Documente Academic

Documente Profesional

Documente Cultură

PT9141

Încărcat de

mohammed8051Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PT9141

Încărcat de

mohammed8051Drepturi de autor:

Formate disponibile

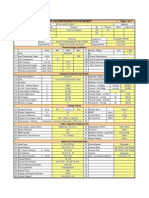

Instrument Data Sheet for Pressure Transmitter

1 GENERAL

60 INSTRUMENT BODY / SEAL CONNECTION

2 Tag number

61 Process Connection Type

PT-9141

3

Service

Flanged

62 Process Connection Standard

ASME B 16.5

63 Process Connection Material

SS 316L

64 Body Material

SS 316

65 Wetted Parts Material

SS 316L

Diesel Metering

4

5 P&ID Number

2014DCME104-D-AF.001

6 Plant / Area

LUBEREF

9000

7 Location

66 Process Connection Size

Field

8 Instrument Type

PRESS.TRANSMITTER WITH DS

2"

300#

68 Flange Finish

RF

10

69 Flange Finish Execution

11 PIPING DATA

70

12 Pipe Class

in

67 Flange Rating

71

3CC9P

13 Design pressure

BarG

30

72 Sensor Type

14 Design temp.

Deg C

70

73 Sensor Material

SS 316L

15 Line size

in

74 Diaphragm Material

SS 316L

16 Line Schedule

17 Inside Pipe Diameter

Std Wall

75 Instrument Process Connection Size

1/2"

102

76 Instrument Process Connection Type

NPT

mm

18 Equipment Number

77 Winterizing / Heating

PT-9141

19 Line Number

78 Tracing temperature

20 PROCESS DATA

79 INSTRUMENT DATA

21 Medium

22 Phase

SINGLE

23 Operating conditions

24 Flow Rate

BarG

81 Accuracy of Full Scale

Min

Norm

Max

82

48

74.8

150

83 Transmitter Acting

BarG

23.6

30

84 Overrange Protection

26 Temperature

Deg C

Amb.

70

85

27

28

29 Dynamic Viscosity

30 Density

cP

7.681

Kg/m3

834

30

0.25

/

-

barg

30

86 Repeatability of Full Scale

0.125

87 Response Time

88 Output Sig. / Communication Protocol

89 Power Supply / External

31

Volts

HART

Loop Powered /

4-20mA

24V dc

90 Transmission Type

32

Electronic

91

33 Pulsating

34 Corrosive Erosive

80 Calibrated Range

25 Pressure (upstream)

m3/h

Diesel

STATE

Diaphragm

92 Cable Entry

Toxic

Fouling

1/2" NPT(F) - 2 Nos. (Note-1)

93 Local Indicator

Required

35

94 Ingress prot (IP) acc EN / IEC 60529

IP 66

36

95 Explosion Protection Standard

Ex"d"

37 DIAPHRAGM SEAL

96 Explosion Protection Execution

38 Diaphragm Seal Required

YES

39 Diaphragm Seal Material

SS 316L

40 Diaphragm Seal Type

VTA

42 Capillary Material

VTA

SS 316L

43 Capillary Type

VTA

in

VTA

VTA

45 SPECIAL REQUIREMENTS

99 Mouting Brackets

Required

100 FOUNDATION FIELDBUS

101 DD-Rev / CFF-Rev

102 LAS / Device Current Draw

103 Device Address

104 HAZARDOUS LOCATION ACC. TO NEC 505

46 Material Certificate acc. to ISO 10474

As per attached Std.(as applicable)

105 Zone / Gas Group / Temp.Class

47 Environmental requirements

As per attached Std.(as applicable)

106 Full NEC Marking @50

48 EMC Standard acc IEC 61000 Series

Die-Casting Aluminium

98 Protective Housing Type

Required 2" Flush Ring,(Note-2)

41 Fill Fluid Name / Density

44 Capillary Length / Int. dia

97 Protective Housing Material

107

IIC

-

T3

49 Hydrostatic Pressure Test Report

50 Custom Configuration Report

51 Calibration Test Report

52 SIL Classification

108 PURCHASING DATA

Required

109 Manufacturer

Yokogawa / Emerson

110 Model

Required

VTA

111 Requisition No

53

112 Requisition Item No

54

113 SAMS Stock Number

55

114

56

115

57

116

58

117

59

118

REMARKS: *Vendor to furnish details.

Note 1) One entry for signal cable & Spare entry shall be Plugged (Plug material : SS316)

Note 2) Vendor should provide 1/2" drain and vent valves along with Flush ring.Vendor shall

optionally quote for Gaskets along with Nuts and Bolts as required.

Note 3) PT shall withstand Full Vaccum

Instrument Specification Sheet for

Pressure Transmitter with diaphragm

Seal

0

07-May-14

No

Date

Issued for Approval

Description

Luberef - 4035.PRS - 07-11-2011 - Rev. 0

MY

ST

By

Chk

Sht No.

MK

Appr Code:

Doc No: LEP-KAR833-2-ODS-0602

Page Name: Pressure Transmitter

1

Rev:00

S-ar putea să vă placă și

- Hydrotechnik Full CatalogueDocument128 paginiHydrotechnik Full CatalogueEysakaylovasÎncă nu există evaluări

- Design Guidelines for Surface Mount TechnologyDe la EverandDesign Guidelines for Surface Mount TechnologyEvaluare: 5 din 5 stele5/5 (1)

- WPS FormatDocument1 paginăWPS FormatAbdullah AnsariÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 paginiData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- WPI-KE-1104-SP141-QM5433 (Datasheet)Document4 paginiWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémÎncă nu există evaluări

- Flame Arrestor DatasheetDocument2 paginiFlame Arrestor DatasheetAmit Pandey67% (6)

- FAHU SubmittalDocument62 paginiFAHU SubmittalEngr.MmosaadÎncă nu există evaluări

- NCR - SampleDocument7 paginiNCR - SamplecamycaxÎncă nu există evaluări

- OSI Spec LibraryDocument120 paginiOSI Spec LibraryClaudio Salvador Vera AranedaÎncă nu există evaluări

- On OFF ValveDocument30 paginiOn OFF ValveAjay TiwariÎncă nu există evaluări

- Pressure Gauge: Max Norm Min UnitsDocument1 paginăPressure Gauge: Max Norm Min Unitssairam2234Încă nu există evaluări

- ARV Process DatasheetDocument3 paginiARV Process DatasheetNaim JasmiÎncă nu există evaluări

- Design Economic Sewage Treatment PlantDocument17 paginiDesign Economic Sewage Treatment PlantDavid LambertÎncă nu există evaluări

- LGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetDocument37 paginiLGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetuyaiekanemÎncă nu există evaluări

- Using Equotip Hardness Test BlocksDocument5 paginiUsing Equotip Hardness Test Blocksanilbabu4Încă nu există evaluări

- Boiler SpecificationDocument18 paginiBoiler SpecificationAtul Jain100% (3)

- Metallic FatigueDocument69 paginiMetallic Fatigueaap1Încă nu există evaluări

- Method StatementDocument13 paginiMethod StatementGrace tpplÎncă nu există evaluări

- ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Document6 paginiZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Vijayaraj KumarÎncă nu există evaluări

- FO14-104 Vacuum Deaerator Datasheet - Rev ADocument3 paginiFO14-104 Vacuum Deaerator Datasheet - Rev AHuzefa Calcuttawala100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe la EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceEvaluare: 5 din 5 stele5/5 (1)

- 008364-001-DS-I001 Dehydration Switching Valves Datasheet - Rev BDocument17 pagini008364-001-DS-I001 Dehydration Switching Valves Datasheet - Rev BNaveen KumarÎncă nu există evaluări

- 00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Document11 pagini00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Alaa RamadanÎncă nu există evaluări

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De la EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Evaluare: 3.5 din 5 stele3.5/5 (3)

- Datasheet For Ball ValveDocument16 paginiDatasheet For Ball ValveDamu JankerboyÎncă nu există evaluări

- APNEA-J-DSH-0002 Rev. 1Document3 paginiAPNEA-J-DSH-0002 Rev. 1Michelle MartinezÎncă nu există evaluări

- Simulation of Unit Operations With HYSYSDocument5 paginiSimulation of Unit Operations With HYSYSĐậu Bắp50% (2)

- Thermal Relief Valve Data SheetDocument1 paginăThermal Relief Valve Data Sheetmihailspiridon100% (1)

- ThermocouplesDocument8 paginiThermocouplesRakesh NayakÎncă nu există evaluări

- FACTS Edited by SongDocument523 paginiFACTS Edited by Songdejan9267% (3)

- STVF5 Trouble REV0 PDFDocument42 paginiSTVF5 Trouble REV0 PDFUpien Ayah MahardikaÎncă nu există evaluări

- Va1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellDocument17 paginiVa1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellKhang TrangÎncă nu există evaluări

- BKDD00-ME-4M-87-001 Data Sheet Control Valve (Rev 0)Document22 paginiBKDD00-ME-4M-87-001 Data Sheet Control Valve (Rev 0)nileshana100% (1)

- Prosertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesDocument1 paginăProsertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesAlba Duaneth Rocabado MendietaÎncă nu există evaluări

- Pressure Safety Valve DatasheetDocument1 paginăPressure Safety Valve DatasheetAlvin Smith100% (5)

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDocument2 paginiHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc NguyenÎncă nu există evaluări

- Data Sheet For Tank Radar Gauge RTG 3920 - Level MeasurementDocument2 paginiData Sheet For Tank Radar Gauge RTG 3920 - Level MeasurementAndrei HorhoianuÎncă nu există evaluări

- HRD Hot Water Pump P001Document6 paginiHRD Hot Water Pump P001nguyenquoc1988Încă nu există evaluări

- HelipadDocument53 paginiHelipadKandregulaPrameelaÎncă nu există evaluări

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDe la EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsEvaluare: 4 din 5 stele4/5 (6)

- Safety Relief Valve DatasheetDocument1 paginăSafety Relief Valve Datasheetalmandhari330% (1)

- Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFDocument15 paginiRev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFNguyễnQuíTrọngÎncă nu există evaluări

- 3 ISO26262 AssessmentDocument19 pagini3 ISO26262 AssessmentOscar Alfonso Iñigo GéneraÎncă nu există evaluări

- HeatExchanger ReportDocument5 paginiHeatExchanger ReportNur Izzati KamrulnizamÎncă nu există evaluări

- Volume3A MechDocument321 paginiVolume3A MechAdeel JamilÎncă nu există evaluări

- Pages From TBDP-A-M-SP-0008 - Rev 0 SPEC FOR CENTRIFUGAL PUMP PDFDocument12 paginiPages From TBDP-A-M-SP-0008 - Rev 0 SPEC FOR CENTRIFUGAL PUMP PDFSamuel JohnsonÎncă nu există evaluări

- Product Drawing: Customer Project Tag No. Unit Description of Service Location PID No./Line NumberDocument6 paginiProduct Drawing: Customer Project Tag No. Unit Description of Service Location PID No./Line NumberMWBABARÎncă nu există evaluări

- LSLL-105: Asme B16.5 Raised FaceDocument1 paginăLSLL-105: Asme B16.5 Raised FacegusbecÎncă nu există evaluări

- General Specifications: DFS Diaphragm Seals For Model YA53 Gauge Pressure TransmitterDocument3 paginiGeneral Specifications: DFS Diaphragm Seals For Model YA53 Gauge Pressure TransmitterJorge GuerreroÎncă nu există evaluări

- Ip Pressure Transmitter Data SheetDocument2 paginiIp Pressure Transmitter Data Sheetneurolepsia3790Încă nu există evaluări

- Ballvalve IsaDocument1 paginăBallvalve IsachandruhbkkÎncă nu există evaluări

- Hoja Tecnica Del ChillerDocument2 paginiHoja Tecnica Del ChillerJoshua CuevasÎncă nu există evaluări

- Diapham Valve PDFDocument8 paginiDiapham Valve PDFthouche007Încă nu există evaluări

- 145B9973 - Off Base Piping List of Lines PDFDocument4 pagini145B9973 - Off Base Piping List of Lines PDFHumayun NawazÎncă nu există evaluări

- ARI-Strainer: Strainer - Screen and Supporting Basket Made of Stainless SteelDocument6 paginiARI-Strainer: Strainer - Screen and Supporting Basket Made of Stainless SteelEmnÎncă nu există evaluări

- Wafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ADocument4 paginiWafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ARadu GanciuÎncă nu există evaluări

- Datasheet of Equipment - ANNAMDocument8 paginiDatasheet of Equipment - ANNAMhuyly34Încă nu există evaluări

- Temp GaugeaDocument1 paginăTemp GaugeaAJAY1381Încă nu există evaluări

- Ed 1 DF 66 DDocument5 paginiEd 1 DF 66 DSurangaG100% (1)

- Submittal Chiller COP 6.02Document3 paginiSubmittal Chiller COP 6.02juan yenqueÎncă nu există evaluări

- Flanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignDocument9 paginiFlanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignSaleh EttehadiÎncă nu există evaluări

- Asco Valve 8327Document2 paginiAsco Valve 8327Yorkist100% (1)

- Aircooler SizingDocument1 paginăAircooler SizingAdeniyi AleseÎncă nu există evaluări

- How to prepare Welding Procedures for Oil & Gas PipelinesDe la EverandHow to prepare Welding Procedures for Oil & Gas PipelinesEvaluare: 5 din 5 stele5/5 (1)

- Tuesday, March 27, 2018: 2 SlicesDocument3 paginiTuesday, March 27, 2018: 2 Slicesmohammed8051Încă nu există evaluări

- Attitude Theory and The Attitude-Behavior Relation.: January 1993Document19 paginiAttitude Theory and The Attitude-Behavior Relation.: January 1993SureshYarlagaddaÎncă nu există evaluări

- The Environmental Attitudes Inventory: A Valid and Reliable Measure To Assess The Structure of Environmental AttitudesDocument16 paginiThe Environmental Attitudes Inventory: A Valid and Reliable Measure To Assess The Structure of Environmental Attitudesmohammed8051Încă nu există evaluări

- Turbine Meter 4 To 20 Sentry SeriesDocument6 paginiTurbine Meter 4 To 20 Sentry Seriesmohammed8051100% (1)

- 31369093Document2 pagini31369093mohammed8051Încă nu există evaluări

- Turbine Meter 1-12 To 4 Guardsman G Series PDFDocument6 paginiTurbine Meter 1-12 To 4 Guardsman G Series PDFmohammed8051Încă nu există evaluări

- 31369093Document2 pagini31369093mohammed8051Încă nu există evaluări

- Piping IndexDocument1 paginăPiping Indexmohammed8051Încă nu există evaluări

- Urgent and ConfidentialDocument1 paginăUrgent and Confidentialmohammed8051Încă nu există evaluări

- 3 Day Metering Principles Training 2016Document1 pagină3 Day Metering Principles Training 2016mohammed8051Încă nu există evaluări

- IP Rating ChartDocument1 paginăIP Rating Chartroy_vijayÎncă nu există evaluări

- Liquid Flow ProversDocument7 paginiLiquid Flow Proversseeralan balakrishnanÎncă nu există evaluări

- MGM ManualDocument33 paginiMGM Manualmohammed8051100% (1)

- DH 10cDocument2 paginiDH 10cmohammed8051Încă nu există evaluări

- Curriculum Vitae Karthikeyan: Contact No: 00971526409227 00971553450466 E-Mail: ObjectiveDocument2 paginiCurriculum Vitae Karthikeyan: Contact No: 00971526409227 00971553450466 E-Mail: Objectivemohammed8051Încă nu există evaluări

- TUBULAÇÃO FLANGEADA 0,5 PolDocument2 paginiTUBULAÇÃO FLANGEADA 0,5 PolFabiano BaldassoÎncă nu există evaluări

- 256 Question To Ahl Al-HadithDocument19 pagini256 Question To Ahl Al-HadithIjaz FazilÎncă nu există evaluări

- Syllabus: Apprenticeship Training SchemeDocument7 paginiSyllabus: Apprenticeship Training Schememohammed8051Încă nu există evaluări

- Curriculum Vitae: Mr. Sandeep Bajrang. KambleDocument3 paginiCurriculum Vitae: Mr. Sandeep Bajrang. Kamblemohammed8051Încă nu există evaluări

- GSM Auto Motor Control AbstractDocument3 paginiGSM Auto Motor Control Abstractmohammed8051Încă nu există evaluări

- 2008-09 B. E. Electronics EngineeringDocument38 pagini2008-09 B. E. Electronics Engineeringmohammed8051Încă nu există evaluări

- Your Hidden Helper: Ambient ElectronicsDocument6 paginiYour Hidden Helper: Ambient ElectronicsPrashanth JayaramÎncă nu există evaluări

- MV PClogDocument1 paginăMV PClogmohammed8051Încă nu există evaluări

- Operational Amplifiers 8Document33 paginiOperational Amplifiers 8Biswapriyo DasÎncă nu există evaluări

- Nanotechnology in Medicine SummaryDocument6 paginiNanotechnology in Medicine Summarymohammed8051Încă nu există evaluări

- Electronics Final ProjectDocument4 paginiElectronics Final Projectmohammed8051Încă nu există evaluări

- Info de Macro Fibra Sintetica de Concrete Org UkDocument1 paginăInfo de Macro Fibra Sintetica de Concrete Org UkMauro GelmiÎncă nu există evaluări

- Software Engineering (PR) : Rishita Jaggi 1140213 B.Tech. Third Year IT-3Document34 paginiSoftware Engineering (PR) : Rishita Jaggi 1140213 B.Tech. Third Year IT-3Sanket Duhoon100% (2)

- Ec 02Document77 paginiEc 02Alberto Hanna Suárez100% (1)

- Specifications BamStrand 3 Part SpecsDocument7 paginiSpecifications BamStrand 3 Part SpecsKimberly MitchellÎncă nu există evaluări

- 2 EquipmentList MV MCCDocument6 pagini2 EquipmentList MV MCCRodrigoCastilloAcostaÎncă nu există evaluări

- Best CNC Machines For Beginners (The Ultimate Guide)Document11 paginiBest CNC Machines For Beginners (The Ultimate Guide)Squickmon's Engineering & AutomationÎncă nu există evaluări

- Mep Project Progress Review: Presented ToDocument21 paginiMep Project Progress Review: Presented Toyousaf ahmedÎncă nu există evaluări

- Highway Engineering Notes - Chapter 5Document33 paginiHighway Engineering Notes - Chapter 5Muhammad Farhan GulÎncă nu există evaluări

- Transcript PattranithDocument1 paginăTranscript Pattranithapi-598948089Încă nu există evaluări

- Multivector PDFDocument3 paginiMultivector PDFlee robert olivar0% (1)

- HVDS BasicDocument67 paginiHVDS Basicjothipriyad100% (1)

- Composite Element DurabilityDocument6 paginiComposite Element Durabilityjklo12Încă nu există evaluări

- Asphalt Plant (PDL)Document9 paginiAsphalt Plant (PDL)Mojammel HaqueÎncă nu există evaluări

- ECEN 3364 - Industrial Electronics and PLC ApplicationDocument6 paginiECEN 3364 - Industrial Electronics and PLC ApplicationItsMeRyanCÎncă nu există evaluări

- CIVL 4403 - Study GuideDocument116 paginiCIVL 4403 - Study GuideShubham SaxenaÎncă nu există evaluări

- RCDLABDocument71 paginiRCDLABMary MarieÎncă nu există evaluări

- Presentation On Contract ManagementDocument17 paginiPresentation On Contract ManagementPradeep Kumar SharmaÎncă nu există evaluări

- SECTION 16010 General Provisions For Electrical Installation Part 1 - General 1.01 GENERALDocument22 paginiSECTION 16010 General Provisions For Electrical Installation Part 1 - General 1.01 GENERALabobeedoÎncă nu există evaluări

- Torsional Behavior of Steel Fiber Reinforced Concrete BeamsDocument7 paginiTorsional Behavior of Steel Fiber Reinforced Concrete BeamssokamantyÎncă nu există evaluări

- "The Big Bang Experiment": A Seminar Report ONDocument4 pagini"The Big Bang Experiment": A Seminar Report ONshuaibmohhamÎncă nu există evaluări

- Francois - Blanciak PublicationsDocument2 paginiFrancois - Blanciak PublicationsJorge Andres AlvarezÎncă nu există evaluări

- The Solution Design Optimization of Breaker Plate in Extrusion MachinesDocument3 paginiThe Solution Design Optimization of Breaker Plate in Extrusion MachinesMehul PatelÎncă nu există evaluări