Documente Academic

Documente Profesional

Documente Cultură

Swimmingpools en

Încărcat de

PereTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Swimmingpools en

Încărcat de

PereDrepturi de autor:

Formate disponibile

Stainless steel for outdoor swimming pools

A refurbishment and upgrading initiative in

Munich

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

Munichs Michaelibad

following renovation.

1 www.euro-inox.org

Stainless steel for public swimming baths

Public swimming pools are subject to a whole

host of regulations and official guidelines.

The legal requirements in terms of hygiene

and safety must be met at the same time as

keeping operating costs low and satisfying

the ever-growing demands of pool users.

Many older facilities fall short of todays expectations and so in recent years there has

been an increased focus on refurbishment

and modernisation.

Using stainless steel for the renovation of

swimming baths brings an array of benefits.

The excellent hygienic qualities of stainless

steel, for example, are a very important argument for its use in pool facilities.

A further advantage comes from the high

degree of prefabrication of components,

which means shorter assembly times for the

stainless steel pools, and therefore faster,

more efficient renovation work. All the various

pool fittings and components, as well as the

water attractions, can be made of the same

material. Altogether, stainless steel offers

superb economy and low follow-on costs,

thanks to the easy cleaning of its continuous,

smooth surfaces and comparatively low

maintenance costs.

As operators of the swimming pools in

Munich, the local public utilities company

(Stadtwerke Mnchen) was also convinced

of the benefits of this material. They have

been using stainless steel in their pool refurbishment programme for over ten years.

Euro Inox 2003, ISBN 2-87997-088-1

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

A range of pools was

created, and many attractions installed, such as

water spouts, massage

jets, a 'lazy river', waterslides and diving towers.

Munichs pool-renovation concept

The first public bathing facilities in Munich

two outdoor swimming pools were inaugurated in 1858. In 1901, the first indoor facility,

the Mllersche Volksbad, went into service.

This Jugendstil building is still well preserved

today. In the Second World War, almost all the

municipal swimming pools were badly damaged but after the war they were gradually

modernised and reopened. When the city

hosted the Olympic Games in 1972, some of

these facilities were used as training pools,

or as venues for the events. In 1991 the city

council of Munich decided on a concept for

extensive refurbishment of the municipal

swimming baths. Basically, the aim was to

In 2002 alone, over one

million people visited

Munichs open-air pools.

Following the renovation

of the swimming pool at

Prinzregentenstadion,

the number of visitors has

doubled, even though

building work is not yet

completely finished.

transform these facilities, which until that

point had been used mainly by keen swimmers, into modern pool centres with an

emphasis on families and leisure. This would

then increase their popularity and their

commercial success.

Implementation of the concept started in

1996. Since that time, a total of ten swimming pools have been modernised, including four outdoor facilities. At present, the

Prinzregentenstadion is undergoing renovation. This much-loved, inner-city leisure centre, erected in the 1930s, offers an outdoor

pool in summer and ice-skating in winter.

Euro Inox 2003

www.euro-inox.org 2

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

Renovating the pools

In the project to modernise the pool at Prinzregentenstadion, a welded stainless steel

construction was used. The new pools were

permanently sealed and made corrosionresistant without having to remove the old,

partly defective lining. In other swimming

baths existing plastic linings were replaced

by stainless steel. At the Prinzregentenstadion baths, the top edge of the existing

reinforced concrete pool was removed to

make way for the new, box-shaped overflow

gutters of 2 mm thick stainless steel sheet.

The original, single pool was divided into

three separate pools by inserting partition

walls of reinforced concrete. Panels of 2 mm

thick stainless were prefabricated in lengths

of up to 6 m and fitted onto the interior walls

of each basin. Once filled with water, the

original walls of the pool took over the job of

supporting the new metal lining. The floors

were made from 1.5 mm thick stainless steel.

1

2

8

9

12

10

11

3 www.euro-inox.org

The new overflow gutter

sits on the walls of the

old pool.

Site plan of the Prinzregentenstadion

scale 1:2000

1 Main building

2 Stands

3 Ice-skating rink / Beach volleyball area

4 Restaurant

5 Outline of old pool

6 Overflow and rinsing water tanks

7 Leisure pool with lazy river and mushroom

8 Swimmers pool

9 Diving pool and tower

10 Long slide

11 Toddlers pool

12 Sunbathing lawns

Euro Inox 2003

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

The black lane markings

on the floor of the swimmers pool were applied

to the panels electrolytically.

Stainless steel used for

the self-supporting walls

of the lazy river.

Here loads are directed onto a base consisting of a gravel bed topped with a layer of

sand.

At water depths of around two metres,

panels of stainless steel can also be erected

as self-supporting structures. In such cases,

2.5 mm thick panels are affixed to a support

frame. When welding stainless steel components together, a certain amount of staining

occurs around the weld seams, so the panels

are pickled after welding to prevent corrosion

later on. This process produces a metallically

clean surface which enables a protective

passive film to automatically reform on the

surface of the stainless steel.

1

2

Euro Inox 2003

Schematic section scale 1:50

1 Top edge of old pool removed

2 Overflow gutter (water circulation)

2.0 mm stainless steel 1.4404,

covered with plastic grid

3 Existing pool walls of reinforced concrete

4 Pool lining with integrated step, stainless

steel 1.4404, 2 mm (wall) and 1.5 mm (floor)

5 Cover plate with inlet jets

6 Floor channel (water circulation)

7 Gravel layer on existing floor

www.euro-inox.org 4

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

The stainless steel pipes

of the hydraulic system

are on view here, prior

to the fitting of the new

floor.

The floor panels just

1.5 mm thick are laid

directly onto a layer of

sand.

To test the watertightness of the whole construction, the pool was filled with water and

monitored over a period of five days. Then a

dye test was performed, to check the proper

functioning of the pool hydraulics.

Building work on the open-air pools at Prinzregentenstadion was carried out in the winter of 2001/02, without closing down the iceskating rink. Thanks to stainless steel and

the fact that it can be easily worked at low

temperatures, the refurbishment could be

carried out in the period from November to

April, at a time when the outdoor pool is

closed, in any case. By the start of the bathing season in 2002, the pool and its new

attractions were ready to welcome visitors.

Three partitions were

inserted into the old,

tiled reinforced concrete

basin to create three

separate pools.

On the lazy river the

water jets are integrated

into the side walls.

5 www.euro-inox.org

Euro Inox 2003

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

Choice of material

For reasons of hygiene, the water in all public

swimming pools has to be specially treated.

In most cases where a pool is renovated, it

is also necessary to modernise the water

treatment installations. In the Prinzregentenstadion a vertical mixing system is operated. Treated water is fed into the pool

via jets located on the floor, then 100% recirculated back into the collector tank of the

treatment system via the overflow gutters.

The rapid, efficient mixing that occurs

through this system means less disinfectant

is required.

Although the open-air pools are generally

filled with drinking water, which has a low

chloride ion content, levels of between 200

and 500 mg/l can occur as the water is recycled within the system. The water temperature in the pools varies from 26 to 32C.

Higher temperatures increase the chemical

aggressiveness still further.

Because of these corrosive conditions, grade

1.4404 stainless steel (approx. 17% chrome,

12% nickel, 2% molybdenum) was chosen.

Overflow gutters transport the pool water back

to the collector tank.

Treated water flows into

the pool through jets in

channels on the floor.

This grade is also used on components that

are not in permanent contact with the water,

protecting them, too, from the corrosive effects

of chlorinated water.

High air and water temperatures, coupled with

constant water movement, raise the chloride

content close to the pool,

even in outdoor facilities.

Euro Inox 2003

www.euro-inox.org 6

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

The benefits of stainless

steel are obvious in the

leisure pool. The material

can be used for a wide

range of applications.

7 www.euro-inox.org

Stainless steel attractions

Part of the renovation programme of Munich

swimming pools also involves building a

whole range of attractions or water amusements. The non-swimmers pools, for example, are turned into real adventure worlds.

Here, stainless steel proves to be an ideal

material, as all the installations water

spouts, lazy rivers, massage jets and diving

towers can be made of the same material

as the pool and its technical installations,

thus creating a pleasing visual harmony.

For the flume slides, rounded sheets of stainless steel sheet were used. The segments

were ground and polished after being

welded together offsite, and stainless steel

tube fitted to the top edges of the flume, to

provide a smooth, safe finish while also

bracing the whole structure.

Corrosion is generally not a problem with

slides, as water constantly runs down the

inner surfaces, which are also kept polished

by the users. The slide surfaces are also

resistant to mechanical wear. At times, the

outer sides may be sprayed with water and a

coloured paint coating is applied to these

surfaces to hide flowmarks and deposits

etc., helping to reduce the cleaning effort.

Euro Inox 2003

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

After assembly, the stainless steel flume slide presents a homogeneous

profile, evenly shaped in

the direction of the slide.

The welds are undetectable to the touch.

The support frame for

the diving tower is made

entirely of stainless steel

sections.

Euro Inox 2003

www.euro-inox.org 8

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

Cleaning and maintenance

During the summer season, dirt inevitably

finds its way into an open-air pool, either

from the surroundings or brought in by the

bathers themselves. Distributed throughout

the pool, most of the particles are captured

by the water treatment system. Nevertheless

a certain proportion stays in the pool where

it can affix itself to walls and floors. However,

these deposits do not adhere for long on the

entirely smooth surfaces of the stainless

steel. Algae, too, the formation of which

cannot entirely be prevented in outdoor

pools, even under optimum water treatment

conditions, find little purchase in a stainless

steel pool, unlike in tiled pools with their

many joints.

On stainless steel components that are not

constantly immersed in water, spray water

drying on the surfaces can lead to the formation of deposits and a concentration of

chlorides. To protect these components

against corrosion, they need to be cleaned

regularly, mainly with agents containing

phosphoric acid. Cleaning materials based

on hydrochloric acid are unsuitable as they

cause corrosion and lead to staining.

At the end of the summer season, the water

level in the pool is reduced, so that the pool

can accommodate the volume of rainfall

that will occur in winter. At the same time an

Water spray can cause

deposits on stainless

steel and an increase

in the concentration of

chlorides. Regular cleaning and maintenance

protects these components against corrosion.

9 www.euro-inox.org

Euro Inox 2003

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

Geothermal heat is

sufficient to prevent ice

freezing on the sides of

the pool.

No special measures

need to be taken to

protect stainless steel

pools for the winter.

anti-scale agent is added to prevent deposits

forming in the pool over the winter months.

In the Prinzregentenstadion pool, no complicated procedures with ice-pressure cushions

are needed. Experience has shown that even

in extremely low temperatures, rising geothermal heat is sufficient to prevent ice freezing on the wall of the pool. The maintenance

carried out each year after the winter break

involves emptying the pool, and then simply

thoroughly cleaning and checking the water

jets and channels in the pool floor. Strong

cleaning agents do remove dirt more efficiently, but they are also more aggressive on

the material. The consumption of cleaning

materials on stainless steel surfaces is comparatively low which of course means lower

maintenance costs and less environmental

pollution.

In the programme to renovate Munichs

open-air swimming pools, stainless steel has

been found to offer long-term, trouble-free

Euro Inox 2003

performance, even in outdoor situations.

The material displays no detectable signs of

ageing. And annual costs for maintenance

and repair of the pools and associated plant

are low when compared to reinforced concrete pools with tiled linings. Through the

high elasticity and ductility of the material,

stainless steel basins are largely tolerant of

settlement and temperature fluctuations.

The covers of the inlet

channels are removed

for cleaning and inspection as part of the

annual maintenance

programme.

www.euro-inox.org 10

STAINLESS STEEL FOR OUTDOOR SWIMMING POOLS

Bathers benefit from

the outstanding hygiene

qualities of stainless

steel.

Light refracting in the

stainless steel pool gives

a fresh, blue appearance

to the water.

Euro Inox

Diamant Building, Bd. A. Reyers 80,

1030 Brussels, Belgium

Tel.

+32 2 706 82 67

Fax

+32 2 706 82 69

E-mail

info@euro-inox.org

Internet

www.euro-inox.org

Client: Stadtwerke Mnchen Badebetriebe,

represented by SWM Facility Management

Text and layout: circa drei, Munich

Translation: Ingrid Taylor, Munich

Photos: IGK, Munich (pp. 3, 4 left, 5, 10 bottom)

Reiner + Weber, Munich (p. 4 right, 5 bottom)

Martina Helzel, Munich

11 www.euro-inox.org

Euro Inox 2003, ISBN 2-87997-088-1

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Design Slab On Grade Postension (ACI 360R & PTI) : I. Input DataDocument2 paginiDesign Slab On Grade Postension (ACI 360R & PTI) : I. Input DataVandaÎncă nu există evaluări

- Spring Manufacturing ProcessDocument4 paginiSpring Manufacturing ProcessUzma sijratÎncă nu există evaluări

- Grade 8 Electric Circuits CompressedDocument18 paginiGrade 8 Electric Circuits Compressedjoesyfer247Încă nu există evaluări

- Dental CeramicsDocument62 paginiDental CeramicsAnamika Thakur Rana100% (2)

- Solubility and Solubilization: Mahendrasingh Ajitsingh Chavan M.Pharm I ST Year (Pharmaceutics) S.P.C.P. NagpurDocument33 paginiSolubility and Solubilization: Mahendrasingh Ajitsingh Chavan M.Pharm I ST Year (Pharmaceutics) S.P.C.P. NagpurBolli SandeepÎncă nu există evaluări

- Congo Red Dye PDFDocument6 paginiCongo Red Dye PDFkiranpatil1014532Încă nu există evaluări

- IIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesDocument81 paginiIIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesAsad Bin Ala QatariÎncă nu există evaluări

- 10 - Confined SpaceDocument53 pagini10 - Confined SpaceghufranahmedkhanÎncă nu există evaluări

- Welding Journal 1959 8Document142 paginiWelding Journal 1959 8AlexeyÎncă nu există evaluări

- Euler's Buckling Analysis of Aluminum TubeDocument14 paginiEuler's Buckling Analysis of Aluminum TubeSyedAmmarSamiÎncă nu există evaluări

- A Presentation On Electrochemical MicromachiningDocument68 paginiA Presentation On Electrochemical MicromachiningVyom SharmaÎncă nu există evaluări

- Sizing (Slashing)Document46 paginiSizing (Slashing)Nikhil Nani100% (1)

- Brocure DuPont ELVALOYDocument3 paginiBrocure DuPont ELVALOYdonni canraÎncă nu există evaluări

- Glass Fiber SpecsDocument4 paginiGlass Fiber SpecsJanus AntonioÎncă nu există evaluări

- DPP3 Gaseous State BansalDocument2 paginiDPP3 Gaseous State BansalBhushanÎncă nu există evaluări

- Shell Cyprina 963 PDFDocument2 paginiShell Cyprina 963 PDFAnonymous oAbjbl4HÎncă nu există evaluări

- Beg 2105 Physical Electronics I - 1 IntroDocument166 paginiBeg 2105 Physical Electronics I - 1 IntroElias keÎncă nu există evaluări

- Advanced Materials for Turbofan Engine Fan BladesDocument9 paginiAdvanced Materials for Turbofan Engine Fan BladesAhmed KhasawnehÎncă nu există evaluări

- Nde Procedure Magnetic Particle TestingDocument20 paginiNde Procedure Magnetic Particle Testingryan.s100% (1)

- ANALYSIS OF REINFORCED CONCRETE BEAM BEHAVIORDocument17 paginiANALYSIS OF REINFORCED CONCRETE BEAM BEHAVIORdonnafaye iresoÎncă nu există evaluări

- 005-Interlloy Grade 4340 Hardened and Tempered BarDocument3 pagini005-Interlloy Grade 4340 Hardened and Tempered BarDhruv MehtaÎncă nu există evaluări

- Formula Sheet Thermodynamics Cengel PaDocument3 paginiFormula Sheet Thermodynamics Cengel PaonatbrossÎncă nu există evaluări

- 2011 Final AnswerDocument8 pagini2011 Final Answerxuan1002Încă nu există evaluări

- Bill of Material Sample For ResidentialDocument4 paginiBill of Material Sample For ResidentialMyra Fe MercadoÎncă nu există evaluări

- 16 - SEC Nickel Cadmium Pocket Plate - I O Manual May 2008Document75 pagini16 - SEC Nickel Cadmium Pocket Plate - I O Manual May 2008PrashantKumarÎncă nu există evaluări

- Contamination and Contamination ControlDocument29 paginiContamination and Contamination ControlRyan 1112Încă nu există evaluări

- Design of Flat Slab Using Equivalent Frame MethodDocument41 paginiDesign of Flat Slab Using Equivalent Frame Methodabadittadesse100% (2)

- Concrete Pavers Roof Decks - Tech Spec 14 PDFDocument12 paginiConcrete Pavers Roof Decks - Tech Spec 14 PDFbatteekhÎncă nu există evaluări

- CH 2 - Properties of MixturesDocument47 paginiCH 2 - Properties of MixturesQuezza Phola S PatulinÎncă nu există evaluări

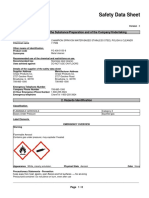

- Stainless Steel Cleaner Safety Data SheetDocument8 paginiStainless Steel Cleaner Safety Data SheetSinai TaxilagaÎncă nu există evaluări