety Significant (SS)

Safety Class (SC)

Pressure Vessels

ASME B&PVC, Section

VIII; ESM Ch 17

ASME B&PVC, Section

VIII, Division 1 or 2;

ESM Ch 17

ASME B&PVC, Section III,

Division 1 or 2 ( Class II or

Section VIII with QA

enhancements 3); ESM Ch 17

Tanks (0-15 psig)

API 620

API 620; ASME B&PVC

Section VIII, Division 1 or

2 (even where they may

be exempt due to pressure

or other reason).

API 620; ASME B&PVC

Section VIII, Division 1 or 2

(even where they may be

exempt due to pressure or other

reason).

Tanks (containing

flammable liquids)

API 620 and 650; NFPA

30

API 620 and 650; NFPA

30

API 620 and 650; NFPA 30

Tanks (atmospheric

pressure)

API 650; AWWA D100

API 650; AWWA D100

API 650; AWWA D100

Pumps

API series; ASME B73

series; ASME B&PVC,

Section VIII; AWWA

E101; Hydraulic

Institute Standards

ASME B73.1, B73.2;

ASME B&PVC, Section

VIII; AWWA ; Hydraulic

Institute Standards

ASME B73.1, B73.2; ASME

B&PVC, Section VIII;

AWWA; Hydraulic Institute

Standards

Piping

ASME B31.3; ESM Ch

17 (ref. REF-3, B31.3

Process Piping Guide)

ASME B31.3; ESM Ch 17

(ref. REF-3, B31.3

Process Piping Guide)

ASME B31.3; ESM Ch 17 (ref.

REF-3, B31.3 Process Piping

Guide)

Valves

ASME B16.5, B31.3

ASME B16.5, B31.3;

ANSI N278.1

ASME B16.5, B31.3; ANSI

N278.1

Heat exchangers

ASHRAE Handbook;

ASME B&PVC, Section

VIII, Division 1; TEMA

B, C, or R

ASHRAE Handbook;

ASME B&PVC, Section

VIII, Division 1; TEMA

B, C, or R

ASHRAE Handbook; ASME

B&PVC, Section VIII, Division

1; TEMA B, C, or R

Gloveboxes 4

AGS Standards

AGS-G006, ASTM C852

AGS-G006, ASTM C852

See note below table

3

Applicability of ASME Sections III and VIII and of B31.1 and B31.3 to DOE Facilities, George Antaki, Paper for the Fourth

DOE Natural Phenomena Hazards Mitigation Conference, October 19-22, 1993, Atlanta. (EMref-18) (Note: EMref refers to an

ESM team system for managing hard-to-find reference hardcopies.)

4

GB leak testing need not include rate-of-rise testing if helium mass spec testing achieving 10E-6 cc/sec sensitivity or better is

performed in lieu of same, since this is more sensitive per ASNTs Nondestructive Testing Handbook, Volume 1 Leak

Testings discussion on page 18 (see EMRef-70 for history of this determination by LANL and NNSA). Also, re AGS-G006, it

is not practical to include GB or ventilation system controls that can respond to the different operating conditions between normal

pressure control and breach pressure control that would limit credible breach face velocities to 12525 ft/min. This is especially

true for air GBs at TA-55 attached directly to the large trolley systems. In light of this limitation, LANL shall use only the criteria

in ASTM C852 (breach velocities to be at least 125 ft/min). By doing so, as long as the ventilation system (e.g., Zone 1) is

operating, any credible breach is in compliance with AGSs interpretation: As long as the pressure inside the glovebox is

maintained below the ambient pressure, and air is flowing into the glovebox, the intent of AGS-G006 is met... See EMRef-71

for the AGS interpretation and correspondence from NNSA to LANL.

Page 6 of 8

LANL Engineering Standards Manual STD-342-100

Section D10+E10 Equipment

Chapter 6, Mechanical

Rev. 4, 9/29/14

Titles for Table E1020-1

AGS G001, Guideline for Gloveboxes

ASME, Cont

AGS G002, Standard of Practice for Design and

Fabrication of Glovebags

B73.2M, Specification for Vertical In-Line

Centrifugal Pumps for Chemical Process

AGS G003, Standard of Practice for the Application

of Linings to Gloveboxes

B73.5M, Thermoplastic and Thermoset Polymer

Material Centrifugal Pumps for Chemical Process

B96.1, Welded Aluminum-Alloy Storage Tanks

ANS 11.16 on gloveboxes if/when issued

API

610, Centrifugal Pumps for Petroleum, Heavy Duty

Chemical, and Gas Industry Services

N278.1, Self-Operated and Power-Operated SafetyRelated Valves Functional Specification Standard

620, Design and Construction of Large, Welded,

Low-Pressure Storage Tanks

ASTM C 852, Standard Guide for Design Criteria for

Plutonium Gloveboxes

650, Welded Steel Tanks for Oil Storage

AWWA D100, Welded Steel Tanks for Water

Storage

674, Positive Displacement Pumps-Reciprocating

675, Positive Displacement Pumps-Controlled

Volume

ASME (or ANSI/ASME)

B&PVC Boiler and Pressure Vessel Code

B16.5, Pipe Flanges and Flanged Fittings

B31.3, Process Piping

B73.1M, Specification for Horizontal End Suction

Centrifugal Pumps for Chemical Process

2.0

AWWA E101, Vertical Turbine Pumps - Line Shaft

and Submersible Types

NFPA 30, Flammable and Combustible Liquids

Code

NFPA 801, Standard for Fire Protection for Facilities

Handling Radioactive Materials (National Fire

Codes, vol. 11)

TEMA 1, Standards of the Tubular Exchanger

Manufacturers Association

GLOVEBOXES

A. Gloveboxes shall be designed, fabricated, and installed per LANL Master Specification

Sections 11 5311.08, 11 5311.10, and 11 5311.12. (For non-nuclear application, delete those

sections that do not apply).

3.0

SPECIAL REQUIREMENTS FOR NUCLEAR-SAFETY-RELATED PROCESS

EQUIPMENT 5

3.1

Confinement Guidance

A. The usual safety function of process equipment is to provide primary confinement and prevent

or mitigate radioactive and/or hazardous material releases to the environment. Process

equipment that would be required to provide primary confinement includes the following:

piping, tanks, pressure vessels, pumps, valves, hoods, and gloveboxes. These examples

represent process system components that could be used to contain radioactive or toxic

materials directly.

All nuclear-related material is based on Section 5.2 of DOE G 420.1-1A, Nonreactor Nuclear Safety Design Criteria and

Explosive Safety Criteria Guide for use with DOE O 420.1C, Facility Safety. The recommended codes and standards tables from

G 420.1-1A were updated and expanded to consider per practice.

Page 7 of 8

LANL Engineering Standards Manual STD-342-100

Section D10+E10 Equipment

Chapter 6, Mechanical

Rev. 4, 9/29/14

B. Process equipment for some applications can provide secondary confinement. Examples

include double-walled piping systems, heat exchangers, double-walled tanks, and gloveboxes.

C. Primary confinement barrier(s) should be provided between the hazardous process material

(gas, liquid or solid) and any auxiliary (e.g. a cooling system) to minimize risk of material

transfer to an unsafe location or introduction of an undesirable medium into the process

area. Differential pressure across the confinement barrier(s) should be used where

appropriate.

3.2

Confinement Requirements

A. Safety-class and safety-significant process equipment providing passive confinement (piping,

tanks, pressure vessels, etc.) must be designed to suitably conservative criteria; redundancy in

their design is typically not required. The need for redundancy is required to be evaluated to

the design of safety-class SSCs that involve active confinement process equipment (e.g.,

pumps, valves, etc.).

B. Guidance: The redundancy criteria should be considered in the design of safety-significant

SSCs that involve active confinement process equipment.

Page 8 of 8

S-ar putea să vă placă și

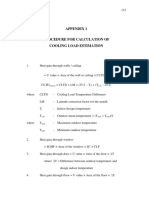

- 13 AppendixDocument9 pagini13 AppendixFaquruddin AliÎncă nu există evaluări

- Ventilating Fan Specification Model FV-38CH8Document3 paginiVentilating Fan Specification Model FV-38CH8Faquruddin AliÎncă nu există evaluări

- 12 Presentation SkalkoDocument25 pagini12 Presentation SkalkoFaquruddin AliÎncă nu există evaluări

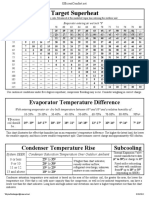

- Charging and TD Chart PlusDocument1 paginăCharging and TD Chart PlusFaquruddin AliÎncă nu există evaluări

- Cooling and Dehumidifying AirDocument5 paginiCooling and Dehumidifying AirFaquruddin AliÎncă nu există evaluări

- Mitsubishi Electric PURY-RP YJM-B Installation Manual EngDocument20 paginiMitsubishi Electric PURY-RP YJM-B Installation Manual EngFaquruddin AliÎncă nu există evaluări

- Rules and Rules of Thumb For Duct SystemsDocument1 paginăRules and Rules of Thumb For Duct SystemssauroÎncă nu există evaluări

- 5.6 Schedule of Electrical RequirementsDocument7 pagini5.6 Schedule of Electrical RequirementsFaquruddin AliÎncă nu există evaluări

- Equipment and Systems - HVAC and Refrigeration PE Exam Tools - Mechanical PE Sample Exams, Technical Study Guides and ToolsDocument35 paginiEquipment and Systems - HVAC and Refrigeration PE Exam Tools - Mechanical PE Sample Exams, Technical Study Guides and ToolsFaquruddin AliÎncă nu există evaluări

- VRV SystemDocument152 paginiVRV SystemKHA120096 StudentÎncă nu există evaluări

- Case Study Nicu PDFDocument35 paginiCase Study Nicu PDFFaquruddin AliÎncă nu există evaluări

- Understanding Temperature and Altitude CorrectionsDocument3 paginiUnderstanding Temperature and Altitude CorrectionsFaquruddin AliÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- ConsignmentDocument2 paginiConsignmentKanniha SuryavanshiÎncă nu există evaluări

- Full Download Fundamentals of Thermodynamics 6th Edition Sonntag Solutions ManualDocument20 paginiFull Download Fundamentals of Thermodynamics 6th Edition Sonntag Solutions Manualadenose.helveo0mvl100% (39)

- 755 1 Air India Commits Over US$400m To Fully Refurbish Existing Widebody Aircraft Cabin InteriorsDocument3 pagini755 1 Air India Commits Over US$400m To Fully Refurbish Existing Widebody Aircraft Cabin InteriorsuhjdrftÎncă nu există evaluări

- Land Laws (MOHD AQIB SF)Document18 paginiLand Laws (MOHD AQIB SF)Mohd AqibÎncă nu există evaluări

- TATA Steel - Group 8Document95 paginiTATA Steel - Group 8Wasim Khan MohammadÎncă nu există evaluări

- COURSE CONTENT in HE 503 Foods Nut. Ed 2nd Sem. 2021 2022 FINALDocument6 paginiCOURSE CONTENT in HE 503 Foods Nut. Ed 2nd Sem. 2021 2022 FINALLISA MÎncă nu există evaluări

- (Mr. Nigel West, Oleg Tsarev) TRIPLEX Secrets Fro (B-Ok - Xyz)Document377 pagini(Mr. Nigel West, Oleg Tsarev) TRIPLEX Secrets Fro (B-Ok - Xyz)conbeÎncă nu există evaluări

- Fundamentals of Product and Service CostingDocument28 paginiFundamentals of Product and Service CostingPetronella AyuÎncă nu există evaluări

- Rong Sun ComplaintDocument22 paginiRong Sun ComplaintErin LaviolaÎncă nu există evaluări

- Prof. Sujata Patel Department of Sociology, University of Hyderabad Anurekha Chari Wagh Department of Sociology, Savitribaiphule Pune UniversityDocument19 paginiProf. Sujata Patel Department of Sociology, University of Hyderabad Anurekha Chari Wagh Department of Sociology, Savitribaiphule Pune UniversityHarish KumarÎncă nu există evaluări

- Our Identity in Christ Part BlessedDocument11 paginiOur Identity in Christ Part BlessedapcwoÎncă nu există evaluări

- Entrepreneurship: The Entrepreneur, The Individual That SteersDocument11 paginiEntrepreneurship: The Entrepreneur, The Individual That SteersJohn Paulo Sayo0% (1)

- Asking Who Is On The TelephoneDocument5 paginiAsking Who Is On The TelephoneSyaiful BahriÎncă nu există evaluări

- Dewi Handariatul Mahmudah 20231125 122603 0000Document2 paginiDewi Handariatul Mahmudah 20231125 122603 0000Dewi Handariatul MahmudahÎncă nu există evaluări

- Sarah Richards: - Professional SummaryDocument3 paginiSarah Richards: - Professional SummaryWendy StarkandÎncă nu există evaluări

- Small Hydro Power Plants ALSTOMDocument20 paginiSmall Hydro Power Plants ALSTOMuzairmughalÎncă nu există evaluări

- Mock 10 Econ PPR 2Document4 paginiMock 10 Econ PPR 2binoÎncă nu există evaluări

- Taller InglesDocument11 paginiTaller InglesMartín GonzálezÎncă nu există evaluări

- Research ProposalDocument21 paginiResearch Proposalkecy casamayorÎncă nu există evaluări

- Digest Pre TrialDocument2 paginiDigest Pre TrialJei Essa AlmiasÎncă nu există evaluări

- EC-21.PDF Ranigunj ChamberDocument41 paginiEC-21.PDF Ranigunj ChamberShabbir MoizbhaiÎncă nu există evaluări

- Problem Solving and Decision MakingDocument14 paginiProblem Solving and Decision Makingabhiscribd5103Încă nu există evaluări

- Rotary HandbookDocument78 paginiRotary HandbookEdmark C. DamaulaoÎncă nu există evaluări

- Dessert Banana Cream Pie RecipeDocument2 paginiDessert Banana Cream Pie RecipeimbuziliroÎncă nu există evaluări

- Transportation Systems ManagementDocument9 paginiTransportation Systems ManagementSuresh100% (4)

- Test 6Document7 paginiTest 6RuslanaÎncă nu există evaluări

- Adv Tariq Writ of Land Survey Tribunal (Alomgir ALo) Final 05.06.2023Document18 paginiAdv Tariq Writ of Land Survey Tribunal (Alomgir ALo) Final 05.06.2023senorislamÎncă nu există evaluări

- NEERJA 7th April 2016 Pre Shoot Draft PDFDocument120 paginiNEERJA 7th April 2016 Pre Shoot Draft PDFMuhammad Amir ShafiqÎncă nu există evaluări

- Online MDP Program VIIIDocument6 paginiOnline MDP Program VIIIAmiya KumarÎncă nu există evaluări

- SEBI Management Summary SheetsDocument398 paginiSEBI Management Summary SheetsPriyanka ChandakÎncă nu există evaluări