Documente Academic

Documente Profesional

Documente Cultură

Pipe Bedding 6pp - 231015 Low Res

Încărcat de

Hoang An TranTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pipe Bedding 6pp - 231015 Low Res

Încărcat de

Hoang An TranDrepturi de autor:

Formate disponibile

Did you know?

Using the correct pipe bedding

class could save you a fortune

Plastic Flexible Pipe with full granular

surround (Class S Bedding)

Concrete Rigid Pipe

(Class N Bedding)

For further details on the materials cost calculator visit the CPSA website:

www.concretepipes.co.uk/calculators/material-cost

Potential savings of up to

137.99 per linear metre*

*Figure quoted is the difference between Class S (Plastic Flexible Pipe) and Class N (Concrete Rigid

Pipe) costs, based on a DN1800 pipe. Potential cost savings are based on normal ground conditions,

including granular bedding costs of 15 per tonne and cost of material being taken off-site to landfill at

6 per tonne (figure shown is independent of pipe costs). The bulk density of granular bedding material

is assumed to be 2.0 and for excavated material is assumed to be 2.1

Class S

360 Granular bedding and surround / Bedding factor = 2.2

Lay, joint and bed pipes as for Class B. Place sidefills and densely compact the layers using the same

bedding material at each side, up to crown level, taking care not to displace the pipes. This is followed by

300mm of the same granular bedding material but lightly compacted directly over the pipe, after which

ordinary backfilling is commenced.

Normal backfill

Degree of compaction

dependent upon surface

design requirements.

Bc

300mm

Well compacted

especially under

haunches of pipe

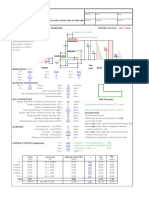

Class S Bedding Costs Full pipe granular surround cost per metre for:

DN1800 225.29 / DN1500 173.63 / DN1350 140.62 / DN1200 110.95

DN1050 88.52 / DN900 68.49 / DN1800 Plastic 221.20

Class B

180 Granular bedding and surround / Bedding factor = 1.9

Lay pipes on a layer of granular bedding material on the formation.

Scoop out socket holes, lay and joint pipes. Place sidefills and densely compact the layers of the

same bedding material at each side of pipes, up to springing level, taking care not to displace them.

Normal backfill

Degree of compaction

dependent upon surface

design requirements.

Bc

300mm

Well compacted

especially under

haunches of pipe

Class B Bedding Costs Partial pipe granular surround cost per metre for:

DN1800 135.77 / DN1500 102.94 / DN1350 83.29

DN1200 65.84 / DN1050 52.23 / DN900 40.14

Class F

Granular bedding / Bedding factor = 1.5

Lay pipes on a flat layer of the granular bedding material on the formation. Scoop out socket holes

with 500mm minimum clearance; lay and joint pipes, which will settle slightly into the bedding.

Place sidefills and densely compact the layers.

Normal backfill

Degree of compaction

dependent upon surface

design requirements.

Bc

300mm

Well compacted

especially under

haunches of pipe

Class F Bedding Costs Partial pipe granular surround cost per metre for:

DN1800 91.35 / DN1500 66.16 / DN1350 53.28

DN1200 42.10 / DN1050 32.72 / DN900 24.52

Class N

Flat Granular layer / Bedding factor = 1.1

Lay pipes on a flat layer of all-in or selected material.

Normal backfill

Degree of compaction

dependent upon surface

design requirements.

Bc

Class S Bedding Costs Partial pipe granular surround cost per metre for:

DN1800 83.21 / DN1500 59.99 / DN1350 48.30

DN1200 38.16 / DN1050 29.60 / DN900 22.13

Potential savings of up to

137.99 per linear metre*

300mm

Well compacted

especially under

haunches of pipe

*Figure quoted is the difference between Class S (Plastic Flexible Pipe) and Class N (Concrete Rigid Pipe) costs, based on a DN1800 pipe. Potential cost savings

are based on normal ground conditions, including granular bedding costs of 15 per tonne and cost of material being taken off-site to landfill at 6 per tonne (figure

shown is independent of pipe costs). The bulk density of granular bedding material is assumed to be 2.0 and for excavated material is assumed to be 2.1

For further details on the materials cost calculator, visit the CPSA website: www.concretepipes.co.uk/calculators/material-cost

Below we have listed eight industry

specifications and guidance references

justifying the use of bedding classes

for rigid pipes with a lower bedding

factor than Class S

BS EN 1295-1: 1997 (incorporating corrigenda May 2006,

July 2008, February 2010 and March 2010).

Structural design of buried pipelines under various conditions of

loading. Part 1: General requirements

Most standard stiffness flexible plastic pipes are 2kN/m2 or 4kN/m2 and this is significantly lower than the

minimum recommended stiffness of 10kN/m2 if Class B bedding is to be considered. In other words, all standard

stiffness flexible plastic pipes will generally require Class S embedment, unlike rigid concrete pipes where there is a

range of bedding choices and the opportunity to reduce installation costs.

Rigid Pipe embedments: Class B (Table NA.7)

Flexible Pipe embedments: Class B (Table NA.8)

B1 and B2

300

B

1.9

Wide trench

1.9 (See ref 4, B.1.12)

2.5 (See ref 9, B.1.12)

Embankment

1.9 to 2.3 (See ref 4, B.1.12)

Class B1:

Upper surround

as for S3 or S4

Lower surround

as for S1 or S2

Class B2:

Upper surround

as for S5

Lower surround

as for S1 or S2

Class B

embedments not

recommended

for use with

pipes of less

than 10 kN/m2

stiffness.

BS 9295:2010 Guide to the structural design of buried pipelines

7. The design of flexible pipelines

7.1 General

It is important to remember that flexible pipes derive much of their structural strength from the embedment that is

the sides of the installed pipeline. Considering the response of flexible pipes to loading (see 4.2), it can be

appreciated that THE EMBEDMENT SELECTION AND COMPACTION ARE VERY IMPORTANT WHERE

CONTROL OF OVALISATION IS REQUIRED.

Annex A: A1 removal of trench support systems

For flexible pipes, the void formed by removing the trench support systems between the trench wall and the

backfill will reduce support from the native soil significantly and increase pipe deflection. Where the pipe

installation relies on the sidefill compaction, then it should be carried out in layers and the trench support pulled

progressively to enable the specified compaction to be achieved.

WITH FLEXIBLE PIPE MORE CARE AND TIME IS NEEDED TO ENSURE THE SIDEFILL EMBEDMENT IS

SATISFACTORY.

Water Industry Information & Guidance Note IGN 4-08-01 February

1994. Issue 4 Section 4.

Selection of suitable bedding and sidefill materials

Where the structural performance of the pipeline does not depend on the sidefill, (e.g. for some rigid pipe

installations), sidefill may contain stones up to 37.5mm and clay lumps up to 75mm for any pipe diameter.

For rigid pipes larger than DN 500, stone sizes up to 10% of the pipe diameter will normally be acceptable.

Sewers for Adoption 6th edition (SfA6) / Sewers for adoption 7th

edition (SfA7) / Civil Engineering Specification for the Water Industry

7th Edition (CESWI7) / Sewers for Scotland 3rd Edition (SfS3)

SfS3: 2.14.7 Bedding details, materials and backfilling of pipelines shall be in accordance with Part 4 of this

specification. Unless otherwise agreed, CLASS B BEDDING SHALL BE USED FOR RIGID PIPES AND CLASS

S BEDDING FOR FLEXIBLE PIPES.

SfS3: 4.5.2 Pipe Bedding. Note (iii) Full bed and surround may not be required for rigid, large diameter pipes.

Reference should be made to the manufacturers instructions.

SfA6: 5.5.2 (iii) Pipe Bedding / 5.5.4 (i) Pipe Surround.

Full bed and surround may not be required for rigid, large diameter pipes. Reference should be made to

manufacturers instructions.

SfA7: E5.2 (iii) Pipe Bedding / E5.4 (i) Pipe Surround

Full bed and surround may not be required for rigid, large diameter pipes. Reference should be made to

manufacturers instructions.

CESWI7: 5.2 (iii) Pipe bedding / 5.4 (i) Pipe Surround

Refer to BS EN 1295-1 for pipe bedding design details. Further guidance is available in BS EN 1295-1.

Water Industry Specification 4-35-01: Issue 1. July 2000

Specification for thermoplastic structured wall pipes

Foreword

For pipes greater than 500, lower long-term stiffness classes than quoted in 6.15 are permitted, but structural

soil calculations must be carried out for every installation technique modified to suit the results of that calculation.

Most standard stiffness flexible plastic pipes are 2kN/m2 or 4kN/m2 and this is significantly lower than the

minimum recommended stiffness of 10kN/m2 if a Class B bedding is to be considered. In other words, all

standard stiffness flexible plastic pipes will generally require Class S embedment, unlike rigid concrete pipes

where there is a range of bedding choices and the opportunity to reduce installation costs.

2)

Nominal short term

2)

8

Design Manual For Roads And Bridges Volume 4 Section 2 Part 5

HA40/01

2.1 Design Considerations. Range of bedding types

Methods of bedding pipes are shown in the Highway Construction Details, drawing F1 (see below) for carrier drains

and F2 for filter drains (see Appendix B). These different beddings provide varying degrees of support to the pipe.

In the case of filter drains, the granular bedding and surround additionally functions as a filter medium. Not all

possibilities that would give a satisfactory bedding are included in the HCD, THE CHOICE HAS BEEN RESTRICTED

TO SAVE GRANULAR MATERIAL and to combinations most likely to be of use. Bed types A, B, F, N and S in

drawing F1 are for use with rigid pipes (section 2.5) and bed types S and T with flexible pipes (section 2.7).

Highway Construction Details - Drawing F1

Specification For Highways Works Series 500 Drainage And Service

Ducts

Bedding, Backfill and Surround Material

(11/03) All systems shall be installed in accordance with the pipe and bedding combinations given in Advice Note

HA 40 (DMRB 4.2.5). Other combinations shall be supported by calculations in accordance with BS EN 1295-1 UK

National Annex. Bedding, backfill and surround materials are classified in Clause 503 and Clause 505.

Building Regulations Approved Document H

Bedding and backfilling

2.41 The choice of bedding and backfilling depends on the depth at

which the pipes are to be laid and the size and strength of the pipes.

2.42 Rigid pipes The types of bedding and backfilling which should be

used for rigid pipes of standard strength laid in a trench of any width are

shown in Diagram 10.

2.43 Flexible pipes THESE WILL BECOME DEFORMED UNDER LOAD

AND REQUIRE SUPPORT TO LIMIT THE DEFORMATION. The bedding

and backfilling should be as shown in Diagram 10.

drainage

& water

management

Technical helpline

01530 240000

fpmccann.co.uk/drainage

Please check our website for

most up-to-date information

S-ar putea să vă placă și

- Example 1 - Geotechnical Data ReportDocument63 paginiExample 1 - Geotechnical Data ReportValar MorghulisÎncă nu există evaluări

- Structural Analysis 1: Statically Determinate StructuresDe la EverandStructural Analysis 1: Statically Determinate StructuresÎncă nu există evaluări

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980De la EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Încă nu există evaluări

- Thermal Stresses and Temperature Control of Mass ConcreteDe la EverandThermal Stresses and Temperature Control of Mass ConcreteÎncă nu există evaluări

- Investigation of the Chirajara Bridge CollapseDe la EverandInvestigation of the Chirajara Bridge CollapseÎncă nu există evaluări

- S406 Specifications For The Supply of Stone PDFDocument6 paginiS406 Specifications For The Supply of Stone PDFMfanelo MbanjwaÎncă nu există evaluări

- Stop LogsDocument8 paginiStop LogsLakshmiWijayasiriÎncă nu există evaluări

- Geotechnical - Instruments SETTLEMENT MARKERDocument5 paginiGeotechnical - Instruments SETTLEMENT MARKERGnabBang100% (1)

- River Bank ProtectionDocument20 paginiRiver Bank Protectionbalajiwr100% (1)

- Construction On Soft SoilDocument82 paginiConstruction On Soft SoilDyah Chandra Kartika Sesunan100% (1)

- Thrust and Anchor Blocks Design PDFDocument26 paginiThrust and Anchor Blocks Design PDFKS LeeÎncă nu există evaluări

- Cement Stabilized SandDocument15 paginiCement Stabilized SandphatmatÎncă nu există evaluări

- Modulus of Subgrade Reaction KsDocument1 paginăModulus of Subgrade Reaction KsmohamedabdelalÎncă nu există evaluări

- Thewes2016 - Clogging EvaluationDocument7 paginiThewes2016 - Clogging EvaluationMoez SelmiÎncă nu există evaluări

- 001-135-12-Design Report-Washout Chamber-R0Document43 pagini001-135-12-Design Report-Washout Chamber-R0Anonymous 3kDy7eÎncă nu există evaluări

- Modulus of Soil ReactionDocument12 paginiModulus of Soil ReactionAnonymous v1blzDsEWAÎncă nu există evaluări

- FP McCann Precast Concrete Headwalls InstallationDocument4 paginiFP McCann Precast Concrete Headwalls InstallationgemotorresÎncă nu există evaluări

- B1-2A Pile ShearDocument8 paginiB1-2A Pile ShearFranklyn P. GenoveÎncă nu există evaluări

- Compaction Grouting - Karst Guide SpecificationDocument7 paginiCompaction Grouting - Karst Guide SpecificationyoyoÎncă nu există evaluări

- Calculo Soil Nail FHWADocument91 paginiCalculo Soil Nail FHWAdiana cristina arias aldanaÎncă nu există evaluări

- 2.6.2 Minimum Spacing Between Reinforcement Bars: The Art of Construction and The DesignDocument6 pagini2.6.2 Minimum Spacing Between Reinforcement Bars: The Art of Construction and The DesignSamuel AntobamÎncă nu există evaluări

- Boiling or Heaving in CofferdamsDocument2 paginiBoiling or Heaving in Cofferdamsslawek780303Încă nu există evaluări

- Buried Pipe - CalcstressDocument17 paginiBuried Pipe - CalcstressAnjani PrabhakarÎncă nu există evaluări

- SANS1200GDocument19 paginiSANS1200GBornfacetumba SotauÎncă nu există evaluări

- Geotechnical Basis of Design ReportDocument74 paginiGeotechnical Basis of Design ReportjoniÎncă nu există evaluări

- AUA Guidelines Backfilling and Contact Grouting Tunnels and ShaftsDocument6 paginiAUA Guidelines Backfilling and Contact Grouting Tunnels and ShaftsSen HuÎncă nu există evaluări

- En 14490 After CEN Enquiry (Soil Nailing)Document59 paginiEn 14490 After CEN Enquiry (Soil Nailing)Abraham FIgueroa ARevaloÎncă nu există evaluări

- Sewer Geotechnical ReportDocument112 paginiSewer Geotechnical ReportAmir Reza Ahmadi MotlaghÎncă nu există evaluări

- Black 1962Document12 paginiBlack 1962Jawad Abidi100% (1)

- GroutingDocument538 paginiGroutingPTchongÎncă nu există evaluări

- Penstocks: Figure: Typical Installaion of PenstocksDocument6 paginiPenstocks: Figure: Typical Installaion of PenstocksTharindu Nuwan JayakodyÎncă nu există evaluări

- Retaining Wall DesignDocument1 paginăRetaining Wall Design// Library SSECÎncă nu există evaluări

- Rational Method Hydrologic Calculations With Excel-R1Document25 paginiRational Method Hydrologic Calculations With Excel-R1Rajkumar SagarÎncă nu există evaluări

- Armtech - Corrugated Steel Pipe PDFDocument24 paginiArmtech - Corrugated Steel Pipe PDFIftiÎncă nu există evaluări

- BS 4466Document25 paginiBS 4466Umange Ranasinghe100% (6)

- Shaft Construction Methods ComparisonDocument16 paginiShaft Construction Methods ComparisonEko Budi WicaksonoÎncă nu există evaluări

- Gabion Wall: Design Information SheetDocument3 paginiGabion Wall: Design Information SheetAnonymous MAQrYFQDzVÎncă nu există evaluări

- Single Chamber ModifiedDocument46 paginiSingle Chamber ModifiedIsmail Magdy IsmailÎncă nu există evaluări

- Installation Guidance For Precast Concrete Headwalls PD81Document7 paginiInstallation Guidance For Precast Concrete Headwalls PD81sosi2020Încă nu există evaluări

- Slurry Wall PDF 02Document15 paginiSlurry Wall PDF 02Syufri HakimÎncă nu există evaluări

- Geotech Buried PipesDocument54 paginiGeotech Buried Pipeserleos100% (2)

- Economic Design of Working Platforms For Tracked PlantDocument3 paginiEconomic Design of Working Platforms For Tracked PlantSalvatore MirandaÎncă nu există evaluări

- Section 130 Jet Blast ScreenDocument10 paginiSection 130 Jet Blast ScreenKwan Chun SingÎncă nu există evaluări

- Ground movements-ITALY PDFDocument35 paginiGround movements-ITALY PDFjack21abÎncă nu există evaluări

- DSI DYWIDAG Z 34.11 225 Permanent Bar Anchors enDocument20 paginiDSI DYWIDAG Z 34.11 225 Permanent Bar Anchors enjeff_56Încă nu există evaluări

- Guidelines For Site Inspection - by Blas R. Cadalso1Document18 paginiGuidelines For Site Inspection - by Blas R. Cadalso1abstickleÎncă nu există evaluări

- Concrete Pipe and Portal Culvert Installation Manual1Document28 paginiConcrete Pipe and Portal Culvert Installation Manual1ChristineNyambe100% (1)

- Design of Thrust Blocks - London - TedDocument21 paginiDesign of Thrust Blocks - London - Tedjdietz4100% (2)

- Effect of Cracking On Corrosion of Steel in Concrete PDFDocument12 paginiEffect of Cracking On Corrosion of Steel in Concrete PDFSteve NolaÎncă nu există evaluări

- Secant Pile Wall Design For Deep ExcavationsDocument1 paginăSecant Pile Wall Design For Deep ExcavationsHorace Prophetic DavisÎncă nu există evaluări

- Shrinkage of Clays Unsat 06Document12 paginiShrinkage of Clays Unsat 06jcazÎncă nu există evaluări

- River Banks Design PDFDocument15 paginiRiver Banks Design PDFpk100% (1)

- Grout MixDocument1 paginăGrout MixThein Htun AungÎncă nu există evaluări

- Cantilever Retaining WallDocument48 paginiCantilever Retaining WallAbhishek BupkyaÎncă nu există evaluări

- Cement GroutingDocument38 paginiCement GroutingpachossÎncă nu există evaluări

- Braithwaite Type Pressed Steel Water Storage TankDocument2 paginiBraithwaite Type Pressed Steel Water Storage TankLawrence CainÎncă nu există evaluări

- Installing Vitrified Clay Pipe Lines: Standard Practice ForDocument9 paginiInstalling Vitrified Clay Pipe Lines: Standard Practice Formhamed1Încă nu există evaluări

- 1.7.5 Define Nodes For Result Out Put: Select Points For CurvesDocument1 pagină1.7.5 Define Nodes For Result Out Put: Select Points For CurvesHoang An TranÎncă nu există evaluări

- Phase Explorer Phases Window ID Box: 1.6 Review The ResultDocument1 paginăPhase Explorer Phases Window ID Box: 1.6 Review The ResultHoang An TranÎncă nu există evaluări

- PipeDesign 21Document1 paginăPipeDesign 21Hoang An TranÎncă nu există evaluări

- Example 2-017-Thick, Example 2-017-Thin: Sap 2000 FileDocument1 paginăExample 2-017-Thick, Example 2-017-Thin: Sap 2000 FileHoang An TranÎncă nu există evaluări

- 1.7.4 Define Staged Construction: Phases Windows ID Box Calculation Type Loading TypeDocument1 pagină1.7.4 Define Staged Construction: Phases Windows ID Box Calculation Type Loading TypeHoang An TranÎncă nu există evaluări

- How About The Sign of The Bending Moment?Document1 paginăHow About The Sign of The Bending Moment?Hoang An TranÎncă nu există evaluări

- Plate Line Load: 1.7.2 Define Material Properties For The FootingDocument1 paginăPlate Line Load: 1.7.2 Define Material Properties For The FootingHoang An TranÎncă nu există evaluări

- Plaxis Study 5Document1 paginăPlaxis Study 5Hoang An TranÎncă nu există evaluări

- Plaxis Study 9Document1 paginăPlaxis Study 9Hoang An TranÎncă nu există evaluări

- Step 13: Click OK To Close Material Sets Window Step 14: Click OK To Close Modify Soil Layers WindowDocument1 paginăStep 13: Click OK To Close Material Sets Window Step 14: Click OK To Close Modify Soil Layers WindowHoang An TranÎncă nu există evaluări

- 4.14.1 Huber-Hencky-von Mises EquationDocument1 pagină4.14.1 Huber-Hencky-von Mises EquationHoang An TranÎncă nu există evaluări

- Water Level Change During Excavation Will Heavily Affect The Design of ERSSDocument1 paginăWater Level Change During Excavation Will Heavily Affect The Design of ERSSHoang An TranÎncă nu există evaluări

- Create Borehole Modify Soil Layers WindowDocument1 paginăCreate Borehole Modify Soil Layers WindowHoang An TranÎncă nu există evaluări

- Vortex Chamber DesignDocument1 paginăVortex Chamber DesignHoang An TranÎncă nu există evaluări

- Vortex ChamberDocument1 paginăVortex ChamberHoang An TranÎncă nu există evaluări

- 1.2 Define Structural Elements: Mesh ModeDocument1 pagină1.2 Define Structural Elements: Mesh ModeHoang An TranÎncă nu există evaluări

- 3 Effect of Flow Variations On Velocities in A Sewer: Example 1Document1 pagină3 Effect of Flow Variations On Velocities in A Sewer: Example 1Hoang An TranÎncă nu există evaluări

- Waste WaterDocument1 paginăWaste WaterHoang An TranÎncă nu există evaluări

- 1.1.1.1 Excessive Movements: 1.1.2 Obseravation Approach in Deep ExcavationDocument1 pagină1.1.1.1 Excessive Movements: 1.1.2 Obseravation Approach in Deep ExcavationHoang An TranÎncă nu există evaluări

- Tunnel Design Is A Interesting Part For Soil Structure Interaction Analysis and DesignDocument1 paginăTunnel Design Is A Interesting Part For Soil Structure Interaction Analysis and DesignHoang An TranÎncă nu există evaluări

- Permeability TestDocument1 paginăPermeability TestHoang An TranÎncă nu există evaluări

- Permeability Test Is Important Because They Can Make The Design ChangeDocument1 paginăPermeability Test Is Important Because They Can Make The Design ChangeHoang An TranÎncă nu există evaluări

- Piping: From Wikipedia, The Free EncyclopediaDocument1 paginăPiping: From Wikipedia, The Free EncyclopediaHoang An TranÎncă nu există evaluări

- Cut Off Wall Is The Special Design in ERSSDocument1 paginăCut Off Wall Is The Special Design in ERSSHoang An TranÎncă nu există evaluări

- Pipelines Buried: Offshore Are Normally For Stability and Mechanical ProtectionDocument1 paginăPipelines Buried: Offshore Are Normally For Stability and Mechanical ProtectionHoang An TranÎncă nu există evaluări

- This Examines The Following Aspects: Loads On (General Principles Of, Conditions of Installation, Fill Load in Narrow Trench, Fill ..Document1 paginăThis Examines The Following Aspects: Loads On (General Principles Of, Conditions of Installation, Fill Load in Narrow Trench, Fill ..Hoang An TranÎncă nu există evaluări

- Von Mises Stress 6Document1 paginăVon Mises Stress 6Hoang An TranÎncă nu există evaluări

- Von Mises Stress 8Document1 paginăVon Mises Stress 8Hoang An TranÎncă nu există evaluări

- Von Mises Stress 7Document1 paginăVon Mises Stress 7Hoang An TranÎncă nu există evaluări

- Astm D2573 D2573M 18Document4 paginiAstm D2573 D2573M 18deptrailaikieuÎncă nu există evaluări

- An Elementary Proof For Fermat's Last Theorem Using An Euler's EquationDocument9 paginiAn Elementary Proof For Fermat's Last Theorem Using An Euler's EquationGagan DeepÎncă nu există evaluări

- Foaming in The Cooling Tower - FlatDocument1 paginăFoaming in The Cooling Tower - FlatJavier GonzalezÎncă nu există evaluări

- Lab 4 Alcohol - 2011-2Document8 paginiLab 4 Alcohol - 2011-2Miisty Raiyen HallÎncă nu există evaluări

- 18-202: Mathematical Foundations of Electrical EngineeringDocument29 pagini18-202: Mathematical Foundations of Electrical EngineeringxxqwertyxxÎncă nu există evaluări

- Personal Care Isostearic Acid & EstersDocument15 paginiPersonal Care Isostearic Acid & EsterssinghsachinkumarÎncă nu există evaluări

- CNC Lathe Machining CatiaDocument82 paginiCNC Lathe Machining CatiamasoudÎncă nu există evaluări

- XR-EBSD 203110007 13thfebDocument12 paginiXR-EBSD 203110007 13thfebVikram ChavanÎncă nu există evaluări

- Cired 2019 - 1606Document5 paginiCired 2019 - 1606romany allamÎncă nu există evaluări

- Boiler Feed Pump KSBDocument9 paginiBoiler Feed Pump KSByogacruiseÎncă nu există evaluări

- Water Stagnant of Solar ModulesDocument6 paginiWater Stagnant of Solar ModulesNITIN MISHRAÎncă nu există evaluări

- Design Tables For Structural Steel Sections (Eurocode 3, EN1993-1-1:2005)Document16 paginiDesign Tables For Structural Steel Sections (Eurocode 3, EN1993-1-1:2005)azhar ahmadÎncă nu există evaluări

- AUC SheetDocument26 paginiAUC SheetTanmay SagarÎncă nu există evaluări

- Method Development and Validation For Estimation of Dosulepin in Pure and Dosage Form by Using HPLCDocument8 paginiMethod Development and Validation For Estimation of Dosulepin in Pure and Dosage Form by Using HPLCBaru Chandrasekhar RaoÎncă nu există evaluări

- Anna University EDDocument48 paginiAnna University EDSivaji SivaÎncă nu există evaluări

- Calculation Method of Permanent-Magnet Pickups For Electric GuitarsDocument6 paginiCalculation Method of Permanent-Magnet Pickups For Electric GuitarsangelaÎncă nu există evaluări

- 03 - Velocity Time GraphsDocument33 pagini03 - Velocity Time GraphsWaqas AhmadÎncă nu există evaluări

- Ch. 9 (B) LecDocument38 paginiCh. 9 (B) LecTom UlesÎncă nu există evaluări

- Autoliv 24GHz Radar ManualDocument16 paginiAutoliv 24GHz Radar ManualvagncarisiusÎncă nu există evaluări

- A Detailed Lesson Plan in Science 10Document9 paginiA Detailed Lesson Plan in Science 10Maricae NathanielÎncă nu există evaluări

- HW1 Phys3041Document3 paginiHW1 Phys3041Sam TseÎncă nu există evaluări

- Design Guideline For Hydraulic Fluid CleanlinessDocument24 paginiDesign Guideline For Hydraulic Fluid CleanlinessCarlosÎncă nu există evaluări

- CE 350 Project2Document22 paginiCE 350 Project2MariaEstherAlguacilRodriguezÎncă nu există evaluări

- Physics - 11Document11 paginiPhysics - 11Ishika GuptaÎncă nu există evaluări

- Modeling The Deformation of Earth Dam During An Earthquake: AbstractDocument6 paginiModeling The Deformation of Earth Dam During An Earthquake: AbstractMahmoud. HlelaiÎncă nu există evaluări

- Cellular Automaton: Automata, Homogeneous Structures, Cellular Structures, Tessellation Structures, and Iterative ArraysDocument18 paginiCellular Automaton: Automata, Homogeneous Structures, Cellular Structures, Tessellation Structures, and Iterative Arraysgerte_yuewÎncă nu există evaluări

- DatasheetDocument2 paginiDatasheetEsteban MaryoryÎncă nu există evaluări

- Pivot Master Floating Roof Drain SystemDocument8 paginiPivot Master Floating Roof Drain Systemnaveenbaskaran1989Încă nu există evaluări

- Prototype To Help The Improvement of E-Toll PaymentDocument14 paginiPrototype To Help The Improvement of E-Toll Paymentfarhan satriyaÎncă nu există evaluări

- CH 3 - AE Analysis and Design of Two-Way SlabsDocument111 paginiCH 3 - AE Analysis and Design of Two-Way Slabsephrem100% (3)